Novel Polyvinyl Alcohol/Starch Electrospun Fibers as a Strategy to Disperse Cellulose Nanocrystals into Poly(lactic acid)

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials and Nanoreinforcements

2.1.1. Polymers and Chemicals

2.1.2. Preparation of Cellulose Nanocrystal Solution

2.1.3. Electrospun PV/Starch Nanofibers

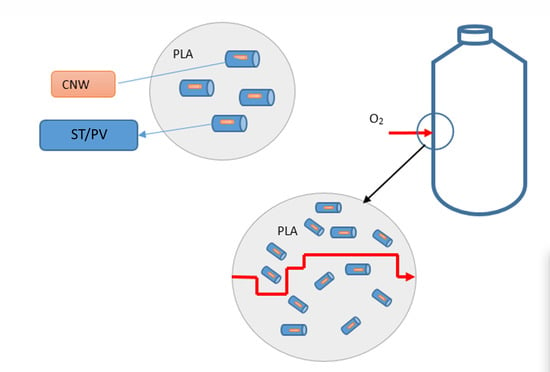

2.2. PLA Nanocomposite Preparation

2.3. Scanning Electronic Microscopy (SEM) Analysis

2.4. X-ray Diffraction (XRD)

2.5. Thermal Properties

2.6. Optical Properties

2.7. Tensile Testing

2.8. Oxygen Permeability

2.9. Statistical Analysis

3. Results and Discussion

3.1. Morphological Results of Nanostructures and Nanocomposites

3.2. X-ray Analysis Results

3.3. Thermal Properties of Nanofillers and Developed Nanocomposites

3.4. Optical Properties

3.5. Mechanical Properties

3.6. Oxygen Permeability

4. Conclusions

Supplementary Materials

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Garrison, T.F.; Murawski, A.; Quirino, R.L. Bio-based polymers with potential for biodegradability. Polymers 2016, 8, 262. [Google Scholar] [CrossRef]

- Raquez, J.M.; Habibi, Y.; Murariu, M.; Dubois, P. Polylactide (PLA)-based nanocomposites. Prog. Polym. Sci. 2013, 38, 1504–1542. [Google Scholar] [CrossRef]

- Dash, R.; Foston, M.; Ragauskas, A.J. Improving the mechanical and thermal properties of gelatin hydrogels cross-linked by cellulose nanowhiskers. Carbohydr. Polym. 2013, 91, 638–645. [Google Scholar] [CrossRef] [PubMed]

- Peng, B.L.; Dhar, N.; Liu, H.L.; Tam, K.C. Chemistry and applications of nanocrystalline cellulose and its derivative: A nanotechnology perspective. Can. J. Chem. Eng. 2011, 89, 1191–1206. [Google Scholar] [CrossRef]

- Mariano, M.; El Kissi, N.; Dufresne, A. Cellulose nanocrystals and related nanocomposites: Review of some properties and challenges. J. Polym. Sci. B Polym. Phys. 2014, 52, 791–806. [Google Scholar] [CrossRef]

- Azizi Samir, M.A.S.; Alloin, F.; Dufresne, A. Review of recent research into cellulosic whiskers, their properties and their application in nanocomposite field. Biomacromolecules 2005, 6, 612–626. [Google Scholar] [CrossRef] [PubMed]

- Dufresne, A.; Kellerhals, M.B.; Witholt, B. Transcrystallization in Mcl-PHAs/cellulose whiskers composites. Macromolecules 1999, 32, 7396–7401. [Google Scholar] [CrossRef]

- Grunert, M.; Winter, W.T. Nanocomposites of cellulose acetate butyrate reinforced with cellulose nanocrystals. J. Polym. Environ. 2002, 10, 27–30. [Google Scholar] [CrossRef]

- Petersson, L.; Kvien, I.; Oksman, K. Structure and thermal properties of poly(lactic acid)/cellulose whiskers nanocomposite materials. Compos. Sci. Technol. 2007, 67, 2535–2544. [Google Scholar] [CrossRef]

- Kalia, S.; Dufresne, A.; Cherian, B.M.; Kaith, B.S.; Avérous, L.; Njuguna, J.; Nassiopoulos, E. Cellulose-based bio-and nanocomposites: A review. Int. J. Polym. Sci. 2011, 2011, 837875. [Google Scholar] [CrossRef]

- Narayanan, G.; Vernekar, V.N.; Kuyinu, E.L.; Laurencin, C.T. Poly(lactic acid)-based biomaterials for orthopedic regenerative engineering. Adv. Drug Deliv. Rev. 2016, 107, 247–276. [Google Scholar] [CrossRef] [PubMed]

- Espino-Pérez, E.; Bras, J.; Ducruet, V.; Guinault, A.; Dufresne, A.; Domenek, S. Influence of chemical surface modification of cellulose nanowhiskers in thermal, mechanical, and barrier properties of poly(lactide) based bionanocomposites. Eur. Polym. J. 2013, 49, 3144–3154. [Google Scholar] [CrossRef]

- Goussé, C.; Chanzy, H.; Excoffier, G.; Soubeyrand, L.; Fleury, E. Stable suspensions of partially silylated cellulose whiskers dispersed in organic solvents. Polymer 2002, 43, 2645–2651. [Google Scholar] [CrossRef]

- Tang, L.; Huang, B.; Lu, Q.; Wang, S.; Ou, W.; Lin, W.; Chen, X. Ultrasonication-assisted manufacture of cellulose nanocrystals esterified with acetic acid. Bioresour. Technol. 2013, 127, 100–105. [Google Scholar] [CrossRef] [PubMed]

- Arias, A.; Heuzey, M.C.; Huneault, M.A.; Ausias, G.; Bendahou, A. Enhanced dispersion of cellulose nanocrystals in melt-processed polylactide-based nanocomposites. Cells 2015, 22, 483–498. [Google Scholar] [CrossRef]

- Ambrosio-Martín, J.; Fabra, M.J.; Lopez-Rubio, A.; Lagaron, J.M. Melt polycondensation to improve the dispersion of bacterial cellulose into polylactide via melt compounding: Enhanced barrier and mechanical properties. Cells 2015, 22, 1201–1226. [Google Scholar] [CrossRef]

- Reneker, D.H.; Yarin, A.L. Electrospinning jets and polymer nanofibers. Polymer 2008, 49, 2387–2425. [Google Scholar] [CrossRef]

- Koski, A.; Yim, K.; Shivkumar, S. Effect of molecular weight on fibrous PVA produced by electrospinning. Mater. Lett. 2004, 58, 493–497. [Google Scholar] [CrossRef]

- Charernsriwilaiwat, N.; Opanasopit, P.; Rojanarata, T.; Ngawhirunpat, T.; Supaphol, P. Preparation and characterization of chitosan-hydroxybenzotriazole/polyvinyl alcohol blend nanofibers by the electrospinning technique. Carbohydr. Polym. 2010, 81, 675–680. [Google Scholar] [CrossRef]

- Kong, L.; Ziegler, G.R. Role of molecular entanglements in starch fiber formation by electrospinning. Biomacromolecules 2012, 13, 2247–2253. [Google Scholar] [CrossRef] [PubMed]

- Gordon, G.C.; Cabell, D.W.; Mackey, L.N.; Michael, J.G.; Trokhan, P.D. Electro-Spinning Process for Making Starch Filaments for Flexible Structure. U.S. Patent 7029620, 18 April 2006. [Google Scholar]

- Kong, L.; Ziegler, G.R. Fabrication of pure starch fibers by electrospinning. Food Hydrocoll. 2014, 36, 20–25. [Google Scholar] [CrossRef]

- Liu, Z.; He, J.H. Polyvinyl alcohol/starch composite nanofibers by bubble electrospinning. Therm. Sci. 2014, 18, 1473–1475. [Google Scholar] [CrossRef]

- Wang, H.; Wang, W.; Jiang, S.; Jian, S.; Zhai, L.; Jiang, Q. Poly(vinyl alcohol)/oxidized starch fibers via electrospinning technique: Fabrication and characterization. Iran. Polym. J. 2011, 20, 551–558. [Google Scholar]

- Narayanan, G.; Gupta, B.S.; Tonelli, A.E. Poly(ε-caprolactone) nanowebs functionalized with α- and γ-cyclodextrins. Biomacromolecules 2014, 15, 4122–4133. [Google Scholar] [CrossRef] [PubMed]

- Narayanan, G.; Martinez-Aguda, R.; Hartman, M.; Chung, C.C.; Boy, R.; Gupta, B.S.; Tonelli, A. Fabrication and characterization of poly(ε-caprolactone)/α-cyclodextrin pseudorotaxane nanofibers. Biomacromolecules 2015, 17, 271–279. [Google Scholar] [CrossRef] [PubMed]

- Narayanan, G.; Gupta, B.S.; Tonelli, A.E. Enhanced mechanical properties of poly(epsilon-caprolactone) nanofibers produced by the addition of non-stoichiometric inclusion complexes of poly(epsilon-caprolactone) and alpha-cyclodextrin. Polymer 2015, 76, 321–330. [Google Scholar] [CrossRef]

- Martínez-Sanz, M.; López-Rubio, A.; Lagaron, L.M. Optimization of the dispersion of unmodified bacterial cellulose nanowhiskers into polylactide via melt compounding to signifincantly enhance barrier and mechanical properties. Biomacromolecules 2012, 13, 3887–3899. [Google Scholar] [CrossRef] [PubMed]

- Bondeson, D.; Mathew, A.; Oksman, K. Optimization of the isolation of nanocrystals from microcrystalline cellulose. Cells 2006, 13, 171–180. [Google Scholar]

- Sèbe, G.; Ham-Pichavant, F.; Ibarboure, E.; Koffi, A.L.C.; Tingaut, P. Supramolecular structure characterization of cellulose II nanowhiskers produced by acid hydrolysis of cellulose I substrates. Biomacromolecules 2012, 13, 570–578. [Google Scholar] [CrossRef] [PubMed]

- Sanchez-Garcia, M.D.; Lagaron, J.M. On the use of plant cellulose nanowhiskers to enhance the barrier properties of polylactic acid. Cells 2010, 17, 987–1004. [Google Scholar] [CrossRef]

- Park, P.; Je, J.; Kim, S. Free radical scavenging activities of differently deacetylated chitosans using an ESR spectrometer. Carbohydr. Polym. 2004, 55, 17–22. [Google Scholar] [CrossRef]

- Liu, D.; Yuan, X.; Bhattacharyya, D. The effects of cellulose nanowhiskers on electrospun poly(lactic acid) nanofibers. J. Mater. Sci. 2012, 47, 3159–3165. [Google Scholar] [CrossRef]

- Lu, P.; Hsieh, Y.L. Multiwalled carbon nanotube (MWCNT) reinforced cellulose fibers by electrospinning. ACS Appl. Mater. Interfaces 2010, 2, 2413–2420. [Google Scholar] [CrossRef] [PubMed]

- Dai, D.; Fan, M.; Collins, P. Fabrication of nanocelluloses from hemp fibers and their application for the reinforcement of hemp fibers. Ind. Crops Prod. 2013, 44, 192–199. [Google Scholar] [CrossRef]

- Hammiche, D.; Boukerrou, A.; Djidjelli, H.; Grohens, Y.; Bendahou, A.; Seantier, B. Characterization of cellulose nanowhiskers extracted from alfa fiber and the effect of their dispersion methods on nanocomposite properties. J. Adhes. Sci. Technol. 2016, 30, 1899–1912. [Google Scholar] [CrossRef]

- Bunn, W.C. Crystal structure of polyvinyl alcohol. Nature 1948, 161, 929–930. [Google Scholar] [CrossRef]

- Li, W.; Li, X.; Chen, Y.; Li, X.; Deng, H.; Wang, T.; Huang, R.; Fan, G. Poly(vinyl alcohol)/sodium alginate/layered silicate based nanofibrous mats for bacterial inhibition. Carbohydr. Polym. 2013, 92, 2232–2238. [Google Scholar] [CrossRef] [PubMed]

- Kuila, S.B.; Ray, S.K. Dehydration of dioxane by pervaporation using filled blend membranes of polyvinyl alcohol and sodium alginate. Carbohydr. Polym. 2014, 101, 1154–1165. [Google Scholar] [CrossRef] [PubMed]

- López-Rubio, A.; Flanagan, B.M.; Gilbert, E.P.; Gidley, M.J. A novel approach for calculating starch crystallinity and its correlation with double helix content: A combined XRD and NMR study. Biopolymers 2008, 89, 761–768. [Google Scholar] [CrossRef] [PubMed]

- Zeng, J.; Li, G.; Gao, H.; Ru, Z. Comparison of A and B starch granules from three wheat varieties. Molecules 2011, 16, 10570–10591. [Google Scholar] [CrossRef] [PubMed]

- Pagés, P.; Carrasco, F.; Gómez-Pérez, J.; Santana, O.O.; Maspoch, M.L. Procesado del ácido poliláctico (PLA) y de nanocompuestos PLA/montmorillonita en planta piloto: Estudio de sus cambios estructurales y de su estabilidad térmica. Afinidad 2010, 67, 107–113. [Google Scholar]

- Wang, N.; Ding, E.; Cheng, R. Thermal degradation behaviours of spherical cellulose nanocrystals with sulfate groups. Polymer 2007, 48, 3486–3493. [Google Scholar] [CrossRef]

- Araki, J.; Wada, M.; Kuga, S. Steric stabilization of a cellulose microcrystal suspension by poly(ethylene glycol) grafting. Langmuir 2001, 17, 21–27. [Google Scholar] [CrossRef]

- Gonzalez, J.S.; Ludueña, L.N.; Ponce, A.; Alvarez, V.A. Poly(vinyl alcohol)/cellulose nanowhiskers nanocomposite hydrogels for potential wound dressings. Mater. Sci. Eng. C 2014, 34, 54–61. [Google Scholar] [CrossRef] [PubMed]

- Barrera, J.E.; Rodríguez, J.A.; Perilla, J.E.; Algecira, N.A. Estudio de la degradación térmica de poli(alcohol vinílico) mediante termogravimetría y termogravimetría diferencial. Ing. Investig. 2007, 27, 100–105. [Google Scholar]

- Yang, L.; Zhang, H.Y.; Yang, Q.; Lu, D.N. Bacterial cellulose-poly(vinyl alcohol) nanocomposite hydrogels prepared by chemical crosslinking. J. Appl. Polym. Sci. 2012, 126, E244–E250. [Google Scholar] [CrossRef]

- Lizundia, E.; Vilas, J.L.; Leon, L.M. Crystallization, structural relaxation and termal degradation in poly(l-lactide)/cellulose nanocrystal renewable nanocomposites. Carbohydr. Polym. 2015, 123, 256–265. [Google Scholar] [CrossRef] [PubMed]

- Fortunati, E.; Armentano, I.; Zhou, Q.; Iannoni, A.; Saino, E.; Visai, L.; Berglund, L.A.; Kenny, J.M. Multifunctional bionanocomposite films of poly(lactic acid), cellulose nanocrystals and silver nanoparticles. Carbohydr. Polym. 2012, 87, 1596–1605. [Google Scholar] [CrossRef]

- Goffin, A.L.; Raquez, J.M.; Duquesne, E.; Siqueira, G.; Habibi, Y.; Dufresne, A.; Dubois, P. From interfacial ring-opening polymerization to melt processing of cellulose nanowhisker-filled polylactide-based nanocomposites. Biomacromolecules 2011, 12, 2456–2465. [Google Scholar] [CrossRef] [PubMed]

- Sanchez-Garcia, M.D.; Gimenez, E.; Lagaron, J.M. Morphology and barrier properties of solvent cast composites of thermoplastic biopolymers and purified cellulose fibers. Carbohydr. Polym. 2008, 71, 235–244. [Google Scholar] [CrossRef]

- Kim, J.J.; Moon, H.J.; Lim, B.S.; Lee, Y.K.; Rhee, S.H.; Yang, H.C. The effect of nanofiller on the opacity of experimental composites. J. Biomed. Mater. Res. B Appl. Biomater. 2006, 80, 332–338. [Google Scholar] [CrossRef] [PubMed]

- Lani, N.S.; Ngadi, N.; Johari, A.; Jusoh, M. Isolation, characterization and application of nanocellulose from oil palm empty fruit brunch fiber as nanocomposites. J. Nanomater. 2014, 2014, 702538. [Google Scholar] [CrossRef]

- Petersson, L.; Oksman, K. Biopolymer based nanocomposites: Comparing layered silicates and microcrystalline cellulose as nanoreinforcements. Compos. Sci. Technol. 2006, 66, 2187–2196. [Google Scholar] [CrossRef]

- López-Rubio, A.; Lagaron, J.M.; Ankerfors, M.; Lindstrom, T.; Nordqvist, D.; Matozzi, A.; Hedenqvist, M.S. Enhanced film forming and film properties of amylopectin using micro-fibrillated cellulose. Carbohydr. Polym. 2007, 68, 718–727. [Google Scholar] [CrossRef]

- Courgneau, C.; Domeneck, S.; Guinault, A.; Averous, L.; Ducruet, V. Analysis of the structure-properties relationships of different multiphase systems based on plasticized poly(lactic acid). J. Polym. Environ. 2011, 19, 362–371. [Google Scholar] [CrossRef]

- Guinault, A.; Sollogoub, C.; Ducruet, V.; Domeneck, S. Impact of crystallinity of poly(lactide) on helium and oxygen barrier properties. Eur. Polym. J. 2012, 48, 779–788. [Google Scholar] [CrossRef]

- Auras, R.; Harte, B.; Selke, S. Effect of water on the oxygen barrier properties of poly(ethylene terephthalate) and polylactide films. J. Appl. Polym. Sci. 2004, 92, 1790–1803. [Google Scholar] [CrossRef]

| Film Samples | PLA | (PVST/CNC)f | (PVST)f | CNC |

|---|---|---|---|---|

| PLA | 100 | - | - | - |

| 0.5PLA(PVST/CNC)f | 96.75 | 3.25 | - | - |

| 0.5PLA(PVST)f | 97.25 | - | 2.75 | - |

| 0.5PLACNC | 99.5 | - | - | 0.5 |

| 1PLA(PVST/CNC)f | 93.5 | 6.5 | - | - |

| 1PLA(PVST)f | 94.5 | - | 5.5 | - |

| 1PLACNC | 99 | - | - | 1.0 |

| 3PLA(PVST/CNC)f | 80.5 | 19.5 | - | - |

| 3PLA(PVST)f | 83.5 | - | 16.5 | - |

| 3PLACNC | 97 | - | - | 3.0 |

| Films | Tdeg | Tg (°C) | Tcc (°C) | ΔHcc (J/g) | Tm (°C) | ΔHm (J/g) | Xc′ (%) |

|---|---|---|---|---|---|---|---|

| PLA | 365.6 ± 2.6 e | 39.0 ± 1.4 b,c | 90.6 ± 0.3 d | 25.7 ± 0.2 c,d,e | 148.2 ± 0.8 c,d | 30.3 ± 0.5 c,d,e | 3.2 ± 1.4 a,b |

| 0.5PLA(PVST/CNC)f | 356.7 ± 2.6 b,c,d | 34.1 ± 0.2 a | 84.6 ± 0.7 a,b | 21.8 ± 1.4 b | 145.7 ± 0.2 b | 28.1 ± 2.1 b,c | 6.8 ± 0.7 d |

| 0.5PLA(PVST)f | 356.4 ± 3.2 b,c,d | 43.8 ± 0.7 d | 94.9 ± 1.1 f | 20.6 ± 0.3 a | 149.8 ± 0.2 e | 23.1 ± 0.9 a | 2.7 ± 0.7 a |

| 0.5PLACNC | 347.3 ± 15.6 a,b | 35.4 ± 0.4 a | 85.4 ± 0.5 b | 24.6 ± 1.1 c | 146.1 ± 0.6 b | 28.9 ± 1.2 b,c,d | 4.7 ± 0.1 b,c |

| 1PLA(PVST/CNC)f | 356.7 ± 3.9 b,c,d | 39.6 ± 0.1 b,c | 88.7 ± 1.7 c | 22.7 ± 0.5 b | 147.0 ± 0.5 b,c | 26.9 ± 0.4 b | 4.5 ± 0.1 b |

| 1PLA(PVST)f | 348.1 ± 6.0 a,b | 39.1 ± 1.0 b,c | 89.3 ± 0.6 c,d | 25.1 ± 0.1 c,d | 148.2 ± 0.1 c,d | 29.2 ± 0.1 b,c,d,e | 4.4 ± 0.2 a,b |

| 1PLACNC | 362.5 ± 1.5 c,d | 38.4 ± 3.7 c | 95.2 ± 1.6 f | 25.4 ± 2.6 d,e | 148.6 ± 0.2 d,e | 26.9 ± 0.7 b | 3.6 ± 0.7 a,b |

| 3PLA(PVST/CNC)f | 353.4 ± 10.4 b,c | 39.4 ± 0.7 c | 82.1 ± 1.8 a | 24.9 ± 1.2 c,d,e | 144.6 ± 0.2 a | 31.0 ± 0.4 d,e,f | 6.5 ± 1.7 d |

| 3PLA(PVST)f | 339.3 ± 3.6 a | 39.8 ± 2.0 c | 83.4 ± 2.2 a | 25.8 ± 2.3 e | 143.6 ± 2.2 a | 31.7 ± 3.8 e,f | 6.4 ± 1.6 c,d |

| 3PLACNC | 363.1 ± 1.2 c,d | 38.5 ± 0.8 b | 92.5 ± 0.8 e | 29.6 ± 0.4 f | 149.7 ± 0.4 e | 32.6 ± 0.2 f | 4.6 ± 1.1 b |

| Films | Opacity Index | P O2 (m3 m/m2 s Pa) |

|---|---|---|

| PLA | 2.2 ± 0.3 a | 2.29. e−18 |

| 0.5PLA(PVST/CNC)f | 6.8 ± 0.8 a,b | 7.45. e−18 |

| 0.5PLA(PVST)f | 5.4 ± 0.8 a,b | 1.52. e−18 |

| 0.5PLACNC | 6.2 ± 1.4 a,b | 1.71. e−18 |

| 1PLA(PVST/CNC)f | 6.4 ± 0.4 a,b | 1.52. e−18 |

| 1PLA(PVST)f | 7.6 ± 1.2 a,b | 6.83. e−19 |

| 1PLACNC | 7.1 ± 2.1 a,b | 1.83. e−18 |

| 3PLA(PVST/CNC)f | 23.9 ± 8.6 d | 9.57. e−19 |

| 3PLA(PVST)f | 14.6 ± 4.2 c | 1.53. e−18 |

| 3PLACNC | 9.0 ± 3.5 b,c | 1.80. e−18 |

| Material | Young’s Modulus | Tensile Strength | Elongation at |

|---|---|---|---|

| (MPa) | (MPa) | Break (%) | |

| PLA | 1607.1 ± 164.2 c | 47.9 ± 4.6 c,d | 3.4 ± 0.4 a,b |

| 0.5PLA(PVST/CNC)f | 1170.3 ± 207.3 a,b | 47.7 ± 2.6 c | 3.9 ± 0.3 d |

| 0.5PLA(PVST)f | 1116.5 ± 248.1 a,b | 43.7 ± 4.9 b,c | 4.1 ± 0.3 d,e |

| 0.5PLACNC | 1608.9 ± 132.3 c | 40.3 ± 2.2 b | 2.8 ± 0.4 a,b |

| 1PLA(PVST/CNC)f | 1342.5 ± 249.8 b,c | 46.9 ± 3.5 c,d | 3.5 ± 0.3 b,c,d |

| 1PLA(PVST)f | 1306.7 ± 73.2 b,c | 43.9 ± 2.5 b,c | 3.7 ± 0.3 c,d |

| 1PLACNC | 1123.8 ± 247.3 a,b | 41.9 ± 4.2 b,c | 2.9 ± 0.6 a,b |

| 3PLA(PVST/CNC)f | 858.2 ± 114.7 a | 32.4 ± 2.1 a | 3.8 ± 0.3 d |

| 3PLA(PVST)f | 860.1 ± 161.6 a | 29.0 ± 2.4 a | 4.7 ± 0.5 e |

| 3PLACNC | 1239.9 ± 220.3 b | 31.2 ± 3.3 a | 2.6 ± 0.3 a |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

López de Dicastillo, C.; Roa, K.; Garrido, L.; Pereira, A.; Galotto, M.J. Novel Polyvinyl Alcohol/Starch Electrospun Fibers as a Strategy to Disperse Cellulose Nanocrystals into Poly(lactic acid). Polymers 2017, 9, 117. https://doi.org/10.3390/polym9040117

López de Dicastillo C, Roa K, Garrido L, Pereira A, Galotto MJ. Novel Polyvinyl Alcohol/Starch Electrospun Fibers as a Strategy to Disperse Cellulose Nanocrystals into Poly(lactic acid). Polymers. 2017; 9(4):117. https://doi.org/10.3390/polym9040117

Chicago/Turabian StyleLópez de Dicastillo, Carol, Karina Roa, Luan Garrido, Alejandro Pereira, and Maria Jose Galotto. 2017. "Novel Polyvinyl Alcohol/Starch Electrospun Fibers as a Strategy to Disperse Cellulose Nanocrystals into Poly(lactic acid)" Polymers 9, no. 4: 117. https://doi.org/10.3390/polym9040117

APA StyleLópez de Dicastillo, C., Roa, K., Garrido, L., Pereira, A., & Galotto, M. J. (2017). Novel Polyvinyl Alcohol/Starch Electrospun Fibers as a Strategy to Disperse Cellulose Nanocrystals into Poly(lactic acid). Polymers, 9(4), 117. https://doi.org/10.3390/polym9040117