Reinforcement Behavior of Chemically Unmodified Cellulose Nanofiber in Natural Rubber Nanocomposites

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of CNF/NR Nanocomposites

2.3. Characterization

2.3.1. Transmission Electron Microscopy (TEM)

2.3.2. Wide-Angle X-ray Diffraction (WAXD) Measurements

2.3.3. Mechanical Property Measurements

2.3.4. Dynamic Mechanical Analysis (DMA)

2.3.5. Bound Rubber

2.3.6. Gel Content

3. Results and Discussion

3.1. Dispersion of CNF in the CNF/NR Nanocomposites

3.2. Stress-Strain Behavior of NR and CNF/NR Nanocomposites

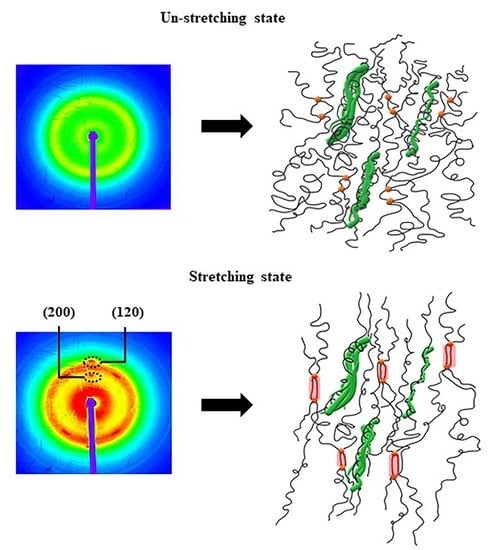

3.3. Strain-Induced Crystallization of the NR and the CNF/NR Nanocomposites

3.4. Dynamic Mechanical Properties of the CNF/NR Nanocomposites

3.5. Bound Rubber and Gel Content of the CNF/NR Nanocomposites

3.6. Model of Reinforcement Mechanism

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Toki, S.; Sics, I.; Ran, S.; Liu, L.; Hsiao, B.S. Molecular orientation and structural development in vulcanized polyisoprene rubbers during uniaxial deformation by in situ synchrotron X-ray diffraction. Polymer 2003, 44, 6003–6011. [Google Scholar] [CrossRef]

- Trabelsi, S.; Albouy, P.-A.; Rault, J. Crystallization and Melting Processes in Vulcanized Stretched Natural Rubber. Macromolecules 2003, 36, 7624–7639. [Google Scholar] [CrossRef]

- Masa, A.; Iimori, S.; Saito, R.; Saito, H.; Sakai, T.; Kaesaman, A.; Lopattananon, N. Strain-induced crystallization behavior of phenolic resin crosslinked natural rubber/clay nanocomposites. J. Appl. Polym. Sci. 2015, 132, 42580. [Google Scholar] [CrossRef]

- Masa, A.; Saito, R.; Saito, H.; Sakai, T.; Kaesaman, A.; Lopattananon, N. Phenolic resin-crosslinked natural rubber/clay nanocomposites: Influence of clay loading and interfacial adhesion on strain-induced crystallization behavior. J. Appl. Polym. Sci. 2016, 133, 43214. [Google Scholar] [CrossRef]

- Masa, A.; Saito, H.; Sakai, T.; Kaesaman, A.; Lopattananon, N. Morphological evolution and mechanical property enhancement of natural rubber/polypropylene blend through compatibilization by nanoclay. J. Appl. Polym. Sci. 2017, 134, 44574. [Google Scholar] [CrossRef]

- Nie, Y.; Qu, L.; Huang, G.; Wang, X.; Weng, G.; Wu, J. Homogenization of Natural Rubber Network Induced by Nanoclay. J. Appl. Polym. Sci. 2014, 131, 40324. [Google Scholar] [CrossRef]

- Hsieh, Y.-C.; Yano, H.; Nogi, M.; Eichhorn, S.J. An estimation of the Young’s modulus of bacterial cellulose filaments. Cellulose 2008, 15, 507–513. [Google Scholar] [CrossRef]

- Rusli, R.; Eichhorn, S.J. Determination of the stiffness of cellulose nanowhiskers and the fiber-matrix interface in a nanocomposite using Raman spectroscopy. Appl. Phys. Lett. 2008, 93, 033111. [Google Scholar] [CrossRef]

- Matsuo, M.; Sawatari, C.; Iwai, Y.; Ozaki, F. Effect of Orientation Distribution and Crystallinity on the Measurement by X-ray Diffraction of the Crystal Lattice Moduli of Cellulose I and II. Macromolecules 1990, 23, 3266–3275. [Google Scholar] [CrossRef]

- Sakurada, I.; Nukushina, Y.; Ito, T. Experimental determination of the elastic modulus of crystalline regions in oriented polymers. J. Polym. Sci. 1962, 57, 651–660. [Google Scholar] [CrossRef]

- Šturcová, A.; Davies, G.R.; Eichhorn, S.J. Elastic Modulus and Stress-Transfer Properties of Tunicate Cellulose Whiskers. Biomacromolecules 2005, 6, 1055–1061. [Google Scholar] [CrossRef]

- Saito, T.; Kuramae, R.; Wohlert, J.; Berglund, L.-A.; Isogai, A. An Ultrastrong Nanofibrillar Biomaterial: The Strength of SingleCellulose Nanofibrils Revealed via Sonication-Induced Fragmentation. Biomacromolecules 2013, 14, 248–253. [Google Scholar] [CrossRef]

- Nechyporchuk, O.; Belgacem, M.N.; Bras, J. Production of cellulose nanofibrils: A review of recent advances. Ind. Crop. Prod. 2016, 93, 2–25. [Google Scholar] [CrossRef]

- Xu, X.; Liu, F.; Jiang, L.; Zhu, J.Y.; Haagenson, D.; Wiesenborn, D.P. Cellulose Nanocrystals vs. Cellulose Nanofibrils: A Comparative Study on Their Microstructures and Effects as Polymer Reinforcing Agents. ACS Appl. Mater. Interfaces 2013, 5, 2999–3009. [Google Scholar] [CrossRef] [PubMed]

- Wang, G.; Yang, X.; Wang, W. Reinforcing Linear Low-Density Polyethylene with Surfactant-Treated Microfibrillated Cellulose. Polymers 2019, 11, 441. [Google Scholar] [CrossRef] [Green Version]

- Yasim-Anuar, T.A.T.; Arin, H.; Norrrahim, M.N.F.; Hassan, M.A.; Andou, Y.; Tsukegi, T.; Nishida, H. Well-Dispersed Cellulose Nanofiber in Low Density Polyethylene Nanocomposite by Liquid-Assisted Extrusion. Polymers 2020, 12, 927. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Siqueira, G.; Bras, J.; Dufresne, A. Cellulose whiskers versus microfibrils: Influence of the nature of the nanoparticle and its surface functionalization on the thermal and mechanical properties of nanocomposites. Biomacromolecules 2009, 10, 425–432. [Google Scholar] [CrossRef] [PubMed]

- Herrera, N.; Mathew, A.P.; Oksman, K. Plasticized polylactic acid/cellulose nanocomposites prepared using melt-extrusion and liquid feeding: Mechanical, thermal and optical properties. Compos. Sci. Technol. 2015, 106, 149–155. [Google Scholar] [CrossRef]

- Lo Re, G.; Engström, J.; Wu, Q.; Malmström, E.; Gedde, U.W.; Olsson, R.T.; Berglund, L. Improved Cellulose Nanofibril Dispersion in Melt-Processed Polycaprolactone Nanocomposites by a Latex-Mediated Interphase and Wet Feeding as LDPE Alternative. ACS Appl. Nano Mater. 2018, 1, 2669–2677. [Google Scholar] [CrossRef]

- Fumagalli, M.; Berriot, J.; Gaudemaris, B.; Veyland, A.; Putaux, J.-L.; Molina-Boisseau, S.; Heux, L. Rubber Materials from Elastomers and Nanocellulose Powders: Filler Dispersion and Mechanical Reinforcement. Soft Matter 2018, 14, 2638–2648. [Google Scholar] [CrossRef] [PubMed]

- Fukui, S.; Ito, T.; Saito, T.; Noguchi, T.; Isogai, A. Surface-hydrophobized TEMPO-nanocellulose/rubber composite films prepared in heterogeneous and homogeneous systems. Cellulose 2019, 26, 463–473. [Google Scholar] [CrossRef]

- Sinclair, A.; Zhou, X.; Tangpong, S.; Bajwa, D.S.; Quadir, M.; Jiang, L. High-Performance Styrene-Butadiene Rubber Nanocomposites Reinforced by Surface-Modified Cellulose Nanofibers. ACS Omega 2019, 4, 13189–13199. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Balachandrakurup, V.; Gopalakrishnan, J. Enhanced performance of cellulose nanofibre reinforced styrene butadiene rubber nanocomposites modified with epoxidised natural rubber. Ind. Crop. Prod. 2022, 183, 114935. [Google Scholar] [CrossRef]

- Abraham, E.; Deepa, B.; Pothan, L.A.; John, M.; Narine, S.S.; Thomas, S.; Anandjiwala, R. Physicomechanical properties of nanocomposites based on cellulose nanofibre and natural rubber latex. Cellulose 2013, 20, 417–427. [Google Scholar] [CrossRef]

- Thomas, M.G.; Abraham, E.; Jyotishkumar, P.; Maria, H.J.; Pothan, L.A.; Thomas, S. Nanocelluloses from jute fibres and their nanocomposites with natural rubber: Preparation and characterization. Int. J. Biol. Macromol. 2015, 81, 768–777. [Google Scholar] [CrossRef]

- Kumagai, A.; Tajima, N.; Iwamoto, S.; Morimoto, T.; Nagatani, A.; Okazaki, T.; Endo, T. Properties of natural rubber reinforced with cellulose nanofibers based on fiber diameter distribution as estimated by differential centrifugal sedimentation. Int. J. Biol. Macromol. 2019, 121, 989–995. [Google Scholar] [CrossRef]

- Dominic, M.; Joseph, R.; Begum, P.M.S.; Joseph, M.; Padmanabhan, D.; Morris, L.A.; Kumar, A.S.; Formela, K. Cellulose Nanofibers Isolated from the Cuscuta Reflexa Plant as a Green Reinforcement of Natural Rubber. Polymers 2020, 12, 814. [Google Scholar] [CrossRef] [Green Version]

- Kato, H.; Nakatsubo, F.; Abe, K.; Yano, H. Crosslinking via sulfur vulcanization of natural rubber and cellulose nanofibers incorporating unsaturated fatty acids. RSC Adv. 2015, 5, 29814–29819. [Google Scholar] [CrossRef]

- Chenal, J.-M.; Gauthier, C.; Chazeau, L.; Guy, L.; Bomal, Y. Parameters governing strain induced crystallization in filled natural rubber. Polymer 2007, 48, 6893–6901. [Google Scholar] [CrossRef] [Green Version]

- Laghmach, R.; Biben, T.; Chazeau, L.; Chenal, J.M.; Munch, E.; Gauthier, C. Strain-induced crystallization in natural rubber: A model for the microstructural evolution. In Constitutive Models for Rubber VIII, 1st ed.; Gil-Negrete, N., Alonso, A., Eds.; CRC Press: London, UK, 2013. [Google Scholar]

- Candau, N.; Laghmach, R.; Chazeau, L.; Chenal, J.-M.; Gauthier, C.; Biben, T.; Munch, E. Strain-Induced Crystallization of Natural Rubber and Cross-Link Densities Heterogeneities. Macromolecules 2014, 47, 5815–5824. [Google Scholar] [CrossRef]

- Masa, A.; Hayeemasae, N.; Soontaranon, S.; Mohd Pisal, M.H.; Mohamad Rasidi, M.S. Effect of Stretching Rate on Tensile Response and Crystallization Behavior of Crosslinked Natural Rubber. Malays. J. Fundam. Appl. Sci. 2021, 17, 217–225. [Google Scholar] [CrossRef]

- Fu, X.; Huang, G.; Xie, Z.; Xing, W. New insights into reinforcement mechanism of nanoclay-filled isoprene rubber during uniaxial deformation by in situ synchrotron X-ray diffraction. RSC Adv. 2015, 5, 25171–25182. [Google Scholar] [CrossRef]

- Ozbas, B.; Toki, S.; Hsiao, B.S.; Chu, B.; Register, R.A.; Aksay, I.A.; Prud’homme, R.K.; Adamson, D.H. Strain-Induced Crystallization and Mechanical Properties of Functionalized Graphene Sheet-Filled Natural Rubber. J. Polym. Sci. B Polym. Phys. 2012, 50, 718–723. [Google Scholar] [CrossRef]

- Beurrot-Borgarino, S.; Huneau, B.; Verron, E.; Rublon, P. Strain-induced crystallization of carbon black-filled natural rubber during fatigue measured by in situ synchrotron X-ray diffraction. Int. J. Fatigue 2013, 47, 1–7. [Google Scholar] [CrossRef] [Green Version]

- Weng, G.; Huang, G.; Qu, L.; Nie, Y.; Wu, J. Large-Scale Orientation in a Vulcanized Stretched Natural Rubber Network: Proved by In Situ Synchrotron X-ray Diffraction Characterization. J. Phys. Chem. B 2010, 114, 7179–7188. [Google Scholar] [CrossRef] [PubMed]

- Wongvasana, B.; Thongnuanchan, B.; Masa, A.; Saito, H.; Sakai, T.; Lopattananon, N. Comparative Structure–Property Relationship between Nanoclay and Cellulose Nanofiber Reinforced Natural Rubber Nanocomposites. Polymers 2022, 14, 3747. [Google Scholar] [CrossRef]

- Arroyo, M.; Lo’pez-Manchado, M.A.; Herrero, B. Organo-montmorillonite as substitute of carbon black in natural rubber compounds. Polymer 2003, 44, 2447–2453. [Google Scholar] [CrossRef]

- Qu, L.; Huang, G.; Liu, Z.; Zhang, P.; Weng, G.; Nie, Y. Remarkable reinforcement of natural rubber by deformation-induced crystallization in the presence of organophilic montmorillonite. Acta Mater. 2009, 57, 5053–5060. [Google Scholar] [CrossRef]

- Dannenberg, E.M. Bound Rubber and Carbon Black Reinforcement. Rubber Chem. Technol. 1986, 59, 512–524. [Google Scholar] [CrossRef]

- Lopattananon, N.; Tanglakwaraskul, S.; Kaesaman, A.; Seadan, M.; Sakai, T. Effect of Nanoclay Addition on Morphology and Elastomeric Properties of Dynamically Vulcanized Natural Rubber/Polypropylene Nanocomposites. Int. Polym. Process. 2014, 29, 332–341. [Google Scholar] [CrossRef]

- Siró, I.; Plackett, D. Microfibrillated cellulose and new nanocomposite materials: A review. Cellulose 2010, 17, 459–494. [Google Scholar] [CrossRef]

- Mishra, R.K.; Sabu, A.; Tiwari, S.K. Materials chemistry and the futurist eco-friendly applications of nanocellulose: Status and prospect. J. Saudi Chem. Soc. 2018, 22, 949–978. [Google Scholar] [CrossRef]

- Kargarzadeh, H.; Mariano, M.; Gopakumar, D.; Ahmad, I.; Thomas, S.; Dufresne, A.; Huang, J.; Lin, N. Advances in cellulose nanomaterials. Cellulose 2018, 25, 2151–2189. [Google Scholar] [CrossRef]

- Fiorote, J.A.; Freire, A.P.; Rodrigues, D.D.S.; Martins, M.A.; Andreani, L.; Valadares, L.F. Preparation of composites from natural rubber and oil palm empty fruit bunch cellulose: Effect of cellulose morphology on properties. Bioresources 2019, 14, 3168–3181. [Google Scholar] [CrossRef]

- Zhang, C.; Zhai, T.; Sabo, R.; Clemons, C.; Dan, Y.; Turng, L.-S. Reinforcing Natural Rubber with Cellulose Nanofibrils Extracted from Bleached Eucalyptus Kraft Pulp. J. Biobased Mater. Bioenergy 2014, 8, 317–324. [Google Scholar] [CrossRef]

- Thomas, S.; Stephen, R. Rubber Nanocomposites: Preparation, Properties and Applications, 1st ed.; Wiley: Singapore, 2010; pp. 291–330. [Google Scholar]

- Karino, T.; Ikeda, Y.; Yasuda, Y.; Kohjiya, S.; Shibayama, M. Nonuniformity in Natural Rubber As Revealed by Small-Angle Neutron Scattering, Small-Angle X-ray Scattering, and Atomic Force Microscopy. Biomacromolecules 2007, 8, 693–699. [Google Scholar] [CrossRef]

- Dalmas, F.; Chazeau, L.; Gauthier, C.; Cavaillé, J.-Y.; Dendievel, R. Large deformation mechanical behavior of flexible nanofiber filled polymer nanocomposites. Polymer 2006, 47, 2802–2812. [Google Scholar] [CrossRef]

- Kristo, E.; Biliaderis, C.G. Physical properties of starch nanocrystal-reinforced pullulan films. Carbohydr. Polym. 2007, 68, 146–158. [Google Scholar] [CrossRef]

- Georgopoulos, S.; Tarantili, P.A.; Avgerinos, E.; Andreopoulos, A.G.; Koukios, E.G. Thermoplastic polymers reinforced with fibrous agricultural residues. Polym. Degrad. Stab. 2005, 90, 303–312. [Google Scholar] [CrossRef]

- Beurrot-Borgarino, S.; Huneau, B.; Verron, E.; Thiaudière, D.; Mocuta, C.; Zozulya, A. Characteristics of Strain-Induced Crystallization in Natural Rubber During Fatigue Testing: In situ Wide-Angle X-ray Diffraction Measurements Using Synchrotron Radiation. Rubb. Chem. Technol. 2014, 87, 184–196. [Google Scholar] [CrossRef] [Green Version]

- French, A.D. Idealized powder diffraction patterns for cellulose polymorphs. Cellulose 2014, 21, 885–896. [Google Scholar] [CrossRef]

- Peng, S.; Iroh, J.O. Dependence of the Dynamic Mechanical Properties and Structure of Polyurethane-Clay Nanocomposites on the Weight Fraction of Clay. Compos. Sci. 2022, 6, 173. [Google Scholar] [CrossRef]

- Visakh, P.M.; Thomas, S.; Oksman, K.; Mathew, A.P. Effect of cellulose nanofibers isolated from bamboo pulp residue on vulcanized natural rubber. BioRes 2012, 7, 2156–2168. [Google Scholar] [CrossRef] [Green Version]

- Ikeda, Y.; Phakkeeree, T.; Junkong, P.; Yokohama, H.; Phinyocheep, P.; Kitano, R.; Kato, A. Reinforcing biofiller “Lignin” for high performance green natural rubber nanocomposites. RSC Adv. 2017, 7, 5222–5231. [Google Scholar] [CrossRef] [Green Version]

- Kumar, V.; Alam, M.N.; Manikkavel, A.; Song, M.; Lee, D.-J.; Park, S.-S. Silicone Rubber Composites Reinforced by Carbon Nanofillers and Their Hybrids for Various Applications: A Review. Polymers 2021, 13, 2322. [Google Scholar] [CrossRef] [PubMed]

- Robertson, C.G.; Hardman, N.J. Nature of Carbon Black Reinforcement of Rubber: Perspective on the Original Polymer Nanocomposite. Polymers 2021, 13, 538. [Google Scholar] [CrossRef]

- Huang, Y.; Gohs, U.; Müller, M.T.; Zschech, C.; Wießner, S. Evaluation of Electron Induced Crosslinking of Masticated Natural Rubber at Different Temperatures. Polymers 2019, 11, 1279. [Google Scholar] [CrossRef] [Green Version]

- Cox, H.L. The elasticity and strength of paper and other fibrous materials. J. Appl. Phys. 1952, 3, 72–79. [Google Scholar] [CrossRef]

- Hull, D.; Clyne, T.W. An Introduction to Composite Materials, 2nd ed.; Cambridge University Press: New York, NY, USA, 1996. [Google Scholar]

| Ingredients | Parts per Hundred Rubber (phr) | |||

|---|---|---|---|---|

| NR | CNF1/NR | CNF3/NR | CNF5/NR | |

| NR | 100 | 100 | 100 | 100 |

| CNF | - | 1 | 3 | 5 |

| Paraffinic oil | 20 | 20 | 20 | 20 |

| TMQ | 2 | 2 | 2 | 2 |

| DCP | 1 | 1 | 1 | 1 |

| Samples | Dimension Range of CNFs (nm) | Average Thickness of the CNFs (nm) |

|---|---|---|

| CNF1/NR | 3–184 | 65 ± 63 |

| CNF3/NR | 30–345 | 140 ± 99 |

| CNF5/NR | 1000–3000 | 1700 ± 700 |

| Samples | 50% Modulus (MPa) | 100% Modulus (MPa) | 300% Modulus (MPa) | Tensile Strength (MPa) | Elongation at Break (%) | Crosslink Density (×10−5 mol/g) |

|---|---|---|---|---|---|---|

| NR | 0.22 ± 0.02 | 0.24 ± 0.03 | 0.49 ± 0.06 | 3.26 ± 0.66 | 759 ± 20 | 3.22 ± 0.20 |

| CNF1/NR | 0.23 ± 0.03 | 0.35 ± 0.02 | 0.70 ± 0.06 | 7.26 ± 1.03 | 757 ± 38 | 3.67 ± 0.14 |

| CNF3/NR | 0.42 ± 0.05 | 0.76 ± 0.08 | 1.56 ± 0.16 | 3.08 ± 0.47 | 470 ± 43 | 4.79 ± 0.20 |

| CNF5/NR | 0.50 ± 0.06 | 0.90 ± 0.03 | 2.55 ± 0.43 | 2.56 ± 0.31 | 302 ± 21 | 4.92 ± 0.11 |

| Samples | Log E′ at 25 °C (MPa) | Tan δ max | Tg (°C) |

|---|---|---|---|

| NR | 5.79 | 2.85 | −60.1 |

| CNF1/NR | 6.18 | 2.55 | −59.2 |

| CNF3/NR | 6.21 | 1.71 | −58.9 |

| CNF5/NR | 6.30 | 1.64 | −58.1 |

| Samples | Bound Rubber Content (%) | Gel Content (%) |

|---|---|---|

| NR | N/A | 80.12 ± 0.11 |

| CNF1/NR | N/A | 80.24 ± 0.32 |

| CNF3/NR | N/A | 80.38 ± 0.08 |

| CNF5/NR | 9.06 ± 1.18 | 80.43 ± 0.73 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wongvasana, B.; Thongnuanchan, B.; Masa, A.; Saito, H.; Sakai, T.; Lopattananon, N. Reinforcement Behavior of Chemically Unmodified Cellulose Nanofiber in Natural Rubber Nanocomposites. Polymers 2023, 15, 1274. https://doi.org/10.3390/polym15051274

Wongvasana B, Thongnuanchan B, Masa A, Saito H, Sakai T, Lopattananon N. Reinforcement Behavior of Chemically Unmodified Cellulose Nanofiber in Natural Rubber Nanocomposites. Polymers. 2023; 15(5):1274. https://doi.org/10.3390/polym15051274

Chicago/Turabian StyleWongvasana, Bunsita, Bencha Thongnuanchan, Abdulhakim Masa, Hiromu Saito, Tadamoto Sakai, and Natinee Lopattananon. 2023. "Reinforcement Behavior of Chemically Unmodified Cellulose Nanofiber in Natural Rubber Nanocomposites" Polymers 15, no. 5: 1274. https://doi.org/10.3390/polym15051274

APA StyleWongvasana, B., Thongnuanchan, B., Masa, A., Saito, H., Sakai, T., & Lopattananon, N. (2023). Reinforcement Behavior of Chemically Unmodified Cellulose Nanofiber in Natural Rubber Nanocomposites. Polymers, 15(5), 1274. https://doi.org/10.3390/polym15051274