How Can We Make Pump and Treat Systems More Energetically Sustainable?

Abstract

:1. Introduction

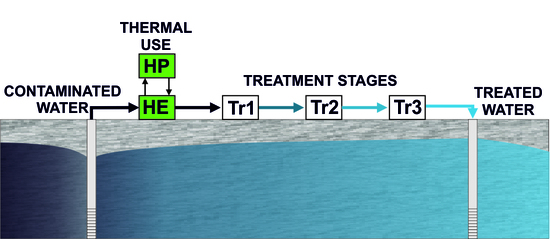

2. Technical Feasibility of Geothermal P&T Systems

2.1. Technical Solutions for the Geothermal Exploitation of P&T Systems

2.2. Expected Impacts on Water Treatment Processes

3. Potential Application to the Italian Contaminated Sites of National Interest (SIN)

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A

| Heavy Metals | Hexavalent Chromium | Arsenic | Mercury | Cyanide | Corrosives | Volatile Organics | Ketones | Semivolatile Organics | Pesticides | PCBs | Dioxins | Floating Products | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Activated carbon | P | P | P | Y | N | N | Y | N | Y | Y | Y | Y | P |

| Air stripping | N | N | N | N | N | N | Y | Y | N | N | N | N | N |

| Biological | N | N | N | N | P | N | P | Y | Y | P | P | P | P |

| Chemical Oxidation | N | N | P | N | Y | N | Y | Y | Y | Y | Y | P | N |

| Coprecipitation/Coagulation | Y | N | Y | Y | N | N | N | N | P | P | Y | Y | Y |

| Distillation | N | N | N | N | N | P | Y | Y | Y | Y | Y | Y | Y |

| Electrochemical | Y | Y | N | N | P | N | N | N | N | N | N | N | N |

| Evaporation | Y | Y | N | N | Y | N | N | N | P | P | Y | Y | Y |

| Filtration | Y | N | Y | Y | N | N | N | N | N | Y | Y | Y | P |

| Flotation | N | N | N | N | N | N | N | N | P | P | Y | Y | Y |

| Gravity separation | Y | N | P | P | N | N | N | N | P | P | Y | Y | Y |

| Ion exchange | Y | Y | Y | Y | Y | N | P | N | Y | Y | Y | Y | Y |

| Membrane separation | Y | P | Y | P | Y | N | P | N | Y | Y | Y | Y | Y |

| Neutralization | N | N | N | N | N | Y | N | N | N | N | N | N | N |

| Precipitation | Y | Y | P | Y | N | Y | N | N | P | P | Y | Y | Y |

| Reduction | P | Y | N | Y | N | N | N | N | N | N | N | N | N |

| Steam stripping | N | N | N | N | N | N | Y | Y | Y | P | N | N | N |

| UV/Ozone | N | N | P | N | Y | N | P | P | Y | Y | Y | Y | N |

Appendix B

Appendix B.1. Different Thermal Uses of a P&T System—Cooling and Heating

- (1)

- Air-water chiller (Carrier 30 RQSY 100, see [50]) with a SEER = 4.26 in medium-temperature comfort applications (23–18 °C);

- (2)

- Free cooling system (Figure 1A) composed of a heat exchanger between the 23–18 °C radiant panel circuit and groundwater through a gasketed plate heat exchanger;

- (3)

- (4)

- GWHP with intermediate heat exchanger (Figure 1C). The same reversible heat pump of case 3, but the efficiency is reduced to SEER = 5.84, a reduction of 0.3, which could be considered as a reasonable estimate for a condensation temperature increase of 5 °C due to the intermediate heat exchanger.

- (5)

- Air-water chiller (Carrier 30 RQSY 100, see [50]) with a SCOP = 3.30 at typical radiant panel temperatures (30–35 °C);

- (6)

- (7)

- GWHP with intermediate heat exchanger (Figure 1C). The same reversible heat pump as case 3, but the efficiency is reduced to SEER = 5.79, a reduction of 0.3, which can be considered as a reasonable estimate for a condensation temperature increase of 5 °C due to the intermediate heat exchanger.

Appendix B.2. Different Thermal Use Schemes in an Air Stripping Unit (ASU)

- (A)

- heat discharge into contaminated water as a pre-heating before the air stripping treatment, thus avoiding (or reducing) further heat inputs to improve the stripping process;

- (B)

- heat recovery after the treatment, if water pre-heating is required for air stripping;

- (C)

- implementation of both the heat exchanges through a heat pump, i.e., extracting heat from the stripping column effluent (connected to the heat pump evaporator) to preheat groundwater before the air stripping with the heat delivered by the heat pump in the condensation phase.

Appendix C

| # | Site Name | Region | Area (ha) | Description | Notes |

|---|---|---|---|---|---|

| 1 | Porto Marghera (Venice) | Veneto | 1618 | Former and active petrochemical plants. | Groundwater drainage system (55 m3/h) installed with a treatment plant [56]. |

| 2 | Eastern Naples | Campania | 834 | Active and former industrial sites | Pumping + recharge wells to avoid saline intrusion [57]. |

| 3 | Gela | Sicily | 795 | Active petrochemical plants | Hydraulic barrier of 78 wells, with groundwater treatment plant, for a flow rate of 250 m3/h [58,59]. |

| 4 | Priolo | Sicily | 5814 | Active petrochemical plants | P&T active (600 m3/h) with sustainable reuse of treated waters [58,60]. |

| 5 | Manfredonia | Apulia | 216 | Former petrochemical plants and 3 landfills | P&T with reinjection wells on the boundary, low permeability aquifer, flow rate 120 m3/h [61]. |

| 6 | Brindisi | Apulia | 5851 | Chemical plants, coal power station | 5 P&T foreseen in the reclamation project for a total flow rate of 215 m3/h [62]. |

| 7 | Taranto | Apulia | 4383 | Steel and cement production, oil refining | Reclamation project still at early phases. Two P&T systems foreseen, with a total flow rate of 100 m3/h [63]. |

| 8 | Cengio and Saliceto | Liguria and Piedmont | 77 | Former chemical plant | P&T installed with a capacity of 600 m3/h [64]. |

| 9 | Piombino | Tuscany | 931 | Steel production plant | P&T with a flow rate of 11 m3/h [65]. |

| 10 | Massa and Carrara | Tuscany | 116 | Numerous industrial activities | P&T system with a flow rate of 160 m3/h [66]. |

| 11 | Casale Monferrato | Piedmont | 73,895 | Asbestos processing (Eternit) | Area contaminated by asbestos. No P&T foreseen. |

| 12 | Balangero | Piedmont | 314 | Former asbestos quarry | Area contaminated by asbestos. Quarry lake but no P&T foreseen. |

| 13 | Pieve Vergonte | Piedmont | 42 | Former chemical plant | P&T active (350–850 m3/day) with a foreseen expansion to 1250 m3/h [67,68]. |

| 14 | Sesto San Giovanni | Lombardy | 255 | Former steel processing plant | P&T active to remediate CAHs, flow rate 200 m3/h [69]. |

| 15 | Pioltello Rodano | Lombardy | 85 | Chemical and pharmaceutical industries | Groundwater remediation activities to be designed [70]. |

| 16 | Bagnoli (Naples) | Campania | 249 | Former steel and cement production plant, former asbestos processing plant | P&T foreseen, 270 m3/h [71]. |

| 17 | Tito | Basilicata | 315 | Former chemical plant | Hydraulic barrier with a capacity of 90 m3/h [72]. |

| 18 | Crotone, Cassano and Cerchiara | Calabria | 530 | Former metal working industries | P&T installed with a capacity of 88 m3/h [73]. |

| 19 | Fidenza | Emilia-Romagna | 25 | Former chemical industry | Hydraulic barrier with 3 wells. New settlement foreseen in the site [74]. |

| 20 | Torviscosa Caffaro | Friuli Venezia Giulia | 201 | Former chemical industry | Hydraulic barriers, flow rate of 47 m3/h [75]. |

| 21 | Trieste | Friuli Venezia Giulia | 506 | Steel production plant | Hydraulic barrier to be realized, with a capacity of 15 m3/h [76]. |

| 22 | Cogoleto Stoppani | Liguria | 45 | Chemical industry | 12 pumping wells (total flow rate 36 m3/h) for emergency dewatering [77]. |

| 23 | Fibronit Bari | Apulia | 15 | Asbestos processing | Asbestos contamination in groundwater [78] but no P&T implemented until now. |

| 24 | Sulcis, Iglesiente, Guspinese | Sardinia | 19,751 | Coal/bauxite mining areas and metal working/chemical industries | In Portovesme, 3 P&T systems, and another barrier of 61 wells is foreseen. Total flow rate: 514 m3/h [79]. |

| 25 | Biancavilla | Sicily | 330 | Asbestos-like mineral (fluoro-edenite) | No P&T foreseen. |

| 26 | Livorno | Tuscany | 206 | Oil refining | Hydraulic barrier with 42 wells [80]. |

| 27 | Terni Papigno | Umbria | 655 | Former and actual chemical, electric, textile, iron & steel industries | Heavy metals found in groundwater. A small P&T system was implemented in 2016 [54]. |

| 28 | Emarèse | Valle d’Aosta | 23 | Former asbestos minerals quarry | No P&T implemented or foreseen. |

| 29 | Northern Trento | Trento | 24 | PAH, aromatic solvents, phenols, Pb and Hg by former petrochemical industries | Hydraulic barrier and GW activated carbon treatment plant [81]. |

| 30 | Brescia Caffaro | Lombardy | 2109 | PCB, PAH, heavy metals | P&T systems in 2 sites (Oto Melara and Baratti) [75,82]. |

| 31 | Broni | Lombardy | 14 | Former asbestos cement industry | No P&T systems [83]. |

| 32 | Falconara Marittima | Marche | 105 | Former refinery and oil products storage. HC, PAH, heavy metals | Hydraulic barrier along coastline as urgent safety measure [84]. |

| 33 | Serravalle Scrivia | Piedmont | 74 | Former industry of oil, lubricants | Hydraulic containment foreseen by means of barrier wall. |

| 34 | Lakes of Mantua and chemical pole | Lombardy | 614 | PAH, organohalogen compounds, HC, heavy metals (esp. Hg) by former refineries, petrochemical industries | Hundreds of wells for hydraulic barrier [85]. |

| 35 | Orbetello (former SITOCO) | Tuscany | 204 | Former chemical industry released heavy metals, PCB, dioxin | 20 wells foreseen in 2009 for water table lowering, with a flow rate of 30 m3/h [86]. Hydraulic barrier for deep aquifer. |

| 36 | Porto Torres | Sardinia | 1874 | Petrochemical, chemical, engineering industry; storage tanks for oil products | P&T system (200 + 50 m3/h, see Ref. [56]) and other remediation techniques (MPE). Water disposal in the sea. |

| 37 | Basento valley | Basilicata | 3300 | Asbestos-like minerals and others | A P&T system foreseen with a flow rate of 90 m3/h [87]. |

| 38 | Milazzo | Sicily | 549 | Refineries and industrial district | P&T foreseen in one of the industrial site [54]. |

| 39 | Bussi | Abruzzo | 232 | Chlorinated solvents by former industrial sites and industrial landfills | P&T system active with a flow rate of 120 m3/h [88]. |

| 40 | Sacco river basin | Latium | ~7200 | Lindane and beta-esachlorocycloesane by former chemical industrial sites | Hydraulic barrier of 29 wells. |

| 41 | Train maintenance workshop of Bologna | Emilia-Romagna | n.a. | Asbestos-like minerals and others | Site characterization ongoing. |

References

- Department of Defence—Australian Government Guidelines for Consideration of Sustainability in Remediation of Contaminated sites. Available online: http://bit.ly/36SiObg (accessed on 20 February 2018).

- Suthersan, S.S.; Horst, J.; Schnobrich, M.; Welty, N.; McDonough, J. Remediation Engineering: Design Concepts; CRC Press: Boca Raton, FL, USA, 2016; ISBN 1-4987-7336-2. [Google Scholar]

- EPA, J. Pump-and-Treat Ground-Water Remediation: A Guide for Decision Makers and Practitioners; US Environmental Protection Agency: Washington, DC, USA, 1996. [Google Scholar]

- Fiedler, L.; Pachon, C. Recent Trends in the Selection of Remedies for Groundwater, Soil, and Sediment at Superfund Sites. Groundw. Monit. Remediat. 2018, 38, 13–18. [Google Scholar] [CrossRef]

- Podobnik, J.C.; Horst, B.I. A Survey of Sites Using Pump and Treat. Remediation Methods and a Survey Study of Applying Geothermal Heat Pump Systems to Pump and Treat. Sites at Lawrence Livermore National Laboratory; Lawrence Livermore National Laboratory: Livermore, CA, USA, 1998. [Google Scholar]

- Patyn, J.; Lookman, R. The Combination of Aquifer Thermal Energy Storage (ATES) and Groundwater Remediation; Terra Energy nv, VITO, OVAM, VMM, Utrecht city, VEA: Mechelen, Belgium, 2012; p. 38. [Google Scholar]

- Potter, T.M. Geothermal/Ground-Source Heat Pump Application Opportunities under the MCP 2015. Available online: http://bit.ly/2Mkir1v (accessed on 20 February 2018).

- Farr, G.; Sadasivam, S.; Watson, I.A.; Thomas, H.R.; Tucker, D. Low enthalpy heat recovery potential from coal mine discharges in the South Wales Coalfield. Int. J. Coal Geol. 2016, 164, 92–103. [Google Scholar] [CrossRef] [Green Version]

- Peralta Ramos, E.; Breede, K.; Falcone, G. Geothermal heat recovery from abandoned mines: A systematic review of projects implemented worldwide and a methodology for screening new projects. Environ. Earth Sci. 2015, 73, 6783–6795. [Google Scholar] [CrossRef]

- Bailey, M.T.; Gandy, C.J.; Watson, I.A.; Wyatt, L.M.; Jarvis, A.P. Heat recovery potential of mine water treatment systems in Great Britain. Int. J. Coal Geol. 2016, 164, 77–84. [Google Scholar] [CrossRef] [Green Version]

- Zajzon, N.; Žibret, G.; Aaltonen, J.; Rossi, C.; Bodo, B.; Silva, E.; Henley, S.; Mata, B.; Huxtable, P.; Fernandez, I.; et al. UNEXMIN: Underwater Explorer for Flooded Mines. Available online: www.unexmin.eu/ (accessed on 20 February 2018).

- Sarbu, I.; Sebarchievici, C. General review of ground-source heat pump systems for heating and cooling of buildings. Energy Build. 2014, 70, 441–454. [Google Scholar] [CrossRef]

- Casasso, A.; Sethi, R. Assessment and Minimization of Potential Environmental Impacts of Ground Source Heat Pump (GSHP) Systems. Water 2019, 11, 1573. [Google Scholar] [CrossRef] [Green Version]

- Menberg, K.; Bayer, P.; Zosseder, K.; Rumohr, S.; Blum, P. Subsurface urban heat islands in German cities. Sci. Total Environ. 2013, 442, 123–133. [Google Scholar] [CrossRef]

- Menberg, K.; Blum, P.; Kurylyk, B.L.; Bayer, P. Observed groundwater temperature response to recent climate change. Hydrol. Earth Syst. Sci. 2014, 18, 4453–4466. [Google Scholar] [CrossRef] [Green Version]

- Piga, B.; Casasso, A.; Pace, F.; Godio, A.; Sethi, R. Thermal Impact Assessment of Groundwater Heat Pumps (GWHPs): Rigorous vs. Simplified Models. Energies 2017, 10, 1385. [Google Scholar] [CrossRef] [Green Version]

- Pophillat, W.; Attard, G.; Bayer, P.; Hecht-Méndez, J.; Blum, P. Analytical solutions for predicting thermal plumes of groundwater heat pump systems. Renew. Energy 2018, 147, 2696–2707. [Google Scholar] [CrossRef]

- Banks, D. Thermogeological assessment of open-loop well-doublet schemes: A review and synthesis of analytical approaches. Hydrogeol. J. 2009, 17, 1149–1155. [Google Scholar] [CrossRef]

- Casasso, A.; Sethi, R. Modelling thermal recycling occurring in groundwater heat pumps (GWHPs). Renew. Energy 2015, 77, 86–93. [Google Scholar] [CrossRef] [Green Version]

- Rafferty, K. Scaling in Geothermal Heat Pump Systems. Available online: http://bit.ly/2NsmubK (accessed on 11 December 2018).

- Bezelgues-Courtade, S.; Martin, J.-C.; Schomburgk, S.; Monnot, P.; Nguyen, D.; Le Brun, M.; Desplan, A. Geothermal Potential of Shallow Aquifers: Decision-Aid Tool for Heat-Pump Installation. In Proceedings of the World Geothermal Congress, Bali Island, Indonesia, 25 April 2010. [Google Scholar]

- EPA Groundwater Pump and Treat Systems: Summary of Selected Cost and Performance Information at Superfund-Financed Sites. Available online: http://bit.ly/3922NkS (accessed on 12 December 2018).

- Marks, P.J.; Wujcik, W.J.; Loncar, A.F. Remediation Technologies Screening Matrix and Reference Guide, 2nd ed.; Roy F Weston Inc.: West Chester, PA, USA, 1994. [Google Scholar]

- Ahamad, K.U.; Jawed, M. Kinetics, equilibrium and breakthrough studies for Fe(II) removal by wooden charcoal: A low-cost adsorbent. Desalination 2010, 251, 137–145. [Google Scholar] [CrossRef]

- Chern, J.-M.; Wu, C.-Y. Desorption of dye from activated carbon beds: Effects of temperature, pH, and alcohol. Water Res. 2001, 35, 4159–4165. [Google Scholar] [CrossRef]

- Iovino, P.; Erto, A.; Capasso, S.; Natale, M.D.; Canzano, S.; Lama, A.; Musmarra, D. Experimental analysis of benzene derivative adsorption in single and binary systems using activated carbon. Int. J. Environ. Waste Manag. 2015, 16, 336–352. [Google Scholar] [CrossRef]

- Gupta, V.K.; Gupta, B.; Rastogi, A.; Agarwal, S.; Nayak, A. Pesticides removal from waste water by activated carbon prepared from waste rubber tire. Water Res. 2011, 45, 4047–4055. [Google Scholar] [CrossRef]

- Salman, J.M.; Njoku, V.O.; Hameed, B.H. Adsorption of pesticides from aqueous solution onto banana stalk activated carbon. Chem. Eng. J. 2011, 174, 41–48. [Google Scholar] [CrossRef]

- Dąbrowski, A.; Podkościelny, P.; Hubicki, Z.; Barczak, M. Adsorption of phenolic compounds by activated carbon—A critical review. Chemosphere 2005, 58, 1049–1070. [Google Scholar] [CrossRef]

- Bhattacharyya, K.G.; Gupta, S.S. Adsorption of a few heavy metals on natural and modified kaolinite and montmorillonite: A review. Adv. Colloid Interface Sci. 2008, 140, 114–131. [Google Scholar] [CrossRef]

- Xu, D.; Tan, X.L.; Chen, C.L.; Wang, X.K. Adsorption of Pb(II) from aqueous solution to MX-80 bentonite: Effect of pH, ionic strength, foreign ions and temperature. Appl. Clay Sci. 2008, 41, 37–46. [Google Scholar] [CrossRef]

- Senthil Kumar, P.; Ramalingam, S.; Senthamarai, C.; Niranjanaa, M.; Vijayalakshmi, P.; Sivanesan, S. Adsorption of dye from aqueous solution by cashew nut shell: Studies on equilibrium isotherm, kinetics and thermodynamics of interactions. Desalination 2010, 261, 52–60. [Google Scholar] [CrossRef]

- Kundu, S.; Gupta, A.K. Arsenic adsorption onto iron oxide-coated cement (IOCC): Regression analysis of equilibrium data with several isotherm models and their optimization. Chem. Eng. J. 2006, 122, 93–106. [Google Scholar] [CrossRef]

- Al-Degs, Y.S.; El-Barghouthi, M.I.; El-Sheikh, A.H.; Walker, G.M. Effect of solution pH, ionic strength, and temperature on adsorption behavior of reactive dyes on activated carbon. Dyes Pigments 2008, 77, 16–23. [Google Scholar] [CrossRef]

- Memon, G.Z.; Bhanger, M.I.; Akhtar, M.; Talpur, F.N.; Memon, J.R. Adsorption of methyl parathion pesticide from water using watermelon peels as a low cost adsorbent. Chem. Eng. J. 2008, 138, 616–621. [Google Scholar] [CrossRef]

- Ball, B.R.; Edwards, M.D. Air Stripping VOCs from Groundwater: Process Design Considerations. Environ. Prog. 1992, 11, 39–48. [Google Scholar] [CrossRef]

- Chuang, K.T.; Cheng, S.; Tong, S. Removal and Destruction of Benzene, Toluene, and Xylene from Wastewater by Air Stripping and Catalytic Oxidation. Ind. Eng. Chem. Res. 1992, 31, 2466–2472. [Google Scholar] [CrossRef]

- Ashworth, R.A.; Howe, G.B.; Mullins, M.E.; Rogers, T.N. Air-water partitioning coefficients of organics in dilute aqueous solutions. J. Hazard. Mater. 1988, 18, 25–36. [Google Scholar] [CrossRef]

- Staudinger, J.; Roberts, P.V. A critical compilation of Henry’s law constant temperature dependence relations for organic compounds in dilute aqueous solutions. Chemosphere 2001, 44, 561–576. [Google Scholar] [CrossRef]

- EPA Cost-Effective Design of Pump and Treat Systems. Available online: https://clu-in.org/download/remed/hyopt/factsheets/cost-effective_design.pdf (accessed on 17 September 2019).

- Langwaldt, J.H.; Puhakka, J.A. On-site biological remediation of contaminated groundwater: A review. Environ. Pollut. 2000, 107, 187–197. [Google Scholar] [CrossRef]

- Beretta, G.P. Some aspects of the state of the art of contaminated sites remediation in Italy. Acque Sotter. Ital. J. Groundw. 2015, 4, 27–40. [Google Scholar] [CrossRef] [Green Version]

- ISPRA, S.I.N. Siti di Interesse Nazionale—Stato delle procedure per la bonifica. Dicembre 2018. Available online: http://bit.ly/2MjNp9P (accessed on 10 April 2019).

- Majone, M.; Rolle, E.; Petrangeli Papini, M.; Beretta, G.; Cicconi, V.; Maffucci, M. Messa in sicurezza e bonifica di falde contaminate: un’analisi delle tecnologie impiegate a partire dall’applicazione del d.m. 471/99. La chimica e l’industria 2009, 1, 104–109. [Google Scholar]

- Beretta, G.P.; Coppola, G.; Pona, L.D. Solute and heat transport in groundwater similarity: Model application of a high capacity open-loop heat pump. Geothermics 2014, 51, 63–70. [Google Scholar] [CrossRef]

- Papakostas, K.T.; Michopoulos, A.K.; Kyriakis, N.A. Equivalent full-load hours for estimating heating and cooling energy requirements in buildings: Greece case study. Appl. Energy 2009, 86, 757–761. [Google Scholar] [CrossRef]

- Rienecker, M.M.; Suarez, M.J.; Gelaro, R.; Todling, R.; Bacmeister, J.; Liu, E.; Bosilovich, M.G.; Schubert, S.D.; Takacs, L.; Kim, G.-K.; et al. MERRA: NASA’s modern-era retrospective analysis for research and applications. J. Clim. 2011, 24, 3624–3648. [Google Scholar] [CrossRef]

- Pfenninger, S.; Staffell, I. Renewables.ninja. Available online: https://www.renewables.ninja/ (accessed on 5 December 2019).

- Casasso, A.; Capodaglio, P.; Simonetto, F.; Sethi, R. Environmental and Economic Benefits from the Phase-out of Residential Oil Heating: A Study from the Aosta Valley Region (Italy). Sustainability 2019, 11, 3633. [Google Scholar] [CrossRef] [Green Version]

- Carrier Heating, Ventilation and Air Cooling. Catalogue 2018/2019. Available online: http://bit.ly/2R3bZ27 (accessed on 29 November 2019).

- Lo Russo, S.; Civita, M. Hydrogeological and thermal characterization of shallow aquifers in the plain sector of Piemonte region (NW Italy): Implications for groundwater heat pumps diffusion. Environ. Earth Sci. 2010, 60, 703–713. [Google Scholar] [CrossRef]

- Provincia Autonoma di Trento Map of Groundwater Temperatures in the Province of Trento. Available online: http://bit.ly/35yqO12 (accessed on 18 December 2019).

- A2A A2A District Heating Network of Brescia. Available online: http://bit.ly/323ShF7 (accessed on 21 September 2019).

- Braga, C.; Zaratti, F. Commissione Parlamentare di Inchiesta Sulle Attività Illecite Connesse al ciclo dei Rifiuti e su Illeciti Ambientali ad esse Correlati. Relazione Sulle Bonifiche nei siti di Interesse Nazionale. Relatori: On. Chiara Braga e On. Filiberto Zaratti. Available online: http://bit.ly/2qasaz8 (accessed on 29 August 2018).

- Rivoire, M.; Casasso, A.; Piga, B.; Sethi, R. Assessment of Energetic, Economic and Environmental Performance of Ground-Coupled Heat Pumps. Energies 2018, 11, 1941. [Google Scholar] [CrossRef] [Green Version]

- SIMAM Groundwater Treatment Plants. Available online: http://bit.ly/2pmd4ql (accessed on 1 September 2019).

- SOGESID Napoli Orientale—Relazione di calcolo dell’impianto TAF. Available online: http://bit.ly/2pximPK (accessed on 15 January 2019).

- Farina, M.; Bifulco, S. Aggiornamenti sullo stato dell’arte dei Procedimenti di Bonifica nei siti SIN di Gela e Priolo (Update on the remediation of National Interest Sites of Gela and Priolo). Available online: http://bit.ly/36ZI9QQ (accessed on 1 September 2019).

- Italian Ministry of Environment SIN “Gela”. Resoconto Tavolo Tecnico del 1 Giugno 2017. Available online: http://bit.ly/2NB1gZa (accessed on 2 March 2018).

- ENI Syndial: Inaugurazione impianto TAF di Priolo. Available online: http://bit.ly/2tBYD2V (accessed on 2 March 2018).

- ARPA Puglia; Fascia, Antonio; Lacarbonara, Mina Focus Siti di Interesse Nazionale. SIN Manfredonia. Available online: http://bit.ly/2q9kUng (accessed on 11 February 2018).

- ARPA Puglia; Siti Contaminati. Available online: http://bit.ly/339TdsP (accessed on 8 February 2018).

- Taranto Port Authority I° Lotto degli Interventi di Messa in Sicurezza e Bonifica della falda in area ex Yard Belleli, Funzionale alla Realizzazione della Cassa di Colmata c.d. “ampliamento V Sporgente”. Available online: http://bit.ly/323aWRD (accessed on 12 January 2019).

- Ambiente Liguria ACNA. Available online: http://bit.ly/33aptMK (accessed on 9 February 2018).

- Italian Ministry of Environment Conferenza dei Servizi Ministeriale del 30 novembre 2012 relativa alla “Progettazione Preliminare del sistema di marginamento della colmata Nord, comprensivo della realizzazione e gestione del sistema di captazione della falda e progettazione preliminare dell’impianto di trattamento e riutilizzo delle acque di falda inquinate derivante dal sistema di marginamento pubblico previsto all’interno del SIN di Piombino” elaborato dalla Sogesid. Available online: http://bit.ly/2NwqGar (accessed on 12 February 2018).

- ENI Rewind ENI Rewind—Activities in the Site of Carrara Avenza. Available online: http://bit.ly/2WAk1Aj (accessed on 1 February 2019).

- Region Piemonte Deliberazione della Giunta Regionale 23 aprile 2013, n. 28-5712. Procedura di Valutazione ex art 12 della L.R. 40/98 con Contestuale Valutazione d’Incidenza per il Progetto Definitivo “Progetto Operativo di Bonifica del sito di Pieve Vergonte (VB)” Presentato da SYNDIAL. Available online: http://bit.ly/2qgMXAU (accessed on 28 February 2018).

- Troni, M. Presentazione casi specifici di Pieve Vergonte e Mantova. Available online: http://bit.ly/2Nqpg0Y (accessed on 16 January 2019).

- ARPA Lombardia; Sito di Interesse Nazionale di Sesto San Giovanni (MI). Relazione sullo stato di Contaminazione delle acque Sotterranee. Campagna Semestrale di Monitoraggio—Settembre 2017. Available online: http://bit.ly/2QdEzLU (accessed on 13 February 2018).

- Regione Lombardia, Sito di Interesse Nazionale di Pioltello e Rodano. Available online: http://bit.ly/2JH7Tbw (accessed on 13 February 2018).

- Invitalia; Programma di risanamento ambientale e di rigenerazione urbana. Sito di Rilevante Interesse Nazionale di Bagnoli-Coroglio. Available online: http://bit.ly/2Sg7jGt (accessed on 14 February 2018).

- D’Aprile, L. SIN Tito—Verbale della Conferenza dei Servizi istruttoria del 12.02.2015. Available online: http://bit.ly/2ShpOuu (accessed on 14 February 2018).

- ENI Rewind ENI Rewind—Activities in the Site of Crotone. Available online: http://bit.ly/3274Qj5 (accessed on 1 February 2019).

- Savigni, G.; Pratissoli, A.; Drufuca, A.; Battaiotto, S.; Denti, R.; Teneggi, S.; Ugolini, C.; Spallanzani, N.; Ganapini, S.; Magnani, G.; et al. VIA sito di Interesse Nazionale di Fidenza. Sintesi Non Tecnica. Available online: http://bit.ly/2WBleqJ (accessed on 12 October 2019).

- Bratti, A.; Compagnone, G.; Cominelli, M. Commissione Parlamentare di Inchiesta sulle attività Illecite Connesse al ciclo dei rifiuti e su Illeciti Ambientali ad esse correlati. Relazione sui siti contaminati gestiti dalla società Caffaro a Torviscosa, Brescia, Colleferro e Galliera. Available online: http://bit.ly/2C7mXKY (accessed on 9 February 2018).

- Invitalia; Accordo di Programma “Disciplina degli Interventi Relativi alla Riqualificazione delle Attività Industriali e Portuali e del Recupero Ambientale nell’area di crisi Industriale Complessa di Trieste”. Available online: http://bit.ly/2ZbJeSE (accessed on 15 February 2018).

- Ambiente Liguria, Stoppani. Available online: http://bit.ly/2Zf5R8I (accessed on 9 February 2018).

- Fracassi, F.; Laricchiuta, S. Bonifica del sito Inquinato Fibronit Bari. Relazione di Consulenza Tecnica per la Procura della Repubblica di Bari. Available online: http://bit.ly/2Wz0KPu (accessed on 2 March 2018).

- Regione Sardegna Focus sulle bonifiche dei suoli e della falda nell’area industriale di Portovesme: I programmi a integrale carico delle aziende. Attuazione al 31 maggio 2017. Available online: http://bit.ly/36p9axj (accessed on 28 February 2018).

- ARPA Toscana Il sito di bonifica di interesse nazionale di Livorno. Available online: http://bit.ly/36Z6Qww (accessed on 2 March 2018).

- Italian Ministry of Environment Sito d’Interesse Nazionale “Trento Nord”. Verbale della conferenza di Servizi decisoria tenutasi presso il Ministero dell’Ambiente e della Tutela del Territorio in data 22 novembre 2005 ai sensi dell’art. 14 L. n. 241/90 e sue successive modifiche ed integrazioni. Available online: http://bit.ly/36rvG95 (accessed on 15 February 2018).

- Official Site of the Commissioner of the Contaminated Site of Brescia—Caffaro. Available online: http://bresciacaffaro.it/ (accessed on 2 March 2018).

- Regione Lombardia Report on the Contaminated Site of Broni. Available online: http://bit.ly/2JWfRh5 (accessed on 3 March 2018).

- Italian Ministry of Environment; Region Marche; Province of Ancona; Municipality of Falconara Marittima; Port authority of Ancona Accordo di programma per la definizione degli interventi di messa in sicurezza e bonifica delle aree comprese nel Sito di Interesse Nazionale di Falconara. Available online: http://bit.ly/338wldo (accessed on 26 February 2018).

- Italian Ministry of Environment—Accordo di Programma per la Definizione degli Interventi di Messa in Sicurezza D’emergenza e Successiva Bonifica nel Sito di Interesse Nazionale di “Laghi di Mantova e Polo Chimico”. Available online: http://bit.ly/2C2oBh5 (accessed on 2 March 2018).

- Italian Ministry of Environment Sito di Interesse Nazionale “Orbetello Area ex SITOCO”. Verbale della Conferenza di Servizi Istruttoria del 29.05.2013. Available online: http://bit.ly/2NaFUTL (accessed on 1 March 2018).

- D’ Aprile, L.; Rolli, A.P.; Gravino, S. Siti D’interesse Nazionale di “Area Industriale di Tito Scalo” e “Area Industriale della Val Basento”. Verbale della Conferenza di Servizi Decisoria Convocata presso il MATTM in data 16.05.2016, ai sensi dell’art. 14 comma 2 della Legge n. 241/90 e Successive Integrazioni e Modifiche. Available online: http://bit.ly/338dpeR (accessed on 29 August 2018).

- Zueblin Umwelttechnik Züblin Umwelttechnik GmbH—Impianto T.A.F. per trattamento acque di falda contaminate da CHC e mercurio, Bussi sul Tirino. Available online: http://bit.ly/2C2o6nf (accessed on 11 January 2019).

| No. | Site | Flow Rate (m3/h) | Thermal Power, ΔT = 4 K (kW) | FLEH Heating (h/a) | FLEH Cooling (h/a) | Avoided GHG (Ton CO2 eq/a) |

|---|---|---|---|---|---|---|

| 30 | Brescia Caffaro | 1400 | 6496 | 2151 | 728 | 3001 |

| 13 | Pieve Vergonte | 1250 | 5800 | 2589 | 268 | 3224 |

| 4 | Priolo | 600 | 2784 | 1423 | 1011 | 851 |

| 8 | Cengio e Saliceto | 600 | 2784 | 2151 | 608 | 1286 |

| 24 | Sulcis-Iglesiente-Guspinese | 514 | 2385 | 1424 | 921 | 729 |

| 32 | Falconara Marittima | 400 | 1856 | 1558 | 934 | 621 |

| 16 | Bagnoli | 270 | 1253 | 1394 | 968 | 375 |

| 2 | Napoli Orientale | 258 | 1197 | 1394 | 968 | 358 |

| 3 | Gela | 250 | 1160 | 1439 | 993 | 359 |

| 36 | Porto Torres | 250 | 1160 | 1470 | 920 | 366 |

| 6 | Brindisi | 215 | 998 | 1193 | 1208 | 256 |

| 14 | Sesto San Giovanni | 200 | 928 | 2202 | 751 | 439 |

| 10 | Massa e Carrara | 160 | 743 | 1752 | 634 | 280 |

| 5 | Manfredonia | 120 | 557 | 1419 | 1051 | 170 |

| 39 | Bussi sul Tirino | 120 | 557 | 2336 | 476 | 279 |

| 7 | Taranto | 100 | 464 | 1416 | 1050 | 141 |

| 17 | Tito | 90 | 418 | 2070 | 601 | 186 |

| 18 | Crotone | 88 | 408 | 1483 | 1109 | 130 |

| 1 | Marghera | 55 | 255 | 1958 | 909 | 107 |

| 20 | Torviscosa Caffaro | 47 | 218 | 1947 | 659 | 91 |

| 22 | Cogoleto Stoppani | 36 | 167 | 1912 | 642 | 69 |

| 29 | Trento Nord | 17 | 79 | 2784 | 138 | 47 |

| 9 | Piombino | 11 | 51 | 1253 | 962 | 14 |

| TOTAL | 7051 | 32,718 | na | na | 13,378 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Casasso, A.; Tosco, T.; Bianco, C.; Bucci, A.; Sethi, R. How Can We Make Pump and Treat Systems More Energetically Sustainable? Water 2020, 12, 67. https://doi.org/10.3390/w12010067

Casasso A, Tosco T, Bianco C, Bucci A, Sethi R. How Can We Make Pump and Treat Systems More Energetically Sustainable? Water. 2020; 12(1):67. https://doi.org/10.3390/w12010067

Chicago/Turabian StyleCasasso, Alessandro, Tiziana Tosco, Carlo Bianco, Arianna Bucci, and Rajandrea Sethi. 2020. "How Can We Make Pump and Treat Systems More Energetically Sustainable?" Water 12, no. 1: 67. https://doi.org/10.3390/w12010067

APA StyleCasasso, A., Tosco, T., Bianco, C., Bucci, A., & Sethi, R. (2020). How Can We Make Pump and Treat Systems More Energetically Sustainable? Water, 12(1), 67. https://doi.org/10.3390/w12010067