1. Introduction

Conventional materials such as metals and ceramics are experiencing reduced importance due to their corrosive nature, high weight, and high maintenance cost [

1]. Polymer composite materials are used as alternatives to conventional materials due to their superior properties [

2,

3,

4,

5]. Fiber-reinforced polymer composites (FRPs) have seized the attention of researchers and are used in automotive, marine, aerospace, defense, and sports with engineering properties [

6,

7,

8,

9]. Having distinct features such as high strength-to-weight ratio, toughness, rigidity, thermal resistance, energy absorption capability, low density, and high stiffness are the major advantages of such materials over conventional materials [

10,

11]. In applications, they may be put through different loading conditions of mechanical and thermal stress. With the passage of time and with loading, there is a loss in strength due to fiber breakage, and delamination in the FRPs [

12,

13]. These are high-performance textiles and several cutting-edge research studies have been reported about applications in modern society [

14,

15,

16,

17,

18,

19].

The performance of the composites can be enhanced by the hybridization of different fibers in the same matrix (hybrid composites) as the remedy for such problems [

20,

21,

22,

23,

24]. Several kinds of research studies about hybrid composites such as carbon/glass, Kevlar/glass, Kevlar/carbon, carbon/flax, polylactic acid (PLA)/hemp, carbon/aramid, jute/glass, and jute/carbon fibers have been reported in literature [

25]. All these thermoset composites are examined through mechanical characterizations. Kevlar fiber has popularity in making FRP composites due to its excellent properties. Kevlar-reinforced composites offer advanced properties due to high-energy absorbance, high tensile strength, and high tensile-to-compression-strength ratio [

26]. Moreover, it has a lower compressive strength as compared to glass fiber and carbon fibers. Therefore, Kevlar-reinforced composites (KRCs) tend to fail easily under compressive loadings. It can improve compressive strength by hybridizing with other fibers, e.g., glass and carbon [

27,

28,

29,

30,

31,

32,

33].

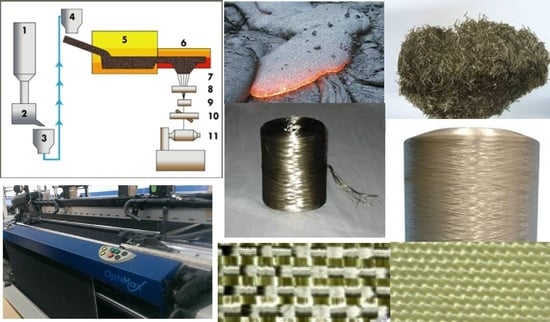

The hybridization of fibers is an effective technique to improve the properties of Kevlar-reinforced composites, allowing the manufacturer to tailor the properties according to the needs [

34]. Recently, basalt fibers gained more importance over glass and carbon fibers due to superior properties, being naturally abundant, and being environmentally friendly [

35]. Basalt and Kevlar work synergistically in terms of their properties. Kevlar shows a lower compressive strength and is weaker in the transverse direction; hence, a basalt/Kevlar hybrid composite is one of the best options for FRP composites with improved mechanical properties. It is cheaper in price and offers eco-friendly options [

36]. From the literature, it can be seen that the impact response is improved by the combination of fibers such as Kevlar with basalt and glass [

37]. Basalt/nylon with varying percentages of nylon showed a significant improvement in impact properties [

38]. Carbon/basalt hybrid composites with various impact energies showed that alternate layers of fibers resulted in high-energy absorption [

39]. In the case of 3-D woven Kevlar/basalt epoxy composites, there was high-energy absorption in interply laminate as compared to intraply energy absorption [

40]. In 3D woven angle-interlock Kevlar/basalt-reinforced polypropylene hybrid composites, superior properties were reported as compared to the individual ones [

41]. In carbon/basalt composites, a positive hybridization effect can be seen in all stacking sequences [

42].

High-performance composites are mostly obtained from thermoset resins that take a longer time for manufacturing and curing. Such composites are difficult to recycle due to the presence of catalyst/hardener along with resin. On the other hand, thermoplastic composites have numerous advantages, e.g., better impact properties, ductility, environmental resistance, and recyclability. However, the problem is their high viscosity, which makes the impregnation of reinforcement difficult, especially when the fiber volume fraction (Vf) is higher. This results in prolonged impregnation time and sometimes poorly impregnated areas, which leads to mechanical failures. To overcome these issues, reactive thermoplastic resin such as PA6 was developed [

43,

44,

45,

46,

47]. Several researchers have reported the mechanical advantages of thermoplastic composites produced by pultrusion and reinforced with fibrous materials [

48,

49,

50,

51].

The novelty of the study is the hybridization of woven basalt and Kevlar fabrics as a reinforcement in thermoplastic composites. The current research aimed to investigate the benefits of fiber hybridization with high-fluidity polyamide-6 thermoplastic resin using different layering/stacking sequences. Individual reinforcement layers of basalt- and Kevlar-woven fabrics were also investigated for comparison. Effects of fabric characteristics and hybridization were evaluated by visual observation, optical microscopy, mechanical performance tests such as tensile, flexural, and impact strength, as well as thermal characterizations such as Thermogravimetric Analysis (TGA) and Differential Scanning Calorimetry (DSC). These novel hybrid composites can be used for high-performance applications such as sports, automotive, and aerospace.

3. Results and Discussion

The samples with hybridization and different sequences of stacking are given in

Table 4. The samples were cut both in the length (warp) and width (weft) direction. Due to the multiple layering of fabrics in alternate directions, the mechanical properties of the composites were observed to be uniform in both directions and the average was calculated. The various mechanical properties that were evaluated are also presented with limits of variation. The thickness and fiber volume fraction of the samples are given in

Table 5.

The composite samples and damage after tensile testing are shown in

Figure 4.

From the nature of fracture, it is evident that the composites are well prepared, and the failure is catastrophic in nature. This is an indication that the load is transferred to the fabric and not the matrix. Such behavior is also a positive sign of adequate impregnation with the resin phase.

3.1. Characterization of Tensile Properties

The results reported in

Table 4 are the average of 20 tests of tensile strength for each composite sample vis-à-vis pure resin (PA6). Mechanical properties of the composites depend on the reinforcement type. Each type of composite sample was prepared with the same thickness and weight ratio and contains four layers of reinforcement fabrics except samples A2 and A6 because a single layer of tight Kevlar has a GSM (areal density) equal to two layers of normal Kevlar.

Figure 5 shows the non-linear tensile stress–strain behavior of the composites. According to the results, the A1 sample shows the maximum stress-to-strain ratio due to the high volume–mass fraction and high tensile strength of the basalt fibers [

52]. A2 and A3 composites show comparatively similar results as they are made of the same fiber material. Hybrid composites (A4–A6) show improved strength and modulus as compared to A2 and A3, but show a lower strength and modulus than the A1 composite does due to the anisotropic nature of the Kevlar fabric, which does not contribute significantly in the transverse direction [

53]. From the results, it can be observed that the A4 hybrid composite configuration behaves better than other hybrid combinations with respect to stress–strain behavior due to the alternative combination of basalt/Kevlar fabric in hybridization. Sample A6 shows the lowest modulus value among the hybrid samples due to the weaker adhesion with the matrix and the relatively compact structure of the tight Kevlar woven fabric, which does not allow as easy impregnation of the resin as in the case of normal Kevlar fabric.

In this study, the tensile modulus was determined by analyzing stress–strain curves. Because of the higher strength of basalt fibers, the composite sample A1 shows the highest tensile modulus values, whereas the other composites achieve lower modulus values. Among hybrid structures, the composite A4 shows superior results and follows a similar pattern as the stress/strain curve. The hybridization of Kevlar with basalt fabric results in an increase in the tensile modulus. Sample A6 shows the lowest modulus among composite samples due to the tight Kevlar structure, which might not facilitate the easy impregnation of resin. Further, the adherence of such a fabric with the adjacent layers of basalt fabrics seems to be less effective. The results are shown in

Figure 6.

3.2. Characterization of Flexural Properties

The results reported are the average of 20 tests of flexural strength for each composite sample with different combinations, mentioned in

Table 1.

Figure 7 shows the flexural strength and flexural modulus of the composites. Composite sample A1 shows the maximum flexural strength as well as modulus due to the higher tensile strength than others. On the other hand, pure Kevlar-based composites A2 and A3 are much weaker in flexural properties due to their lower tensile strength [

54]. Hybrid composites (A4–A6) show improved flexural strength due to the supportiveness of the basalt layer. Among the hybrid composites, sample A6 shows the maximum flexural strength due to the high volume–mass ratio of the Kevlar in (tight Kevlar). The flexural modulus follows a similar trend as flexural strength.

3.3. Characterization of Impact Properties

The average of 20 impact measurements is reported for each type of composite sample. All the samples show partial breakage.

Figure 8 shows the impact energy absorbance capabilities of the composites. From the figure, it is clear that sample A1 shows the maximum impact strength and impact energy absorption among all the composites due to its high impact resistance [

55]. Composite samples A2 and A3 show the minimum energy absorbance capabilities. Hybrid composites A4–A6 show improved energy absorbance capacity. Among hybrid composites, sample A5 shows better impact results due to the energy absorption capacity of double layers of loose Kevlar fabric in the middle layer. In sample A4, the alternate combination of basalt/Kevlar, and in sample A6, the tight Kevlar in the middle result in lower impact energy absorption capabilities. The impact strength shows the same behavior as impact energy absorbance capabilities. The higher tensile and bending strengths of basalt fabric help achieve improved impact performance in the hybrid composites. However, an appropriate layering arrangement is to be selected. Furthermore, the compression and resilience of the individual layers play an important role in determining the impact energy absorption capacities of the reinforced composites. This explains the slightly different trend in the case of impact strength and impact energy absorption [

56].

3.4. Statistical Analysis of Mechanical Properties

One-way analysis of variance (ANOVA) was carried out in order to study the significance of the results obtained through mechanical testing in the tensile, flexural, and impact category. The results of

p-value and R-square are given in

Table 6.

From

Table 6, it is evident that the

p-value of all responses are less than 0.05, which indicates a significant effect of fiber properties on the responses (mechanical properties of composites). The R-square value obtained for tensile properties is lower, which means that the type of fiber is less effective in determining the tensile properties among the samples studied. The interval plots are shown in

Figure 9.

Interval plots of all properties were also studied. The overlapping of samples in this plot shows an insignificant difference between their mean values. Especially in case of tensile properties, the overlapping indicates that the difference in means is not as significant as in the case of flexural and impact properties.

3.5. Morphological Analysis of Fracture Surfaces

The composite samples after tensile failure were analyzed. SEM images were taken to study the fiber rupture, pullout, or delamination between layers of fabrics in the composites. The images are shown in

Figure 10.

From the SEM images, it is visible that sample A1 mostly shows fiber rupture. This is indicative of excellent consolidation among the different layers of the basalt fabric. Thus, the sample exhibited the best tensile, bending, and impact performance. Samples A2 and A3 mostly show delamination zones, indicating poor bonding between the layers of Kevlar fabric. In the case of hybrid samples (A4–A6), there are some delamination and some fiber rupture zones. This indicates that the load is distributed between the fabric layers as well as among the fibers in each layer. Thus, an improved mechanical performance is observed as compared to pure Kevlar-fabric-based composites. However, the optimum load distribution depends on the appropriate selection of layer sequencing and the density of individual layers of component fabrics.

3.6. Thermogravimetric Analysis

Thermogravimetric analysis was carried out in order to determine the thermal stability of composite samples across the temperature limits they may be exposed to before they begin to show signs of wear and tear. TGA was used to determine the weight loss of the composite samples as a function of increasing temperature. To assess the thermal stability of composites, the TGA study was carried out, which was followed by comparative analysis between various kinds of composites, as shown in

Figure 11.

The thermogram shows a progressive weight loss as the temperature is raised, with the weight loss beginning in the interval of 360–390 °C. It has been discovered that quantitative chain rupture causes a significant deterioration phase in neat polyamide-6 resin at temperatures between 360 and 400 °C. Other studies have also reported that the maximum degradation for pure polyamide-6 occurs at this temperature [

57]. Under extreme temperatures, the composites degrade in two stages: first, they become brittle and then crumble [

58]. The temperature ranging from 360 to 390 °C denotes the first stage, which corresponds to the decomposition of the matrix. The temperature ranging from 500 to 580 °C indicates the second stage, which corresponds to the decomposition of fabrics and the decomposition temperature of the Kevlar fiber. Sample A1 exhibits the highest resistance against thermal degradation with the least amount of weight loss. Following that, hybrid structures such as A5, A4, and A6 result in reasonably improved resistance to degradation and lower weight loss. Because Kevlar has a lower degradation temperature as compared to basalt, it could not perform as well as the basalt sample. This was observed when Kevlar is used as an exterior layer in hybrid samples and also as a pure component in the composites. Sample A4 results in a higher weight loss as compared to A3 owing to the use of Kevlar on the outer layers of the composite on one side of the composite. However, as compared to other hybrid constructions, the composite sample A6 has one thick layer of dense Kevlar. That is why it results in a higher weight loss and lower resistance to thermal degradation. Sample A2, which is composed of tight Kevlar, achieves slightly better outcomes than the composite sample A3, which is composed of loose Kevlar. The pure matrix/resin sample A7 degrades linearly in a single step. The temperature range of 360–398 °C denotes the decomposition of PA6 resin. For the pure basalt sample, there is a minimal loss of weight until 700 °C, which is mainly due to decomposition of the matrix/resin phase. The basalt fiber is highly resistant to thermal degradation and almost remains intact [

59]. The use of this material in pure or hybrid form improves the overall thermal stability of the composite. This observation is supported by the findings of the FTIR analysis (ATR mode) and EDX of the basalt fabric. Basalt is mainly composed of Si, Al, and C, which are responsible for the thermal stability of the overall composite.

3.7. Differential Scanning Calorimetry (DSC) Analysis

The differential scanning calorimeter (DSC) monitors the heat flow resulting from different transitions as a function of time and temperature. This approach provides both qualitative and quantitative information on physical and chemical changes that occur because of endothermic (heat absorption) and exothermic (heat release) processes, respectively. The magnitudes of the exothermic and endothermic peaks reflect the thermal phase change of the composites [

60,

61,

62]. The glass transition temperature (Tg) of the matrix in the composites is critical as it determines how the materials behave at various temperatures. Below this temperature, the materials become stiffer, and only little deformation occurs when the materials are subjected to thermal loading. When the temperature is raised beyond this point, the material shows rubber-like properties [

62].

Figure 12 shows the DSC curves of the composites that were studied, in which two events are more prevalent than the others (endothermic and exothermic).

It is observed that the endothermic peak emerges in composite samples A1 and A6 as the temperature increases from room temperature to 180 °C. It is linked to the dehydration process of the composite samples. However, the endothermic peak of the other composite samples A2–A5 is somewhat greater, reaching a temperature around 350–370 °C, owing to the hybridization effect of sandwich materials. As is well known, the greater the adhesion, the higher the energy needed to break the bonds. A possible explanation is that composites with a hybrid effect of basalt and Kevlar fibers exhibit dehydration and bond breakages at much higher temperatures due to the adhesivity of the adjacent layers. It is observed that the pure-Kevlar-fiber-based samples A2 and A3 do not show the endothermic peak. This may be attributed to the higher crystallinity and lower moisture content of the fibers as compared to basalt. The exothermic peak in samples A2–A5 is seen at about 200–220 °C, which is caused by the degradation of the matrix (PA6). The hybridization of basalt and Kevlar offers higher peaks of heat flow. This indicates better thermal stability of such composite materials. As compared to the pure resin, the composite samples show significantly superior thermal peaks and, therefore, superior thermal stability.

A summary of the composites developed in terms of their practical application is shown in

Table 7.

4. Conclusions

The basalt- and Kevlar-fiber-reinforced hybrid thermoplastic polymer composites with different stacking sequences were fabricated and evaluated. The mechanical and thermomechanical properties were investigated. According to the results of the mechanical testing of the composites, the pure basalt composite exhibited the highest tensile strength and modulus. Pure-Kevlar-based samples produced results that were comparable to one another but inferior to pure basalt. In comparison to the pure-Kevlar-based composite, hybrid composites demonstrated a higher strength and yielded a significantly higher modulus. In the stress–strain curve, the A4 hybrid composite structure performed much better than the other hybrid configurations did, due to the most adequate layering sequence and hybridization. Pure-basalt-based composites exhibited a significantly higher flexural strength and modulus as compared to pure Kevlar-based composites. Hybrid composites showed better flexural characteristics because of the basalt fibers. Composite sample A6 exhibited the highest flexural strength among the hybrid composites due to the dense layer of Kevlar in the core. The highest impact strength was observed for the pure-basalt-fabric-based composite. The hybrid composites exhibited a higher energy absorption capability as compared to the pure Kevlar sample. Sample A5 performed better than other hybrid composites due to the presence of two layers of normal Kevlar in the core of the composite.

The TGA analysis showed a gradual weight loss as the temperature was elevated, with the weight loss commencing at around 360–390 °C. The pure-basalt-based composite achieved the best performance with minimal weight reduction. Hybrid composites performed better than pure-Kevlar-based samples due to the higher thermal stability of the basalt component. The DSC analysis also proved that the hybrid composites of basalt and Kevlar can endure higher temperatures and exhibited exothermic peaks at about 200–220 °C owing to the presence of Kevlar component.

Overall, the mechanical and thermomechanical characteristics of the basalt–Kevlar hybrid thermoplastic polymeric composites are promising, and the results of the research demonstrate that the hybrid composites can be used for high-load-bearing and high-temperature applications, e.g., defense, aerospace, automotive, and energy sectors. Due to the advanced mechanical and thermal performance of basalt/Kevlar hybrid composites, they are potential high-performance materials to be used in several other industrial practices. Further research should be conducted to understand the novel material from specific applications. Further, the durability can be studied under severe environmental conditions, e.g., in marine applications. Fatigue tests can be performed under cyclic and dynamic loading. Basalt fibers can be used in other technologies, e.g., pultrusion, winding, resin film infusion, and 3D printing.