Macro-Micro Simulation for Polymer Crystallization in Couette Flow

Abstract

:1. Introduction

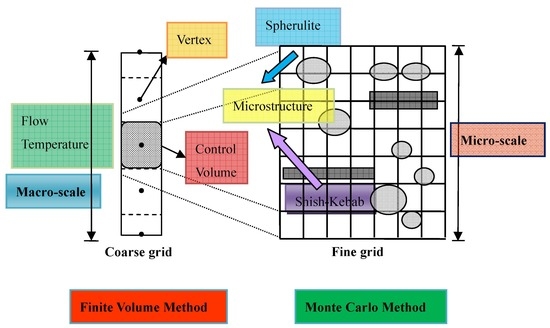

2. Macro-Micro Model

2.1. The Model for Heat and Mass Transfer of Polymeric Flow at the Macroscopic Level

2.2. The Model for Nucleation and Growth of Spherulites and Shish-Kebabs at the Microscopic Level

3. Macro-Micro Algorithm

3.1. Finite Volume Method at the Macroscopic Level

3.2. The Model for Heat and Mass Transfer of Polymeric Flow at the Macroscopic Level

3.3. Implement of the Macro-Micro Algorithm

4. Results and Discussion

4.1. Validity of Model and Algorithm on the Single-Scale

4.1.1. Validity of Finite Volume Method at the Macroscopic Level

4.1.2. Validity of Model and Monte Carlo Method at the Microscopic Level

4.2. Numerical Results Obtained by the Macro-Micro Model and Algorithm

4.2.1. Macro-Micro Results

4.2.2. Effects of Shear Rate

4.2.3. Effects of Shear Time

4.2.4. Effects of Wall Temperature

5. Conclusions

- (1)

- By comparing our simulated results with the experimental data and other numerical results, we can conclude that the macro-micro model and the macro-micro algorithm were effectively constructed. Our simulated results not only predicted the change in temperature and relative crystallinity, but also predicted the correct trends in the spherulite and shish-kebab evolution.

- (2)

- The increase of the shear rate or shear time increased the contribution of shish-kebabs on the relative crystallinity, and caused high nucleation density and high anisotropy of shish-kebabs.

- (3)

- The decrease of the wall temperature increased the contribution of spherulites to the relative crystallinity, and causes a high nucleation density of spherulites.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Kennedy, P.K.; Zheng, R. Flow Analysis of Injection Molds; MunichCarl Hanser Verlag: Munich, Geramny, 2013. [Google Scholar]

- Pantanin, R.; Coccorullo, I.; Speranza, V.; Titomanlio, G. Modeling of morphology evolution in the injection molding process of thermoplastic polymers. Prog. Polym. Sci. 2005, 30, 1185–1222. [Google Scholar] [CrossRef]

- Zuidema, H. Flow Induced Crystallization of Polymers; Eindhoven Technische University: Eindhoven, The Netherlands, 2001. [Google Scholar]

- Charbon, C.; Swaminarayar, S. A multiscale model for polymer crystallization. II: Solidification of a macroscopic part. Polym. Eng. Sci. 1998, 38, 644–656. [Google Scholar] [CrossRef]

- Goff, R.; Boyard, N.; Sobotka, V.; Lefevre, N.; Delaunay, D. Inverse estimation of the crystallization kinetic function of semi-crystalline polymer and shot fiber reinforced composites in moderate cooling conditions. Polym. Test. 2011, 30, 678–687. [Google Scholar] [CrossRef]

- Yang, B.; Fu, X.; Yang, W.; Liang, S.; Sun, N.; Hu, S.; Yang, M.B. Effects of melt and mold temperatures on the solidification behavior of HDPE during Gas-assisted injection molding: An enthalpy transformation approach. Macromol. Mater. Eng. 2009, 294, 336–344. [Google Scholar] [CrossRef]

- Raabe, D.; Godara, A. Mesoscale simulation of the kinetics and topology of spherulite growth during crystallization of isotactic polypropylene (iPP) by using a cellular automaton. Model. Simul. Mater. Sci. Eng. 2005, 13, 733–751. [Google Scholar] [CrossRef]

- Liu, Z.J.; Ouyang, J.; Ruan, C.L.; Liu, Q.S. Simulation of polymer crystallization under isothermal and temperature gradient conditions using praticle level set method. Crystals 2016, 6, 90. [Google Scholar] [CrossRef]

- Wang, X.D.; Ouyang, J.; Zhou, W.; Liu, Z.J. A phase field technique for modeling and predicting flow induced crystallization morphology of semi-crystalline polymers. Polymers 2016, 8, 230. [Google Scholar] [CrossRef]

- Ruan, C. Multiscale numerical study of 3D polymer crystallization during cooling stage. Math. Probl. Eng. 2012, 2012, 802420. [Google Scholar] [CrossRef]

- Ruan, C.; Ouyang, J.; Liu, S. Multi-scale modeling and simulation of crystallization during cooling in short fiber reinforced composites. Int. J. Heat Mass Transf. 2012, 55, 1911–1921. [Google Scholar] [CrossRef]

- Liu, Z.J.; Ouyang, J.; Zhou, W.; Wang, X.D. Numerical simulation of the polymer crystallization during cooling stage by using level set method. Comput. Mater. Sci. 2015, 97, 245–253. [Google Scholar] [CrossRef]

- Spina, R.; Spekowius, M.; Hopmann, C. Multi-scale thermal simulation of polymer crystallization. Int. J. Mater. Form. 2015, 8, 497–504. [Google Scholar] [CrossRef]

- Spina, R.; Spekowius, M.; Hopmann, C. Multiphysics simulation of thermoplatic polymer crystallization. Mater. Des. 2016, 95, 455–469. [Google Scholar] [CrossRef]

- Zinet, M.; Otmani, R.E.; Boutaous, M.; Chantrenne, P. Numerical modeling of nonisothermal polymer crystallization kinetics: Flow and thermal effects. Polym. Eng. Sci. 2010, 50, 2044–2059. [Google Scholar] [CrossRef]

- Mu, Y.; Zhao, G.; Chen, A.; Wu, X. Numerical investigation of the thermally and flow induced crystallization behavior of semi-crystalline polymers by using finite element-finite difference method. Comput. Chem. Eng. 2012, 46, 190–204. [Google Scholar] [CrossRef]

- Rong, Y.; He, H.; Cao, W.; Shen, C.; Chen, J. Multi-scale molding and numerical simulation of the flow-induced crystallization. Comput. Mater. Sci. 2013, 67, 35–39. [Google Scholar] [CrossRef]

- Zheng, R.; Kennedy, P.K. A model for post-flow induced crystallization: General equations and predictions. J. Rheol. 2004, 48, 823–842. [Google Scholar] [CrossRef]

- Eder, G.; Janeschitz-Kriegl, H. Materials Science and Technology; VCH A Wiley Company: Weinheim, Germany, 1997. [Google Scholar]

- Ruan, C. Kinetics and morphology of flow induced polymer crystallization in 3D shear flow investigated by Monte Carlo simulation. Crystals 2017, 7, 51. [Google Scholar] [CrossRef]

- Koscher, E.; Fulchiron, R. Influence of shear on polypropylene crystallization: Morphology development and kinetics. Polymer 2002, 43, 6931–6942. [Google Scholar] [CrossRef]

- Hoffman, J.D.; Miller, R.L. Kinetics of crystallization from the melt and chain folding in polyethylene fractions revisited: Theory and experiment. Polymer 1997, 38, 3151–3212. [Google Scholar] [CrossRef]

- Owens, R.G.; Phillips, T.N. Computational Rheology; Imperial College Press: London, UK, 2002. [Google Scholar]

- Raabe, D. Mesoscale simulation of spherulite growth during polymer crystallization by use of a cellular automaton. Acta Mater. 2004, 52, 2653–2664. [Google Scholar] [CrossRef]

- Ruan, C.; Liu, C.; Zheng, G. Monte carlo simulation for the morphology and kinetics of spherulites and shish-kebabs in isothermal polymer crystallization. Math. Probl. Eng. 2015, 2015, 50624. [Google Scholar] [CrossRef]

- Liu, D.; Ouyang, J.; Zhang, H. Micro-macro methods for deterministic simulation of dilute polymeric fluids. CIESC J. 2008, 59, 582–589. [Google Scholar]

- Kumaraswamy, G.; Issaian, A.M.; Kornfield, J.A. Shear-enhanced crystallization in isotactic polypropylene. 1. Correspondence between in situ rheo-optics and situ structure determination. Macromolecules 1999, 32, 7537–7547. [Google Scholar] [CrossRef]

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ruan, C.; Liang, K.; Liu, E. Macro-Micro Simulation for Polymer Crystallization in Couette Flow. Polymers 2017, 9, 699. https://doi.org/10.3390/polym9120699

Ruan C, Liang K, Liu E. Macro-Micro Simulation for Polymer Crystallization in Couette Flow. Polymers. 2017; 9(12):699. https://doi.org/10.3390/polym9120699

Chicago/Turabian StyleRuan, Chunlei, Kunfeng Liang, and Enli Liu. 2017. "Macro-Micro Simulation for Polymer Crystallization in Couette Flow" Polymers 9, no. 12: 699. https://doi.org/10.3390/polym9120699

APA StyleRuan, C., Liang, K., & Liu, E. (2017). Macro-Micro Simulation for Polymer Crystallization in Couette Flow. Polymers, 9(12), 699. https://doi.org/10.3390/polym9120699