A Comprehensive Study of Polyurethane Potting Compounds Doped with Magnesium Oxide Nanoparticles

Abstract

:1. Introduction

2. Materials

2.1. Polyurethane Matrices

2.2. Magnesium Oxide Filler

2.3. PUR/MgO Preparation and Fundamental Optical Characterization

3. Methods

3.1. Nuclear Magnetic Resonance Spectroscopy Measurements

3.2. Thermogravimetric Analyses

3.3. Broadband Dielectric Spectroscopy Measurement

3.4. Vector Bridge Measurements

3.5. Resistivity Measurements

3.6. Dielectric Strength Measurements

3.7. Tensile Tests

4. Results and Discussion

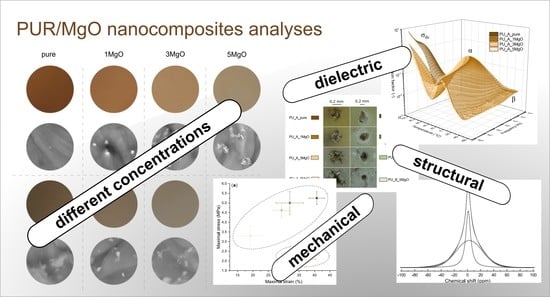

4.1. Effect of MgO on the Structural Properties of Polyurethane

4.1.1. Nuclear Magnetic Resonance Spectroscopy

4.1.2. Thermogravimetric Analyses

4.2. Effect of MgO on the Dielectric Properties of Polyurethane

4.2.1. Volume Resistivity and Surface Resistivity

4.2.2. Relative Permittivity and Dissipation Factor under Different Measurement Conditions

4.2.3. Breakdown Voltage Measurement

4.3. Effect of MgO on the Mechanical Properties of Polyurethane

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Szycher, M. Polyurethanes. In Szycher’S Handbook of Polyurethanes; CRC Press Taylor & Francis Group: Boca Raton, FL, USA, 2013; pp. 1–12. [Google Scholar]

- Volkova, E.R.; Tereshatov, V.V.; Karmanov, V.I.; Makarova, M.A.; Slobodinyuk, A.I. Polyurethane adhesive composition cured at room temperature. Polym. Sci. Ser. D 2013, 6, 120–124. [Google Scholar] [CrossRef]

- Liu, S.H.; Shen, M.Y.; Kuan, C.F.; Kuan, H.C.; Ke, C.Y.; Chiang, C.L. Improving Thermal Stability of Polyurethane through the Addition of Hyperbranched Polysiloxane. Polymers 2019, 11, 697. [Google Scholar] [CrossRef] [Green Version]

- Pagacz, J.; Hebda, E.; Janowski, B.; Sternik, D.; Jancia, M.; Pielichowski, K. Thermal decomposition studies on polyurethane elastomers reinforced with polyhedral silsesquioxanes by evolved gas analysis. Polym. Degrad. Stab. 2018, 149, 129–142. [Google Scholar] [CrossRef]

- Amado, J.C.Q. Thermal Resistance Properties of Polyurethanes and Its Composites. In Thermosoftening Plastics; Evingür, G.A., Pekcan, Ö., Achilias, D.S., Eds.; IntechOpen: London, UK, 2019. [Google Scholar] [CrossRef] [Green Version]

- Gaboriaud, F.; Vantelon, J.P. Mechanism of thermal degradation of polyurethane based on MDI and propoxylated trimethylol propane. J. Polym. Sci. Polym. Chem. Ed. 1982, 20, 2063–2071. [Google Scholar] [CrossRef]

- Kumagai, S.; Motokucho, S.; Yabuki, R.; Anzai, A.; Kameda, T.; Watanabe, A.; Nakatani, H.; Yoshioka, T. Effects of hard- and soft-segment composition on pyrolysis characteristics of MDI, BD, and PTMG-based polyurethane. JAAP 2017, 126, 337–345. [Google Scholar] [CrossRef]

- Bugrov, A.N.; Gorshkova, Y.E.; Ivan’kova, E.M.; Kopitsa, G.P.; Pavlova, A.A.; Popova, E.N.; Smirnova, V.E.; Smyslov, R.Y.; Svetlichnyi, V.M.; Vaganov, G.V.; et al. Domain Structure, Thermal and Mechanical Properties of Polycaprolactone-Based Multiblock Polyurethane-Ureas under Control of Hard and Soft Segment Lengths. Polymers 2022, 14, 4145. [Google Scholar] [CrossRef]

- Jiang, L.; Ren, Z.; Zhao, W.; Liu, W.; Liu, H.; Zhu, C. Synthesis and structure/properties characterizations of four polyurethane model hard segments. R. Soc. Open Sci. 2018, 5, 180536. [Google Scholar] [CrossRef] [Green Version]

- Jin, X.; Guo, N.; You, Z.; Tan, Y. Design and Performance of Polyurethane Elastomers Composed with Different Soft Segments. Materials 2020, 13, 4991. [Google Scholar] [CrossRef]

- Klinedinst, D.B.; Yilgör, I.; Yilgör, E.; Zhang, M.; Wilkes, G.L. The effect of varying soft and hard segment length on the structure–property relationships of segmented polyurethanes based on a linear symmetric diisocyanate, 1,4-butanediol and PTMO soft segments. Polymer 2012, 53, 5358–5366. [Google Scholar] [CrossRef]

- Liu, H.; Bi, Z.; Wan, Z.; Wang, X.; Wan, Y.; Guo, X.; Cai, Z. Preparation and Performance Optimization of Two-Component Waterborne Polyurethane Locomotive Coating. Coatings 2020, 10, 4. [Google Scholar] [CrossRef] [Green Version]

- Vaca, M.L.A.; Gonzalez, J.S.; Hoppe, C.E. Soft Elastomers Based on the Epoxy–Amine Chemistry and Their Use for the Design of Adsorbent Amphiphilic Magnetic Nanocomposites. Macromol 2022, 2, 426–439. [Google Scholar] [CrossRef]

- Saeedi, I.A.; Andritsch, T.; Vaughan, A.S. On the Dielectric Behavior of Amine znd Anhydride Cured Epoxy Resins Modified Using Multi-Terminal Epoxy Functional Network Modifier. Polymers 2019, 11, 1271. [Google Scholar] [CrossRef] [Green Version]

- Petrović, Z.S.; Ferguson, J. Polyurethane elastomers. Prog. Polym. Sci. 1991, 16, 695–836. [Google Scholar] [CrossRef]

- Ouellette, R.J.; Rawn, J.D. Synthetic Polymers. In Principles of Organic Chemistry; Elsevier: Amsterdam, The Netherlands, 2015; pp. 397–419. [Google Scholar] [CrossRef]

- Heath, D.E.; Guelcher, S.A.; Cooper, S.L. Polyurethanes. In Biomaterials Science: An Introduction to Materials in Medicine, 3rd ed.; Academic Press: Amsterdam, The Netherlands, 2013; pp. 79–82. [Google Scholar] [CrossRef]

- Janik, H.; Sienkiewicz, M.; Kucinska-Lipka, J. Polyurethanes. In Handbook of Thermoset Plastics, 3rd ed.; William Andrew Publishing: Norwich, NY, USA, 2014; pp. 253–295. [Google Scholar] [CrossRef]

- Ma, S.; Webster, D.C. Degradable thermosets based on labile bonds or linkages: A review. Prog. Polym. Sci. 2018, 76, 65–110. [Google Scholar] [CrossRef]

- Montarnal, D.; Capelot, M.; Tournilhac, F.; Leibler, L. Silica-Like Malleable Materials from Permanent Organic Networks. Science 2011, 334, 965–968. [Google Scholar] [CrossRef]

- Frisch, K.C., Jr. Chapter 16—Chemistry and technology of polyurethane adhesives. Adhes. Sci. Eng. 2002, 2, 759–812. [Google Scholar] [CrossRef]

- Rao, R.R.; Mondy, L.A.; Long, K.N.; Celina, M.C.; Wyatt, N.; Roberts, C.C.; Soehnel, M.M.; Brunini, V.E. The kinetics of polyurethane structural foam formation: Foaming and polymerization. AIChE J. 2017, 63, 2945–2957. [Google Scholar] [CrossRef]

- Abram, E.R.; Bowler, N. Effect of relative humidity on the curing and dielectric properties of polyurethane-based composites. In Proceedings of the CEIDP’05. 2005 Annual Report Conference on Electrical Insulation and Dielectric Phenomena, Nashville, TN, USA, 16–19 October 2005. [Google Scholar] [CrossRef]

- Chen, X.; Hu, C.; Xu, H.; Qu, R.; Hu, X.; Yang, J.; Song, X. Synthesized polyurethane from p-toluenesulfonyl isocyanate and epichlorohydrin via salen catalysis. Polym. Adv. Technol. 2022, 33, 1892–1897. [Google Scholar] [CrossRef]

- Członka, S.; Kairytė, A.; Miedzińska, K.; Strąkowska, A.; Adamus-Włodarczyk, A. Mechanically Strong Polyurethane Composites Reinforced with Montmorillonite-Modified Sage Filler (Salvia officinalis L.). Int. J. Mol. Sci. 2021, 22, 3744. [Google Scholar] [CrossRef]

- Kúdelčík, J.; Hardoň, Š.; Trnka, P.; Michal, O.; Hornak, J. Dielectric Responses of Polyurethane/Zinc Oxide Blends for Dry-Type Cast Cold-Curing Resin Transformers. Polymers 2021, 13, 375. [Google Scholar] [CrossRef] [PubMed]

- Wondu, E.; Lule, Z.; Kim, J. Thermal Conductivity and Mechanical Properties of Thermoplastic Polyurethane-/Silane-Modified Al2O3 Composite Fabricated via Melt Compounding. Polymers 2019, 11, 1103. [Google Scholar] [CrossRef] [Green Version]

- Altafim, R.A.C.; Murakami, C.R.; Neto, S.C.; Araújo, L.C.R.; Chierice, G.O. The Effects of Fillers on Polyurethane Resin-based Electrical Insulators. Mater. Res. 2003, 6, 187–197. [Google Scholar] [CrossRef]

- Vedage, G.A.; Burdeniuc, J.J.; Arnold, A.R., Jr.; Tobias, J.D. Crosslinkers for Improving Stability of Polyurethane Foams. U.S. Patent 8,552,078, 8 October 2013. Available online: https://patents.google.com/patent/US8552078B2/en (accessed on 20 February 2023).

- Tramontano, J.; Blank, W.J. Crosslinking of Water-Borne Polyurethane Dispersions. In Proceedings of the 21st Annual Waterborne, High-Solids, and Powder Coatings Symposium, New Orleans, LA, USA, 9–11 February 1994; Available online: https://www.paint.org/wp-content/uploads/2021/09/jctSEPT95-Tramontano.pdf (accessed on 20 February 2023).

- Ionescu, M. Polymer Polyols (Filled Polyols) Chemistry and Technology of Polyols for Polyurethanes, 2nd ed.; Smithers Rapra Technology Ltd.: Shropshire, UK, 2016. [Google Scholar]

- Cheremisinoff, N.P.V. Condensed Encyclopedia of Polymer Engineering Terms; Cheremisinoff, N.P., Ed.; Butterworth-Heinemann: Boston, MA, USA, 2001; pp. 340–347. ISBN 978-0-08-050282-3. [Google Scholar]

- Akinwekomi, A.D.; Tang, C.-Y.; Tsui, G.C.-P.; Law, W.-C.; Chen, L.; Yang, X.-S.; Hamdi, M. Synthesis and Characterisation of Floatable Magnesium Alloy Syntactic Foams with Hybridised Cell Morphology. Mater. Des. 2018, 160, 591–600. [Google Scholar] [CrossRef]

- Singh, J.P.; Chae, K.H. D∘ Ferromagnetism of Magnesium Oxide. Condens. Matter 2017, 2, 36. [Google Scholar] [CrossRef] [Green Version]

- Hornak, J. Synthesis, Properties, and Selected Technical Applications of Magnesium Oxide Nanoparticles: A Review. Int. J. Mol. Sci. 2021, 22, 12752. [Google Scholar] [CrossRef] [PubMed]

- Fernandes, M.; RB Singh, K.; Sarkar, T.; Singh, P.; Pratap Singh, R. Recent Applications of Magnesium Oxide (MgO) Nanoparticles in Various Domains. Adv. Mater. Lett. 2020, 11, 1–10. [Google Scholar] [CrossRef]

- Fan, S.; Zhang, X.; Lu, Y.; Gao, Y. Characterization of HTV Silicone Rubber with Different Content of ATH Filler by Mechanical Measurements, FTIR and XPS Analyzes. In Proceedings of the 2018 12th International Conference on the Properties and Applications of Dielectric Materials (ICPADM), Xi’an, China, 20–24 May 2018. [Google Scholar] [CrossRef]

- Asefnejad, A.; Khorasani, T.M.; Behnamghader; Farsadzadeh, B. Bonakdar Manufacturing of biodegradable polyurethane scaffolds based on polycaprolactone using a phase separation method: Physical properties and in vitro assay. Int. J. Nanomed. 2011, 6, 2375–2384. [Google Scholar] [CrossRef] [Green Version]

- Diasa, R.C.M.; Serakides, A.M.G.R.; Ayresa, E.; Oréfice, R.L. Porous Biodegradable Polyurethane Nanocomposites: Preparation, Characterization, and Biocompatibility Tests. Mater. Res. 2010, 13, 211–218. [Google Scholar] [CrossRef]

- Bandekar, J.; Klima, S. FT-IR spectroscopic studies of polyurethanes Part I. Bonding between urethane COC groups and the NH Groups. J. Mol. Struct. 1991, 263, 45–57. [Google Scholar] [CrossRef]

- Dalpech, M.; Miranda, G. Waterborne polyurethanes: Influence of chain extender in ftir spectra profiles. Open Eng. 2012, 2, 231–238. [Google Scholar] [CrossRef]

- VUKI, a.s. Zalévací hmoty VUKUR. VUKOL O22. 2018. Available online: https://www.vuki.sk/files/technicke_listy/TDS-VUKOL-O22-ver-2018-04-30-sk.pdf (accessed on 20 February 2023).

- VUKI, a.s. Zalévací hmoty VUKUR. VUKOL O33n. 2019. Available online: https://www.vuki.sk/files/technicke_listy/TDS-VUKOL-O33-n-n-ver-2019-03-28-sk.pdf (accessed on 20 February 2023).

- Hornak, J.; Trnka, P.; Kadlec, P.; Michal, O.; Mentlík, V.; Šutta, P.; Csányi, G.M.; Tamus, Z.Á. Magnesium Oxide Nanoparticles: Dielectric Properties, Surface Functionalization and Improvement of Epoxy-Based Composites Insulating Properties. Nanomaterials 2018, 8, 381. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Rahman, M.M. Polyurethane/Zinc Oxide (PU/ZnO) Composite—Synthesis, Protective Property and Application. Polymers 2020, 12, 1535. [Google Scholar] [CrossRef]

- Bittmann, B.; Haupert, F.; Schlarb, A.K. Ultrasonic dispersion of inorganic nanoparticles in epoxy resin. Ultrason. Sonochem. 2009, 16, 622–628. [Google Scholar] [CrossRef] [PubMed]

- Goyat, M.S.; Ray, S.; Ghosh, P.K. Innovative application of ultrasonic mixing to produce homogeneously mixed nanoparticulate-epoxy composite of improved physical properties. Compos. Part A Appl. Sci. Manuf. 2011, 42, 1421–1431. [Google Scholar] [CrossRef]

- Kúdelčík, J.; Hardoň, Š.; Hockicko, P.; Kúdelčíková, M.; Hornak, J.; Prosr, P.; Trnka, P. Study of the Complex Permittivity of a Polyurethane Matrix Modified by Nanoparticles. IEEE Access 2020, 9, 49547–49556. [Google Scholar] [CrossRef]

- Palimi, M.J.; Rostami, M.; Mahdavian, M.; Ramezanzadeh, B. Surface modification of Fe2O3 nanoparticles with 3-aminopropyltrimethoxysilane (APTMS): An attempt to investigate surface treatment on surface chemistry and mechanical properties of polyurethane/Fe2O3 nanocomposites. Appl. Surf. Sci. 2014, 320, 60–72. [Google Scholar] [CrossRef]

- Guo, Z.; Park, S.; Wei, S.; Pereira, T.; Moldovan, M.; Karki, A.B.; Young, D.P.; Hahn, H.T. Flexible high-loading particle-reinforced polyurethane magnetic nanocomposite fabrication through particle-surface-initiated polymerization. Nanotechnology 2007, 18, 33. [Google Scholar] [CrossRef]

- Sabzi, M.; Mirabedini, S.M.; Zohuriaan-Mehr, J.; Atai, M. Surface modification of TiO2 nano-particles with silane coupling agent and investigation of its effect on the properties of polyurethane composite coating. Prog. Org. Coat. 2009, 65, 222–228. [Google Scholar] [CrossRef]

- Choi, J.Y.; Park, C.H.; Lee, J. Effect of Polymer Molecular Weight on Nanocomminution of Poorly Soluble Drug. Drug Deliv. 2008, 15, 347–353. [Google Scholar] [CrossRef] [PubMed]

- Corbierre, M.K.; Cameron, N.S.; Sutton, M.; Laaziri, K.; Lennox, B.R. Gold Nanoparticle/Polymer Nanocomposites: Dispersion of Nanoparticles as a Function of Capping Agent Molecular Weight and Grafting Density. Langmuir 2005, 21, 6063–6072. [Google Scholar] [CrossRef]

- Hornak, J.; Kadlec, P.; Polanský, R. Halloysite Nanotubes as an Additive to Ensure Enhanced Characteristics of Cold-Curing Epoxy Resins under Fire Conditions. Polymers 2020, 12, 1881. [Google Scholar] [CrossRef]

- Zahir, M.H.; Rahman, M.M.; Irshad, K.; Rahman, M.M. Shape-Stabilized Phase Change Materials for Solar Energy Storage: MgO and Mg(OH)2 Mixed with Polyethylene Glycol. Nanomaterials 2019, 9, 1773. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Salzer, R. Peter R. Griffiths, James A. de Haseth: Fourier Transform Infrared Spectrometry, 2nd ed.; Wiley-Interscience: Hoboken, NJ, USA, 2008; ISBN 978-0-471-19404-0. [Google Scholar]

- Baran, A.; Vrábel, P.; Kovaľaková, M.; Hutníková, M.; Fričová, O.; Olčák, D. Effects of sorbitol and formamide plasticizers on molecular motion in corn starch studied using NMR and DMTA. J. Appl. Polym. Sci. 2020, 137, 33. [Google Scholar] [CrossRef]

- Mujbil, H.H.; Al Jebur, L.A.; Yousif, E.; Kadhom, M.; Mohammed, A.; Ahmed, D.S.; Ali, M.; Hashim, H. Utilization of Metal Oxides Nanoparticles in Modulating Polyvinyl Chloride Films to Resist Ultraviolet Light. Metals 2022, 12, 1413. [Google Scholar] [CrossRef]

- Polanský, R.; Prosr, P.; Čermák, M. Determination of the thermal endurance of PCB FR4 epoxy laminates via thermal analyses. Polym. Degrad. Stab. 2014, 104, 107–115. [Google Scholar] [CrossRef]

- Havran, P.; Cimbala, R.; Király, J.; Rajňák, M.; Bucko, S.; Kurimský, J.; Dolník, B. Frequency-Dependent Dielectric Spectroscopy of Insulating Nanofluids Based on GTL Oil during Accelerated Thermal Aging. Processes 2022, 10, 2405. [Google Scholar] [CrossRef]

- Kremer, F.; Schönhals, A. (Eds.) Broadband Dielectric Spectroscopy; Springer: Berlin/Heidelberg, Germany, 2003. [Google Scholar]

- Kao, K.C. Dielectric Phenomena in Solids with Emphasis on Physical Concepts of Electronic Processes; Elsevier Academic Press: Amsterdam, The Netherlands, 2004. [Google Scholar]

- Lee, H.G.; Kim, J.G. Volume and Surface Resistivity Measurement of Insulating Materials Using Guard-Ring Terminal Electrodes. Energies 2020, 13, 2811. [Google Scholar] [CrossRef]

- Kadota, Y. Dielectric Breakdown from a Reliability and Safety Viewpoint. Test Navi Rep. 2022, 135, 42. Available online: https://www.test-navi.com/eng/report/pdf/DielectricBreakdownFromAReliabilitysAndSafetyViewpoint.pdf (accessed on 20 February 2023).

- Spěváček, J.; Brus, J.; Divers, T.; Grohens, Y. Solid-state NMR study of biodegradable starch/polycaprolactone blends. Eur. Polym. J. 2007, 43, 1866–1875. [Google Scholar] [CrossRef]

- Azari, M.; Sadeghi, M.; Aroon, M.; Matsuura, T. Polyurethane Mixed Matrix Membranes for Gas Separation: A Systematic Study on Effect of SiO2/TiO2 Nanoparticles. J. Membr. Sci. Res. 2019, 5, 33–43. [Google Scholar] [CrossRef]

- Shi, X.; Jiang, S.; Zhu, J.; Li, G.; Peng, X. Establishment of a highly efficient flame-retardant system for rigid polyurethane foams based on bi-phase flame-retardant actions. RSC Adv. 2018, 8, 9985–9995. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Jianjun, M.; Junxiao, Y.; Yawen, H.; Ke, C. Aluminum–organophosphorus hybrid nanorods for simultaneously enhancing the flame retardancy and mechanical properties of epoxy resin. J. Mater. Chem. 2012, 22, 2007–2017. [Google Scholar] [CrossRef]

- Rani, N.; Chahal, S.; Kumar, P.; Shukla, R.; Singh, S.K. A comparative study on magnesium hydroxide and magnesium oxide nanostructures. Dae Solid State Phys. Symp. 2019, 2115, 030163. [Google Scholar] [CrossRef]

- Akram, M.W.; Fakhar-e-Alam, M.; Atif, M.; Butt, A.R.; Asghar, A.; Jamil, Y.; Alimgeer, K.S.; Wang, Z.M. In vitro evaluation of the toxic effects of MgO nanostructure in Hela cell line. Sci. Rep. 2018, 8, 4576. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Bi, W.; Sun, J.; Yu, G.; Goegelein, C.H.; Hoch, M.; Klaassen, J.; Kirchhoff, J.; Zhao, S. Study on Interaction between Aluminum Hydroxide and Vinyltriethoxy Silane by Gas Chromatography-Mass Spectrometry. In Proceedings of the IOP Conference Series: Earth and Environmental Science, Ordos, China, 27–28 April 2019; Volume 300. [Google Scholar] [CrossRef]

- Wenhu, Y.; Ran, Y.; Xu, Y.; Man, X.; Sisi, H.; Xiaolong, C. Effect of Particle Size and Dispersion on Dielectric Properties in ZnO/Epoxy Resin Composites. Trans. Electr. Electron. Mater. 2012, 13, 116–120. [Google Scholar] [CrossRef] [Green Version]

- Andritsch, T.; Kochetov, R.; Morshuis, P.H.F.; Smit, J.J. Dielectric properties and space charge behavior of MgO-epoxy nanocomposites. In Proceedings of the 2010 10th IEEE International Conference on Solid Dielectrics, Potsdam, Germany, 4–9 July 2010. [Google Scholar] [CrossRef]

- Khan, M.Z.; Wang, F.; Li, J.; Hassan, M.A.S.; Ahmad, J.; He, L.; Kaizhen, W. AC Breakdown Strength and Volume Resistivity Characteristics of Epoxy Resin Composite with Surface Modified Alumina Nanoparticles. In Proceedings of the 2018 IEEE International Conference on High Voltage Engineering and Application (ICHVE), Athens, Greece, 10–13 September 2018. [Google Scholar] [CrossRef]

- Wang, Y.; Xiao, K.; Wang, C.; Yang, L.; Wang, F. Effect of Nanoparticle Surface Modification and Filling Concentration on Space Charge Characteristics in TiO2/XLPE Nanocomposites. J. Nanomater. 2016, 2016, 2840410. [Google Scholar] [CrossRef] [Green Version]

- Kyokane, J.; Tsujimoto, N.; Ishida, M.; Fukuma, M. Space charge characteristics of fullerenol and carbon nanotube doped polyurethane elastomer (PUE) actuators. In Proceedings of the 2005 International Symposium on Electrical Insulating Materials, Kitakyushu, Japan, 5–9 June 2005. [Google Scholar] [CrossRef]

- Watanabe, M.; Hirai, T. Space charge distribution in bending-electrostrictive polyurethane films doped with salts. J. Appl. Polym. Sci. 2004, 42, 523–531. [Google Scholar] [CrossRef]

- Watanabe, M.; Wakimoto, N.; Shirai, H.; Hirai, T. Bending electrostriction and space-charge distribution in polyurethane films. J. Appl. Phys. 2003, 94, 2494. [Google Scholar] [CrossRef]

- Andritch, T. Epoxy Based Nanodielectrics for High Voltage DC-Applications—Synthesis, Dielectric Properties and Space Charge Dynamics. Ph.D. Thesis, Delft University of Technology, Delft, The Netherlands, 2010. [Google Scholar]

- Awad, S.; Al-Rashdi, A.; Abdel-Hady, E.E.; Van Horn, J.D. Free volume properties of the zinc oxide nanoparticles/waterborne polyurethane coating system studied by a slow positron beam. J. Compos. Mater. 2018, 53, 1765–1775. [Google Scholar] [CrossRef] [Green Version]

- Park, S.H.; Hwang, J.; Park, G.S.; Ha, J.H.; Zhang, M.; Kim, D.; Yun, D.J.; Lee, S.; Lee, S.H. Modeling the electrical resistivity of polymer composites with segregated structures. Nat. Commun. 2019, 10, 2537. [Google Scholar] [CrossRef] [Green Version]

- Ge, G.; Tang, Y.; Li, Y.; Huang, L. Effect of Environmental Temperature on the Insulating Performance of Epoxy/MgO Nanocomposites. Appl. Sci. 2020, 10, 7018. [Google Scholar] [CrossRef]

- Hu, S.; Zhou, Y.; Yuan, C.; Wang, W.; Hu, J.; Li, Q.; He, J. Surface-modification effect of MgO nanoparticles on the electrical properties of polypropylene nanocomposite. High Volt. 2020, 5, 249–255. [Google Scholar] [CrossRef]

- Shah, Z.M.; Khanday, F.A.; Malik, G.F.A.; Jhat, Z.A. Fabrication of Polymer Nanocomposite-Based Fractional-Order Capacitor: A Guide. In Fractional-Order Design; Academic Press: Cambridge, MA, USA, 2022; pp. 437–483. [Google Scholar] [CrossRef]

- Habeeb, M.; Hamza, R.S.A. Synthesis of (polymer blend –MgO) nanocomposites and studying electrical properties for piezoelectric application. Indones. J. Electr. Eng. Inform. 2018, 6, 428–435. [Google Scholar] [CrossRef]

- Bertasius, P.; Meisak, D.; Macutkevic, J.; Kuzhir, P.; Selskis, A.; Volnyanko, E.; Banys, J. Fine Tuning of Electrical Transport and Dielectric Properties of Epoxy/Carbon Nanotubes Composites via Magnesium Oxide Additives. Polymers 2019, 11, 2044. [Google Scholar] [CrossRef] [Green Version]

- Ahmad, Z. Polymer Dielectric Materials. Dielectr. Mater. 2012, 1–24. [Google Scholar] [CrossRef] [Green Version]

- Boiteux, G.; Seytre, G.; Cuve, L.; Pascault, J.P. Dielectric studies of segmented polyurethanes based on polyolefine: Relations between structure and dielectric behaviour. J. Non. Cryst. Solids 1991, 131–133, 1131–1135. [Google Scholar] [CrossRef]

- Kanapitsas, A.; Pissis, P.; Gomez Ribelles, J.L.; Monleon Pradas, M.; Privalko, E.G.; Privalko, V.P. Molecular mobility and hydration properties of segmented polyurethanes with varying structure of soft- and hard-chain segments. J. Appl. Polym. Sci. 1999, 71, 1209–1221. [Google Scholar] [CrossRef]

- Karabanova, L.V.; Boiteux, G.; Gain, O.; Seytre, G.; Sergeeva, L.M.; Lutsyk, E.D. Semiinterpenetrating polymer networks based on polyurethane and polyvinylpyrrolidone. I. Thermodynamic state and dynamic mechanical analysis. J. Appl. Polym. Sci. 2001, 80, 852–862. [Google Scholar] [CrossRef]

- Pissis, P.; Apekis, L.; Christodoulides, C.; Niaounakis, M.; Kyritsis, A.; Nedbal, J. Water effects in polyurethane block copolymers. J. Polym. Sci. 1996, 34, 1529–1539. [Google Scholar] [CrossRef]

- Oprea, S.; Potolinca, O.; Oprea, V. Dielectric properties of castor oil cross-linked polyurethane. High Perform. Polym. 2010, 23, 49–58. [Google Scholar] [CrossRef]

- Madbouly, S.A.; Kessler, M.R. Dielectric spectroscopy for biorenewable plant oil-based polyurethane. In Proceedings of the 2014 IEEE Conference on Electrical Insulation and Dielectric Phenomena (CEIDP), Des Moines, IA, USA, 19–22 October 2014. [Google Scholar] [CrossRef]

- Pissis, P.; Kanapitsas, A.; Savelyev, Y.V.; Akhranovich, E.R.; Privalko, E.G.; Privalko, V.P. Influence of chain extenders and chain end groups on properties of segmented polyurethanes. II. Dielectric study. Polymer 1998, 39, 3431–3435. [Google Scholar] [CrossRef]

- Ersoy, A.; Hiziroglu, H.R. Electrical breakdown of polyurethane-based nanocomposites. In Proceedings of the 2010 10th IEEE International Conference on Solid Dielectrics, Potsdam, Germany, 4–9 July 2010. [Google Scholar] [CrossRef]

- Ha Thuc, C.N.; Cao, H.T.; Nguyen, D.M.; Tran, M.A.; Duclaux, L.; Grillet, A.-C.; Ha Thuc, H. Preparation and Characterization of Polyurethane Nanocomposites Using Vietnamese Montmorillonite Modified by Polyol Surfactants. J. Nanomater. 2014, 2014, 302735. [Google Scholar] [CrossRef]

- Butyrskaya, E.; Nechaeva, L.; Shaposhnikov, V.; Selemenev, V. Determining role of hydrogen bonding in electrically driven membrane transport: Quantum-chemical and molecular dynamics study. Pet. Chem. 2015, 55, 918–926. [Google Scholar] [CrossRef]

- Zou, C.; Fothergill, J.C.; Rowe, S.W. The effect of water absorption on the dielectric properties of epoxy nanocomposite. IEEE Trans. Dielectr. Electr. Insul. 2008, 15, 106–117. [Google Scholar] [CrossRef]

- Anancharoenwong, E.; Chueangchayaphan, W.; Rakkapao, N.; Marthosa, S.; Chaisrikhwun, B. Thermo-mechanical and antimicrobial properties of natural rubber-based polyurethane nanocomposites for biomedical applications. Polym. Bull. 2021, 78, 833–848. [Google Scholar] [CrossRef]

- D’Orazio, L.; Grippo, A. A water dispersed Titanium dioxide/poly(carbonate urethane) nanocomposite for protecting cultural heritage: Preparation and properties. Prog. Org. Coat. 2015, 79, 1–7. [Google Scholar] [CrossRef]

- Ginzburg, V.V.; Bicerano, J.; Christenson, C.P.; Schrock, A.K.; Patashinski, A.Z. Modeling Mechanical Properties of Segmented Polyurethanes. In Nano- and Micromechanics of Polymer Blends and Composites; Carl Hanser Verlag: Munich, Germany, 2009; pp. 59–89. [Google Scholar] [CrossRef]

- Wongsamut, C.; Suwanpreedee, R.; Manuspiya, H. Thermoplastic polyurethane-based polycarbonate diol hot melt adhesives: The effect of hard-soft segment ratio on adhesion properties. Int. J. Adhes. Adhes. 2020, 102, 102677. [Google Scholar] [CrossRef]

| Line | PU_A | PU_B | ||||||

|---|---|---|---|---|---|---|---|---|

| Width | Pure | 1MgO | 3MgO | 5MgO | Pure | 1MgO | 3MgO | 5MgO |

| BL (kHz) | 20.2 | 18.7 | 20.3 | 21.2 | 21.8 | 18.9 | 22.1 | 21.4 |

| (0.73) | (0.70) | (0.84) | (0.78) | (0.77) | (0.64) | (0.80) | (0.73) | |

| NL (kHz) | 5.0 | 3.7 | 4.6 | 4.9 | 5.0 | 3.5 | 6.1 | 5.0 |

| (0.27) | (0.30) | (0.16) | (0.22) | (0.23) | (0.36) | (0.20) | (0.27) | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hornak, J.; Černohous, J.; Prosr, P.; Rous, P.; Trnka, P.; Baran, A.; Hardoň, Š. A Comprehensive Study of Polyurethane Potting Compounds Doped with Magnesium Oxide Nanoparticles. Polymers 2023, 15, 1532. https://doi.org/10.3390/polym15061532

Hornak J, Černohous J, Prosr P, Rous P, Trnka P, Baran A, Hardoň Š. A Comprehensive Study of Polyurethane Potting Compounds Doped with Magnesium Oxide Nanoparticles. Polymers. 2023; 15(6):1532. https://doi.org/10.3390/polym15061532

Chicago/Turabian StyleHornak, Jaroslav, Jakub Černohous, Pavel Prosr, Pavel Rous, Pavel Trnka, Anton Baran, and Štefan Hardoň. 2023. "A Comprehensive Study of Polyurethane Potting Compounds Doped with Magnesium Oxide Nanoparticles" Polymers 15, no. 6: 1532. https://doi.org/10.3390/polym15061532

APA StyleHornak, J., Černohous, J., Prosr, P., Rous, P., Trnka, P., Baran, A., & Hardoň, Š. (2023). A Comprehensive Study of Polyurethane Potting Compounds Doped with Magnesium Oxide Nanoparticles. Polymers, 15(6), 1532. https://doi.org/10.3390/polym15061532