Study on an Improved Phosphate Cement Binder for the Development of Fiber-Reinforced Inorganic Polymer Composites

Abstract

:1. Introduction

2. Experimental Program

2.1. Materials and Mix Proportions

| Type | MPC paste/mortar | MPC paste | MPC mortar | |

|---|---|---|---|---|

| No. | FA:M | W:(FA + M + P) | MPP:M | MPP:M:Sand |

| 1 | 0.4 | 0.22 | 1:1 | None |

| 2 | 0.5 | 0.22 | 1:1 | None |

| 3 | 0.6 | 0.22 | 1:1 | 1:1:1 |

| 4 | 0.8 | 0.22 | 1:1 | 1:1:1 |

| 5 | 1.0 | 0.22 | 1:1 | 1:1:1 |

| 6 | 1.0 | 0.26 | 1:1 | None |

| 7 | 1.0 | 0.30 | 1:1 | None |

2.2. Test Methods

3. Results and Discussion

3.1. Physical Properties of MPC Paste

3.2. Mechanical Properties of MPC Paste/Mortar

3.2.1. Compressive Strength

3.2.2. Flexural Strength

3.3. Mechanical Properties of MPC-Based FRIP Composites

3.3.1. Pullout strength of fiber sheets

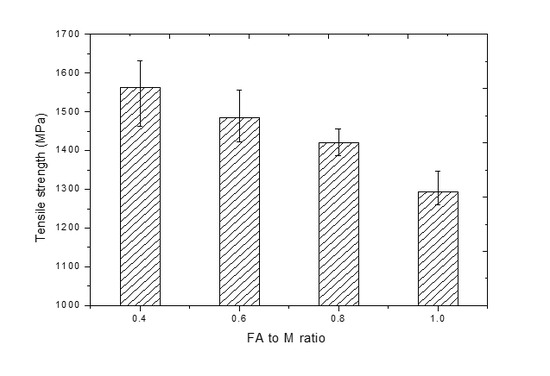

3.3.2. Tensile Strength of MPC-Based FRIP Composites

3.4. Microscopic Observations

3.4.1. XRD Analysis

3.4.2. SEM Analysis of MPC Pastes

3.4.3. SEM Analysis of FRIP Composites

4. Conclusions

- The workability of fresh mixed MPC paste was improved and an initial setting time of around 25 min was achieved by using the boric acid when the W/B ratio was 0.22.The flow of the MPC paste reached up to 145 mm when the addition of FA was 80% by the weight of magnesia. The improved workability of MPC paste can allow its use in situ.

- The compressive strength development of MPC paste and mortar samples was determined respectively. The compressive strength is inverselyproportional to the W/B ratio. When the W/B ratio was fixed, the compressive strength of the MPC paste reached its peak value when the fly ash-to-magnesia ratio (FA/M) is 0.8. However, in the case of MPC mortar, the samples with FA/M = 0.6 had the highest compressive strength.

- The flexural strength for different mix proportions of MPC pastes and mortar was tested at 7 days. The MPC mortar exhibited higher flexural strength than the MPC paste given the same W/B ratio. The reason is that the high density of sand particles increased the toughness of the pastes. An increase in the flexural strength of MPC pastes was also observed with the increase in the FA/M ratio up to 0.8.

- Pullout tests were conducted to determine the bond strength of carbon fiber sheets in the MPC matrix. FA has shown an insignificant effect on the pullout strength of fiber sheets when the FA/M ratio increased from0.4 to 1.0 by weight in the current study.The tensile strength ofMPC-based carbon FRIP composites was also tested. The tensile strength of the FRIP composites decreased in sequence when the FA/M ratio increased from 0.4 to 1.0.

- According to the XRD analysis, unreacted magnesia (MgO) and both crystal and amorphous forms of MgKPO4·6H2O (MKP) can be identified in the MPC matrix. SEM analyses of hardened MPC pastes showed a dense and acicular structure, which was formed by these crystals, amorphous products and fly ash particles. The micrograph of MPC-based FRIP composites also showed good impregnation of MPC pastes in the fibers, but the bond between fibers and the MPC matrix needs to be improved in a future study.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Harries, K.A.; Porter, M.L.; Busel, J.P. FRP materials and concrete—Research needs. Concr. Int. 2003, 25, 69–74. [Google Scholar]

- Keller, T.; Tracy, C.; Huge, E. Fire endurance of loaded and liquid-cooled GFRPslabs for construction. Compos. A Appl. Sci. Manufact. 2006, 37, 1055–1067. [Google Scholar]

- Wiberg, A. Strengthening of Concrete Beams Using Cementitious Carbon Fibre Composites. Ph.D. Thesis, Royal Institute of Technology, Stockholm, Sweden, 2003. [Google Scholar]

- Trapko, T. The effect of high temperature on the performance of CFRP and FRCM confined concrete elements. Compos. B Eng. 2013, 54, 138–145. [Google Scholar]

- Wang, K.; Young, B.; Smith, S.T. Mechanical properties of pultruded carbon fibre-reinforced polymer (CFRP) plates at elevated temperatures. Eng. Struct. 2011, 33, 2154–2161. [Google Scholar]

- Hashemi, S.; Al-Mahaidi, R. Experimental and finite element analysis of flexural behavior of FRP-strengthened RC beams using cement-based adhesives. Constr. Build. Mater. 2012, 26, 268–273. [Google Scholar]

- Fang, Z.Z.; Wu, C.W.; Sun, T.F.; Wu, M.X. Applying geopolymer-bonded fibrepastes to RC beam to enhance shear reinforcement. J. Build. Mater. 2009, 12, 361–365. (In Chinese) [Google Scholar]

- Zheng, W.Z.; Chen, W.H.; Xu, W.; Wang, Y. Experimental research on alkali-activated slag high temperature resistant inorganic adhesive pasting CFRP sheets on surface of concrete. J. Build. Mater. 2009, 30, 138–145. (In Chinese) [Google Scholar]

- Zhang, X.; Li, S.B.; Yang, W.L. Experimental study on flexural behavior of RC beams strengthened with inorganic adhesive CFRP sheets. J. Build. Struct. 2010, 2, 249–254. (In Chinese) [Google Scholar]

- Sarkar, A.K. Hydration/dehydration characteristics of struvite and dittmaritepertaining to magnesium ammonium phosphate cement system. J. Mater. Sci. 1991, 26, 2514–2518. [Google Scholar]

- Yang, Q.B.; Zhang, S.; Wu, X.L. Deicer-scaling resistance of phosphate cement-basedbinder for rapid repair of concrete. Cem. Concr. Res. 2002, 32, 165–168. [Google Scholar]

- Wagh, A.S.; Jeong, S.Y. Chemically bonded phosphate ceramics: A dissolution model of formation. J. Soc. 2003, 86, 1838–1844. [Google Scholar]

- Ding, Z.; Li, Z.J. High-early-strength magnesium phosphate cement with fly ash. ACI Mater. J. 2005, 102, 375–381. [Google Scholar]

- Li, Y.; Chen, B. Factors that affect the properties of magnesium phosphate cement. Constr. Build. Mater. 2013, 47, 977–983. [Google Scholar]

- Ding, Z.; Dong, B.; Xing, F.; Han, N.X.; Li, Z.J. Cementing mechanism of potassium phosphate based magnesium phosphate cement. Ceram. Int. 2012, 38, 6281–6288. [Google Scholar]

- Ding, Z.; Lu, Z.X.; Li, Y. Feasibility of basalt fiber reinforced inorganic adhesive for concrete strengthening. Adv. Mater. Res. 2011, 287–290, 1197–1200. [Google Scholar]

- Dai, J.G.; Munir, S.; Ding, Z. Comparative study of different cement-based ofinorganic paste towards the development of FRIP strengthening of technology. J. Compos. Constr. 2014, 18. [Google Scholar] [CrossRef]

- Ding, Z.; Li, Z.J. Effect of aggregates and water contents on the propertiesof magnesium phosphor-silicate cement. Cem. Concr. Compos. 2005, 27, 11–18. [Google Scholar]

- Tregger, N.; Ferrara, L.; Shah, S.; Pagination, P. Identifying viscosity of cement paste from mini-slump-flow test. ACI Mater. J. 2008, 106, 558–566. [Google Scholar]

- Bouvet, A.; Ghorbel, E.; Bennacer, R. The mini-conical slump flow test: Analysis and numerical study. Cem. Concr. Res. 2010, 40, 1517–1523. [Google Scholar]

© 2014 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ding, Z.; Dai, J.-G.; Muner, S. Study on an Improved Phosphate Cement Binder for the Development of Fiber-Reinforced Inorganic Polymer Composites. Polymers 2014, 6, 2819-2831. https://doi.org/10.3390/polym6112819

Ding Z, Dai J-G, Muner S. Study on an Improved Phosphate Cement Binder for the Development of Fiber-Reinforced Inorganic Polymer Composites. Polymers. 2014; 6(11):2819-2831. https://doi.org/10.3390/polym6112819

Chicago/Turabian StyleDing, Zhu, Jian-Guo Dai, and Sarfraz Muner. 2014. "Study on an Improved Phosphate Cement Binder for the Development of Fiber-Reinforced Inorganic Polymer Composites" Polymers 6, no. 11: 2819-2831. https://doi.org/10.3390/polym6112819

APA StyleDing, Z., Dai, J. -G., & Muner, S. (2014). Study on an Improved Phosphate Cement Binder for the Development of Fiber-Reinforced Inorganic Polymer Composites. Polymers, 6(11), 2819-2831. https://doi.org/10.3390/polym6112819