Volume Hologram Formation in SU-8 Photoresist

Abstract

:1. Introduction

2. Materials and Methods

2.1. Sample Preparation

2.2. Holographic Exposure

2.3. Real-Time Observation of Holographic Grating Growth

3. Results and Discussion

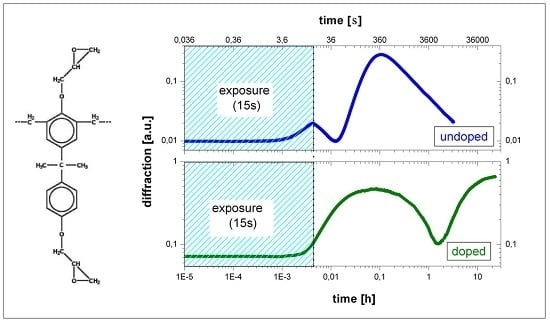

3.1. Time Response

3.2. Impact of the Exposure Duration

3.3. Explanation Approach for the First Growth Step

3.4. Impact of Flood Exposure

4. Conclusions

Acknowledgments

Conflicts of Interest

References

- Zhao, G.; Mouroulis, P. Diffusion model of hologram formation in dry photopolymer Materials. J. Mod. Opt. 1994, 41, 1929–1939. [Google Scholar] [CrossRef]

- Sabel, T.; Lensen, M.C. Volume holography: Novel materials, methods and applications. In Holographic Materials and Optical Systems; Naydenova, I., Babeva, T., Nazarova, D., Eds.; InTech: Rijeka, Croatia, 2017. [Google Scholar]

- Liu, S.; Gleeson, M.R.; Guo, J.; Sheridan, J.T. High intensity response of photopolymer materials for holographic grating formation. Macromolecules 2010, 43, 9462–9472. [Google Scholar] [CrossRef]

- Sheridan, J.T.; Lawrence, J.R. Nonlocal-response diffusion model of holographic recording in photopolymer. J. Opt. Soc. Am. A 2000, 17, 1108–1114. [Google Scholar] [CrossRef]

- Sabel, T.; Orlic, S.; Pfeiffer, K.; Ostrzinski, U.; Grützner, G. Free-surface photopolymerizable recording material for volume holography. Opt. Mater. Express 2013, 3, 329–338. [Google Scholar] [CrossRef]

- Sabel, T. Spatially resolved analysis of Bragg selectivity. Appl. Sci. 2015, 5, 1064–1075. [Google Scholar] [CrossRef]

- Sabel, T.; Zschocher, M. Transition of refractive index contrast in course of grating growth. Sci. Rep. 2013, 3, 1–7. [Google Scholar] [CrossRef] [PubMed]

- Sabel, T.; Zschocher, M. Dynamic Bragg angle shift in the course of volume hologram formation. Mater. Res. Lett. 2014, 2, 76–81. [Google Scholar] [CrossRef]

- Sabel, T.; Zschocher, M. Imaging of volume phase gratings in a photosensitive polymer, recorded in transmission and reflection geometry. Appl. Sci. 2014, 4, 19–27. [Google Scholar] [CrossRef]

- Close, D.H.; Jacobson, A.D.; Margerum, J.D.; Brault, R.G.; McClung, F.J. Hologram recording on Photopolymer materials. Appl. Phys. Lett. 1969, 14, 159–160. [Google Scholar] [CrossRef]

- Guo, J.; Gleeson, M.R.; Sheridan, J.T. A review of the optimisation of photopolymer materials for holographic data storage. Phys. Res. Int. 2012, 2012. [Google Scholar] [CrossRef]

- Gallego, S.; Fernández, R.; Márquez, A.; Ortuño, M.; Neipp, C.; Gleeson, M.R.; Sheridan, J.T.; Beléndez, A. Two diffusion photopolymer for sharp diffractive optical elements recording. Opt. Lett. 2015, 40, 3221–3224. [Google Scholar] [CrossRef] [PubMed]

- Voit, K.M.; Imlau, M. Holographic spectroscopy: Wavelength-dependent analysis of photosensitive materials by means of holographic techniques. Materials 2013, 6, 334–358. [Google Scholar] [CrossRef]

- Zhang, X.-Y.; Gao, H.-T.; Zhou, C.; Liu, Q.; Xing, T.; Yao, H. Three-dimension photonic crystals fabrication using SU-8 photoresist. J. Inorg. Mater. 2007, 34, 28–31. [Google Scholar]

- Zhang, J.; Tan, K.L.; Hong, G.D.; Yang, L.J.; Gong, H.Q. Polymerization optimization of SU-8 photoresist and its applications in microfluidic systems and MEMS. J. Micromech. Microeng. 2001, 11, 20. [Google Scholar] [CrossRef]

- Shaw, J.M.; Gelorme, J.D.; LaBianca, N.C.; Conley, W.E.; Holmes, S.J. Negative photoresists for optical lithography. IBM J. Res. Dev. 1997, 41, 81–94. [Google Scholar] [CrossRef]

- Yang, R.; Soper, S.A.; Wang, W. A new UV lithography photoresist based on composite of EPON resins 165 and 154 for fabrication of high-aspect-ratio microstructures. Sens. Actuators A 2007, 135, 625–636. [Google Scholar] [CrossRef]

- Colburn, W.S.; Haines, K.A. Volume hologram formation in photopolymer materials. Appl. Opt. 1971, 10, 1636–1641. [Google Scholar] [CrossRef] [PubMed]

- Lee, J.B.; Choi, K.H.; Yoo, K. Innovative SU-8 lithography techniques and their applications. Micromachines 2015, 6, 1–18. [Google Scholar] [CrossRef]

- Chen, Q.; Li, G.; Zhao, J. CURVED SU-8 structure fabrication based on the acid-diffusion effect. In Proceedings of the IEEE International Conference on Micro Electro Mechanical Systems (MEMS), Cancun, Mexico, 23–27 January 2011; pp. 225–228. [Google Scholar]

- Matusevich, V.; Matusevich, A.; Kowarschik, R.; Krul, L.P. Holographic volume absorption grating in glass-like polymer recording material. Opt. Express 2008, 16, 1552–1558. [Google Scholar] [CrossRef] [PubMed]

- Li, C.; Cao, L.; He, Q.; Jin, G. Holographic kinetics for mixed volume gratings in gold nanoparticles doped photopolymer. Opt. Express 2014, 22, 5017–5028. [Google Scholar] [CrossRef] [PubMed]

| Grating Growth | SU-8 Photoresist (Undoped) | Host–Guest System (Doped SU-8) |

|---|---|---|

| First growth step | Temporal absorption grating | Temporal phase grating |

| Second growth step | Temporal phase grating | Permanent phase grating |

© 2017 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sabel, T. Volume Hologram Formation in SU-8 Photoresist. Polymers 2017, 9, 198. https://doi.org/10.3390/polym9060198

Sabel T. Volume Hologram Formation in SU-8 Photoresist. Polymers. 2017; 9(6):198. https://doi.org/10.3390/polym9060198

Chicago/Turabian StyleSabel, Tina. 2017. "Volume Hologram Formation in SU-8 Photoresist" Polymers 9, no. 6: 198. https://doi.org/10.3390/polym9060198

APA StyleSabel, T. (2017). Volume Hologram Formation in SU-8 Photoresist. Polymers, 9(6), 198. https://doi.org/10.3390/polym9060198