Orchard Spray Study: A Prediction Model of Droplet Deposition States on Leaf Surfaces

Abstract

:1. Introduction

2. Materials and Methods

2.1. The Deposition State of Spray Droplet

2.2. The Parameter Acquisition Test of the Target Leaf Adhesion Work Model

2.2.1. Experimental Materials

2.2.2. Leaf Surface Structure Measurement

2.2.3. Contact Angle Measurement

2.2.4. Critical Sliding Volume Test

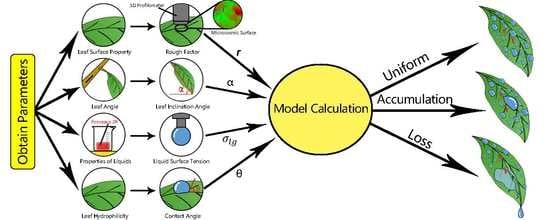

2.3. Establishment of the Prediction Model

2.3.1. Establishment of the Target Leaf Adhesion Work Model

2.3.2. Establishment of the Critical Sliding Particle Size Model of Droplets

2.3.3. Prediction Model of the Droplet Deposition State

2.4. Determination Test of the Droplet Deposition State

2.4.1. Materials and Methods

2.4.2. Experimental Procedure

3. Results and Discussion

3.1. Model Parameters

3.1.1. Rough Factor

3.1.2. Contact Angle

3.1.3. Critical Sliding Volume

3.2. Discussion of the Adhesion Work Model

- (1)

- The relationships between leaf characteristics and the droplet deposition state

- (2)

- The relationship between the droplet diameter and the droplet deposition state

- (3)

- The relationship between the leaf inclination angle and the spray droplet deposition state

- (4)

- Effect of droplet sliding traces on droplet sliding

3.3. Target Leaf Adhesion Work Model Establishment

4. Conclusions

- (1)

- The surface characteristics of four different target leaves were observed and analyzed, and droplet deposition testing was conducted on the reverse and obverse sides of each target leaf. A relationship model between the foliar adhesion work and foliar rough factor, contact angle, and initial dip angle of the airborne spray target was constructed. The model has a coefficient of fit of 0.917 and can be used for adhesion work calculations. Further analysis results show that the leaf adhesion work is proportional to the leaf contact angle and quadratic function containing the rough factor. In the range of rough factors from 1.0 to 1.6, the adhesion work increases with the increase of the rough factor. When the rough factor is greater than 1.6, the adhesion work begins to decrease. Additionally, based on the energy conservation relationship during the sliding process of the droplets, the critical sliding particle size model of the leaf droplets was proposed.

- (2)

- Axial flow air spray based on the Box–Behnken Design response surface method was designed. In the test, the droplet coverage was obtained under different droplet sizes, application distances, air delivery speeds, and target leaf surfaces. The minimum kinetic energy of the corresponding deposited droplets was selected as the fitting parameter when the droplets slid on the target leaf, and a regression equation between the droplet adhesion work and the turbulent energy of the deposited droplets was constructed. On this basis, combined with the droplet coverage conditions corresponding to the different deposition states of the droplets, the final prediction model of the airborne spray droplet deposition state was proposed. Upon comparing the actual deposited structures with the model-predicted results, it was found that the prediction accuracies of the three states of uniform, accumulation, and loss were 87.5%, 80%, and 100%, respectively.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| Droplet coverage (%) | ||

| d | Diameter of the spray droplet () | |

| Diameter of the deposited droplet () | ||

| Spray distance (m) | ||

| Critical diameter of the droplet slide on the leaf surface () | ||

| The droplet instantaneous kinetic energy of landing () | ||

| Gravitational potential energy of the droplet () | ||

| Kinetic energy of the droplet on the leaf () | ||

| Total work () | ||

| h | Height of the leaf from the ground (m) | |

| i | Droplet number at one point | |

| m | Droplet weight(g) | |

| Rough factor | ||

| Droplet volume (μL) | ||

| Value of the target-leaf aerodynamic velocity () | ||

| Adhesion work () | ||

| α | Leaf inclination angle (°) | |

| Droplet density () | ||

| Static contact angle (°) | ||

| Surface tension of the liquid () | ||

| The mass of the drop as it falls to the ground (g) | ||

| The instantaneous velocity of the drop as it falls to the ground |

References

- Miranda-Fuentes, A.; Llorens, J.; Lizana, A.R.; Cuenca, A.; Gil, E.; Blanco-Roldán, G.; Gil-Ribes, J. Assessing the optimal liquid volume to be sprayed on isolated olive trees according to their canopy volumes. Sci. Total Environ. 2016, 568, 296–305. [Google Scholar] [CrossRef] [PubMed]

- Massinon, M.; De Cock, N.; Forster, W.A.; Nairn, J.J.; McCue, S.W.; Zabkiewicz, J.A.; Lebeau, F. Spray droplet impaction outcomes for different plant species and spray formulations. Crop. Prot. 2017, 99, 65–75. [Google Scholar] [CrossRef] [Green Version]

- Taylor, P. The wetting of leaf surfaces. Curr. Opin. Colloid Interface Sci. 2011, 16, 326–334. [Google Scholar] [CrossRef]

- Aranberri, I.; Beverley, K.J.; Binks, B.P.; Clint, J.H.; Fletcher, P.D.I. How Do Emulsions Evaporate? Langmuir 2002, 18, 3471–3475. [Google Scholar] [CrossRef]

- Aranberri, I.; Binks, B.P.; Clint, J.H.; Fletcher, P.D.I. Evaporation Rates of Water from Concentrated Oil-in-Water Emulsions. Langmuir 2004, 20, 2069–2074. [Google Scholar] [CrossRef]

- Wang, F.; Hu, Z.; Abarca, C.; Fefer, M.; Liu, J.; Brook, M.A.; Pelton, R.H. Factors influencing agricultural spray deposit structures on hydrophobic surfaces. Colloids Surf. A Physicochem. Eng. Asp. 2018, 553, 288–294. [Google Scholar] [CrossRef]

- Gil, Y.; Sinfort, C.; Brunet, Y.; Polveche, V.; Bonicelli, B. Atmospheric loss of pesticides above an artificial vineyard during air-assisted spraying. Atmospheric Environ. 2007, 41, 2945–2957. [Google Scholar] [CrossRef]

- Doruchowski, G.; Hołownicki, R.; Godyń, A.; Świechowski, W. Sprayer calibration training—Concept and performance. Jul. Kuhn Arch. 2012, 4, 228–233. [Google Scholar]

- Vance, B.; Daniel, B.; Jean, Y.M.; Louis, V. Controlling droplet deposition with polymer additives. Nature 2000, 405, 772–775. [Google Scholar]

- Cross, J.; Walklate, P.; Murray, R.; Richardson, G. Spray deposits and losses in different sized apple trees from an axial fan orchard sprayer: Effects of air volumetric flow rate. Crop. Prot. 2003, 22, 381–394. [Google Scholar] [CrossRef]

- Zetian, F.; Jun, W.; Lijun, Q.; Hongtao, W. CFD simulation and experimental verification of air-velocity distribution of air-assisted orchard sprayer. Trans. Chin. Soc. Agric. Eng. 2009, 25, 69–74. [Google Scholar]

- Musiu, E.M.; Qi, L.; Wu, Y. Spray deposition and distribution on the targets and losses to the ground as affected by application volume rate, airflow rate and target position. Crop. Prot. 2019, 116, 170–180. [Google Scholar] [CrossRef]

- Larbi, P.A.; Salyani, M. Model to Predict Spray Deposition in Citrus Airblast Sprayer Applications: Part 2. Spray Deposition. Trans. ASABE 2012, 55, 41–48. [Google Scholar] [CrossRef]

- Cunningham, G.P.; Harden, J. Reducing spray volumes applied to mature citrus trees. Crop. Prot. 1998, 17, 289–292. [Google Scholar] [CrossRef]

- Zabkiewicz, J.A. Spray formulation efficacy—Holistic and futuristic perspectives. Crop. Prot. 2007, 26, 312–319. [Google Scholar] [CrossRef]

- Wirth, W.; Storp, S.; Jacobsen, W. Mechanisms controlling leaf retention of agricultural spray solutions. Pest Manag. Sci. 1991, 33, 411–420. [Google Scholar] [CrossRef]

- Reuveni, O.; Raviv, M. Importance of Leaf Retention to Rooting of Avocado Cuttings. J. Amer. Soc. Hort. Sci. 1980, 106, 127–130. [Google Scholar]

- De Ruiter, H.; Uffing, A.J.; Meinen, E.; Prins, A. Influence of Surfactants and Plant Species on Leaf Retention of Spray Solutions. Weed Sci. 1990, 38, 567–572. [Google Scholar] [CrossRef]

- Yu, Y.; Zhu, H.; Frantz, J.; Reding, M.; Chan, K.; Ozkan, H. Evaporation and coverage area of pesticide droplets on hairy and waxy leaves. Biosyst. Eng. 2009, 104, 324–334. [Google Scholar] [CrossRef]

- Damak, M.; Mahmoudi, S.R.; Hyder, N.; Varanasi, K.K. Enhancing droplet deposition through in-situ precipitation. Nat. Commun. 2016, 7, 12560. [Google Scholar] [CrossRef] [Green Version]

- Forster, W.A.; Mercer, G.N.; Schou, W.C. Spray droplet impaction models and their use within AGDISP software to predict retention. N.Z. Plant. Prot. 2012, 65, 85–92. [Google Scholar] [CrossRef] [Green Version]

- Durickovic, B.; Varland, K. Between Bouncing and Splashing: Water Dropson A Solid Surface; University of Arizona: Tucson, AZ, USA, 2005. [Google Scholar]

- Dorr, G.J.; Kempthorne, D.M.; Mayo, L.C.; Forster, W.A.; Zabkiewicz, J.A.; McCue, S.W.; Belward, J.A.; Turner, I.; Hanan, J. Towards a model of spray–canopy interactions: Interception, shatter, bounce and retention of droplets on horizontal leaves. Ecol. Model. 2014, 290, 94–101. [Google Scholar] [CrossRef] [Green Version]

- Dorr, G.J.; Wang, S.; Mayo, L.C.; McCue, S.W.; Forster, W.A.; Hanan, J.; He, X. Impaction of spray droplets on leaves: Influence of formulation and leaf character on shatter, bounce and adhesion. Exp. Fluids 2015, 56, 1–17. [Google Scholar] [CrossRef] [Green Version]

- Gaskin, R.; Steele, K.; Forster, W. Characterising plant surfaces for spray adhesion and retention. N.Z. Plant Prot. 2005, 58, 179–183. [Google Scholar] [CrossRef]

- Papierowska, E.; Mazur, R.; Stańczyk, T.; Beczek, M.; Szewińska, J.; Sochan, A.; Ryżak, M.; Szatyłowicz, J.; Bieganowski, A. Influence of leaf surface wettability on the drop splash phenomenon. Biol. Agric. For. Meteorol. 2019, 279, 107762. [Google Scholar] [CrossRef]

- Xu, L.; Zhu, H.; Ozkan, H.E.; Thistle, H.W. Evaporation rate and development of wetted area of water droplets with and without surfactant at different locations on waxy leaf surfaces. Biosyst. Eng. 2010, 106, 58–67. [Google Scholar] [CrossRef]

- Al-Sharafi, A.; Yilbas, B.S.; Ali, H.; Al-Qahtani, H. Adhesion of a water droplet on inclined hydrophilic surface and internal fluidity. Int. J. Adhes. Adhes. 2020, 96, 102464. [Google Scholar] [CrossRef]

- Bergeron, V. Designing intelligent fluids for controlling spray applications. Comptes Rendus Phys. 2003, 4, 211–219. [Google Scholar] [CrossRef]

- Ellis, M.B.; Tuck, C.; Miller, P. How surface tension of surfactant solutions influences the characteristics of sprays produced by hydraulic nozzles used for pesticide application. Colloids Surf. A Physicochem. Eng. Asp. 2001, 180, 267–276. [Google Scholar] [CrossRef]

- Massinon, M.; Lebeau, F. Experimental method for the assessment of agricultural spray retention based on high-speed imaging of drop impact on a synthetic superhydrophobic surface. Biosyst. Eng. 2012, 112, 56–64. [Google Scholar] [CrossRef]

- Zwertvaegher, I.K.; Verhaeghe, M.; Brusselman, E.; Verboven, P.; Lebeau, F.; Massinon, M.; Nicolai, B.; Nuyttens, D. The impact and retention of spray droplets on a horizontal hydrophobic surface. Biosyst. Eng. 2014, 126, 82–91. [Google Scholar] [CrossRef] [Green Version]

- Chandler, D.L. Explained: Hydrophobic and Hydrophilic; MIT News Office: Cambridge, MA, USA, 2013. [Google Scholar]

- Baek, Y.; Kang, J.; Theato, P.; Yoon, J. Measuring hydrophilicity of RO membranes by contact angles via sessile drop and captive bubble method: A comparative study. Desalination 2012, 303, 23–28. [Google Scholar] [CrossRef]

- Symmons, P.; Dobson, H.; Sissoko, M. Pesticide droplet size and efficacy: A series of trials on grasshoppers. Crop. Prot. 1991, 10, 136–144. [Google Scholar] [CrossRef]

- Cross, J.V.; Berrie, A.M.; Murray, R.A. Effect of Drop Size and Spray Volume on Deposits and Efficacy of Strawberry Spraying. Asp. Appl. Biol. 2000, 57, 313–320. [Google Scholar]

- Babu, G.D.; Babu, B.J.; Sumanth, K.B.; Babu, K.S. Experimental investigation on surface roughness of turned Nano-Khorasan based pineapple leaf fiber-reinforced polymer composites using response surface methodology. Mater. Today Proc. 2019, 2214–7853. [Google Scholar] [CrossRef]

- Tang, Y.; Hou, C.; Luo, S.; Lin, J.; Yang, Z.; Huang, W. Effects of operation height and tree shape on droplet deposition in citrus trees using an unmanned aerial vehicle. Comput. Electron. Agric. 2018, 148, 1–7. [Google Scholar] [CrossRef]

| Test Number | S (m) | Predicted Result | Experimental Result | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 1.0 | 7.8 | 4.14 | 35.0 | 8.8 | 0.12 | 0.26 | 11.8 | 25.1 | accumulation | accumulation |

| 2 | 1.0 | 11.5 | 3.42 | 35.0 | 3.78 | 0.22 | 0.07 | 9.77 | 10.8 | accumulation | accumulation |

| 3 | 1.6 | 0 | 4.14 | 43.5 | 4.14 | 0 | 0 | 9.52 | 4.1 | uniform | uniform |

| 4 | 0.4 | 7.8 | 4.80 | 35.0 | 9.27 | 0.19 | 0.75 | 13.71 | 26.5 | accumulation | accumulation |

| 5 | 1.0 | 0 | 3.42 | 43.5 | 3.96 | 0 | 0 | 7.86 | 9.1 | accumulation | uniform |

| 6 | 0.4 | 0 | 4.14 | 43.5 | 10.54 | 0 | 0 | 9.52 | 24.2 | accumulation | accumulation |

| 7 | 1.6 | 7.8 | 4.80 | 35.0 | 6.13 | 0.05 | 0.02 | 13.71 | 17.5 | accumulation | uniform |

| 8 | 0.4 | 7.8 | 3.42 | 35.0 | 8.54 | 0.19 | 0.59 | 9.77 | 24.4 | accumulation | accumulation |

| 9 | 1.0 | 11.5 | 4.80 | 35.0 | 5.53 | 0.22 | 0.21 | 13.71 | 15.8 | accumulation | accumulation |

| 10 | 1.6 | 11.5 | 4.14 | 35.0 | 4.14 | 0.13 | 0.03 | 11.83 | 9.8 | uniform | uniform |

| 11 | 1.6 | 7.8 | 3.42 | 35.0 | 3.42 | 0.05 | 0.003 | 9.77 | 1.4 | uniform | uniform |

| 12 | 0.4 | 11.5 | 4.14 | 35.0 | 7.01 | 0.31 | 0.87 | 11.83 | 20.04 | accumulation | loss |

| 13 | 1.0 | 0 | 4.80 | 43.5 | 11.70 | 0 | 0 | 11.03 | 26.9 | accumulation | accumulation |

| Test Number | S (m) | Predicted Result | Experimental Result | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 1.0 | 7.8 | 4.14 | 28.3 | 5.93 | 0.12 | 0.08 | 14.63 | 20.94 | Accumulation | Accumulation |

| 2 | 1.0 | 11.5 | 3.42 | 28.3 | 3.42 | 0.22 | 0.05 | 12.08 | 9.50 | Uniform | Uniform |

| 3 | 1.6 | 0 | 4.14 | 39.0 | 4.14 | 0 | 0 | 10.62 | 2.24 | Uniform | Uniform |

| 4 | 0.4 | 7.8 | 4.80 | 28.3 | 5.20 | 0.19 | 0.13 | 16.96 | 18.35 | Accumulation | Accumulation |

| 5 | 1.0 | 0 | 3.42 | 39.0 | 3.42 | 0 | 0 | 8.77 | 5.80 | Uniform | Uniform |

| 6 | 0.4 | 0 | 4.14 | 39.0 | 9.65 | 0 | 0 | 10.62 | 24.75 | Accumulation | Accumulation |

| 7 | 1.6 | 7.8 | 4.80 | 28.3 | 4.80 | 0.05 | 0.007 | 16.96 | 9.68 | Uniform | Uniform |

| 8 | 0.4 | 7.8 | 3.42 | 28.3 | 5.19 | 0.19 | 0.13 | 12.08 | 18.33 | Accumulation | Accumulation |

| 9 | 1.0 | 11.5 | 4.80 | 28.3 | 5.26 | 0.22 | 0.18 | 16.96 | 18.59 | Accumulation | Accumulation |

| 10 | 1.6 | 11.5 | 4.14 | 28.3 | 4.14 | 0.13 | 0.03 | 14.63 | 6.92 | Uniform | Uniform |

| 11 | 1.6 | 7.8 | 3.42 | 28.3 | 3.42 | 0.05 | 0.003 | 12.08 | 1.30 | Uniform | Uniform |

| 12 | 0.4 | 11.5 | 4.14 | 28.3 | 4.14 | 0.31 | 0.18 | 14.63 | 14.51 | Uniform | Loss |

| 13 | 1.0 | 0 | 4.80 | 39.0 | 10.11 | 0 | 0 | 12.31 | 25.93 | Accumulation | Accumulation |

| Test Number | S (m) | Predicted Result | Experimental Result | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 1.0 | 7.8 | 4.14 | 29.9 | 5.48 | 0.09 | 0.03 | 13.85 | 18.32 | Accumulation | Accumulation |

| 2 | 1.0 | 11.5 | 3.42 | 29.9 | 4.73 | 0.17 | 0.08 | 11.44 | 15.81 | Accumulation | Accumulation |

| 3 | 1.6 | 0 | 4.14 | 37.0 | 4.14 | 0 | 0 | 11.19 | 5.80 | Uniform | Uniform |

| 4 | 0.4 | 7.8 | 4.80 | 29.9 | 6.21 | 0.14 | 0.34 | 16.05 | 29.16 | Loss | Loss |

| 5 | 1.0 | 0 | 3.42 | 37.0 | 3.43 | 0 | 0 | 9.24 | 9.28 | Accumulation | Uniform |

| 6 | 0.4 | 0 | 4.14 | 37.0 | 9.85 | 0 | 0 | 11.19 | 26.63 | Accumulation | Accumulation |

| 7 | 1.6 | 7.8 | 4.80 | 29.9 | 5.24 | 0.04 | 0.006 | 16.05 | 17.50 | Accumulation | Accumulation |

| 8 | 0.4 | 7.8 | 3.42 | 29.9 | 10.13 | 0.14 | 0.53 | 11.44 | 33.87 | Loss | Loss |

| 9 | 1.0 | 11.5 | 4.80 | 29.9 | 4.80 | 0.17 | 0.08 | 16.05 | 15.68 | Uniform | Accumulation |

| 10 | 1.6 | 11.5 | 4.14 | 29.9 | 4.14 | 0.10 | 0.02 | 13.85 | 8.57 | Uniform | Uniform |

| 11 | 1.6 | 7.8 | 3.42 | 29.9 | 3.42 | 0.04 | 0.002 | 11.44 | 4.35 | Uniform | Uniform |

| 12 | 0.4 | 11.5 | 4.14 | 29.9 | 8.13 | 0.24 | 0.81 | 13.85 | 27.22 | Loss | Loss |

| 13 | 1.0 | 0 | 4.80 | 37.0 | 7.57 | 0 | 0 | 12.97 | 20.45 | Accumulation | Accumulation |

| Test Number | S (m) | Predicted Result | Experimental Result | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 1.0 | 7.8 | 4.14 | 31.0 | 6.05 | 0.09 | 0.05 | 13.35 | 19.5 | Accumulation | Accumulation |

| 2 | 1.0 | 11.5 | 3.42 | 31.0 | 3.60 | 0.17 | 0.04 | 11.03 | 11.6 | Accumulation | Accumulation |

| 3 | 1.6 | 0 | 4.14 | 37.9 | 4.14 | 0 | 0 | 10.92 | 9.25 | Uniform | Uniform |

| 4 | 0.4 | 7.8 | 4.80 | 31.0 | 9.91 | 0.14 | 0.50 | 15.48 | 31.95 | Loss | Loss |

| 5 | 1.0 | 0 | 3.42 | 37.9 | 3.90 | 0 | 0 | 9.02 | 10.3 | Accumulation | Uniform |

| 6 | 0.4 | 0 | 4.14 | 37.9 | 12.43 | 0 | 0 | 10.92 | 32.8 | Accumulation | Accumulation |

| 7 | 1.6 | 7.8 | 4.80 | 31.0 | 5.96 | 0.04 | 0.009 | 15.48 | 19.20 | Accumulation | Accumulation |

| 8 | 0.4 | 7.8 | 3.42 | 31.0 | 6.61 | 0.14 | 0.15 | 11.03 | 21.29 | Accumulation | Accumulation |

| 9 | 1.0 | 11.5 | 4.80 | 31.0 | 8.80 | 0.17 | 0.52 | 15.48 | 28.36 | Loss | Loss |

| 10 | 1.6 | 11.5 | 4.14 | 31.0 | 5.52 | 0.10 | 0.0004 | 13.35 | 17.80 | Accumulation | Uniform |

| 11 | 1.6 | 7.8 | 3.42 | 31.0 | 3.42 | 0.04 | 0.002 | 11.03 | 7.69 | Uniform | Uniform |

| 12 | 0.4 | 11.5 | 4.14 | 31.0 | 7.45 | 0.24 | 0.62 | 13.35 | 24.03 | Loss | Loss |

| 13 | 1.0 | 0 | 4.80 | 37.9 | 8.58 | 0 | 0 | 12.66 | 22.65 | Accumulation | Accumulation |

| Nozzle Type | Droplet Diameter (μm) | |

|---|---|---|

| ATR-RED | 0.69 0.09 | 120 18 |

| ATR-GREEN | 1.39 0.12 | 165 21 |

| ATR-BLUE | 2.31 0.18 | 240 28 |

| Spray Parameters | Value |

|---|---|

| Outlet airflow velocity (m.s−1) | 0, 7.8, 11.5 |

| Spray distance (m) | 0.4, 1.0, 1.6 |

| Nozzle type | ATR-RED, ATR-GREEN, ATR-BLUE |

| Target leaves | obverse and reverse sides of the Citrus leaf obverse and reverse sides of the Litchi leaf |

| Experimental Factor | Coding and Level | ||

|---|---|---|---|

| −1 | 0 | +1 | |

| Spraying distance (m) Fan outlet wind speed (m.s−1) Particle diameter (μm) | 0.4 0 120 | 1.0 7.8 165 | 1.6 11.5 240 |

| Leaf Surfaces | Plants | |||

|---|---|---|---|---|

| Citrus | Litchi | Longan | Psidium guajava L. | |

| Obverse of leaf | 1.13 0.06a | 1.17 0.04b | 1.15 0.03b | 1.32 0.06b |

| Reverse of leaf | 1.18 0.05a | 1.45 0.06a | 1.81 0.05a | 1.92 0.07a |

| Leaf Surface | Plants | |||

|---|---|---|---|---|

| Citrus | Litchi | Longan | Psidium guajava L. | |

| Obverse sides of leaves | 73.4 3.7a | 95.4 2.5b | 72.9 6.4b | 63.1 5.6b |

| Reverse sides of leaves | 76.1 5.2a | 130.5 4.3a | 134.8 4.3a | 82.5 7.2a |

| Leaf Surfaces | Leaf Inclination Angle | Plant Droplet Sliding Critical Volume/μL | |||

|---|---|---|---|---|---|

| Citrus | Litchi | Longan | Psidium guajava L. | ||

| Obverse of leaf | 30 | 70 0.7 | 90 0.9 | 90 0.9 | 40 0.4 |

| 60 | 30 0.3 | 30 0.3 | 30 0.3 | 20 0.2 | |

| 90 | 20 0.2 | 10 0.1 | 10 0.1 | 10 0.1 | |

| Reverse of leaf | 30 | 80 0.8 | 100 2 | 90 0.9 | 90 0.9 |

| 60 | 30 0.3 | 40 0.4 | 30 0.3 | 30 0.3 | |

| 90 | 20 0.2 | 30 0.3 | 10 0.1 | 20 0.2 | |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, J.; Cui, H.; Ma, Y.; Xun, L.; Li, Z.; Yang, Z.; Lu, H. Orchard Spray Study: A Prediction Model of Droplet Deposition States on Leaf Surfaces. Agronomy 2020, 10, 747. https://doi.org/10.3390/agronomy10050747

Li J, Cui H, Ma Y, Xun L, Li Z, Yang Z, Lu H. Orchard Spray Study: A Prediction Model of Droplet Deposition States on Leaf Surfaces. Agronomy. 2020; 10(5):747. https://doi.org/10.3390/agronomy10050747

Chicago/Turabian StyleLi, Jun, Huajun Cui, Yakun Ma, Lu Xun, Zhiqiang Li, Zhou Yang, and Huazhong Lu. 2020. "Orchard Spray Study: A Prediction Model of Droplet Deposition States on Leaf Surfaces" Agronomy 10, no. 5: 747. https://doi.org/10.3390/agronomy10050747

APA StyleLi, J., Cui, H., Ma, Y., Xun, L., Li, Z., Yang, Z., & Lu, H. (2020). Orchard Spray Study: A Prediction Model of Droplet Deposition States on Leaf Surfaces. Agronomy, 10(5), 747. https://doi.org/10.3390/agronomy10050747