Styrene-Assisted Maleic Anhydride Grafted Poly(lactic acid) as an Effective Compatibilizer for Wood Flour/Poly(lactic acid) Bio-Composites

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Samples

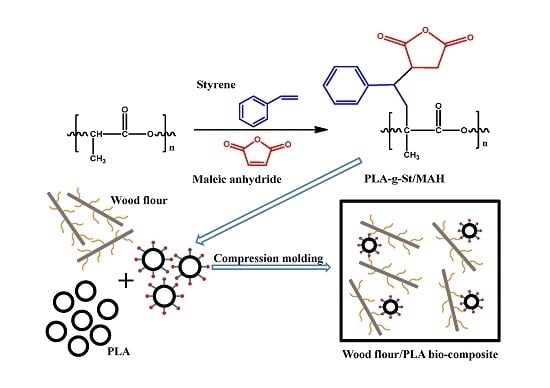

2.2.1. PLA-g-St/MAH

2.2.2. Wood Flour/PLA Composites

2.3. Characterizations

2.3.1. Fourier Transform Infrared (FT-IR) Spectroscopy

2.3.2. Rotational Rheometry

2.3.3. Torque Rheometry

2.3.4. Mechanical Property Tests

2.3.5. Scanning Electron Microscopy (SEM)

3. Results and Discussion

3.1. Characterization of PLA-g-St/MAH

3.2. Dynamic Rheological Properties

3.3. Torque Rheometry

3.4. Mechanical Properties

3.5. SEM

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Ashori, A. Wood-plastic composites as promising green-composites for automotive industries! Bioresour. Technol. 2008, 99, 4661–4667. [Google Scholar] [CrossRef] [PubMed]

- Khoshkava, V.; Kamal, M.R. Effect of cellulose nanocrystals (CNC) particle morphology on dispersion and rheological and mechanical properties of polypropylene/CNC nanocomposites. ACS Appl. Mater. Interfaces 2014, 6, 8146–8157. [Google Scholar] [CrossRef] [PubMed]

- Zhou, X.; Yu, Y.; Lin, Q.; Chen, L. Effects of maleic anhydride-grafted polypropylene (MAPP) on the physico-mechanical properties and rheological behavior of bamboo powder-polypropylene foamed composites. Bioresources 2013, 8, 6263–6279. [Google Scholar] [CrossRef]

- Charlet, K.; Saulnier, F.; Dubois, M.; Béakou, A. Improvement of wood polymer composite mechanical properties by direct fluorination. Mater. Des. 2015, 74, 61–66. [Google Scholar] [CrossRef]

- Petchwattana, N.; Covavisaruch, S. Mechanical and morphological properties of wood plastic biocomposites prepared from toughened poly(lactic acid) and rubber wood sawdust (Hevea brasiliensis). J. Bionic. Eng. 2014, 11, 630–637. [Google Scholar] [CrossRef]

- Bax, B.; Müssig, J. Impact and tensile properties of PLA/cordenka and PLA/flax composites. Compos. Sci. Technol. 2008, 68, 1601–1607. [Google Scholar] [CrossRef]

- Terzopoulou, Z.N.; Papageorgiou, G.Z.; Papadopoulou, E.; Athanassiadou, E.; Reinders, M.; Bikiaris, D.N. Development and study of fully biodegradable composite materials based on poly(butylene succinate) and hemp fibers or hemp shives. Polym. Compos. 2016, 37, 407–421. [Google Scholar] [CrossRef]

- Marques, M.F.V.; Lunz, J.N.; Aguiar, V.O.; Grafova, I.; Kemell, M.; Visentin, F.; Sartori, A.; Grafov, A. Thermal and mechanical properties of sustainable composites reinforced with natural fibers. J. Polym. Environ. 2014, 23, 251–260. [Google Scholar] [CrossRef]

- Koronis, G.; Silva, A.; Fontul, M. Green composites: A review of adequate materials for automotive applications. Compos. B 2013, 44, 120–127. [Google Scholar] [CrossRef]

- Fazita, M.R.N.; Jayaraman, K.; Bhattacharyya, D.; Hossain, M.S.; Haafiz, M.K.M.; Abdul Khalil, H.P.S. Disposal options of bamboo fabric-reinforced poly(lactic) acid composites for sustainable packaging: Biodegradability and recyclability. Polymers 2015, 7, 1476–1496. [Google Scholar] [CrossRef]

- Farah, S.; Anderson, D.G.; Langer, R. Physical and mechanical properties of PLA, and their functions in widespread applications—A comprehensive review. Adv. Drug Deliv. Rev. 2016, 107, 367–392. [Google Scholar] [CrossRef] [PubMed]

- Chieng, B.; Ibrahim, N.; Yunus, W.; Hussein, M. Poly(lactic acid)/poly(ethylene glycol) polymer nanocomposites: Effects of graphene nanoplatelets. Polymers 2013, 6, 93–104. [Google Scholar] [CrossRef]

- Vp, S.; Mohanty, S.; Nayak, S.K. Effect of poly (lactic acid)-graft-glycidyl methacrylate as a compatibilizer on properties of poly (lactic acid)/banana fiber biocomposites. Polym. Adv. Technol. 2016, 27, 515–524. [Google Scholar] [CrossRef]

- Lei, B.; Zhang, Y.; He, Y.; Xie, Y.; Xu, B.; Lin, Z.; Huang, L.; Tan, S.; Wang, M.; Cai, X. Preparation and characterization of wood-plastic composite reinforced by graphitic carbon nitride. Mater. Des. (1980–2015) 2015, 66, 103–109. [Google Scholar] [CrossRef]

- Petinakis, E.; Yu, L.; Edward, G.; Dean, K.; Liu, H.; Scully, A.D. Effect of matrix-particle interfacial adhesion on the mechanical properties of poly(lactic acid)/wood-flour micro-composites. J. Polym. Environ. 2009, 17, 83–94. [Google Scholar] [CrossRef]

- Csikós, Á.; Faludi, G.; Domján, A.; Renner, K.; Móczó, J.; Pukánszky, B. Modification of interfacial adhesion with a functionalized polymer in PLA/wood composites. Eur. Polym. J. 2015, 68, 592–600. [Google Scholar] [CrossRef] [Green Version]

- Takatani, M.; Ikeda, K.; Sakamoto, K.; Okamoto, T. Cellulose esters as compatibilizers in wood/poly(lactic acid) composite. J. Wood Sci. 2007, 54, 54–61. [Google Scholar] [CrossRef]

- Zhang, H. Effect of a novel coupling agent, alkyl ketene dimer, on the mechanical properties of wood-plastic composites. Mater. Des. 2014, 59, 130–134. [Google Scholar] [CrossRef]

- Islam, M.S.; Pickering, K.L.; Foreman, N.J. Influence of alkali treatment on the interfacial and physico-mechanical properties of industrial hemp fibre reinforced polylactic acid composites. Compos. Part A Appl. Sci. Manuf. 2010, 41, 596–603. [Google Scholar] [CrossRef]

- Lv, S.; Tan, H.; Gu, J.; Zhang, Y. Silane modified wood flour blended with poly(lactic acid) and its effects on composite performance. Bioresources 2015, 10, 5426–5439. [Google Scholar] [CrossRef]

- Huda, M.S.; Drzal, L.T.; Mohanty, A.K.; Misra, M. Effect of fiber surface-treatments on the properties of laminated biocomposites from poly(lactic acid) (PLA) and kenaf fibers. Compos. Sci. Technol. 2008, 68, 424–432. [Google Scholar] [CrossRef]

- Qin, L.; Qiu, J.; Liu, M.; Ding, S.; Shao, L.; Lü, S.; Zhang, G.; Zhao, Y.; Fu, X. Mechanical and thermal properties of poly(lactic acid) composites with rice straw fiber modified by poly(butyl acrylate). Chem. Eng. J. 2011, 166, 772–778. [Google Scholar] [CrossRef]

- Tingaut, P.; Zimmermann, T.; Lopezsuevos, F. Synthesis and characterization of bionanocomposites with tunable properties from poly(lactic acid) and acetylated microfibrillated cellulose. Biomacromolecules 2010, 11, 454–464. [Google Scholar] [CrossRef] [PubMed]

- Lee, S.-H.; Wang, S. Biodegradable polymers/bamboo fiber biocomposite with bio-based coupling agent. Compos. A 2006, 37, 80–91. [Google Scholar] [CrossRef]

- Gregorova, A.; Hrabalova, M.; Wimmer, R.; Saake, B.; Altaner, C. Poly(lactide acid) composites reinforced with fibers obtained from different tissue types ofpicea sitchensis. J. Appl. Polym. Sci. 2009, 114, 2616–2623. [Google Scholar] [CrossRef]

- Zhu, R.; Liu, H.; Zhang, J. Compatibilizing effects of maleated poly(lactic acid) (PLA) on properties of pla/soy protein composites. Ind. Eng. Chem. Res. 2012, 51, 7786–7792. [Google Scholar] [CrossRef]

- Huneault, M.A.; Li, H. Morphology and properties of compatibilized polylactide/thermoplastic starch blends. Polymer 2007, 48, 270–280. [Google Scholar] [CrossRef]

- Hwang, S.W.; Shim, J.K.; Selke, S.; Soto-Valdez, H.; Rubino, M.; Auras, R. Effect of maleic-anhydride grafting on the physical and mechanical properties of poly(L-lactic acid)/starch blends. Macromol. Mater. Eng. 2013, 298, 624–633. [Google Scholar] [CrossRef]

- Detyothin, S.; Selke, S.E.M.; Narayan, R.; Rubino, M.; Auras, R.A. Effects of molecular weight and grafted maleic anhydride of functionalized polylactic acid used in reactive compatibilized binary and ternary blends of polylactic acid and thermoplastic cassava starch. J. Appl. Polym. Sci. 2015, 132, 42230. [Google Scholar] [CrossRef]

- Chow, W.S.; Tham, W.L.; Seow, P.C. Effects of maleated-pla compatibilizer on the properties of poly(lactic acid)/halloysite clay composites. J. Thermoplast. Compos. Mater. 2012, 26, 1349–1363. [Google Scholar] [CrossRef]

- Nyambo, C.; Mohanty, A.K.; Misra, M. Effect of maleated compatibilizer on performance of PLA/wheat straw-based green composites. Macromol. Mater. Eng. 2011, 296, 710–718. [Google Scholar] [CrossRef]

- Wu, C.-S. Renewable resource-based green composites of surface-treated spent coffee grounds and polylactide: Characterisation and biodegradability. Polym. Degrad. Stab. 2015, 121, 51–59. [Google Scholar] [CrossRef]

- Gao, H.; Xie, Y.; Ou, R.; Wang, Q. Grafting effects of polypropylene/polyethylene blends with maleic anhydride on the properties of the resulting wood-plastic composites. Compos. A 2012, 43, 150–157. [Google Scholar] [CrossRef]

- Sombatsompop, N.; Yotinwattanakumtorn, C.; Thongpin, C. Influence of type and concentration of maleic anhydride grafted polypropylene and impact modifiers on mechanical properties of PP/wood sawdust composites. J. Appl. Polym. Sci. 2005, 97, 475–484. [Google Scholar] [CrossRef]

- Li, Y.; Xie, X.M.; Guo, B.H. Study on styrene-assisted melt free-radical grafting of maleic anhydride onto polypropylene. Polymer 2001, 42, 3419–3425. [Google Scholar] [CrossRef]

- Ma, P.; Jiang, L.; Ye, T.; Dong, W.; Chen, M. Melt free-radical grafting of maleic anhydride onto biodegradable poly(lactic acid) by using styrene as a comonomer. Polymers 2014, 6, 1528–1543. [Google Scholar] [CrossRef]

- Wu, C.-S. Renewable resource-based composites of recycled natural fibers and maleated polylactide bioplastic: Characterization and biodegradability. Polym. Degrad. Stab. 2009, 94, 1076–1084. [Google Scholar] [CrossRef]

- Yu, T.; Jiang, N.; Li, Y. Study on short ramie fiber/poly(lactic acid) composites compatibilized by maleic anhydride. Compos. A 2014, 64, 139–146. [Google Scholar] [CrossRef]

- Ma, P.; Cai, X.; Lou, X.; Dong, W.; Chen, M.; Lemstra, P.J. Styrene-assisted melt free-radical grafting of maleic anhydride onto poly(β-hydroxybutyrate). Polym. Degrad. Stab. 2014, 100, 93–100. [Google Scholar] [CrossRef]

- Hwang, S.W.; Lee, S.B.; Lee, C.K.; Lee, J.Y.; Shim, J.K.; Selke, S.E.M.; Soto-Valdez, H.; Matuana, L.; Rubino, M.; Auras, R. Grafting of maleic anhydride on poly(L-lactic acid). Effects on physical and mechanical properties. Polym. Test. 2012, 31, 333–344. [Google Scholar] [CrossRef]

- Hristov, V.; Vlachopoulos, J. Influence of coupling agents on melt flow behavior of natural fiber composites. Macromol. Mater. Eng. 2007, 292, 608–619. [Google Scholar] [CrossRef]

- Li, T.Q.; Wolcott, M.P. Rheology of wood plastics melt, part 2: Effects of lubricating systems in hdpe/maple composites. Polym. Eng. Sci. 2006, 46, 464–473. [Google Scholar] [CrossRef]

- Yang, W.; Liu, Z.-Y.; Shan, G.-F.; Li, Z.-M.; Xie, B.-H.; Yang, M.-B. Study on the melt flow behavior of glass bead filled polypropylene. Polym. Test. 2005, 24, 490–497. [Google Scholar] [CrossRef]

- Mohanty, S.; Nayak, S.K. Interfacial, dynamic mechanical, and thermal fiber reinforced behavior of mape treated sisal fiber reinforced hdpe composites. J. Appl. Polym. Sci. 2006, 102, 3306–3315. [Google Scholar] [CrossRef]

- Mohanty, S.; Verma, S.; Nayak, S. Dynamic mechanical and thermal properties of mape treated jute/hdpe composites. Compos. Sci. Technol. 2006, 66, 538–547. [Google Scholar] [CrossRef]

- Rana, A.K.; Mandal, A.; Bandyopadhyay, S. Short jute fiber reinforced polypropylene composites: Effect of compatibiliser, impact modifier and fiber loading. Compos. Sci. Technol. 2003, 63, 801–806. [Google Scholar] [CrossRef]

| Sample | Wood flour (wt %) | PLA(wt %) | Relative to the weight of wood flour and PLA | |

|---|---|---|---|---|

| PLA-g-St/MAH (wt %) | PE wax (wt %) | |||

| WP | 30 | 70 | 0 | 0.5 |

| WPS1 | 30 | 70 | 1 | 0.5 |

| WPS2 | 30 | 70 | 2 | 0.5 |

| WPS3 | 30 | 70 | 3 | 0.5 |

| WPS4 | 30 | 70 | 4 | 0.5 |

| Sample | Te (N·m) | ΔT (°C) |

|---|---|---|

| WP | 2.7 | 8.40 |

| WPS1 | 3.9 | 9.89 |

| WPS2 | 4.0 | 10.10 |

| WPS3 | 4.3 | 11.51 |

| WPS4 | 3.9 | 10.60 |

| Sample | Tensile strength (MPa) | Flexural strength (MPa) | Impact strength (kJ·m−2) | Elongation at break (%) |

|---|---|---|---|---|

| WP | 30.29 ± 1.71 | 77.48 ± 3.41 | 7.78 ± 1.92 | 1.75 ± 0.23 |

| WPM3 | 45.93 ± 1.30 | 86.21 ± 2.97 | 8.11 ± 0.99 | 2.69 ± 0.17 |

| WPS3 | 49.39 ± 0.12 | 89.17 ± 1.84 | 9.26 ± 1.49 | 2.87 ± 0.06 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Du, J.; Wang, Y.; Xie, X.; Xu, M.; Song, Y. Styrene-Assisted Maleic Anhydride Grafted Poly(lactic acid) as an Effective Compatibilizer for Wood Flour/Poly(lactic acid) Bio-Composites. Polymers 2017, 9, 623. https://doi.org/10.3390/polym9110623

Du J, Wang Y, Xie X, Xu M, Song Y. Styrene-Assisted Maleic Anhydride Grafted Poly(lactic acid) as an Effective Compatibilizer for Wood Flour/Poly(lactic acid) Bio-Composites. Polymers. 2017; 9(11):623. https://doi.org/10.3390/polym9110623

Chicago/Turabian StyleDu, Jun, Youyong Wang, Xinfeng Xie, Min Xu, and Yongming Song. 2017. "Styrene-Assisted Maleic Anhydride Grafted Poly(lactic acid) as an Effective Compatibilizer for Wood Flour/Poly(lactic acid) Bio-Composites" Polymers 9, no. 11: 623. https://doi.org/10.3390/polym9110623

APA StyleDu, J., Wang, Y., Xie, X., Xu, M., & Song, Y. (2017). Styrene-Assisted Maleic Anhydride Grafted Poly(lactic acid) as an Effective Compatibilizer for Wood Flour/Poly(lactic acid) Bio-Composites. Polymers, 9(11), 623. https://doi.org/10.3390/polym9110623