The Long-Term Hydrological Performance of Permeable Pavement Systems in Northern Spain: An Approach to the “End-of-Life” Concept

Abstract

:1. Introduction

2. Materials and Methods

2.1. Location and Climatic Conditions

2.2. Materials

2.2.1. PMPC

- Voids: 25.0%.

- Apparent density: 1778 kg/m3.

2.2.2. PA

- Voids: 23.5%.

- Apparent density: 2050 kg/m3.

2.2.3. ICBP-1

2.2.4. ICBP-2

2.3. Monitoring Methods Used in the Field

2.3.1. Spanish NLT-327/00

- LCS Permeameter. The device was placed at the point where the test was going to be developed, placing the weight on top of the LCS base.

- Pre-wetting. Water was poured into the LCS up to 15 cm over the upper mark. Then, the water was allowed to infiltrate in order to saturate the pavement.

- Testing. Water is poured into the LCS again up to the same point from the pre-wetting and measurements are taken of the time until the level of the water reach the lower mark of the device.

- K = Permeability, cm/s × 10−2,

- t = time required for measured amount of water to infiltrate the surface between the upper and lower marks of the LCS, s.

2.3.2. ASTM C1701/C1701M-17a

- 4.

- Infiltration ring installation. The pavement surface was cleaned and plumber’s putty was applied around the bottom edge of the infiltration ring in order to seal its perimeter.

- 5.

- Pre-wetting: 3.60 kg of water were poured into the ring, maintaining a constant head of water between 100 and 150 mm from the pavement surface. We measured the time taken between the water coming into contact with the surface and it fully infiltrating the pavement.

- 6.

- Test. The test started within 2 min after the pre-wetting stage; 3.60 kg of water were utilized again when the elapsed time measured during the pre-wetting stage was above 30 s. Otherwise, 18.00 kg were poured into the ring. The time was recorded following the same procedure indicated in the previous step.

- I = Infiltration rate, mm/h,

- M = Mass of infiltrated water, kg,

- D = Inside diameter of infiltration ring, mm,

- t = time required for measured amount of water to infiltrate the surface, s,

- K = constant value 4,583,666,000 in SI units.

2.3.3. ASTM C1781/C1781M-15

3. Results and Discussions

3.1. Hydrological Performance—Field Monitoring Results

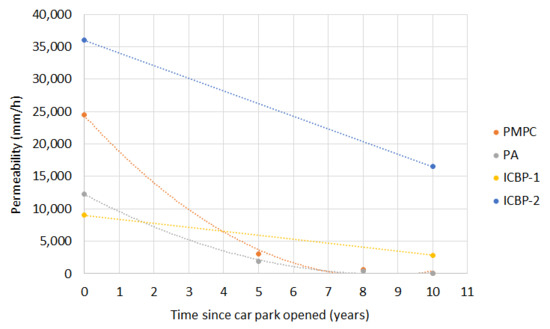

3.1.1. Permeability Recorded at Year 0

3.1.2. Permeability Recorded after Five Years

3.1.3. Permeability Recorded after Eight Years

3.1.4. Permeability Recorded after 10 Years

3.2. End of Life Analysis

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Fletcher, T.D.; Shuster, W.; Hunt, W.F.; Ashley, R.; Butler, D.; Arthur, S.; Trowsdale, S.; Barraud, S.; Semadeni-Davies, A.; Bertrand-Krajewski, J.-L.; et al. SUDS, LID, BMPs, WSUD and more—The evolution and application of terminology surrounding urban drainage. Urban Water J. 2015, 12, 525–542. [Google Scholar] [CrossRef]

- Nnadi, E.O.; Coupe, S.J.; Sañudo-Fontaneda, L.A.; Rodriguez-Hernandez, J. An evaluation of enhanced geotextile layer in permeable pavement to improve stormwater infiltration and attenuation. Int. J. Pavement Eng. 2014, 15, 925–932. [Google Scholar] [CrossRef]

- Castro-Fresno, D.; Andrés-Valeri, V.C.; Sañudo-Fontaneda, L.A.; Rodriguez-Hernandez, J. Sustainable drainage practices in Spain, specially focused on pervious pavements. Water (Switz.) 2013, 5, 67–93. [Google Scholar] [CrossRef]

- Jato-Espino, D.; Sañudo-Fontaneda, L.A.; Andrés-Valeri, V.C. Green Infrastructure: Cost-Effective Nature-Based Solutions for Safeguarding the Environment and Protecting Human Health and Well-Being. In Handbook of Environmental Materials Management, 1st ed.; Hussain, C., Ed.; Springer: Cham, Switzerland, 2018; ISBN 78-3-319-58538-3. [Google Scholar]

- Stormwater Design Manual. North Carolina Department of Environmental Quality. Available online: https://deq.nc.gov/sw-bmp-manual (accessed on 28 February 2018).

- Woods Ballard, B.; Wilson, S.; Udale-Clarke, H.; Illman, S.; Scott, T.; Ashley, R.; Kellagher, R. The SuDS Manual; CIRIA: London, UK, 2015; p. 968. ISBN 979-0-86017-760-9. [Google Scholar]

- Sañudo Fontaneda, L.A. The Analysis of Rainwater Infiltration into Permeable Pavements, with Concrete Blocks and Porous Mixtures, for the Source Control of Flooding. Ph.D. Thesis, University of Cantabria, Santander, Spain, 10 June 2014. Available online: https://repositorio.unican.es/xmlui/handle/10902/5053 (accessed on 28 February 2018).

- Nichols, P.W.B.; Lucke, T. A Detailed Analysis of Sediment Particle Sizes and Clogging in Permeable Pavements. Clean Soil Air Water 2017, 45, 1700078. [Google Scholar] [CrossRef]

- Lucke, T.; Beecham, S. Field investigation of clogging in a permeable pavement system. Build. Res. Inf. 2011, 39, 603–615. [Google Scholar] [CrossRef]

- Rodriguez-Hernandez, J.; Castro-Fresno, D.; Fernández-Barrera, A.H.; Vega-Zamanillo, Á. Characterization of Infiltration Capacity of Permeable Pavements with Porous Asphalt Surface Using Cantabrian Fixed Infiltrometer. J. Hydrol. Eng. 2012, 17, 597–603. [Google Scholar] [CrossRef]

- McLaughlin, A.-M.; Charlesworth, S.; Coupe, S.; de Miguel, E. Resilience and sustainable drainage: End-of-life. In Proceedings of the 9th International Conference Novatech, Lyon, France, 28 June 2016; ISBN 978-2-917199-06-0. [Google Scholar]

- Li, H.; Kayhanian, M.; Harvey, J.T. Comparative field permeability measurement of permeable pavements using ASTM C1701 and NCAT permeameter methods. J. Environ. Manag. 2013, 118, 144–152. [Google Scholar] [CrossRef] [PubMed]

- Al-Rubaei, A.M.; Stenglein, A.L.; Viklander, M.; Blecken, G.T. Long-Term hydraulic performance of porous asphalt pavements in Northern Sweden. J. Irrig. Drain. Eng. 2013, 139, 499–505. [Google Scholar] [CrossRef]

- Fernández-Barrera, A.H.; Castro-Fresno, D.; Rodríguez-Hernández, J.; Calzada-Pérez, M.A. Infiltration capacity assessment of urban pavements using the LCS permeameter and the CP infiltrometer. J. Irrig. Drain. Eng. 2008, 134, 659–665. [Google Scholar] [CrossRef]

- Sañudo-Fontaneda, L.A.; Rodriguez-Hernandez, J.; Calzada-Pérez, M.A.; Castro-Fresno, D. Infiltration behaviour of Polymer-Modified Porous Concrete and Porous Asphalt surfaces used in SUDS techniques. Clean Soil Air Water 2013, 42, 139–145. [Google Scholar] [CrossRef]

- Essenwanger, O.M. General Climatology 1C: Classification of Climates; Elsevier Science: Amsterdam, The Netherlands, 2001; pp. 1–102. [Google Scholar]

- Sañudo-Fontaneda, L.A.; Charlesworth, S.M.; Castro-Fresno, D.; Andres-Valeri, V.C.A.; Rodriguez-Hernandez, J. Water quality and quantity assessment of pervious pavements performance in experimental car park areas. Water Sci. Technol. 2014, 69, 1526–1533. [Google Scholar] [CrossRef] [PubMed]

- García Couto, M.A. Iberian Climate Atlas Air Temperature and Precipitation (1971–2000); Instituto de Meteorologia de Portugal; Agencia Estatal de Meteorología y Ministerio de Medio Ambiente y Medio Rural y Marino del gobierno de España: Madrid, Spain, 2011; ISBN 978-84-7837-079-5. [Google Scholar]

- Sañudo-Fontaneda, L.A.; Andrés-Valeri, V.C.A.; Rodriguez-Hernandez, J.; Castro-Fresno, D. Field study of infiltration capacity reduction of porous mixture surfaces. Water (Switz.) 2014, 6, 661–669. [Google Scholar] [CrossRef]

- European Standard EN 12390-1, Testing Hardened Concrete—Part 1: Shape, Dimensions and other Requirements for Specimens and Moulds; European Committee for Standardization: Brussels, Belgium, 2012.

- European Standard EN 12390-2, Testing Hardened Concrete—Part 2: Making and Curing Specimens for Strength Tests; European Committee for Standardization: Brussels, Belgium, 2009.

- European Standard EN 12390-3, Testing Hardened Concrete—Part 3: Compressive Strength of Test Specimens; European Committee for Standardization: Brussels, Belgium, 2009.

- Pindado, M.Á.; Aguado, A.; Josa, A. Fatigue behavior of polymer-modified porous concretes. Cem. Concr. Res. 1999, 29, 1077–1083. [Google Scholar] [CrossRef]

- European Standard EN 933-1. Ensayos Para Determinar Las Propiedades Geométricas de los Áridos. Parte 1: Determinación de la Granulometría de las Partículas, Método del Tamizado; AENOR: Madrid, Spain, 2012.

- Bustos, G.; Pérez, E. Pliego de Prescripciones Técnicas Generales Para Obras de Carreteras y Puentes, 5th ed.; Ediciones LITEAM: Madrid, Spain, 2007. [Google Scholar]

- BS EN 1338:2003. Concrete Paving Blocks—Requirements and Test Methods; European Committee for Standardization: Brussels, Belgium, 2003.

- NLT-327/00. Permeabilidad in Situ de Pavimentos Drenantes Con el Permeámetro LCS; Gabinete de Formación y Documentación; Centro de Estudios y Experimentación de Obras Públicas (CEDEX): Madrid, Spain, 1996.

- European Standard EN 12697-40, Bituminous Mixtures—Test Methods for Hot Mix Asphalt—Part 40: In Situ Drainability; European Committee for Standardization: Brussels, Belgium, 2012.

- ASTM C1701/C1701M-17a. Standard Test Method for Infiltration Rate of In Place Pervious Concrete; ASTM International: West Conshohocken, PA, USA, 2017. [Google Scholar] [CrossRef]

- ASTM C1781/C1781M-15. Standard Test Method for Surface Infiltration Rate of Permeable Unit Pavement Systems; ASTM International: West Conshohocken, PA, USA, 2015. [Google Scholar] [CrossRef]

- Pérez Jiménez, F.E.; Calzada Pérez, M.A. Analysis and Evaluation of the Performance of Porous Asphalt: The Spanish Experience. Surface characteristics of roadways: International research and technologies. In Proceedings of the First International Symposium on Surface Characteristics, Pennsylvania, PA, USA, 8–9 June 1988; ASTM STP 1031. Reichert, M., Ed.; ASTM: West Conshohocken, PA, USA, 1988. [Google Scholar]

- Arruti, A.; Fernández-Olmo, I.; Irabien, A. Evaluation of the contribution of local sources to trace metals levels in urban PM2.5 and PM10 in the Cantabria region (Northern Spain). J. Environ. Monit. 2010, 12, 1451–1458. [Google Scholar] [CrossRef] [PubMed]

- Bean, E.Z.; Hunt, W.F.; Bidelspach, D.A. Field survey of permeable pavement surface infiltration rates. J. Irrig. Drain. Eng. 2007, 133, 249–255. [Google Scholar] [CrossRef]

- Andrés-Valeri, V.C.; Marchioni, M.; Sañudo-Fontaneda, L.A.; Giustozzi, F.; Becciu, G. Laboratory assessment of the infiltration capacity reduction in clogged porous mixture surfaces. Sustainability (Switz.) 2016, 8, 751. [Google Scholar] [CrossRef] [Green Version]

- Sañudo-Fontaneda, L.A.; Rodriguez-Hernandez, J.; Vega-Zamanillo, A.; Castro-Fresno, D. Laboratory analysis of the infiltration capacity of interlocking concrete block pavements in car parks. Water Sci. Technol. 2013, 67, 675–681. [Google Scholar] [CrossRef] [PubMed]

| Layer | Type of Surface | |||

|---|---|---|---|---|

| PMPC | PA | ICBP-1 | ICBP-2 | |

| Surface | 80 mm | 80 mm | 80 mm | 100 mm |

| Base | Clean limestone aggregates (50 mm) | |||

| Geotextile | Polyfelt TS30 (4 bays) | Polyfelt TS30 (4 bays) | Inbitex (4 bays) | Polyfelt TS30 (4 bays) |

| Danofelt PY150 (4 bays) | Danofelt PY150 (4 bays) | One-Way (4 bays) | Danofelt PY150 (4 bays) | |

| Without geotextile (bay1) | Without geotextile (bay1) | Without geotextile (2 bays) | Without geotextile (1 bay) | |

| Sub-base | Clean limestone aggregates (350 mm) | |||

| Test Used | Average Permeability (mm/h) | |||

|---|---|---|---|---|

| PMPC (9 bays) | PA (9 bays) | ICBP-1 (10 bays) | ICBP-2 (9 bays) | |

| NLT-327/00 | 24,480 | 12,312 | 9000 | 36,000 |

| Test Used | Average Permeability (mm/h) | |||

|---|---|---|---|---|

| PMPC (9 bays) | PA (9 bays) | ICBP-1 (10 bays) | ICBP-2 (9 bays) | |

| NLT-327/00 | 3096 | 1872 | ― | ― |

| Test Used | Average Permeability (mm/h) | |||

|---|---|---|---|---|

| PMPC (9 bays) | PA (9 bays) | ICBP-1 (10 bays) | ICBP-2 (9 bays) | |

| NLT-327/00 | 612 | 432 | ― | ― |

| Test Used | Average Permeability (mm/h) | |||

|---|---|---|---|---|

| PMPC (9 bays) | PA (9 bays) | ICBP-1 (10 bays) | ICBP-2 (9 bays) | |

| NLT-327/00 | <5–10 mm/h | <5–10 mm/h | ― | ― |

| C1701/1701M-09 | <5–10 mm/h | <5–10 mm/h | ― | ― |

| C1781/C1781M-15 | ― | ― | 2872 | 16,510 |

| Type of Surface | Equation | Range of Time to Reach 0 Permeability (years) |

|---|---|---|

| PMPC | y = 348,32x2 − 5874.3x + 24,366 | 7–8 |

| PA | y = 163,45x2 − 2839.9x + 12,260 | 7–8 |

| ICBP-1 | y = −612.8x + 9000 | 14–15 |

| ICBP-2 | y = −1949x + 36,000 | 18–19 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sañudo-Fontaneda, L.A.; Andres-Valeri, V.C.; Costales-Campa, C.; Cabezon-Jimenez, I.; Cadenas-Fernandez, F. The Long-Term Hydrological Performance of Permeable Pavement Systems in Northern Spain: An Approach to the “End-of-Life” Concept. Water 2018, 10, 497. https://doi.org/10.3390/w10040497

Sañudo-Fontaneda LA, Andres-Valeri VC, Costales-Campa C, Cabezon-Jimenez I, Cadenas-Fernandez F. The Long-Term Hydrological Performance of Permeable Pavement Systems in Northern Spain: An Approach to the “End-of-Life” Concept. Water. 2018; 10(4):497. https://doi.org/10.3390/w10040497

Chicago/Turabian StyleSañudo-Fontaneda, Luis A., Valerio C. Andres-Valeri, Carlos Costales-Campa, Iñigo Cabezon-Jimenez, and Fernando Cadenas-Fernandez. 2018. "The Long-Term Hydrological Performance of Permeable Pavement Systems in Northern Spain: An Approach to the “End-of-Life” Concept" Water 10, no. 4: 497. https://doi.org/10.3390/w10040497

APA StyleSañudo-Fontaneda, L. A., Andres-Valeri, V. C., Costales-Campa, C., Cabezon-Jimenez, I., & Cadenas-Fernandez, F. (2018). The Long-Term Hydrological Performance of Permeable Pavement Systems in Northern Spain: An Approach to the “End-of-Life” Concept. Water, 10(4), 497. https://doi.org/10.3390/w10040497