Improving Dispersion of Carbon Nanotubes in Natural Rubber by Using Waterjet-Produced Rubber Powder as a Carrier

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

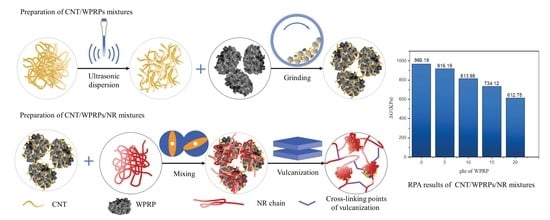

2.2. Preparation of CNT/WPRP/NR Composites

2.2.1. Preparation of CNT/WPRP Mixtures

2.2.2. Preparation of CNT/WPRP/NR Composites

2.3. Characterization and Measurements

2.3.1. Characterization of the Dispersion of CNT and CNT/WPRP Mixtures

2.3.2. Characterization of the Properties of the CNT/WPRP/NR Composites

3. Results and Discussion

3.1. Ultrasonic Grinding Dispersion Mechanism of CNT

3.2. Dispersion of CNT

3.2.1. Structural Characterization of CNT/WPRP Mixtures

3.2.2. Structural Characterization of CNT/WPRP/NR Composites

3.2.3. “Payne Effect”

3.3. Properties of the CNT/WPRP/NR Composites

3.3.1. Vulcanization Properties

3.3.2. Physical and Mechanical Properties

3.3.3. Dynamic Mechanical Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Gao, J.; He, Y.; Gong, X.; Xu, J. The role of carbon nanotubes in promoting the properties of carbon black-filled natural rubber/butadiene rubber composites. Results Phys. 2017, 7, 4352–4358. [Google Scholar] [CrossRef]

- Chen, L.; Pang, X.; Kang, Y. Comparison between the effects of partial replacement of carbon black by carbon nanotubes and graphene on the performances of natural rubber composites. J. Appl. Polym. Sci. 2022, 139, 51837. [Google Scholar] [CrossRef]

- Mat Desa, M.S.Z.; Hassan, A.; Arsad, A.; Arjmandi, R.; Mohammad, N.N.B. Influence of rubber content on mechanical, thermal, and morphological behavior of natural rubber toughened poly (lactic acid)–multiwalled carbon nanotube nanocomposites. J. Appl. Polym. Sci. 2016, 133, 44344. [Google Scholar] [CrossRef] [Green Version]

- Liu, D.; Kong, Q.Q.; Jia, H.; Xie, L.J.; Chen, J.; Tao, Z.; Wang, Z.; Jiang, D.; Chen, C.-M. Dual-functional 3D multi-wall carbon nanotubes/graphene/silicone rubber elastomer: Thermal management and electromagnetic interference shielding. Carbon 2021, 183, 216–224. [Google Scholar] [CrossRef]

- Mei, H.; Xia, J.; Zhang, D.; Han, D.; Xiao, S.; Cheng, L. Highly conductive and high-strength carbon nanotube film reinforced silicon carbide composites. Ceram. Int. 2017, 43, 8873–8878. [Google Scholar] [CrossRef]

- Chani, M.T.S.; Karimov, K.S.; Marwani, H.M.; Rahman, M.M.; Asiri, A.M. Electric Properties of Deformable Rubber/CNTs/p-Si Composites under Pressure. Int. J. Electrochem. Sci. 2021, 16, 210566. [Google Scholar] [CrossRef]

- Ma, P.C.; Siddiqui, N.A.; Marom, G.; Kim, J.K. Dispersion and functionalization of carbon nanotubes for polymer-based nanocomposites: A review. Compos. Part A Appl. Sci. Manuf. 2010, 41, 1345–1367. [Google Scholar] [CrossRef]

- Chen, S.; Chen, J.; Xu, K.; Pan, R.; Peng, Z.; Ma, L.; Wu, S. Effect of coal gangue/carbon black/multiwall carbon nanotubes hybrid fillers on the properties of natural rubber composites. Polym. Compos. 2016, 37, 3083–3092. [Google Scholar] [CrossRef]

- Basirjafari, S.; Khadem, S.E.; Malekfar, R. Radial breathing mode frequencies of carbon nanotubes for determination of their diameters. Curr. Appl. Phys. 2013, 13, 599–609. [Google Scholar] [CrossRef]

- Sethulekshmi, A.S.; Saritha, A.; Joseph, K. A comprehensive review on the recent advancements in natural rubber nanocomposites. Int. J. Biol. Macromol. 2022, 194, 819–842. [Google Scholar] [CrossRef]

- Wang, L.; Wang, X.; Li, Y. Relation between repeated uniaxial compressive pressure and electrical resistance of carbon nanotube filled silicone rubber composite. Compos. Part A Appl. Sci. Manuf. 2012, 43, 268–274. [Google Scholar] [CrossRef]

- Ismail, H.; Ramly, F.; Othman, N. Multiwall carbon nanotube-filled natural rubber: The effects of filler loading and mixing method. Polym. Plast. Technol. Eng. 2010, 49, 260–266. [Google Scholar] [CrossRef]

- Fawaz, J.; Mittal, V. Synthesis of polymer nanocomposites: Review of various techniques. In Synthesis Techniques for Polymer Nanocomposites; Wiley: Hoboken, NJ, USA, 2014; pp. 1–30. [Google Scholar] [CrossRef]

- Anand, K.A.; Jose, T.S.; Alex, R.; Joseph, R. Natural rubber-carbon nanotube composites through latex compounding. Int. J. Polym. Mater. 2009, 59, 33–44. [Google Scholar] [CrossRef]

- Peng, Z.; Feng, C.; Luo, Y.; Li, Y.; Kong, L.X. Self-assembled natural rubber/multi-walled carbon nanotube composites using latex compounding techniques. Carbon 2010, 48, 4497–4503. [Google Scholar] [CrossRef]

- Bian, H.; Xue, J.; Hao, G.; Hao, Y.; Xie, M.; Wang, C.; Wang, Z.; Zhu, L.; Xiao, Y. High thermal conductivity graphene oxide/carbon nanotubes/butyl rubber composites prepared by a dry ice expansion pre-dispersion flocculation method. J. Appl. Polym. Sci. 2022, 139, 51897. [Google Scholar] [CrossRef]

- Waesateh, K.; Saiwari, S.; Ismail, H.; Othman, N.; Soontaranon, S.; Hayeemasae, N. Features of crystallization behavior of natural rubber/halloysite nanotubes composites using synchrotron wide-angle X-ray scattering. Int. J. Polym. Anal. Charact. 2018, 23, 260–270. [Google Scholar] [CrossRef]

- Raman, V.S.; Rooj, S.; Das, A.; Stöckelhuber, K.W.; Simon, F.; Nando, G.B.; Heinrich, G. Reinforcement of solution styrene butadiene rubber by silane functionalized halloysite nanotubes. J. Macromol. Sci. Part A 2013, 50, 1091–1106. [Google Scholar] [CrossRef]

- Nakaramontri, Y.; Nakason, C.; Kummerlöwe, C.; Vennemann, N. Enhancement of electrical conductivity and other related properties of epoxidized natural rubber/carbon nanotube composites by optimizing concentration of 3-aminopropyltriethoxy silane. Polym. Eng. Sci. 2017, 57, 381–391. [Google Scholar] [CrossRef]

- Gao, J.S.; Liu, Z.; Yan, Z.; He, Y. A novel slurry blending method for a uniform dispersion of carbon nanotubes in natural rubber composites. Results Phys. 2019, 15, 102720. [Google Scholar] [CrossRef]

- Abdullateef, A.A.; Thomas, S.P.; Al-Harthi, M.A.; De, S.K.; Bandyopadhyay, S.; Basfar, A.A.; Atieh, M.A. Natural rubber nanocomposites with functionalized carbon nanotubes: Mechanical, dynamic mechanical, and morphology studies. J. Appl. Polym. Sci. 2012, 125, E76–E84. [Google Scholar] [CrossRef]

- Li, Y.; Wu, J.; Zhang, Q.; Dong, F.; Xiong, Y. Novel architecture of ZnO nanobundles grown on porous silica as high performance vulcanization accelerators that reinforce rubber composites. Ind. Eng. Chem. Res. 2020, 59, 4493–4503. [Google Scholar] [CrossRef]

- Zefeng, W.; Yong, K.; Zhao, W.; Yi, C. Recycling waste tire rubber by water jet pulverization: Powder characteristics and reinforcing performance in natural rubber composites. J. Polym. Eng. 2018, 38, 51–62. [Google Scholar] [CrossRef]

- Yu, M.F.; Lourie, O.; Dyer, M.J.; Moloni, K.; Kelly, T.F.; Ruoff, R.S. Strength and breaking mechanism of multiwalled carbon nanotubes under tensile load. Science 2000, 287, 637–640. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Miculescu, F.; Jepu, I.; Porosnicu, C.; Lungu, C.P.; Miculescu, M.; Burhala, B. A study on the influence of the primary electron beam on nanodimensional layers analysis. Dig. J. Nanomater. Biostruct. 2011, 6, 335–345. [Google Scholar]

- Payne, A.R.; Whittaker, R.E. Low strain dynamic properties of filled rubbers. Rubber Chem. Technol. 1971, 44, 440–478. [Google Scholar] [CrossRef]

- Xu, Z.; Song, Y.; Zheng, Q. Payne effect of carbon black filled natural rubber compounds and their carbon black gels. Polymer 2019, 185, 121953. [Google Scholar] [CrossRef]

- Nah, C.; Lim, J.Y.; Cho, B.H.; Hong, C.K.; Gent, A.N. Reinforcing rubber with carbon nanotubes. J. Appl. Polym. Sci. 2010, 118, 1574–1581. [Google Scholar] [CrossRef]

- Adov, M.V.; Pichkhidze, S.Y.; Kandyrin, K.L. The Payne effect in vulcanisates containing activated rubber powder. Int. Polym. Sci. Technol. 2011, 38, 25–27. [Google Scholar] [CrossRef]

- Sreeja, T.D.; Kutty, S.K.N. Cure characteristics and mechanical properties of natural rubber/reclaimed rubber blends. Polym.-Plast. Technol. Eng. 2000, 39, 501–512. [Google Scholar] [CrossRef]

- Song, J.; Li, X.; Tian, K.; Ma, L.; Li, W.; Yao, S. Thermal conductivity of natural rubber nanocomposites with hybrid fillers. Chin. J. Chem. Eng. 2019, 27, 928–934. [Google Scholar] [CrossRef]

- Ismail, H.; Nordin, R.; Noor, A.M. Cure characteristics, tensile properties and swelling behaviour of recycled rubber powder-filled natural rubber compounds. Polym. Test. 2002, 21, 565–569. [Google Scholar] [CrossRef]

- Jin, Y.; Zheng, X.; Wang, L.; Chen, J.; Wang, C.; Li, B. Improved mechanical properties of natural rubber composites reinforced by novel SiO2@ HCNFs nanofillers at a low filler loading. J. Appl. Polym. Sci. 2020, 137, 49225. [Google Scholar] [CrossRef]

- Vleugels, N.; Pille-Wolf, W.; Dierkes, W.K.; Noordermeer, J.W.M. Understanding the influence of oligomeric resins on traction and rolling resistance of silica-reinforced tire treads. Rubber Chem. Technol. 2015, 88, 65–79. [Google Scholar] [CrossRef]

| Ingredient | phr | ||||||

|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | |

| NR | 100 | 100 | 100 | 100 | 100 | 100 | 100 |

| ZnO | 3 | 3 | 3.3 | 3.15 | 3.3 | 3.45 | 3.6 |

| Stearic acid | 1 | 1 | 1.1 | 1.05 | 1.1 | 1.15 | 1.2 |

| NS | 1.6 | 1.6 | 1.76 | 1.68 | 1.76 | 1.84 | 1.92 |

| Sulfur | 1.2 | 1.2 | 1.32 | 1.26 | 1.32 | 1.38 | 1.44 |

| Antioxidant (4020) | 2 | 2 | 2.2 | 2.1 | 2.2 | 2.3 | 2.4 |

| Microcrystalline wax | 1 | 1 | 1.1 | 1.05 | 1.1 | 1.15 | 1.2 |

| CTP | 0.3 | 0.3 | 0.33 | 0.315 | 0.33 | 0.345 | 0.36 |

| CB (N234) | 50 | 50 | 50 | 50 | 50 | 50 | 50 |

| Mixture of CNT/WPRP | 0/0 | 3/0 | 0/10 | 3/5 | 3/10 | 3/15 | 3/20 |

| Sample Number | MH nm | ML nm | MH-ML nm | t10 min | t90 min |

|---|---|---|---|---|---|

| 1 | 17.65 | 1.59 | 16.06 | 3.94 | 7.98 |

| 2 | 19.40 | 2.16 | 17.24 | 3.03 | 6.91 |

| 3 | 18.14 | 1.92 | 16.22 | 3.54 | 7.35 |

| 4 | 19.58 | 2.34 | 17.24 | 2.82 | 7.03 |

| 5 | 19.62 | 2.35 | 17.27 | 2.59 | 6.85 |

| 6 | 19.75 | 2.49 | 17.26 | 2.49 | 6.03 |

| 7 | 20.45 | 2.63 | 17.82 | 2.63 | 6.26 |

| Sample Number | 1 | 2 | 4 | 5 | 6 | 7 |

|---|---|---|---|---|---|---|

| Tanδ (0 °C) | 0.163 | 0.173 | 0.170 | 0.170 | 0.168 | 0.170 |

| Tanδ (60 °C) | 0.102 | 0.119 | 0.117 | 0.110 | 0.106 | 0.105 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guo, X.; Guo, S.; Liu, G.; Bai, L.; Liu, H.; Xu, Y.; Zhao, J.; Chai, H.; Jian, X.; Guo, L.; et al. Improving Dispersion of Carbon Nanotubes in Natural Rubber by Using Waterjet-Produced Rubber Powder as a Carrier. Polymers 2023, 15, 477. https://doi.org/10.3390/polym15030477

Guo X, Guo S, Liu G, Bai L, Liu H, Xu Y, Zhao J, Chai H, Jian X, Guo L, et al. Improving Dispersion of Carbon Nanotubes in Natural Rubber by Using Waterjet-Produced Rubber Powder as a Carrier. Polymers. 2023; 15(3):477. https://doi.org/10.3390/polym15030477

Chicago/Turabian StyleGuo, Xiurui, Shouyun Guo, Gongxu Liu, Lichen Bai, Haichao Liu, Yuan Xu, Jinyang Zhao, Hailin Chai, Xingao Jian, Lei Guo, and et al. 2023. "Improving Dispersion of Carbon Nanotubes in Natural Rubber by Using Waterjet-Produced Rubber Powder as a Carrier" Polymers 15, no. 3: 477. https://doi.org/10.3390/polym15030477

APA StyleGuo, X., Guo, S., Liu, G., Bai, L., Liu, H., Xu, Y., Zhao, J., Chai, H., Jian, X., Guo, L., & Liu, F. (2023). Improving Dispersion of Carbon Nanotubes in Natural Rubber by Using Waterjet-Produced Rubber Powder as a Carrier. Polymers, 15(3), 477. https://doi.org/10.3390/polym15030477