Engineering Polypropylene–Calcium Sulfate (Anhydrite II) Composites: The Key Role of Zinc Ionomers via Reactive Extrusion

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Production of PP–AII Composites

2.2.1. Melt Compounding with Internal Mixers

2.2.2. Reactive Extrusion (REx) Using Twin-Screw Extruders (TSE)

2.3. Methods of Characterization

3. Results and Discussion

3.1. Preliminary Considerations

3.2. PP–AII Composites Produced within Internal Mixers

3.2.1. Morphology of Composites

3.2.2. Thermal Properties

3.2.3. Mechanical Properties

3.2.4. Key Considerations and Findings

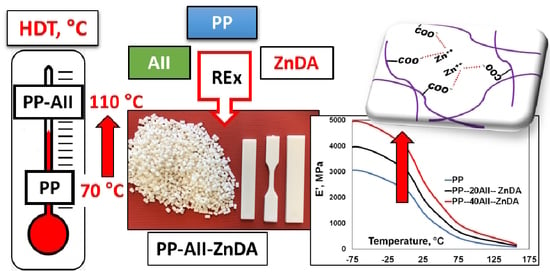

3.3. Current Prospects: Production of PP–AII Composites by REx

3.3.1. Characterization of PP–AII Composites Produced by REx

3.3.2. Other Properties of Interest for Engineering Applications

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Greene, J.P. Chapter 7-Commodity plastics. In Automotive Plastics and Composites; Greene, J.P., Ed.; William Andrew Publishing: Oxford, UK, 2021; pp. 83–105. [Google Scholar]

- Klein, J.; Wiese, J. High performance engineered polypropylene compounds for high temperature automotive under-the-hood applications. In Proceedings of the Society of Plastics Engineers-11th-Annual Automotive Composites Conference and Exhibition (ACCE 2011), Troy, MI, USA, 13–15 September 2011. [Google Scholar]

- Alsabri, A.; Tahir, F.; Al-Ghamdi, S.G. Environmental impacts of polypropylene (PP) production and prospects of its recycling in the GCC region. Mater. Today Proc. 2022, 56, 2245–2251. [Google Scholar] [CrossRef]

- Dennis, B.; Malpass, E.I.B. (Eds.) The future of polypropylene. In Introduction to Industrial Polypropylene; John Wiley & Sons, Inc.: Hoboken, NJ, USA; Scrivener Publishing LLC: Salem, MA, USA, 2012; pp. 269–278. [Google Scholar]

- Elaheh, G. Materials in automotive application, state of the art and prospects. In New Trends and Developments in Automotive Industry; Marcello, C., Ed.; IntechOpen: Rijeka, Croatia, 2011; pp. 365–394. [Google Scholar] [CrossRef]

- Wang, S.; Muiruri, J.K.; Soo, X.Y.D.; Liu, S.; Thitsartarn, W.; Tan, B.H.; Suwardi, A.; Li, Z.; Zhu, Q.; Loh, X.J. Bio-PP and PP-based biocomposites: Solutions for a sustainable future. Chem.-Asian J. 2023, 18, e202200972. [Google Scholar] [CrossRef] [PubMed]

- Jansz, J. Polypropylene in automotive applications. In Polypropylene: An A-Z Reference; Karger-Kocsis, J., Ed.; Springer: Dordrecht, The Netherlands, 1999; pp. 643–651. [Google Scholar]

- Thenepalli, T.; Jun, A.Y.; Han, C.; Ramakrishna, C.; Ahn, J.W. A strategy of precipitated calcium carbonate (CaCO3) fillers for enhancing the mechanical properties of polypropylene polymers. Korean J. Chem. Eng. 2015, 32, 1009–1022. [Google Scholar] [CrossRef]

- Sadiku, R.; Ibrahim, D.; Agboola, O.; Owonubi, S.J.; Fasiku, V.O.; Kupolati, W.K.; Jamiru, T.; Eze, A.A.; Adekomaya, O.S.; Varaprasad, K.; et al. 15-Automotive components composed of polyolefins. In Polyolefin Fibres (Second Edition); Ugbolue, S.C.O., Ed.; Woodhead Publishing (imprint of Elsevier): Duxford, UK, 2017; pp. 449–496. [Google Scholar]

- Patil, A.; Patel, A.; Purohit, R. An overview of polymeric materials for automotive applications. Mater. Today Proc. 2017, 4, 3807–3815. [Google Scholar] [CrossRef]

- Delli, E.; Gkiliopoulos, D.; Bikiaris, D.; Chrissafis, K. Thermomechanical characterization of E-glass fiber reinforced random polypropylene. Macromol. Symp. 2022, 405, 2100226. [Google Scholar] [CrossRef]

- Doddalli Rudrappa, S.; Yellampalli Srinivasachar, V. Significance of the type of reinforcement on the physicomechanical behavior of short glass fiber and short carbon fiber-reinforced polypropylene composites. Eng. Rep. 2020, 2, e12098. [Google Scholar] [CrossRef]

- Mihalic, M.; Sobczak, L.; Pretschuh, C.; Unterweger, C. Increasing the impact toughness of cellulose fiber reinforced polypropylene composites—Influence of different impact modifiers and production scales. J. Compos. Sci. 2019, 3, 82. [Google Scholar] [CrossRef]

- Shirvanimoghaddam, K.; Balaji, K.V.; Yadav, R.; Zabihi, O.; Ahmadi, M.; Adetunji, P.; Naebe, M. Balancing the toughness and strength in polypropylene composites. Compos. Part B Eng. 2021, 223, 109121. [Google Scholar] [CrossRef]

- Abreu, F.O.M.S.; Forte, M.M.C.; Liberman, S.A. Sbs and SEBS block copolymers as impact modifiers for polypropylene compounds. J. Appl. Polym. Sci. 2005, 95, 254–263. [Google Scholar] [CrossRef]

- Zhao, W.; Kumar Kundu, C.; Li, Z.; Li, X.; Zhang, Z. Flame retardant treatments for polypropylene: Strategies and recent advances. Compos. Part A: Appl. Sci. Manuf. 2021, 145, 106382. [Google Scholar] [CrossRef]

- Zhang, C.; Jiang, Y.; Li, S.; Huang, Z.; Zhan, X.-Q.; Ma, N.; Tsai, F.-C. Recent trends of phosphorus-containing flame retardants modified polypropylene composites processing. Heliyon 2022, 8, e11225. [Google Scholar] [CrossRef] [PubMed]

- Móczó, J.; Pukánszky, B. Particulate fillers in thermoplastics. In Fillers for Polymer Applications; Rothon, R., Ed.; Springer International Publishing: Cham, Switzerland, 2017; pp. 51–93. [Google Scholar]

- Bertini, F.; Canetti, M.; Audisio, G.; Costa, G.; Falqui, L. Characterization and Thermal Degradation of Polypropylene-Montmorillonite Nanocomposites. Polym. Degrad. Stab. 2006, 91, 600–605. [Google Scholar] [CrossRef]

- Morajane, D.; Sinha Ray, S.; Bandyopadhyay, J.; Ojijo, V. Impact of melt-processing strategy on structural and mechanical properties: Clay-containing polypropylene nanocomposites. In Processing of Polymer-based Nanocomposites; Sinha Ray, S., Ed.; Springer Series in Materials Science; Springer: Cham, Switzerland, 2018; Volume 277, pp. 127–154. [Google Scholar]

- Delva, L.; Ragaert, K.; Allaer, K.; Gaspar-Cunha, A.; Degrieck, J.; Cardon, L. Influence of twin-screw configuration on the mechanical and morphological properties of polypropylene-clay composites. Int. J. Mater. Prod. Technol. 2016, 52, 176–192. [Google Scholar] [CrossRef]

- Al-Samhan, M.; Al-Attar, F. Comparative analysis of the mechanical, thermal and barrier properties of polypropylene incorporated with CaCO3 and nano CaCO3. Surf. Interfaces 2022, 31, 102055. [Google Scholar] [CrossRef]

- Goldman, A.Y.; Copsey, C.J. Polypropylene toughened with calcium carbonate mineral filler. Mater. Res. Innov. 2000, 3, 302–307. [Google Scholar] [CrossRef]

- Jing, Y.; Nai, X.; Dang, L.; Zhu, D.; Wang, Y.; Dong, Y.; Li, W. Reinforcing polypropylene with calcium carbonate of different morphologies and polymorphs. Sci. Eng. Compos. Mater. 2018, 25, 745–751. [Google Scholar] [CrossRef]

- Peng, Y.; Musah, M.; Via, B.; Wang, X. Calcium Carbonate Particles Filled Homopolymer Polypropylene at Different Loading Levels: Mechanical Properties Characterization and Materials Failure Analysis. J. Compos. Sci. 2021, 5, 302. [Google Scholar] [CrossRef]

- de Oliveira, C.I.R.; Rocha, M.C.G.; de Assis, J.T.; da Silva, A.L.N. Morphological, mechanical, and thermal properties of PP/SEBS/talc composites. J. Thermoplast. Compos. Mater. 2022, 35, 281–299. [Google Scholar] [CrossRef]

- Putfak, N.; Larpkasemsuk, A. Wollastonite and talc reinforced polypropylene hybrid composites: Mechanical, morphological and thermal properties. J. Met. Mater. Miner. 2021, 31, 92–99. [Google Scholar] [CrossRef]

- Leong, Y.W.; Abu Bakar, M.B.; Ishak, Z.A.M.; Ariffin, A.; Pukanszky, B. Comparison of the mechanical properties and interfacial interactions between talc, kaolin, and calcium carbonate filled polypropylene composites. J. Appl. Polym. Sci. 2004, 91, 3315–3326. [Google Scholar] [CrossRef]

- Várdai, R.; Schäffer, Á.; Ferdinánd, M.; Lummerstorfer, T.; Jerabek, M.; Gahleitner, M.; Faludi, G.; Móczó, J.; Pukánszky, B. Crystalline structure and reinforcement in hybrid PP composites. J. Therm. Anal. Calorim. 2022, 147, 145–154. [Google Scholar] [CrossRef]

- Chen, X.; Zhang, T.; Sun, P.; Yu, F.; Li, B.; Dun, L. Study on the performance and mechanism of modified mica for improving polypropylene composites. Int. J. Low-Carbon Technol. 2022, 17, 176–184. [Google Scholar] [CrossRef]

- García-Martínez, J.-M.; Collar, E.P. The Variance of the Polypropylene α Relaxation Temperature in iPP/a-PP-pPBMA/Mica Composites. J. Compos. Sci. 2022, 6, 57. [Google Scholar] [CrossRef]

- Yang, N.; Zhang, Z.C.; Ma, N.; Liu, H.L.; Zhan, X.Q.; Li, B.; Gao, W.; Tsai, F.C.; Jiang, T.; Chang, C.J.; et al. Effect of surface modified kaolin on properties of polypropylene grafted maleic anhydride. Results Phys. 2017, 7, 969–974. [Google Scholar] [CrossRef]

- Liu, G.; Xu, H.; Song, S.; Wang, H.; Fan, B.; Lu, H.; Liu, Q. Preparation and properties of PP/modified kaolin composites. Gaofenzi Cailiao Kexue Yu Gongcheng/Polym. Mater. Sci. Eng. 2012, 28, 121–124. [Google Scholar]

- Zhang, S.; Jiang, P.; Liu, X.; Gu, X.; Zhao, Q.; Hu, Z.; Tang, W. Effects of kaolin on the thermal stability and flame retardancy of polypropylene composite. Polym. Adv. Technol. 2014, 25, 912–919. [Google Scholar] [CrossRef]

- Wang, K.; Wu, J.; Ye, L.; Zeng, H. Mechanical properties and toughening mechanisms of polypropylene/barium sulfate composites. Compos. Part A: Appl. Sci. Manuf. 2003, 34, 1199–1205. [Google Scholar] [CrossRef]

- Móczó, J.; Pukánszky, B. Particulate filled polypropylene: Structure and properties. In Polypropylene Handbook: Morphology, Blends and Composites; Karger-Kocsis, J., Bárány, T., Eds.; Springer International Publishing: Cham, Switzerland, 2019; pp. 357–417. [Google Scholar]

- Nofar, M.; Ozgen, E.; Girginer, B. Injection-molded PP composites reinforced with talc and nanoclay for automotive applications. J. Thermoplast. Compos. Mater. 2020, 33, 1478–1498. [Google Scholar] [CrossRef]

- de Medeiros, E.S.; Tocchetto, R.S.; de Carvalho, L.H.; Santos, I.M.G.; Souza, A.G. Nucleating effect and dynamic crystallization of a poly(propylene)/talc system. J. Therm. Anal. Calorim. 2001, 66, 523–531. [Google Scholar] [CrossRef]

- Ammar, O.; Bouaziz, Y.; Haddar, N.; Mnif, N. Talc as reinforcing filler in polypropylene compounds: Effect on morphology and mechanical properties. Polym. Sci. 2017, 3, 1–7. [Google Scholar] [CrossRef] [Green Version]

- Leong, Y.W.; Abu Bakar, M.B.; Ishak, Z.A.M.; Ariffin, A. Filler treatment effects on the weathering of talc-, CaCO3- and kaolin-filled polypropylene hybrid composites. Compos. Interfaces 2006, 13, 659–684. [Google Scholar] [CrossRef]

- Leong, Y.W.; Bakar, M.B.A.; Ishak, Z.A.M.; Ariffin, A. Effects of filler treatments on the mechanical, flow, thermal, and morphological properties of talc and calcium carbonate filled polypropylene hybrid composites. J. Appl. Polym. Sci. 2005, 98, 413–426. [Google Scholar] [CrossRef]

- Balköse, D. Influence of filler surface modification on the properties of PP composites. In Surface Modification of Nanoparticle and Natural Fiber Fillers; Wiley-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2015; pp. 83–108. [Google Scholar]

- Othman, N.; Ismail, H.; Mariatti, M. Effect of compatibilisers on mechanical and thermal properties of bentonite filled polypropylene composites. Polym. Degrad. Stab. 2006, 91, 1761–1774. [Google Scholar] [CrossRef]

- Bischoff, E.; Simon, D.A.; Liberman, S.A.; Mauler, R.S. Compounding sequence as a critical factor in the dispersion of OMMT/hydrocarbon resin/PP-g-MA/PP nanocomposites. Polym. Bull. 2019, 76, 849–863. [Google Scholar] [CrossRef]

- Morlat, S.; Mailhot, B.; Gonzalez, D.; Gardette, J.-L. Photo-oxidation of polypropylene/montmorillonite nanocomposites. 1. Influence of nanoclay and compatibilizing agent. Chem. Mater. 2004, 16, 377–383. [Google Scholar] [CrossRef]

- Toro, P.; Quijada, R.; Peralta, R.; Yazdani-Pedram, M. Influence of grafted polypropylene on the mechanical properties of mineral-filled polypropylene composites. J. Appl. Polym. Sci. 2007, 103, 2343–2350. [Google Scholar] [CrossRef]

- Hejna, A.; Przybysz-Romatowska, M.; Kosmela, P.; Zedler, Ł.; Korol, J.; Formela, K. Recent advances in compatibilization strategies of wood-polymer composites by isocyanates. Wood Sci. Technol. 2020, 54, 1091–1119. [Google Scholar] [CrossRef]

- DeArmitt, C.; Rothon, R. Surface modifiers for use with particulate fillers. In Fillers for Polymer Applications; Rothon, R., Ed.; Springer International Publishing: Cham, Switzerland, 2017; pp. 29–49. [Google Scholar]

- Leong, Y.W.; Ishak, Z.A.M.; Ariffin, A. Mechanical and thermal properties of talc and calcium carbonate filled polypropylene hybrid composites. J. Appl. Polym. Sci. 2004, 91, 3327–3336. [Google Scholar] [CrossRef]

- Chen, D.; Yang, H. Polypropylene/combinational inorganic filler micro-/nanocomposites: Synergistic effects of micro-/nanoscale combinational inorganic fillers on their mechanical properties. J. Appl. Polym. Sci. 2010, 115, 624–634. [Google Scholar] [CrossRef]

- Gahleitner, M.; Grein, C.; Bernreitner, K. Synergistic mechanical effects of calcite micro- and nanoparticles and β-nucleation in polypropylene copolymers. Eur. Polym. J. 2012, 48, 49–59. [Google Scholar] [CrossRef]

- Mittal, P.; Naresh, S.; Luthra, P.; Singh, A.; Dhaliwal, J.S.; Kapur, G.S. Polypropylene composites reinforced with hybrid inorganic fillers: Morphological, mechanical, and rheological properties. J. Thermoplast. Compos. Mater. 2019, 32, 848–864. [Google Scholar] [CrossRef]

- Saujanya, C.; Radhakrishnan, S. Structure development in PP/CaSO4 composites: Part I Preparation of the filler by an in situ technique. J. Mater. Sci. 1998, 33, 1063–1068. [Google Scholar] [CrossRef]

- Dong, F.; Liu, J.; Tan, H.; Wu, C.; He, X.; He, P. Preparation of calcium sulfate hemihydrate and application in polypropylene composites. J. Nanosci. Nanotechnol. 2017, 17, 6970–6975. [Google Scholar] [CrossRef]

- Xiang, G.; Liu, T.; Zhang, Y.; Xue, N. Synthesis of polypropylene composites with modified calcium sulfate whisker prepared from shale vanadium neutralization slag. Results Phys. 2018, 10, 28–35. [Google Scholar] [CrossRef]

- Dou, Q.; Duan, J. Melting and crystallization behaviors, morphology, and mechanical properties of β-polypropylene/polypropylene-graft-maleic anhydride/calcium sulfate whisker composites. Polym. Compos. 2016, 37, 2121–2132. [Google Scholar] [CrossRef]

- Murariu, M.; Paint, Y.; Murariu, O.; Laoutid, F.; Dubois, P. Recent advances in production of ecofriendly polylactide (PLA)-calcium sulfate (anhydrite II) composites: From the evidence of filler stability to the effects of PLA matrix and filling on key properties. Polymers 2022, 14, 2360. [Google Scholar] [CrossRef]

- Murariu, M.; Dubois, P. PLA composites: From production to properties. Adv. Drug Deliv. Rev. 2016, 107, 17–46. [Google Scholar] [CrossRef]

- Wirsching, F. Calcium sulfate. In Ullmann’s Encyclopedia of Industrial Chemistry; Wiley-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2012; Volume 6, pp. 519–550. [Google Scholar]

- Murariu, M.; Paint, Y.; Murariu, O.; Laoutid, F.; Dubois, P. Tailoring and long-term preservation of the properties of PLA composites with green plasticizers. Polymers 2022, 14, 4836. [Google Scholar] [CrossRef]

- Maddah, H. Polypropylene as a promising plastic: A review. Am. J. Polym. Sci. 2016, 6, 1–11. [Google Scholar] [CrossRef]

- Liang, J.-Z. Toughening and reinforcing in rigid inorganic particulate filled poly(propylene): A review. J. Appl. Polym. Sci. 2002, 83, 1547–1555. [Google Scholar] [CrossRef]

- Zuiderduin, W.C.J.; Westzaan, C.; Huetink, J.; Gaymans, R.J. Toughening of polypropylene with calcium carbonate particles. Polymer 2003, 44, 261–275. [Google Scholar] [CrossRef]

- Shubhra, Q.T.H.; Alam, A.K.M.M.; Quaiyyum, M.A. Mechanical properties of polypropylene composites: A review. J. Compos. 2011, 26, 362–391. [Google Scholar] [CrossRef]

- Tucker, J.D.; Lear, P.L.; Atkinson, G.S.; Lee, S.; Lee, S.J. Use of polymeric compatibilizers in polypropylene/calcium carbonate composites. Korean J. Chem. Eng. 2000, 17, 506–509. [Google Scholar] [CrossRef]

- Liu, H.; Tag Lim, H.; Hyun Ahn, K.; Jong Lee, S. Effect of ionomer on clay dispersions in polypropylene-layered silicate nanocomposites. J. Appl. Polym. Sci. 2007, 104, 4024–4034. [Google Scholar] [CrossRef]

- Santamaría, P.; Eguiazábal, J.I.; Nazábal, J. Structure and properties of polyethylene ionomer based nanocomposites. J. Appl. Polym. Sci. 2010, 116, 2374–2383. [Google Scholar] [CrossRef]

- Giordano, G. Finetuning process performance. Plast. Eng. 2021, 77, 18–21. [Google Scholar] [CrossRef]

- Technical data sheet Dymalink® 9200 (rev aug/2022). Cray Valley TotalEnergies. 2022. Available online: https://www.crayvalley.com/products/metallic-monomers/9200-series/ (accessed on 12 December 2022).

- Rivera-Armenta, J.L.; Salazar-Cruz, B.A.; Espindola-Flores, A.C.; Villarreal-Lucio, D.S.; De León-Almazán, C.M.; Estrada-Martinez, J. Thermal and thermomechanical characterization of polypropylene-seed shell particles composites. Appl. Sci. 2022, 12, 8336. [Google Scholar] [CrossRef]

- Lushnikova, N.; Dvorkin, L. Sustainability of gypsum products as a construction material. In Sustainability of Construction Materials; Elsevier: Amsterdam, The Netherlands, 2016; pp. 643–681. [Google Scholar]

- Murariu, M.; Da Silva Ferreira, A.; Degée, P.; Alexandre, M.; Dubois, P. Polylactide compositions. Part 1: Effect of filler content and size on mechanical properties of PLA/calcium sulfate composites. Polymer 2007, 48, 2613–2618. [Google Scholar] [CrossRef]

- Ma, Y.; Yang, G.; Xie, L. Morphology, nonisothermal crystallization behavior and mechanical properties of polypropylene modified by ionomers. J. Macromol. Sci. Part B 2014, 53, 1829–1845. [Google Scholar] [CrossRef]

- Naebpetch, W.; Junhasavasdikul, B.; Saetung, A.; Tulyapitak, T.; Nithi-Uthai, N. The influence of zinc dimethacrylate on crosslink density, physical properties and heat aging resistance of sulfur vulcanized styrene butadiene rubber. Adv. Mater. Res. 2014, 844, 45–48. [Google Scholar] [CrossRef]

- Chen, Y.; Xu, C.; Liang, X.; Cao, L. In situ reactive compatibilization of polypropylene/ethylene–propylene–diene monomer thermoplastic vulcanizate by zinc dimethacrylate via peroxide-induced dynamic vulcanization. J. Phys. Chem. B 2013, 117, 10619–10628. [Google Scholar] [CrossRef]

- Total Cray Valley develops ionomeric additives to improve polyolefin performance. Addit. Polym. 2015, 2015, 1–2. [CrossRef]

- Li, Y.; Yao, Z.; Chen, Z.-h.; Qiu, S.-l.; Zeng, C.; Cao, K. High melt strength polypropylene by ionic modification: Preparation, rheological properties and foaming behaviors. Polymer 2015, 70, 207–214. [Google Scholar] [CrossRef]

- Wu, M.-H.; Wang, C.-C.; Chen, C.-Y. Preparation of high melt strength polypropylene by addition of an ionically modified polypropylene. Polymer 2020, 202, 122743. [Google Scholar] [CrossRef]

- Cai, D.; Li, Y.; Wang, W.; Ma, Y.; Cao, N.; Zhang, J.; Pan, D.; Naik, N.; Wei, S.; Huang, M.; et al. Reinforcing and toughening blends of recycled acrylonitrile-butadiene-styrene/recycled high-impact polystyrene through ionic crosslinking. Surf. Interfaces 2022, 28, 101607. [Google Scholar] [CrossRef]

- Robb, B. An additive approach to tailored melt strength in PP and TPO. In Proceedings of the 21st SPE Automotive TPO Engineered Polyolefins Global Conference 2019 (SPE Automotive TPO 2019), Troy, MI, USA, 6–9 October 2019. [Google Scholar]

- Zhou, S.; Zhou, J.; Li, L.; Zhao, S.; Shi, Y.; Xin, Z. Relationship between peroxide initiators and properties of styrene grafted polypropylene via reactive extrusion. J. Macromol. Sci. Part B 2018, 57, 377–394. [Google Scholar] [CrossRef]

- Stanic, S.; Gottlieb, G.; Koch, T.; Göpperl, L.; Schmid, K.; Knaus, S.; Archodoulaki, V.-M. Influence of different types of peroxides on the long-chain branching of PP via reactive extrusion. Polymers 2020, 12, 886. [Google Scholar] [CrossRef]

- Saikrishnan, S.; Jubinville, D.; Tzoganakis, C.; Mekonnen, T.H. Thermo-mechanical degradation of polypropylene (PP) and low-density polyethylene (LDPE) blends exposed to simulated recycling. Polym. Degrad. Stab. 2020, 182, 109390. [Google Scholar] [CrossRef]

- Rätzsch, M.; Arnold, M.; Borsig, E.; Bucka, H.; Reichelt, N. Radical reactions on polypropylene in the solid state. Prog. Polym. Sci. 2002, 27, 1195–1282. [Google Scholar] [CrossRef]

- Marozsan, A.; Lodefier, P.; Robb, B.; Chabrol, V. A New Method to Modify PP for Improved Melt Strength. In Proceedings of the SPE International Polyolefin Conference 2017, Houston, TX, USA, 26 February 2017. [Google Scholar]

- Capek, I. Dispersions of polymer ionomers: I. Adv. Colloid Interface Sci. 2004, 112, 1–29. [Google Scholar] [CrossRef]

- Wurm, F.; Rietzler, B.; Pham, T. Multivalent ions as reactive crosslinkers for biopolymers-a review. Molecules 2020, 25, 1840. [Google Scholar] [CrossRef]

- Najeeb, S.; Khurshid, Z.; Zafar, M.S.; Khan, A.S.; Zohaib, S.; Martí, J.M.N.; Sauro, S.; Matinlinna, J.P.; Rehman, I.U. Modifications in glass ionomer cements: Nano-sized fillers and bioactive nanoceramics. Int. J. Mol. Sci. 2016, 17, 1134. [Google Scholar] [CrossRef]

- Li, J.; Li, J.; Feng, D.; Zhao, J.; Sun, J.; Li, D. Excellent rheological performance and impact toughness of cellulose nanofibers/PLA/ionomer composite. RSC Adv. 2017, 7, 28889–28897. [Google Scholar] [CrossRef]

- Villanueva, M.P.; Cabedo, L.; Lagarón, J.M.; Giménez, E. Comparative study of nanocomposites of polyolefin compatibilizers containing kaolinite and montmorillonite organoclays. J. Appl. Polym. Sci. 2010, 115, 1325–1335. [Google Scholar] [CrossRef]

- Pluta, M.; Murariu, M.; Da Silva Ferreira, A.; Alexandre, M.; Galeski, A.; Dubois, P. Polylactide compositions. II. Correlation between morphology and main properties of PLA/calcium sulfate composites. J. Polym. Sci. Part B Polym. Phys. 2007, 45, 2770–2780. [Google Scholar] [CrossRef]

| Sample Code | PP, wt.% | AII, wt.% | Modifier, wt.% |

|---|---|---|---|

| PP | 100 | - | - |

| PP–20AII | 80 | 20 | - |

| PP–20AII–PPMA1 | 75 | 20 | 5 |

| PP–20AII–ZnDA | 78 | 20 | 2 |

| PP–40AII | 60 | 40 | - |

| PP–40AII–PPMA1 | 55 | 40 | 5 |

| PP–40AII–ZnDA | 58 | 40 | 2 |

| Sample Code | T5%, °C | Td, °C | Residual Product at 600 °C, wt.% |

|---|---|---|---|

| PP | 283 | 349 | 0.1 |

| PP–20AII | 295 | 374 | 19.4 |

| PP–20AII–PPMA1 | 293 | 365 | 20.6 |

| PP–20AII–ZnDA | 308 | 412 | 21.8 |

| PP–40AII | 316 | 400 | 40.3 |

| PP–40AII–PPMA1 | 314 | 404 | 40.5 |

| PP–40AII–ZnDA | 332 | 415 | 41.2 |

| Sample | DSC Cooling | Second DSC Heating | |||

|---|---|---|---|---|---|

| Tc, °C | ΔHc, J/g | Tm, °C | ΔHm, J/g | χ, % | |

| PP | 116 | 93.2 | 161 | 93.6 | 45.2 |

| PP–20AII | 121 | 97.2 | 163 | 98.2 | 47.4 |

| PP–20AII–PPMA1 | 115 | 94.6 | 160 | 94.8 | 45.8 |

| PP–20AII–ZnDA | 126 | 96.4 | 164 | 99.5 | 48.1 |

| PP–40AII | 120 | 94.5 | 163 | 96.6 | 46.7 |

| PP–40AII–PPMA1 | 119 | 91.2 | 161 | 92.5 | 44.7 |

| PP–40AII–ZnDA | 126 | 93.2 | 164 | 99.9 | 48.3 |

| Properties | PP (TSE) | PP–20AII–ZnDA (TSE) | PP–40AII–ZnDA (TSE) |

|---|---|---|---|

| Tensile properties * | |||

| 29 (±1)/yield | 34 (±1) | 35 (±1) |

| 34 (±1) | 33 (±1) | 34 (±1) |

| 1300 (±50) | 1800 (±10) | 2200 (±50) |

| 8.4 (±0.5)/yield | 6.1 (±0.2) | 4.8 (±0.1) |

| 476 (±30) | 8.1 (±0.5) | 5.1 (±0.1) |

| Flexural properties * | |||

| 37 (±2) | 48 (±2) | 52 (±1) |

| 1160 (±70) | 1850 (±40) | 2550 (±90) |

| >20 | >20 | 14 (±1) |

| Izod impact resistance, kJ/m2 * | 1.9 (±0.4) | 2.7 (±0.1) | 2.8 (±0.1) |

| Rheological properties | |||

| 15.3 | 8.7 | 5.5 |

| Sample | Temperature, °C | |||

|---|---|---|---|---|

| −50 | 0 | 50 | 100 | |

| ↓ Storage Modulus, MPa | ||||

| PP (TSE) | 2950 | 2300 | 850 | 250 |

| PP–20AII–ZnDA (TSE) | 3850 | 3100 | 1250 | 450 |

| PP–40AII–ZnDA (TSE) | 4800 | 3950 | 1750 | 650 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Murariu, M.; Paint, Y.; Murariu, O.; Laoutid, F.; Dubois, P. Engineering Polypropylene–Calcium Sulfate (Anhydrite II) Composites: The Key Role of Zinc Ionomers via Reactive Extrusion. Polymers 2023, 15, 799. https://doi.org/10.3390/polym15040799

Murariu M, Paint Y, Murariu O, Laoutid F, Dubois P. Engineering Polypropylene–Calcium Sulfate (Anhydrite II) Composites: The Key Role of Zinc Ionomers via Reactive Extrusion. Polymers. 2023; 15(4):799. https://doi.org/10.3390/polym15040799

Chicago/Turabian StyleMurariu, Marius, Yoann Paint, Oltea Murariu, Fouad Laoutid, and Philippe Dubois. 2023. "Engineering Polypropylene–Calcium Sulfate (Anhydrite II) Composites: The Key Role of Zinc Ionomers via Reactive Extrusion" Polymers 15, no. 4: 799. https://doi.org/10.3390/polym15040799

APA StyleMurariu, M., Paint, Y., Murariu, O., Laoutid, F., & Dubois, P. (2023). Engineering Polypropylene–Calcium Sulfate (Anhydrite II) Composites: The Key Role of Zinc Ionomers via Reactive Extrusion. Polymers, 15(4), 799. https://doi.org/10.3390/polym15040799