Indirect Prediction of Welding Fume Diffusion inside a Room Using Computational Fluid Dynamics

Abstract

:1. Introduction

2. Methodology

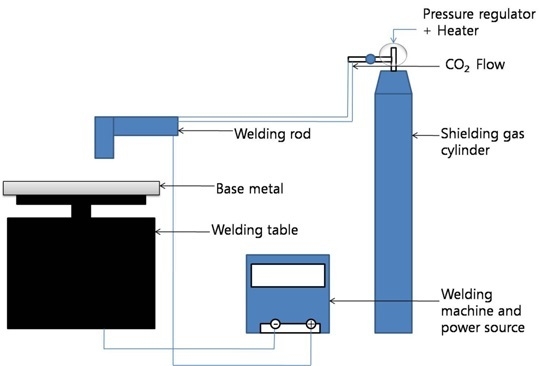

2.1. Experimental Setup

2.2. Field Measurement

2.3. CFD Simulation

3. Results and Discussion

3.1. Welding Fume Particle Size Distribution

3.2. Measured and Simulated Concentration of Welding Fume and CO2

3.2.1. Measured Welding Fume vs. Measured CO2 Concentrations

3.2.2. Measured CO2 vs. Simulated CO2 Concentrations

3.3.3. Measured Welding Fume vs. Simulated CO2 Concentrations

4. Conclusions

Supplementary Materials

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Escala, S.; Nooij, M.; Quintino, L. Economically welding in a healthy way. In Proceedings of the First South-East European Welding Congress, Timisoara, Romania, May 2006; pp. 244–251.

- Hashmi, S.; Batalha, G.; van Tyne, C.; Yilbas, B. Comprehensive Materials Processing; Elsevier: Oxford, UK, 2014; pp. 3–71. [Google Scholar]

- Amza, G.; Dobrotă, D.; Groza Dragomir, M.; Paise, S.; Apostolescu, Z. Research on environmental impact assessment of flame oxyacetylene welding processes. Metalurgija 2013, 52, 457–460. [Google Scholar]

- Fume and Gases. Available online: http://www.webcitation.org/6gjMEC5zn (accessed on 13 April 2016).

- Suban, M.; Tušek, J. Dependence of melting rate in MIG/MAG welding on the type of shielding gas used. J. Mater. Proc. Technol. 2001, 119, 185–192. [Google Scholar] [CrossRef]

- Kielhorn, W.H.; Adonyi, Y.; Holdren, R.L.; Horrocks, R.C.; Nissley, N.E. Survey of Joining, Cutting, and Allied Processes; AWS Welding Handbook: New York, NY, USA, 2001; p. 50. [Google Scholar]

- Shibata, N.; Tanaka, M.; Ojima, J.; Iwasaki, T. Numerical simulations to determine the most appropriate welding and ventilation conditions in small enclosed workspace. Ind. Health 2000, 38, 356–365. [Google Scholar] [CrossRef] [PubMed]

- Gomes, J.F.; Albuquerque, P.C.; Miranda, R.M.; Santos, T.G.; Vieira, M.T. Comparison of deposited surface area of airborne ultrafine particles generated from two welding processes. Inhal. Toxicol. 2012, 24, 774–781. [Google Scholar] [CrossRef] [PubMed]

- Gomes, J.F.P.; Albuquerque, P.C.S.; Miranda, R.M.M.; Vieira, M.T.F. Determination of airborne nanoparticles from welding operations. J. Toxicol. Environ. Health 2012, 75, 747–755. [Google Scholar] [CrossRef] [PubMed]

- Antonini, J.; Lewis, A.; Roberts, J.; Whaley, D. Pulmonary effects of welding fumes: Review of worker and experimental animal studies. Am. J. Ind. Med. 2003, 43, 350–360. [Google Scholar] [CrossRef] [PubMed]

- Popović, O.; Prokić-Cvetković, R.; Burzić, M.; Lukić, U.; Beljić, B. Fume and gas emission during arc welding: Hazards and recommendation. Renew. Sustain. Energy Rev. 2014, 37, 509–516. [Google Scholar] [CrossRef]

- Oprya, M.; Kiro, S.; Worobiec, A.; Horemans, B.; Darchuk, L.; Novakovic, V.; Ennan, A.; van Grieken, R. Size distribution and chemical properties of welding fumes of inhalable particles. J. Aerosol Sci. 2012, 45, 50–57. [Google Scholar] [CrossRef]

- Chang, T.; Kao, H.; Hsieh, Y. Numerical study of the effect of ventilation pattern on coarse, fine, and very fine particulate matter removal in partitioned indoor environment. J. Air Waste Manag. Assoc. 2007, 57, 179–189. [Google Scholar] [CrossRef] [PubMed]

- The National Institute for Occupational Safety and Health (NIOSH). Welding, Fumes and Gases; Australian Government Publishing Service: Canberra, Australia, 1990; p. 32. [Google Scholar]

- Kulmala, I. Advanced Design of Local Ventilation Systems; Technical Research Centre of Finland: Espoo, The Netherlands, 1997; p. 80. [Google Scholar]

- The National Institute for Occupational Safety and Health (NIOSH). Criteria for a Recommended Standard: Welding, Brazing, and Thermal Cutting. Available online: http://www.cdc.gov/niosh/docs/88-110/pdfs/88-110.pdf (assessed on 23 May 2016).

- Lu, W.; Howarth, A.; Adam, N.; Riffat, S. Modelling and measurement of airflow and aerosol particle distribution in a ventilated two-zone chamber. Build. Environ. 1996, 31, 417–423. [Google Scholar] [CrossRef]

- Karthikeyan, C.; Samuel, A. CO2-dispersion studies in an operation theatre under transient conditions. Energy Build. 2008, 40, 231–239. [Google Scholar] [CrossRef]

- Kavgic, M.; Mumovic, D.; Stevanovic, Z.; Young, A. Analysis of thermal comfort and indoor air quality in a mechanically ventilated theatre. Energy Build. 2008, 40, 1334–1343. [Google Scholar] [CrossRef]

- Lambert, A.R.; Lin, C.L.; Mardorf, E.; O’shaughnessy, P. CFD simulation of contaminant decay for high Reynolds flow in a controlled environment. Ann. Occup. Hyg. 2010, 54, 88–99. [Google Scholar] [CrossRef] [PubMed]

- Handy, R.G.; Jackson, M.; Rodriguez, M.; Goodman, D.; Robinson, G.; Lafreniera, M. The characterization of particles generated and removed during a bone drilling process with surface coated tools. In Proceedings of the 5th International Surface Engineering Conference, Washington State Convention Center, Seattle, WA, USA, 15–17 May 2006; Jackson, M.J., Ed.; ASM International Materials Park: Novelty, OH, USA, 2006; pp. 47–52. [Google Scholar]

- Mei, C.C. 2.7 Aerosols and Coagulation-MIT. Available online: http://www.webcitation.org/archive.php (accessed on 13 April 2016).

- Yang, L.; Ye, M.; He, B. CFD simulation research on residential indoor air quality. Sci. Total Environ. 2014, 472, 1137–1144. [Google Scholar] [CrossRef] [PubMed]

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dahal, S.; Kim, T.; Ahn, K. Indirect Prediction of Welding Fume Diffusion inside a Room Using Computational Fluid Dynamics. Atmosphere 2016, 7, 74. https://doi.org/10.3390/atmos7060074

Dahal S, Kim T, Ahn K. Indirect Prediction of Welding Fume Diffusion inside a Room Using Computational Fluid Dynamics. Atmosphere. 2016; 7(6):74. https://doi.org/10.3390/atmos7060074

Chicago/Turabian StyleDahal, Sujit, Taehyeung Kim, and Kwangseog Ahn. 2016. "Indirect Prediction of Welding Fume Diffusion inside a Room Using Computational Fluid Dynamics" Atmosphere 7, no. 6: 74. https://doi.org/10.3390/atmos7060074

APA StyleDahal, S., Kim, T., & Ahn, K. (2016). Indirect Prediction of Welding Fume Diffusion inside a Room Using Computational Fluid Dynamics. Atmosphere, 7(6), 74. https://doi.org/10.3390/atmos7060074