Comparison of in Situ and ex Situ Methods for Synthesis of Two-Photon Polymerization Polymer Nanocomposites

Abstract

:1. Introduction

2. Experimental Section

2.1. In Situ Preparation of Nanocomposites

2.1.1. Synthesis of TiO2 Nanoparticles

2.1.2. Preparation of Photosensitive Nanocomposites Using TiO2 Sol

2.2. Ex Situ Preparation of Nanocomposites

Preparation of High Refractive Index Polymer/TiO2 Nanocomposites

2.3. 2PP of Nanocomposites

3. Results and Discussion

3.1. In Situ Process

3.1.1. X-ray Diffraction (XRD) Analysis

3.1.2. TEM/SEM Characterization

3.1.3. Refractive Index Measurements

3.1.4. Optical Characterization

3.1.5. 2PP Results

3.2. Ex Situ Process

3.2.1. SEM Characterization

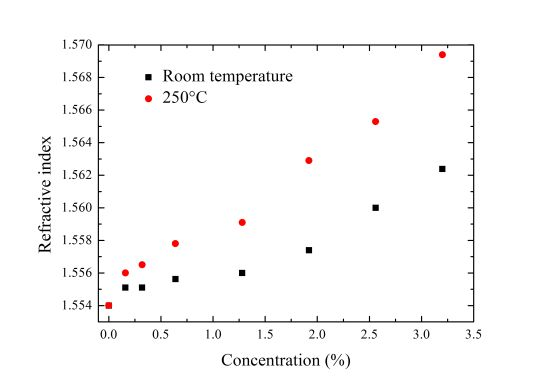

3.2.2. Refractive Index Measurements

3.2.3. Optical Characterization

3.2.4. 2PP Results

4. Conclusions

Acknowledgments

Conflicts of Interest

References

- Cui, Z.; Lü, C.; Yang, B.; Shen, J.; Yang, H. The research on syntheses and properties of novel epoxy/polymercaptan curing optical resins with high refractive indices. Polymer 2001, 42, 10095–10100. [Google Scholar] [CrossRef]

- Okutsu, R.; Ando, S.; Ueda, M. Sulfur-containing poly(meth)acrylates with high refractive indices and high Abbe’s numbers. Chem. Mater. 2008, 20, 4017–4023. [Google Scholar] [CrossRef]

- Nebioglu, A.; Leon, J.A.; Khudyakov, I.V. New UV-curable high refractive index oligomers. Ind. Eng. Chem. Res. 2008, 47, 2155–2159. [Google Scholar] [CrossRef]

- Hart, S.D.; Maskaly, G.R.; Temelkuran, B.; Prideaux, P.H.; Joannopoulos, J.D.; Fink, Y. External reflection from omnidirectional dielectric mirror fibers. Science 2002, 296, 510–513. [Google Scholar] [CrossRef]

- Dobrowolski, J.A.; Ho, F. High performance step-down AR coating for high refractive–index IR materials. Appl. Opt. 1982, 21, 288–292. [Google Scholar] [CrossRef]

- Yablonovitch, E. How to be truly photonic. Science 2000, 289, 557–559. [Google Scholar] [CrossRef]

- Hornak, L.A. Polymers for Lightwave and Integrated Optics: Technology and Applications; Marcel Dekker, Inc.: New York, NY, USA, 1992. [Google Scholar]

- Kitai, A.H. Solid State Luminescence; Chapman & Hall: London, UK, 1993. [Google Scholar]

- Zimmermann, L.; Weibel, M.; Caseri, W.; Suter, U.W. High refractive index films of polymer nanocomposites. J. Mater. Res. 1993, 8, 1742–1748. [Google Scholar] [CrossRef]

- Kyprianidou-Leodidou, T.; Caseri, W.; Suter, U.W. Size variation of PbS particles in high-refractive-index nanocomposites. J. Phys. Chem. 1994, 98, 8992–8997. [Google Scholar] [CrossRef]

- Wang, B.; Wilkes, G.L. High Refractive-Index Ceramic/Polymer Hybrid Material. U.S. Patent 5,109,080, 13 July 1992. [Google Scholar]

- Lee, L.H.; Chen, W.C. High-refractive-index thin films prepared from trialkoxysilane-capped poly(methyl methacrylate)-tiania materials. Chem. Mater. 2001, 13, 1137–1142. [Google Scholar] [CrossRef]

- Duan, X.M.; Sun, H.B.; Kaneko, K.; Kawata, S. Two-photon polymerization of metal ions doped acrylate monomers and oligomers for three-dimensional structure fabrication. Thin Solid Films 2004, 453, 518–521. [Google Scholar]

- Ostendorf, A.; Chakif, M.; Guo, Q. Laser direct writing of nanocompounds. In Proceedings of Materials Research Society Spring Meeting and Exhibits, San Francisco, CA, USA, 26–29 April 2011.

- Guo, Q.; Ghadiri, R.; Xiao, S.; Esen, C.; Medenbach, O.; Ostendorf, A. Laser direct writing of high refractive index polymer/TiO2 nanocomposites. In Proceedings of SPIE Photonics West, San Francisco, CA, USA, 21 January 2012.

- Sakellari, I.; Gaidukeviciute, A.; Giakoumaki, A.; Gray, D.; Fotakis, D.; Farsari, M.; Vamvakaki, M.; Reihardt, C.; Ovsianikov, A.; Chichkov, B.N. Two-photon polymerization of titanium-containing sol-gel composites for three-dimensional structure fabrication. Appl. Phys. A 2010, 100, 359–364. [Google Scholar] [CrossRef]

- Ashkin, A.; Dziedzic, J.M.; Bjorkholm, J.E.; Chu, S. Observation of a single-beam gradient force optical trap for dielectric particles. Opt. Lett. 1986, 11, 288–290. [Google Scholar] [CrossRef]

- Kelemenen, L.; Valkai, S.; Ormos, P. Integrated optical motor. Appl. Opt. 2006, 45, 2777–2780. [Google Scholar] [CrossRef]

- Harada, T.; Yoshikawa, K. Mode switching of an optical motor. Appl. Phys. Lett. 2002, 81, 4850–4852. [Google Scholar] [CrossRef] [Green Version]

- Jean, J.H.; Ring, T.A. Nucleation and growth of monosized TiO2 powders from alcohol solution. Langmuir 1986, 2, 251–255. [Google Scholar] [CrossRef]

- Kim, T.H.; Lim, D.Y.; Yu, B.S.; Lee, J.H.; Goto, M. Effect of stirring and heating rate on the formation of TiO2 powders using supercritical fluid. Ind. Eng. Chem. Res. 2000, 39, 4702–4706. [Google Scholar] [CrossRef]

- Hirai, T.; Sato, H.; Komasawa, I. Mechanism of formation of titanium dioxide ultrafine particles in reverse micelles by hydrolysis of titanium tetrabutoxide. Ind. Eng. Chem. Res. 1993, 32, 3014–3019. [Google Scholar] [CrossRef]

- Wu, C.I.; Huang, J.W.; Wen, Y.L.; Wen, S.B.; Shen, Y.H.; Yeh, M.Y. Preparation of TiO2 nanoparticles by supercritical carbon dioxide. Mater. Lett. 2008, 62, 1923–1926. [Google Scholar] [CrossRef]

- Lide, D.R. Handbook of Chemistry and Physics, 76th ed.; CRC Press: Boca Raton, FL, USA, 1995. [Google Scholar]

- Hu, M.Z.-C.; Kurian, V.; Payzant., E.A.; Rawn, C.J.; Hunt, R.D. Wet-chemical synthesis of monodispersed barium titanate particles—Hydrothermal conversion of TiO2 microspheres to nanocrystalline BaTiO3. Powder Technol. 2000, 110, 2–14. [Google Scholar] [CrossRef]

© 2014 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Guo, Q.; Ghadiri, R.; Weigel, T.; Aumann, A.; Gurevich, E.L.; Esen, C.; Medenbach, O.; Cheng, W.; Chichkov, B.; Ostendorf, A. Comparison of in Situ and ex Situ Methods for Synthesis of Two-Photon Polymerization Polymer Nanocomposites. Polymers 2014, 6, 2037-2050. https://doi.org/10.3390/polym6072037

Guo Q, Ghadiri R, Weigel T, Aumann A, Gurevich EL, Esen C, Medenbach O, Cheng W, Chichkov B, Ostendorf A. Comparison of in Situ and ex Situ Methods for Synthesis of Two-Photon Polymerization Polymer Nanocomposites. Polymers. 2014; 6(7):2037-2050. https://doi.org/10.3390/polym6072037

Chicago/Turabian StyleGuo, Qingchuan, Reza Ghadiri, Thomas Weigel, Andreas Aumann, Evgeny L. Gurevich, Cemal Esen, Olaf Medenbach, Wei Cheng, Boris Chichkov, and Andreas Ostendorf. 2014. "Comparison of in Situ and ex Situ Methods for Synthesis of Two-Photon Polymerization Polymer Nanocomposites" Polymers 6, no. 7: 2037-2050. https://doi.org/10.3390/polym6072037

APA StyleGuo, Q., Ghadiri, R., Weigel, T., Aumann, A., Gurevich, E. L., Esen, C., Medenbach, O., Cheng, W., Chichkov, B., & Ostendorf, A. (2014). Comparison of in Situ and ex Situ Methods for Synthesis of Two-Photon Polymerization Polymer Nanocomposites. Polymers, 6(7), 2037-2050. https://doi.org/10.3390/polym6072037