Thermosensitive Scattering Hydrogels Based on Triblock Poly-Ethers: A Novel Approach to Solar Radiation Regulation

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Cloud Point Test and Thermosensitive Scattering Hydrogel Synthesis

2.3. Characterization

2.4. Weather Resistance Test

3. Results and Discussion

3.1. Cloud Point Test

3.2. Testing the Molecular Size of the Triblock Polyether at High Temperatures

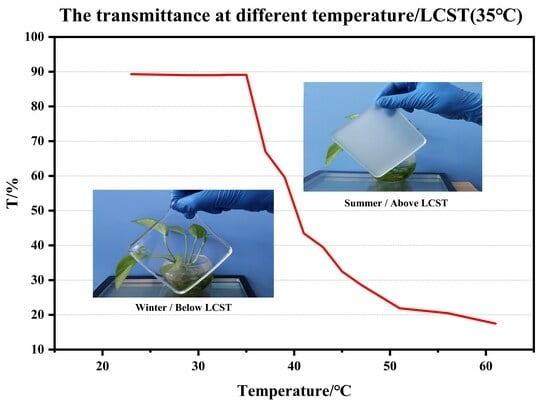

3.3. Testing the Photothermal Parameters of the Thermosensitive Scattering (TS) Glass

3.4. The Stability of the TS Glass

3.5. Simulation of the Application of TS Glass to Buildings

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Tian, J.; Peng, H.; Du, X.; Wang, H.; Cheng, X.; Du, Z. Hybrid thermochromic microgels based on UCNPs/PNIPAm hydrogel for smart window with enhanced solar modulation. J. Alloy. Compd. 2020, 858, 157725. [Google Scholar] [CrossRef]

- Nejat, P.; Jomehzadeh, F.; Taheri, M.M.; Gohari, M.; Majid, M.Z.A. A global review of energy consumption, CO2 emissions and policy in the residential sector (with an overview of the top ten CO2 emitting countries). Renew. Sustain. Energy Rev. 2015, 43, 843–862. [Google Scholar] [CrossRef]

- Zhou, Y.; Cai, Y.; Hu, X.; Long, Y. VO2/hydrogel hybrid nanothermochromic material with ultra-high solar modulation and luminous transmission. J. Mater. Chem. A Mater. Energy Sustain. 2015, 3, 1121–1126. [Google Scholar] [CrossRef]

- Ke, Y.; Zhou, C.; Zhou, Y.; Wang, S.; Chan, S.H.; Long, Y. Emerging Thermal-Responsive Materials and Inte-grated Techniques Targeting the Energy-Efficient Smart Window Application. Adv. Funct. Mater. 2018, 28, 1800113. [Google Scholar] [CrossRef]

- Kang, S.K.; Ho, D.H.; Lee, C.H.; Lim, H.S.; Cho, J.H. Actively Operable Thermoresponsive Smart Windows for Reducing Energy Consumption. ACS Appl. Mater. Interfaces 2020, 12, 33838–33845. [Google Scholar] [CrossRef] [PubMed]

- Grosse, P.; Hertling, R.; Müggenburg, T. Design of low emissivity systems based on a three-layer coating. J. Non-Cryst. Solids 1997, 218, 38–43. [Google Scholar] [CrossRef]

- Mann, D.; Yeung, C.; Habets, R.; Vroon, Z.; Buskens, P. Comparative Building Energy Simulation Study of Static and Thermochromically Adaptive Energy-Efficient Glazing in Various Climate Regions. Energies 2020, 13, 2842. [Google Scholar] [CrossRef]

- Pont, U.; Wölzl, M.; Schober, P.; Khosravi, S.N.; Schuss, M.; Mahdavi, A. Recent progress in the development of windows with vacuum glass. In MATEC Web of Conferences; EDP Sciences: Les Ulis, France, 2019; Volume 282, p. 2020. [Google Scholar]

- Baetens, R.; Jelle, B.P.; Gustavsen, A. Properties, requirements and possibilities of smart windows for dynamic daylight and solar energy control in buildings: A state-of-the-art review. Sol. Energy Mater. Sol. Cells 2010, 94, 87–105. [Google Scholar] [CrossRef]

- Debije, M.G. Solar Energy Collectors with Tunable Transmission. Adv. Funct. Mater. 2010, 20, 1498–1502. [Google Scholar] [CrossRef]

- Wang, N.; Magdassi, S.; Mandler, D.; Long, Y. Simple sol–gel process and one-step annealing of vanadium dioxide thin films: Synthesis and thermochromic properties. Thin Solid Film. 2013, 534, 594–598. [Google Scholar] [CrossRef]

- Seeboth, A.; Schneider, J.; Patzak, A. Materials for intelligent sun protecting glazing. Sol. Energy Mater. Sol. Cells 2000, 60, 263–277. [Google Scholar] [CrossRef]

- Chen, S.; Wang, Z.; Ren, H.; Chen, Y.; Yan, W.; Wang, C.; Li, B.; Jiang, J.; Zou, C. Gate-controlled VO2 phase transition for high-performance smart windows. Sci. Adv. 2019, 5, eaav6815. [Google Scholar] [CrossRef] [PubMed]

- Wu, M.; Shi, Y.; Li, R.; Wang, P. Spectrally Selective Smart Window with High Near-Infrared Light Shielding and Controllable Visible Light Transmittance. ACS Appl. Mater. Interfaces 2018, 10, 39819–39827. [Google Scholar] [CrossRef] [PubMed]

- Xu, Z.; Wang, S.; Hu, X.Y.; Jiang, J.; Sun, X.; Wang, L. Sunlight-Induced Photo-Thermochromic Supramolecular Nanocomposite Hydrogel Film for Energy-Saving Smart Window. Sol. Rrl 2018, 2, 1800204. [Google Scholar] [CrossRef]

- Chen, Z.; Gao, Y.; Kang, L.; Du, J.; Zhang, Z.; Luo, H.; Miao, H.; Tan, G. VO2-based double-layered films for smart windows: Optical design, all-solution preparation and improved properties. Sol. Energy Mater. Sol. Cells 2011, 95, 2677–2684. [Google Scholar] [CrossRef]

- Kang, L.; Gao, Y.; Luo, H.; Chen, Z.; Du, J.; Zhang, Z. Nanoporous thermochromic VO2 films with low opti-cal constants, enhanced luminous transmittance and thermochromic properties. ACS Appl. Mater. Interfaces 2011, 3, 135–138. [Google Scholar] [CrossRef]

- Kang, L.; Gao, Y.; Zhang, Z.; Du, J.; Cao, C.; Chen, Z.; Luo, H. Effects of Annealing Parameters on Optical Properties of Thermochromic VO2 Films Prepared in Aqueous Solution. J. Phys. Chem. C 2010, 114, 1901–1911. [Google Scholar] [CrossRef]

- Kim, Y.-A.; Jeong, J.-O.; Park, J.-S. Preparation and Characterization of Ionic Conductive Poly(acrylic Acid)-Based Silicone Hydrogels for Smart Drug Delivery System. Polymers 2021, 13, 406. [Google Scholar] [CrossRef]

- Bardajee, G.R.; Hooshyar, Z. Drug release study by a novel thermo sensitive nanogel based on salep modified graphene oxide. J. Polym. Res. 2017, 24, 49. [Google Scholar] [CrossRef]

- Zrínyi, M.; Szilágyi, A.; Filipcsei, G.; Fehér, J.; Szalma, J.; Móczár, G. Smart gel-glass based on the responsive properties of polymer gels. Polym. Adv. Technol. 2001, 12, 501–505. [Google Scholar] [CrossRef]

- Chou, H.T.; Chen, Y.C.; Lee, C.Y.; Chang, H.Y.; Tai, N.H. Switchable transparency of dual-controlled smart glass pre-pared with hydrogel-containing graphene oxide for energy efficiency. Sol. Energy Mater. Sol. Cells 2017, 166, 45–51. [Google Scholar] [CrossRef]

- Wang, L.; Jiang, L.; Su, D.; Sun, C.; Chen, M.; Goh, K.; Chen, Y. Non-covalent synthesis of thermo-responsive graphene oxide–perylene bisimides-containing poly(N-isopropylacrylamide) hybrid for organic pigment removal. J. Colloid Interface Sci. 2014, 430, 121–128. [Google Scholar] [CrossRef] [PubMed]

- He, Q.; Wang, Y.; Zhou, Y.; He, M.; Xu, R.; Hu, S.; Wu, W.; Wang, R. PAM-PNIPAM/W-doped VO2 thermo-chromic hydrogel film with high solar modulation capability for smart windows deployment. Opt. Mater. 2019, 97, 109367. [Google Scholar] [CrossRef]

- Lei, Q.; Wang, L.; Xie, H.; Yu, W. Active-passive dual-control smart window with thermochromic synergis-tic fluidic glass for building energy efficiency. Build. Environ. 2022, 222, 109407. [Google Scholar] [CrossRef]

- Xie, L.; Wang, X.; Zou, X.; Bai, Z.; Liang, S.; Wei, C.; Zha, S.; Zheng, M.; Zhou, Y.; Yue, O.; et al. Engineering Self-Adaptive Multi-Response Thermochromic Hydrogel for Energy-Saving Smart Windows and Wearable Temperature-Sensing. In Small; Weinheim an der Bergstrasse: Weinheim, Germany, 2023; p. e2304321. [Google Scholar]

- Chen, G.; Wang, K.; Yang, J.; Huang, J.; Chen, Z.; Zheng, J.; Wang, J.; Yang, H.; Li, S.; Miao, Y.; et al. Printable Thermochromic Hydrogel-Based Smart Window for All-Weather Building Temperature Regulation in Diverse Climates. Adv. Mater. 2023, 35, e2211716. [Google Scholar] [CrossRef]

- Pan, G.; Cao, H.; Guo, R.; Li, W.; Guo, J.; Yang, Z.; Huang, W.; He, W.; Liang, X.; Zhang, D.; et al. A polymer stabilized liquid crystal film with thermal switching characteristics between light transmission and adjustable light scattering. Opt. Mater. 2009, 31, 1163–1166. [Google Scholar] [CrossRef]

- Liang, X.; Chen, M.; Wang, Q.; Guo, S.; Zhang, L.; Yang, H. Active and passive modulation of solar light transmittance in a hybrid thermochromic soft-matter system for energy-saving smart window applications. J. Mater. Chem. C 2018, 6, 7054–7062. [Google Scholar] [CrossRef]

- Yang, Y.S.; Zhou, Y.; Chiang, F.B.Y.; Long, Y. Temperature-responsive hydroxypropylcellulose based ther-mochromic material and its smart window application. RSC Adv. 2016, 6, 61449–61453. [Google Scholar] [CrossRef]

- Guo, M.; Yu, Q.; Wang, X.; Xu, W.; Wei, Y.; Ma, Y.; Yu, J.; Ding, B. Tailoring Broad-Band-Absorbed Thermo-plasmonic 1D Nanochains for Smart Windows with Adaptive Solar Modulation. ACS Appl. Mater. Interfaces 2021, 13, 5634–5644. [Google Scholar] [CrossRef]

- Zhang, L.; Du, Y.; Xia, H.; Xia, F.; Yang, G.; Gao, Y. HPC-PAA hydrogel smart windows with and without Cs0.32WO3: High solar modulation ability and luminous transmittance. Ceram. Int. 2022, 48, 37122–37131. [Google Scholar] [CrossRef]

- Wang, K.; Chen, G.; Weng, S.; Hou, L.; Ye, D.; Jiang, X. Thermo-Responsive Poly(N isopropylacrylamide)/Hydroxypropylmethyl Cellulose Hydrogel with High Luminous Transmittance and Solar Modulation for Smart Windows. ACS Appl. Mater. Interfaces 2023, 15, 4385–4397. [Google Scholar] [CrossRef] [PubMed]

- Gong, X.; Li, J.; Chen, S.; Wen, W. Copolymer solution-based “smart window”. Appl. Phys. Lett. 2009, 95, 251907. [Google Scholar] [CrossRef]

- Wang, S.; Xu, Z.; Wang, T.; Xiao, T.; Hu, X.-Y.; Shen, Y.-Z.; Wang, L. Warm/cool-tone switchable thermochromic material for smart windows by orthogonally integrating properties of pillar[6]arene and ferrocene. Nat. Commun. 2018, 9, 1737. [Google Scholar] [CrossRef]

- Zhang, R.; Xiang, B.; Shen, Y.; Xia, L.; Xu, L.; Guan, Q.; Tang, S. Energy-efficient smart window based on a thermochromic microgel with ultrahigh visible transparency and infrared transmittance modulation. J. Mater. Chem. A 2021, 9, 17481–17491. [Google Scholar] [CrossRef]

- Li, X.H.; Liu, C.; Feng, S.P.; Fang, N.X. Broadband Light Management with Thermochromic Hydrogel Micropar-ticles for Smart Windows. Joule 2019, 3, 290–302. [Google Scholar] [CrossRef]

- Feng, Y.; Yang, M.; Zhang, Y.; Liu, H.; Ju, H.; Zhang, G.; Ma, W.; Wu, Y.; Yu, Y.; Yang, Y.; et al. Hybrid thermo-chromic hydrogels based on HPC/PVA for smart windows with enhanced solar modulation. J. Chem. Sci. 2022, 134, 24. [Google Scholar] [CrossRef]

- Tian, J.; Peng, H.; Du, X.; Wang, H.; Cheng, X.; Du, Z. Durable, broadband-light-manageable thermochromic hydrogel with adjustable LCST for smart windows application. Prog. Org. Coat. 2021, 157, 106287. [Google Scholar] [CrossRef]

- Madry, H.; Gao, L.; Rey-Rico, A.; Venkatesan, J.K.; Müller-Brandt, K.; Cai, X.; Goebel, L.; Schmitt, G.; Speicher-Mentges, S.; Zurakowski, D.; et al. Thermosensitive Hydrogel Based on PEO–PPO–PEO Poloxamers for a Controlled In Situ Release of Recombinant Adeno-Associated Viral Vectors for Effective Gene Therapy of Cartilage Defects. Adv. Mater. 2020, 32, 1906508. [Google Scholar] [CrossRef]

- Zhao, D.; Feng, M.; Zhang, L.; He, B.; Chen, X.; Sun, J. Facile synthesis of self-healing and layered sodium al-ginate/polyacrylamide hydrogel promoted by dynamic hydrogen bond. Carbohydr. Polym. 2021, 256, 117580. [Google Scholar] [CrossRef]

- Yue, Y.; Wang, X.; Han, J.; Yu, L.; Chen, J.; Wu, Q.; Jiang, J. Effects of nanocellulose on sodium algi-nate/polyacrylamide hydrogel: Mechanical properties and adsorption-desorption capacities. Carbohydr. Polym. 2019, 206, 289–301. [Google Scholar] [CrossRef]

- Xu, G.; Xia, H.; Chen, P.; She, W.; Zhang, H.; Ma, J.; Ruan, Q.; Zhang, W.; Sun, Z. Thermochromic Hydrogels with Dynamic Solar Modulation and Regulatable Critical Response Temperature for Energy-Saving Smart Windows. Adv. Funct. Mater. 2022, 32, 2109597. [Google Scholar] [CrossRef]

| Polyether | LCST (°C) (1% Aqueous Solution) | Hydrogel LCST (°C) |

|---|---|---|

| E2000 | 27 | ≤25 |

| E1100 | 36 | 25–50 |

| P2000 | 73 | ≥50 |

| Test Temperature | Tvis | Rvis | SHGC |

|---|---|---|---|

| <35 °C | 0.833 | 0.09 | 0.68 |

| 40 °C | 0.109 | 0.083 | 0.362 |

| 45 °C | 0.089 | 0.107 | 0.346 |

| 50 °C | 0.081 | 0.128 | 0.337 |

| 55 °C | 0.079 | 0.140 | 0.334 |

| Smart Glass | Solar | UV | / | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Status | Structure | Tsol * | Rfsol * | Rbsol * | Absol1 * | Absol2 * | Tuv * | SHGC | U(w/m2k) |

| White | (From outside) * 6G + 2T + 6G + 12A + 6G | 0.1225 | 0.1835 | 0.2039 | 0.6766 | 0.0174 | 0.1476 | 0.2580 | 2.7780 |

| (From outside) 6G + 12A + 6G + 2T + 6G | 0.1225 | 0.2039 | 0.1835 | 0.1607 | 0.5129 | 0.1476 | 0.4700 | 2.7600 | |

| Clear | (From outside) 6G + 2T + 6G + 12A + 6G | 0.4445 | 0.0996 | 0.1264 | 0.3910 | 0.0649 | 0.5728 | 0.5560 | 2.7580 |

| (From outside) 6G + 12A + 6G + 2T + 6G | 0.4445 | 0.1264 | 0.0996 | 0.1518 | 0.2773 | 0.5473 | 0.6410 | 2.7250 | |

| Aging Mode | Parameter | Test Points (Cycle or h) * | ||||

|---|---|---|---|---|---|---|

| 0 | 50 | 100 | 150 | 200 | ||

| Cold and hot cycle (test points unit: cycle) | Tvis | 83.8% | 83.2% | 83.1% | 83.1% | 82.9% |

| SHGC | 0.35 | 0.35 | 0.34 | 0.34 | 0.34 | |

| Ultraviolet aging (test points unit: h) | Tvis | 83.4% | 82.9% | 82.5% | 82.1% | 81.9% |

| SHGC | 0.35 | 0.34 | 0.33 | 0.33 | 0.33 | |

| Types of Glass | U (w/m2k) | SHGC (Clear) | SHGC (White) |

|---|---|---|---|

| TS glass (25 °C/50 °C) | 1.69 | 0.31 | 0.13 |

| Triple silvers glass | 1.65 | 0.21 | / |

| Ordinary glass | 2.80 | 0.67 | / |

| Orientation | Type of Glass | Sunmmer Cooling Demand (kWh) | Winter Heating Demand (kWh) |

|---|---|---|---|

| West window | Ordinary glass | 2705.8 | 2642.4 |

| Triple silvers glass | 1575.4 | 2578.3 | |

| TS glass (25 °C) | 1484.7 | 2569.0 | |

| TS glass (50 °C) | 1720.8 | 2534.7 | |

| Skylight | Ordinary glass | 11135.2 | 3876.9 |

| Triple silvers glass | 4376.8 | 3368.9 | |

| TS glass (25 °C) | 3204.5 | 3353.9 | |

| TS glass (50 °C) | 5792.6 | 3307.2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qian, D.; Yang, S.; Wang, X.; Tian, Y.; Wen, W. Thermosensitive Scattering Hydrogels Based on Triblock Poly-Ethers: A Novel Approach to Solar Radiation Regulation. Polymers 2024, 16, 8. https://doi.org/10.3390/polym16010008

Qian D, Yang S, Wang X, Tian Y, Wen W. Thermosensitive Scattering Hydrogels Based on Triblock Poly-Ethers: A Novel Approach to Solar Radiation Regulation. Polymers. 2024; 16(1):8. https://doi.org/10.3390/polym16010008

Chicago/Turabian StyleQian, Dewei, Siyu Yang, Xiaofang Wang, Yang Tian, and Weijia Wen. 2024. "Thermosensitive Scattering Hydrogels Based on Triblock Poly-Ethers: A Novel Approach to Solar Radiation Regulation" Polymers 16, no. 1: 8. https://doi.org/10.3390/polym16010008

APA StyleQian, D., Yang, S., Wang, X., Tian, Y., & Wen, W. (2024). Thermosensitive Scattering Hydrogels Based on Triblock Poly-Ethers: A Novel Approach to Solar Radiation Regulation. Polymers, 16(1), 8. https://doi.org/10.3390/polym16010008