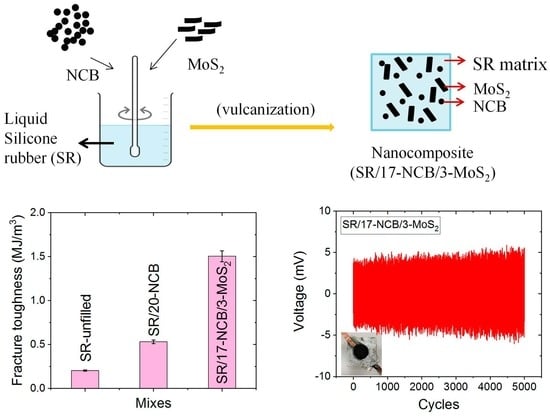

Nanocarbon Black and Molybdenum Disulfide Hybrid Filler System for the Enhancement of Fracture Toughness and Electromechanical Sensing Properties in the Silicone Rubber-Based Energy Harvester

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Characterization of Fillers

2.3. Preparation of Rubber Nanocomposites

2.4. Measurement of Cross-Link Density

2.5. Mechanical and Hysteresis Properties

2.6. Filler Distribution Studies

2.7. Fabrication of Energy Harvesting Device

3. Results and Discussion

3.1. Crystal Structure and Morphology of Filler

3.2. Curing Properties

3.3. Mechanical Properties of Rubber Nanocomposites

3.3.1. Compressive Mechanical Properties

3.3.2. Tensile Mechanical Properties

3.3.3. Hysteresis Losses on Dynamic Loading–Unloading Cycles

3.4. Filler Dispersion

3.5. Electromechanical Sensing Performance of Energy Harvester

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Shit, S.C.; Shah, P. A review on silicone rubber. Natl. Acad. Sci. Lett. 2013, 36, 355–365. [Google Scholar] [CrossRef]

- Wolf, M.P.; Salieb-Beugelaar, G.B.; Hunziker, P. PDMS with designer functionalities—Properties, modifications strategies, and applications. Prog. Polym. Sci. 2018, 83, 97–134. [Google Scholar] [CrossRef]

- Liu, J.; Yao, Y.; Li, X.; Zhang, Z. Fabrication of advanced polydimethylsiloxane-based functional materials: Bulk modifications and surface functionalizations. Chem. Eng. J. 2021, 408, 127262. [Google Scholar] [CrossRef]

- Lo, T.Y.; Krishnan, M.R.; Lu, K.Y.; Ho, R.M. Silicon-containing block copolymers for lithographic applications. Prog. Polym. Sci. 2018, 77, 19–68. [Google Scholar] [CrossRef]

- Lv, X.; Tang, Y.; Tian, Q.; Wang, Y.; Ding, T. Ultra-stretchable membrane with high electrical and thermal conductivity via electrospinning and in-situ nanosilver deposition. Compos. Sci. Technol. 2020, 200, 108414. [Google Scholar] [CrossRef]

- Kumar, V.; Alam, M.N.; Manikkavel, A.; Song, M.; Lee, D.J.; Park, S.S. Silicone rubber composites reinforced by carbon nanofillers and their hybrids for various applications: A review. Polymers 2021, 13, 2322. [Google Scholar] [CrossRef]

- Schmitt, F.; Piccin, O.; Barbé, L.; Bayle, B. Soft robots manufacturing: A review. Front. Robot. AI 2018, 5, 84. [Google Scholar] [CrossRef]

- Pang, C.; Lee, G.Y.; Kim, T.I.; Kim, S.M.; Kim, H.N.; Ahn, S.H.; Suh, K.Y. A flexible and highly sensitive strain-gauge sensor using reversible interlocking of nanofibres. Nat. Mater. 2012, 11, 795–801. [Google Scholar] [CrossRef]

- Huang, X.; Yin, Z.; Wu, H. Structural Engineering for High-Performance Flexible and Stretchable Strain Sensors. Adv. Intell. Syst. 2021, 3, 2000194. [Google Scholar] [CrossRef]

- Luo, X.; Yang, G.; Schubert, D.W. Electrically conductive polymer composite containing hybrid graphene nanoplatelets and carbon nanotubes: Synergistic effect and tunable conductivity anisotropy. Adv. Compos. Hybrid Mater. 2022, 5, 250–262. [Google Scholar] [CrossRef]

- Rattanasom, N.; Saowapark, T.; Deeprasertkul, C. Reinforcement of natural rubber with silica/carbon black hybrid filler. Polym. Test. 2007, 26, 369–377. [Google Scholar] [CrossRef]

- Liu, Y.; Li, L.; Wang, Q. Effect of carbon black/nanoclay hybrid filler on the dynamic properties of natural rubber vulcanizates. J. Appl. Polym. Sci. 2010, 118, 1111–1120. [Google Scholar] [CrossRef]

- Zhang, H.; Wang, C.; Zhang, Y. Preparation and properties of styrene-butadiene rubber nanocomposites blended with carbon black-graphene hybrid filler. J. Appl. Polym. Sci. 2015, 132, 41309. [Google Scholar] [CrossRef]

- Socher, R.; Krause, B.; Hermasch, S.; Wursche, R.; Pötschke, P. Electrical and thermal properties of polyamide 12 composites with hybrid fillers systems of multiwalled carbon nanotubes and carbon black. Compos. Sci. Technol. 2011, 71, 1053–1059. [Google Scholar] [CrossRef]

- Gao, J.; He, Y.; Gong, X.; Xu, J. The role of carbon nanotubes in promoting the properties of carbon black-filled natural rubber/butadiene rubber composites. Results Phys. 2017, 7, 4352–4358. [Google Scholar] [CrossRef]

- Xu, M.; Liang, T.; Shi, M.; Chen, H. Graphene-like two-dimensional materials. Chem. Rev. 2013, 113, 3766–3798. [Google Scholar] [CrossRef] [PubMed]

- Wan, C.; Zhou, L.; Xu, S.; Jin, B.; Ge, X.; Qian, X.; Xu, L.; Chen, F.; Zhan, X.; Yang, Y.; et al. Defect engineered mesoporous graphitic carbon nitride modified with AgPd nanoparticles for enhanced photocatalytic hydrogen evolution from formic acid. Chem. Eng. J. 2022, 429, 132388. [Google Scholar] [CrossRef]

- Perkins, F.K.; Friedman, A.L.; Cobas, E.; Campbell, P.M.; Jernigan, G.G.; Jonker, B.T. Chemical vapor sensing with monolayer MoS2. Nano Lett. 2013, 13, 668–673. [Google Scholar] [CrossRef] [PubMed]

- Zong, X.; Yan, H.; Wu, G.; Ma, G.; Wen, F.; Wang, L.; Li, C. Enhancement of photocatalytic H2 evolution on CdS by loading MoS2 as cocatalyst under visible light irradiation. J. Am. Chem. Soc. 2008, 130, 7176–7177. [Google Scholar] [CrossRef]

- Castellanos-Gomez, A.; Poot, M.; Steele, G.A.; Van Der Zant, H.S.; Agraït, N.; Rubio-Bollinger, G. Elastic properties of freely suspended MoS2 nanosheets. Adv. Mater. 2012, 24, 772–775. [Google Scholar] [CrossRef] [PubMed]

- Zhu, H.; Wang, Y.; Xiao, J.; Liu, M.; Xiong, S.; Wong, Z.J.; Ye, Z.; Ye, Y.; Yin, X.; Zhang, X. Observation of piezoelectricity in free-standing monolayer MoS2. Nat. Nanotechnol. 2015, 10, 151–155. [Google Scholar] [CrossRef]

- Zhou, K.; Liu, J.; Zeng, W.; Hu, Y.; Gui, Z. In situ synthesis, morphology, and fundamental properties of polymer/MoS2 nanocomposites. Compos. Sci. Technol. 2015, 107, 120–128. [Google Scholar] [CrossRef]

- Wang, D.; Song, L.; Zhou, K.; Yu, X.; Hu, Y.; Wang, J. Anomalous nano-barrier effects of ultrathin molybdenum disulfide nanosheets for improving the flame retardance of polymer nanocomposites. J. Mater. Chem. A 2015, 3, 14307–14317. [Google Scholar] [CrossRef]

- Eksik, O.; Gao, J.; Shojaee, S.A.; Thomas, A.; Chow, P.; Bartolucci, S.F.; Lucca, D.A.; Koratkar, N. Epoxy nanocomposites with two-dimensional transition metal dichalcogenide additives. ACS Nano 2014, 8, 5282–5289. [Google Scholar] [CrossRef]

- Zhou, K.; Jiang, S.; Shi, Y.; Liu, J.; Wang, B.; Hu, Y.; Gui, Z. Multigram-scale fabrication of organic modified MoS2 nanosheets dispersed in polystyrene with improved thermal stability, fire resistance, and smoke suppression properties. RSC Adv. 2014, 4, 40170–40180. [Google Scholar] [CrossRef]

- Wang, X.; Kalali, E.N.; Wang, D.Y. An in situ polymerization approach for functionalized MoS2/nylon-6 nanocomposites with enhanced mechanical properties and thermal stability. J. Mater. Chem. A 2015, 3, 24112–24120. [Google Scholar] [CrossRef]

- Tang, Z.; Wei, Q.; Guo, B. A generic solvent exchange method to disperse MoS2 in organic solvents to ease the solution process. Chem. Commun. 2014, 50, 3934–3937. [Google Scholar] [CrossRef]

- Tsai, C.Y.; Lin, S.Y.; Tsai, H.C. Butyl rubber nanocomposites with monolayer MoS2 additives: Structural characteristics, enhanced mechanical, and gas barrier properties. Polymers 2018, 10, 238. [Google Scholar] [CrossRef] [PubMed]

- Fuming, K.; Xincong, Z.; Jian, H.; Xiaoran, Z.; Jun, W. Tribological properties of Nitrile Rubber/UHMWPE/Nano-MoS2 water-lubricated bearing material under low speed and heavy duty. J. Tribol. 2018, 140, 61301. [Google Scholar] [CrossRef]

- Geng, H.; Zhao, P.; Mei, J.; Chen, Y.; Yu, R.; Zhao, Y.; Ding, A.; Peng, Z.; Liao, L.; Liao, J. Improved microwave absorbing performance of natural rubber composite with multi-walled carbon nanotubes and molybdenum disulfide hybrids. Polym. Adv. Technol. 2020, 31, 2752–2762. [Google Scholar] [CrossRef]

- Tang, Z.; Zhang, C.; Wei, Q.; Weng, P.; Guo, B. Remarkably improving performance of carbon black-filled rubber composites by incorporating MoS2 nanoplatelets. Compos. Sci. Technol. 2016, 132, 93–100. [Google Scholar] [CrossRef]

- Alam, M.N.; Kumar, V.; Lee, D.J.; Choi, J. Synergistically toughened silicone rubber nanocomposites using carbon nanotubes and molybdenum disulfide for stretchable strain sensors. Compos. Part B Eng. 2023, 259, 110759. [Google Scholar] [CrossRef]

- Kumar, V.; Lee, J.Y.; Lee, D.J. Synergistic effects of hybrid carbon nanomaterials in room-temperature-vulcanized silicone rubber. Polym. Int. 2017, 66, 450–458. [Google Scholar] [CrossRef]

- Ding, H.; Zang, W.; Li, J.; Jiang, Y.; Zou, H.; Ning, N.; Tian, M.; Zhang, L. CB/PDMS electrodes for dielectric elastomer generator with low energy loss, high energy density and long life. Compos. Commun. 2022, 31, 101132. [Google Scholar] [CrossRef]

- Li, W.; Liu, X.; Jiang, Y.; Wu, W.; Yu, B.; Ning, N.; Tian, M.; Zhang, L. Extremely high energy density and long fatigue life of nano-silica/polymethylvinylsiloxane dielectric elastomer generator by interfacial design. Nano Energy 2022, 104, 107969. [Google Scholar] [CrossRef]

- Pantea, D.; Darmstadt, H.; Kaliaguine, S.; Roy, C. Electrical conductivity of conductive carbon blacks: Influence of surface chemistry and topology. Appl. Surf. Sci. 2003, 217, 181–193. [Google Scholar] [CrossRef]

- Yang, X.; Li, Z.; Jiang, Z.; Wang, S.; Liu, H.; Xu, X.; Wang, D.; Miao, Y.; Shang, S.; Song, Z. Mechanical reinforcement of room-temperature-vulcanized silicone rubber using modified cellulose nanocrystals as cross-linker and nanofiller. Carbohydr. Polym. 2020, 229, 115509. [Google Scholar] [CrossRef] [PubMed]

- Kumar, V.; Alam, M.N.; Park, S.S. Soft composites filled with iron oxide and graphite nanoplatelets under static and cyclic strain for different industrial applications. Polymers 2022, 14, 2393. [Google Scholar] [CrossRef]

- Moretto, H.-H.; Schulze, M.; Wagner, G. “Silicones” in Ullmann’s Encyclopedia of Industrial Chemistry; Wiley-VCH: Weinheim, Germany, 2005. [Google Scholar]

- Kochanke, A.; Nagel, J.; Üffing, C.; Hartwig, A. Influence of addition curing silicone formulation and surface aging of aluminum adherends on bond strength. Int. J. Adhes. Adhes. 2019, 95, 102424. [Google Scholar] [CrossRef]

- Kang, M.J.; Heo, Y.J.; Jin, F.L.; Park, S.J. A review: Role of interfacial adhesion between carbon blacks and elastomeric materials. Carbon Lett. 2016, 18, 1–10. [Google Scholar] [CrossRef]

- Martin-Gallego, M.; Bernal, M.M.; Hernandez, M.; Verdejo, R.; López-Manchado, M.A. Comparison of filler percolation and mechanical properties in graphene and carbon nanotubes filled epoxy nanocomposites. Eur. Polym. J. 2013, 49, 1347–1353. [Google Scholar] [CrossRef]

- Alam, M.N.; Kumar, V.; Potiyaraj, P.; Lee, D.J.; Choi, J. Mutual dispersion of graphite–silica binary fillers and its effects on curing, mechanical, and aging properties of natural rubber composites. Polym. Bull. 2021, 79, 2707–2724. [Google Scholar] [CrossRef]

- Liu, Y.; Huang, Y.; Duan, X. Van der Waals integration before and beyond two-dimensional materials. Nature 2019, 567, 323–333. [Google Scholar] [CrossRef]

- Wang, J.; Li, Q.; Wu, C.; Xu, H. Thermal conductivity and mechanical properties of carbon black filled silicone rubber. Polym. Polym. Compos. 2014, 22, 393–400. [Google Scholar] [CrossRef]

- Song, P.; Song, J.; Zhang, Y. Stretchable conductor based on carbon nanotube/carbon black silicone rubber nanocomposites with highly mechanical, electrical properties and strain sensitivity. Compos. Part B Eng. 2020, 191, 107979. [Google Scholar] [CrossRef]

- Kucherskii, A.M. Hysteresis losses in carbon-black-filled rubbers under small and large elongations. Polym. Test. 2005, 24, 733–738. [Google Scholar] [CrossRef]

- Wang, L.; Choi, J. Highly stretchable strain sensors with improved sensitivity enabled by a hybrid of carbon nanotube and graphene. Micro Nano Syst. Lett. 2022, 10, 17. [Google Scholar] [CrossRef]

- Persons, A.K.; Ball, J.E.; Freeman, C.; Macias, D.M.; Simpson, C.L.; Smith, B.K.; Burch, V.R.F. Fatigue testing of wearable sensing technologies: Issues and opportunities. Materials 2021, 14, 4070. [Google Scholar] [CrossRef]

- Amorim, B.; Cortijo, A.; De Juan, F.; Grushin, A.G.; Guinea, F.; Gutiérrez-Rubio, A.; Ochoa, H.; Parente, V.; Roldán, R.; San-Jose, P.; et al. Novel effects of strains in graphene and other two dimensional materials. Phys. Rep. 2016, 617, 1–54. [Google Scholar] [CrossRef]

- Neri, I.; López-Suárez, M.; Gammaitoni, L. Tunable MoS2 strain sensor. IEEE Instrum. Meas. Mag. 2020, 23, 30–33. [Google Scholar] [CrossRef]

- Trung, T.Q.; Lee, N.E. Flexible and stretchable physical sensor integrated platforms for wearable human-activity monitoringand personal healthcare. Adv. Mater. 2016, 28, 4338–4372. [Google Scholar] [CrossRef] [PubMed]

- Zhao, S.; Li, J.; Cao, D.; Zhang, G.; Li, J.; Li, K.; Yang, Y.; Wang, W.; Jin, Y.; Sun, R.; et al. Recent advancements in flexible and stretchable electrodes for electromechanical sensors: Strategies, materials, and features. ACS Appl. Mater. Interfaces 2017, 9, 12147–12164. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Liu, X.; Schubert, D.W. Highly sensitive ultrathin flexible thermoplastic polyurethane/carbon black fibrous film strain sensor with adjustable scaffold networks. Nano-Micro Lett. 2021, 13, 64. [Google Scholar] [CrossRef] [PubMed]

- Zang, Y.; Zhang, F.; Di, C.A.; Zhu, D. Advances of flexible pressure sensors toward artificial intelligence and health care applications. Mater. Horiz. 2015, 2, 140–156. [Google Scholar] [CrossRef]

| Formulation | RTV-SR (phr) | NCB (phr) | MoS2 (phr) | Vulcanizing Agent (phr) |

|---|---|---|---|---|

| SR-unfilled | 100 | - | - | 2 |

| SR/20-NCB | 100 | 20 | - | 2 |

| SR/19-NCB/1-MoS2 | 100 | 19 | 1 | 2 |

| SR/17-NCB/3-MoS2 | 100 | 17 | 3 | 2 |

| SR/15-NCB/5-MoS2 | 100 | 15 | 5 | 2 |

| SR/5-MoS2 | 100 | - | 5 | 2 |

| Composites | Filler (Grade) | Amount of Filler | Tensile Strength (MPa) | Elongation at Break (%) | References |

|---|---|---|---|---|---|

| SR/CB (N990) | CB (N990) | 20 phr | 0.61 | 93.5 | [45] |

| SR/CB (Vulcan XC-72) | CB (Vulcan XC-72) | 20 phr | 3.6 | 257.3 | [45] |

| SR/CNT/CB (BP 2000) | CNT/CB (BP 2000) | 5.76 vol% | 4.5 | 211 | [46] |

| SR/17-NCB/3-MoS2 | CB (Conductex SC Ultra)/MoS2 | 20 phr | 1.57 | 177.67 | This study |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alam, M.N.; Kumar, V.; Jeong, T.; Park, S.-S. Nanocarbon Black and Molybdenum Disulfide Hybrid Filler System for the Enhancement of Fracture Toughness and Electromechanical Sensing Properties in the Silicone Rubber-Based Energy Harvester. Polymers 2023, 15, 2189. https://doi.org/10.3390/polym15092189

Alam MN, Kumar V, Jeong T, Park S-S. Nanocarbon Black and Molybdenum Disulfide Hybrid Filler System for the Enhancement of Fracture Toughness and Electromechanical Sensing Properties in the Silicone Rubber-Based Energy Harvester. Polymers. 2023; 15(9):2189. https://doi.org/10.3390/polym15092189

Chicago/Turabian StyleAlam, Md Najib, Vineet Kumar, Taemin Jeong, and Sang-Shin Park. 2023. "Nanocarbon Black and Molybdenum Disulfide Hybrid Filler System for the Enhancement of Fracture Toughness and Electromechanical Sensing Properties in the Silicone Rubber-Based Energy Harvester" Polymers 15, no. 9: 2189. https://doi.org/10.3390/polym15092189

APA StyleAlam, M. N., Kumar, V., Jeong, T., & Park, S. -S. (2023). Nanocarbon Black and Molybdenum Disulfide Hybrid Filler System for the Enhancement of Fracture Toughness and Electromechanical Sensing Properties in the Silicone Rubber-Based Energy Harvester. Polymers, 15(9), 2189. https://doi.org/10.3390/polym15092189