Perspectives of Water Distribution Networks with the GreenValve System

Abstract

:1. Introduction

Study Methodology

2. Data Set Classification and Analysis

Limitations

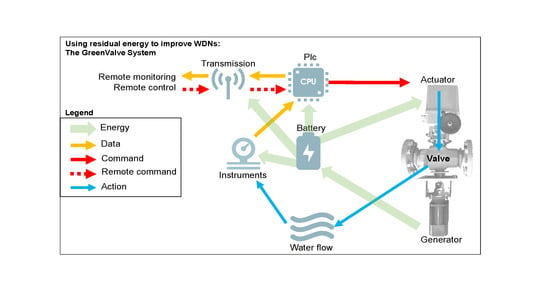

3. GreenValve System (GVS)

GVS Sizing Procedure

4. GVS Applicability to Dataset

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

Appendix A

- -

- “avg” indicates that they are obtained by averaging measurement data;

- -

- “avg model” indicates that they are obtained by averaging data from a network model;

- -

- “project” indicates that they are design quantities based on project calculations.

| Ref. | Location | n° | Kind of Application | Type of Data | Q (L/s) | ΔP (bar) | PD (KW) | |

|---|---|---|---|---|---|---|---|---|

| Data from bibliography | [23] | Benevento Municipality DMA Santa Colomba | 1 | PRV | avg | 26.9 | 0.34 | 0.91 |

| [24] | Northern Italy | 2 | RTC | avg | 58.6 | 1.17 | 6.55 | |

| [38] | York, North of Toronto, Ontario, Canada | 3 | PRV | avg | 98.5 | 0.99 | 2.66 | |

| York, North of Toronto, Ontario, Canada | 4 | PRV | avg | 73.8 | 0.78 | 1.43 | ||

| [39] | Durban, South Africa | 5 | PRV | avg | 390.7 | 3.17 | 121.1 | |

| [40] | El Dorado Irrigation District, Ca, USA | 6 | PRV | avg | 15.1 | 7.92 | 11.9 | |

| [41] | Halifax, Canada | 7 | PRV | avg | 53.6 | 1.90 | 2.95 | |

| [42] | Coviolo, Italy | 8 | PRV | avg | 3.67 | 2.30 | 0.90 | |

| [43] | Razgrad, Bulgaria | 9 | PRV | avg | 8.75 | 0.44 | 0.38 | |

| [44] | Skopje, Macedonia | 10 | PRV | avg | 44.3 | 1.30 | 4.87 | |

| [45] | Naples (EAST), Italy | 11 | PRV | avg model | 323.0 | 1.00 | 32.21 | |

| [46] | UK | 12 | PRV | avg | 12.14 | 3.76 | 4.24 | |

| UK | 13 | PRV | avg | 1.34 | 4.04 | 0.53 | ||

| UK | 14 | PRV | avg | 9.19 | 0.56 | 0.52 | ||

| [47] | Rural area in northern Germany | 15 | PRV | avg | 6.89 | 5.36 | 3.65 | |

| [48] | Philadephia, USA | 16 | PRV | avg model | 33.6 | 0.71 | 2.40 | |

| [49] | Selangor, Malaysia | 17 | PRV | avg | 18.9 | 1.57 | 2.68 | |

| Selangor, Malaysia | 18 | PRV | avg | 22.6 | 0.84 | 1.79 | ||

| Selangor, Malaysia | 19 | PRV | avg | 14.5 | 0.86 | 0.93 | ||

| [50] | n.d. | 20 | PRV | avg model | 103.6 | 1.39 | 14.4 | |

| [51] | n.d. | 21 | PRV | avg model | 17.0 | 2.43 | 4.12 | |

| n.d. | 22 | PRV | avg model | 101.9 | 2.39 | 23.6 | ||

| [52] | n.d | 23 | PRV | avg model | 36.0 | 1.80 | 5.93 | |

| n.d | 24 | PRV | avg model | 47.4 | 0.71 | 2.83 | ||

| [53] | Central Arava Valley, Israel | 25 | PRV | avg model | 23.3 | 0.04 | 0.09 | |

| Central Arava Valley, Israel | 26 | PRV | avg model | 15.3 | 1.94 | 2.96 | ||

| Central Arava Valley, Israel | 27 | PRV | avg model | 58.1 | 6.93 | 40.3 | ||

| Central Arava Valley, Israel | 28 | PRV | avg model | 31.4 | 3.16 | 9.92 | ||

| Central Arava Valley, Israel | 29 | PRV | avg model | 33.3 | 1.02 | 3.40 | ||

| Central Arava Valley, Israel | 30 | PRV | avg model | 12.5 | 1.94 | 2.42 | ||

| Central Arava Valley, Israel | 31 | PRV | avg model | 41.7 | 2.45 | 10.2 | ||

| Central Arava Valley, Israel | 32 | PRV | avg model | 41.7 | 0.20 | 0.85 | ||

| Central Arava Valley, Israel | 33 | PRV | avg model | 46.9 | 0.10 | 0.48 | ||

| Central Arava Valley, Israel | 34 | PRV | avg model | 86.7 | 4.39 | 38.0 | ||

| Central Arava Valley, Israel | 35 | PRV | avg model | 57.2 | 1.12 | 6.42 | ||

| Central Arava Valley, Israel | 36 | PRV | avg model | 57.2 | 0.10 | 0.58 | ||

| [54] | Pato Branco, Brasil | 37 | PRV | avg | 19.6 | 3.13 | 6.15 | |

| Pato Branco, Brasil | 38 | PRV | avg | 23.8 | 0.20 | 0.47 | ||

| Pato Branco, Brasil | 39 | PRV | avg | 12.6 | 1.37 | 1.72 | ||

| Pato Branco, Brasil | 40 | PRV | avg | 19.6 | 2.84 | 5.58 | ||

| Pato Branco, Brasil | 41 | PRV | avg | 19.6 | 5.68 | 11.2 | ||

| Pato Branco, Brasil | 42 | PRV | avg | 19.7 | 1.47 | 2.89 | ||

| Pato Branco, Brasil | 43 | PRV | avg | 8.1 | 6.17 | 4.97 | ||

| Pato Branco, Brasil | 44 | PRV | avg | 19.6 | 2.06 | 4.04 | ||

| Pato Branco, Brasil | 45 | PRV | avg | 19.6 | 2.25 | 4.43 | ||

| Pato Branco, Brasil | 46 | PRV | avg | 19.6 | 3.33 | 6.54 | ||

| Pato Branco, Brasil | 47 | PRV | avg | 28.3 | 6.56 | 18.6 | ||

| Pato Branco, Brasil | 48 | PRV | avg | 19.6 | 2.94 | 5.77 | ||

| Pato Branco, Brasil | 49 | PRV | avg | 19.6 | 3.43 | 6.73 | ||

| Pato Branco, Brasil | 50 | PRV | avg | 19.6 | 4.31 | 8.47 | ||

| Pato Branco, Brasil | 51 | PRV | avg | 19.6 | 7.35 | 14.4 | ||

| Pato Branco, Brasil | 52 | PRV | avg | 19.7 | 2.35 | 4.62 | ||

| Pato Branco, Brasil | 53 | PRV | avg | 28.3 | 3.04 | 8.59 | ||

| Pato Branco, Brasil | 54 | PRV | avg | 95.1 | 3.04 | 28.9 | ||

| Pato Branco, Brasil | 55 | PRV | avg | 19.6 | 4.11 | 8.08 | ||

| Pato Branco, Brasil | 56 | PRV | avg | 19.7 | 3.72 | 7.31 | ||

| [55] | Kozani, Greece | 57 | PRV | avg model | 22.1 | 2.77 | 6.11 | |

| Kozani, Greece | 58 | PRV | avg model | 55.8 | 3.25 | 18.1 | ||

| Kozani, Greece | 59 | PRV | avg model | 12.6 | 2.48 | 3.13 | ||

| Kozani, Greece | 60 | PRV | avg model | 24.1 | 3.59 | 8.65 | ||

| Kozani, Greece | 61 | PRV | avg model | 13.1 | 2.51 | 3.29 | ||

| Kozani, Greece | 62 | PRV | avg model | 10.2 | 3.11 | 3.18 | ||

| Kozani, Greece | 63 | PRV | avg model | 8.26 | 3.40 | 2.81 | ||

| Data by water utilities | Switzerland | 64 | PRV | avg | 2.0 | 4.31 | 0.86 | |

| Romania | 65 | PRV | avg | 1.25 | 0.40 | 0.05 | ||

| Romania | 66 | PRV | avg | 19.4 | 0.20 | 0.39 | ||

| Belluno, Italy | 67 | PRV | avg | 11.3 | 1.21 | 1.37 | ||

| Piemonte, Italy | 68 | PRV | avg model | 4.50 | 3.56 | 1.60 | ||

| Piemonte, Italy | 69 | PRV | avg model | 2.00 | 6.65 | 1.33 | ||

| Emilia Romagna, Italy | 70 | PRV | avg | 4.14 | 2.18 | 0.90 | ||

| Emilia Romagna, Italy | 71 | PRV | avg | 13.0 | 1.54 | 2.01 | ||

| Emilia Romagna, Italy | 72 | PRV | avg | 5.30 | 2.50 | 1.33 | ||

| Emilia Romagna, Italy | 73 | PRV | avg | 1.88 | 3.42 | 0.64 | ||

| Emilia Romagna, Italy | 74 | PRV | avg | 1.68 | 4.52 | 0.76 | ||

| Emilia Romagna, Italy | 75 | PRV | avg | 10.3 | 4.69 | 4.83 | ||

| Emilia Romagna, Italy | 76 | PRV | avg | 7.88 | 1.11 | 0.87 | ||

| Emilia Romagna, Italy | 77 | PRV | avg | 5.15 | 1.42 | 0.73 | ||

| Lombardia, Italy | 78 | PRV | avg | 27.9 | 12.8 | 35.5 | ||

| Lombardia, Italy | 79 | PRV | avg | 45.8 | 12.8 | 58.4 | ||

| Lombardia, Italy | 80 | PRV | avg | 4.30 | 16.2 | 6.95 | ||

| Lombardia, Italy | 81 | PRV | avg | 3.67 | 1.96 | 0.72 | ||

| Lombardia, Italy | 82 | PRV | avg | 22.8 | 1.96 | 4.47 | ||

| Lombardia, Italy | 83 | PRV | avg | 24.6 | 5.00 | 12.3 | ||

| Lombardia, Italy | 84 | PRV | avg | 8.40 | 7.84 | 6.59 | ||

| Lombardia, Italy | 85 | PRV | avg | 28.4 | 4.90 | 13.9 | ||

| Lombardia, Italy | 86 | PRV | avg | 10.3 | 14.7 | 15.1 | ||

| Lombardia, Italy | 87 | PRV | avg | 24.5 | 4.41 | 10.8 | ||

| Lombardia, Italy | 88 | PRV | avg | 19.0 | 8.40 | 16.0 | ||

| Lombardia, Italy | 89 | PRV | avg | 4.50 | 1.70 | 0.77 | ||

| Lombardia, Italy | 90 | PRV | avg | 4.50 | 4.40 | 1.98 | ||

| Lombardia, Italy | 91 | PRV | avg | 7.00 | 4.00 | 2.80 | ||

| Lombardia, Italy | 92 | PRV | avg | 6.00 | 13.0 | 7.80 | ||

| Lombardia, Italy | 93 | PRV | avg | 6.00 | 1.10 | 0.66 | ||

| Lombardia, Italy | 94 | PRV | avg | 20.0 | 1.20 | 2.40 | ||

| Lombardia, Italy | 95 | PRV | avg | 30.1 | 4.77 | 14.4 | ||

| Lombardia, Italy | 96 | PRV | avg | 57.1 | 3.44 | 19.7 | ||

| Lombardia, Italy | 97 | PRV | avg | 16.8 | 0.50 | 0.84 | ||

| Lombardia, Italy | 98 | PRV | avg | 10.7 | 1.00 | 1.07 | ||

| Lombardia, Italy | 99 | PRV | avg | 44.3 | 0.6 | 2.81 | ||

| Lombardia, Italy | 100 | PRV | avg | 3.08 | 0.69 | 0.21 | ||

| Lombardia, Italy | 101 | PRV | project | 5.50 | 9.30 | 5.12 | ||

| Lombardia, Italy | 102 | PRV | project | 5.50 | 9.75 | 5.36 | ||

| Lombardia, Italy | 103 | PRV | project | 3.00 | 11.5 | 3.44 | ||

| Lombardia, Italy | 104 | PRV | project | 3.00 | 11.9 | 3.57 | ||

| Lombardia, Italy | 105 | PRV | project | 17.6 | 0.70 | 1.23 | ||

| Lombardia, Italy | 106 | PRV | project | 17.6 | 0.85 | 1.50 | ||

| Lombardia, Italy | 107 | PRV | project | 15.0 | 6.00 | 9.00 |

References

- Abd Rahman, N.; Muhammad, N.S.; Wan Mohtar, W.H.M. Evolution of research on water leakage control strategies: Where are we now? Urban Water J. 2018, 15, 812–826. [Google Scholar] [CrossRef]

- Xu, Q.; Liu, R.; Chen, Q.; Li, R. Review on water leakage control in distribution networks and the associated environmental benefits. J. Environ. Sci. 2014, 26, 955–961. [Google Scholar] [CrossRef]

- Giugni, M.; Fontana, N.; Ranucci, A. Optimal location of PRVs and turbines in water distribution systems. J. Water Resour. Plan. Manag. 2014, 140, 06014004. [Google Scholar] [CrossRef]

- Creaco, E.; Pezzinga, G. Comparison of algorithms for the optimal location of control valves for leakage reduction in WDNs. Water 2018, 10, 466. [Google Scholar] [CrossRef] [Green Version]

- Covelli, C.; Cozzolino, L.; Cimorelli, L.; Della Morte, R.; Pianese, D. Optimal Location and Setting of PRVs in WDS for Leakage Minimization. Water Resour. Manag. 2016, 30, 1803–1817. [Google Scholar] [CrossRef] [Green Version]

- Reis, L.F.R.; Porto, R.M.; Chaudhry, F.H. Optimal location of control valves in pipe networks by genbetic algorithms. J. Water Resour. Plan. Manag. 1997, 123, 317–326. [Google Scholar] [CrossRef]

- Tucciarelli, T.; Criminisi, A.; Termini, D. Leak analysis in pipeline system by means of optimal valve regulation. J. Hydraul. Eng. 1999, 125, 277–285. [Google Scholar] [CrossRef]

- Pezzinga, G.; Pititto, G. Combined optimization of pipes and control valves in water distribution networks. J. Hydraul. Res. 2005, 43, 668–677. [Google Scholar] [CrossRef]

- Araujo, L.S.; Ramos, H.; Coelho, S.T. Pressure control for leakage minimisation in water distribution systems management. Water Resour. Manag. 2006, 20, 133–149. [Google Scholar] [CrossRef]

- Nicolini, M.; Zovato, L. Optimal location and control of pressure reducing valves in water networks. J. Water Resour. Plan. Manag. 2009, 135, 13–22. [Google Scholar] [CrossRef]

- Jowitt, B.P.W.; Xu, C. Optimal valve control in water distribution networks. J. Water Resour. Plan. Manag. 1990, 116, 455–472. [Google Scholar] [CrossRef]

- Vairavamoorthy, K.; Lumbers, J. Leakage reduction in water distribution systems: Optimal valve control. J. Hydraul. Eng. 1998, 124, 1146–1154. [Google Scholar] [CrossRef]

- Awad, H.; Kapelan, Z.; Savic, D. Analysis of pressure management economics in water distribution systems. In Proceedings of the 10th Annual Water Distribution Systems Analysis Conference (WDSA2008), Kruger National Park, South Africa, 17–20 August 2008. [Google Scholar]

- Giustolisi, O.; Savic, D.; Kapelan, Z. Pressure-driven demand and leakage simulation for water distribution network. J. Hydraul. Eng. 2008, 134, 625–635. [Google Scholar] [CrossRef] [Green Version]

- Raei, E.; Nikoo, M.R.; Pourshahabi, S.; Sadegh, M. Optimal joint deployment of flow and pressure sensors for leak identification in water distribution networks. Urban Water J. 2018, 15, 837–846. [Google Scholar] [CrossRef]

- Alvisi, S.; Franchini, M. A procedure for the design of district metered areas in water distribution systems. Procedia Eng. 2014, 70, 41–50. [Google Scholar] [CrossRef] [Green Version]

- Giustolisi, O.; Ridolfi, L. New modularity-based approach to segmentation of water distribution networks. J. Hydraul. Eng. 2014, 140, 04014049. [Google Scholar] [CrossRef]

- Ferrari, G.; Savic, D. Economic performance of DMAs in water distribution systems. Procedia Eng. 2015, 119, 189–195. [Google Scholar] [CrossRef] [Green Version]

- Simone, A.; Lucelli, D.; Berardi, L.; Giustolisi, O. Modularity Index for optimal sensor placement in WDNs. In Advances in Hydroinformatics; Philippe, G., Jean, C., Guy, C., Eds.; Springer: Singapore, 2018; pp. 433–446. ISBN 9789811072178. [Google Scholar]

- Page, P.R.; Abu-Mahfouz, A.M.; Yoyo, S. Parameter-Less remote real-time control for the adjustment of pressure in water distribution systems. J. Water Resour. Plan. Manag. 2017, 143, 04017050. [Google Scholar] [CrossRef] [Green Version]

- Campisano, A.; Modica, C.; Reitano, S.; Ugarelli, R.; Bagherian, S. Field-oriented methodology for real-time pressure control to reduce leakage in water distribution networks. J. Water Resour. Plan. Manag. 2016, 142, 04016057. [Google Scholar] [CrossRef]

- Fontana, N.; Giugni, M.; Glielmo, L.; Marini, G.; Verrilli, F. Real-Time control of a PRV in water distribution networks for pressure regulation: Theoretical framework and laboratory experiments. J. Water Resour. Plan. Manag. 2017, 144, 04017075. [Google Scholar] [CrossRef]

- Fontana, N.; Giugni, M.; Glielmo, L.; Marini, G.; Zollo, R. Real-time control of pressure for leakage reduction in water distribution network: Field experiments. J. Water Resour. Plan. Manag. 2018, 144, 04017096. [Google Scholar] [CrossRef]

- Page, P.; Creaco, E. Comparison of flow-dependent controllers for remote real-time pressure control in a water distribution system with stochastic consumption. Water 2019, 11, 422. [Google Scholar] [CrossRef] [Green Version]

- Sammartano, V.; Aricò, C.; Carravetta, A.; Fecarotta, O.; Tucciarelli, T. Banki-Michell optimal design by computational fluid dynamics testing and hydrodynamic analysis. Energies 2013, 6, 2362–2385. [Google Scholar] [CrossRef]

- Sinagra, M.; Sammartano, V.; Aricò, C.; Collura, A.; Tucciarelli, T. Cross-Flow turbine design for variable operating conditions. Procedia Eng. 2014, 70, 1539–1548. [Google Scholar] [CrossRef] [Green Version]

- Chapallaz, J.M.; Eichenberg, P.; Fisher, G. Manual on Pumps Used As Turbines. In Harnessing Water Power on Small Scale; Vieweg: Braunschweig, Germany, 1992; Volume 11, p. 221. [Google Scholar]

- Carravetta, A.; del Giudice, G.; Fecarotta, O.; Ramos, H.M. PAT design strategy for energy recovery in water distribution networks by electrical regulation. Energies 2013, 6, 411–424. [Google Scholar] [CrossRef] [Green Version]

- Carravetta, A.; Fecarotta, O.; Ramos, H.M. A new low-cost installation scheme of PATs for pico-hydropower to recover energy in residential areas. Renew. Energy 2018, 125, 1003–1014. [Google Scholar] [CrossRef]

- Malavasi, S.; Rossi, M.M.A.; Ferrarese, G. GreenValve: Hydrodynamics and applications of the control valve for energy harvesting. Urban Water J. 2018, 15, 200–209. [Google Scholar] [CrossRef]

- The International Electrotechnical Commission IEC 60534.2.1 Industrial Process Control Valves—Part 2.1: Flow Capacity—Sizing Equations for Fluid Flow under Installed Conditions, 2nd ed.; IEC: Geneva, Switzerland, 2011; ISBN 9782889123995.

- Corcoran, L.; Coughlan, P.; McNabola, A. Energy recovery potential using micro hydropower in water supply networks in the UK and Ireland. Water Sci. Technol. Water Supply 2013, 13, 552–560. [Google Scholar] [CrossRef]

- CSA. Available online: www.csasrl.it (accessed on 29 May 2020).

- Apollovalves. Available online: www.apollovalves.com (accessed on 29 May 2020).

- Flomatic. Available online: www.flomatic.com (accessed on 29 May 2020).

- WATTS. Available online: www.watts.com (accessed on 29 May 2020).

- Honeywell. Available online: www.honeywell.com (accessed on 29 May 2020).

- Lalonde, A.M. Use of flow modulated pressure management in York Region, Ontario, Canada. Proc. Leakage 2005, 2026, 1–9. [Google Scholar]

- Shepherd, M. Reducing Non-Revenue Water in the Durban Central Business District; African Utility Week. Available online: https://www.esi-africa.com/wp-content/uploads/Mark_Shepherd.pdf (accessed on 29 May 2020).

- Strum, R.; Thorton, J. Proactive leakage management using district metered areas (DMA) and pressure management–Is it applicable in North America. In Proceedings of the IWA Leakage 2005 Conference, Halifax, NS, Canada, 12–14 September 2005; pp. 1–13. [Google Scholar]

- Yates, C. Pressure Management—Not Your Father’s Approach. In Proceedings of the IWA Water Loss Control Conference, Cape Town, South Africa, 8 May 2018. [Google Scholar]

- Fantozzi, M.; Calza, F.; Kingdom, A. Introducing advanced pressure management at Enia utility (Italy): Experience and results achieved. In Proceedings of the IWA Water Loss Conference, San Paolo, Brazil, June 2010; Available online: http://www.miya-water.com/fotos/artigos/introducing_advanced_pressure_management_at_enia_utility_italy_experience_and_results_achieved_6466516865a3002110bf05.pdf (accessed on 29 May 2020).

- Paskalev, A.; Ivanov, S.; Tanev, M. Water loss reduction in Razgrad demonstrative project through active leakage control, pressure management and the relationship between pressure management and leakage: The case of Kooperative Pazar DMA. Water Util. J. 2011, 2, 3–21. [Google Scholar]

- Ristovski, B. Pressure management and active leakage control in particular DMA (Lisiche) in the city of Skopje, FYROM. Water Util. J. 2011, 2, 45–49. [Google Scholar]

- Fontana, N.; Giugni, M.; Portolano, D. Losses reduction and energy production in water-distribution networks. J. Water Resour. Plan. Manag. 2011, 138, 237–244. [Google Scholar] [CrossRef]

- Wright, R.; Stoianov, I.; Parpas, P. Dynamic topology in water distribution networks. Procedia Eng. 2014, 70, 1735–1744. [Google Scholar] [CrossRef] [Green Version]

- Parra, S.; Krause, S. Pressure management by combining pressure reducing valves and pumps as turbines for water loss reduction and energy recovery. Int. J. Sustain. Dev. Plan. 2017, 12, 89–97. [Google Scholar] [CrossRef]

- Stokes, J.R.; Horvath, A.; Sturm, R. Water loss control using pressure management: Life-cycle energy and air emission effects. Environ. Sci. Technol. 2013, 47, 10771–10780. [Google Scholar] [CrossRef]

- Wyeth, G.; Chalk, R. Delivery of 30 Ml/d leakage reduction through intelligent pressure control. In Proceedings of the IWA International Specialized Conference Water Loss, Hague, The Netherlands, 26–29 February 2012. [Google Scholar]

- Gomes, R.; Sousa, J.; Sá Marques, A. The influence of pressure/leakage relationships from existing leaks in the benefits yielded by pressure management. Water Util. J. 2013, 5, 25–32. [Google Scholar]

- Gomes, R.; Marques, A.S.; Sousa, J. Estimation of the benefits yielded by pressure management in water distribution systems. Urban. Water J. 2011, 8, 65–77. [Google Scholar] [CrossRef]

- Gomes, R.; Sá Marques, A.; Sousa, J. Identification of the optimal entry points at District Metered Areas and implementation of pressure management. Urban Water J. 2012, 9, 365–384. [Google Scholar] [CrossRef]

- Cohen, D.; Shamir, U.; Sinai, G. Optimisation of complex water supply systems with water quality, hydraulic and treatment plant aspects. Civ. Eng. Environ. Syst. 2009, 26, 295–321. [Google Scholar] [CrossRef]

- Da Silva, B.L.A.; Lafay, J.M.S.; Tofoli, F.L.; Scartazzini, L.S. Case study: Hydroelectric generation employing the water distribution network in Pato Branco, Brazil. In Proceedings of the Tenth IASTED European Conference on Power and Energy Systems, Creta, Greece, 2–24 June 2011; pp. 50–54. [Google Scholar]

- Patelis, M.; Kanakoudis, V.; Gonelas, K. Combining pressure management and energy recovery benefits in a water distribution system installing PATs. J. Water Supply Res. Technol. AQUA 2017, 66, 520–527. [Google Scholar] [CrossRef] [Green Version]

- Gaius-obaseki, T. Hydropower opportunities in the water industry. Int. J. Environ. Sci. 2010, 1, 392–402. [Google Scholar]

- Colombo, A.; Kleiner, Y. Energy recovery in water distribution systems using microturbines. In Proceedings of the Probabilistic Methodologies in Water and Wastewater Engineering, Toronto, ON, Canada, 23 September 2011; pp. 1–9. [Google Scholar]

- Chacón, M.C.; Díaz, J.A.R.; Morillo, J.G.; McNabola, A. Pump-as-turbine selection methodology for energy recovery in irrigation networks: Minimising the payback period. Water 2019, 11, 149. [Google Scholar] [CrossRef] [Green Version]

- McNabola, A.; Coughlan, P.; Williams, A.P. Energy recovery in the water industry: An assessment of the potential of micro-hydropower. Water Environ. J. 2014, 28, 294–304. [Google Scholar] [CrossRef]

- Malavasi, S. Energy Recovering Flow Control Valve. U.S. Patent Number US9599252B2, 21 March 2017. [Google Scholar]

- Giudicianni, C.; Herrera, M.; di Nardo, A.; Carravetta, A.; Ramos, H.M.; Adeyeye, K. Zero-net energy management for the monitoring and control of dynamically-partitioned smart water systems. J. Clean. Prod. 2020, 252, 119745. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ferrarese, G.; Malavasi, S. Perspectives of Water Distribution Networks with the GreenValve System. Water 2020, 12, 1579. https://doi.org/10.3390/w12061579

Ferrarese G, Malavasi S. Perspectives of Water Distribution Networks with the GreenValve System. Water. 2020; 12(6):1579. https://doi.org/10.3390/w12061579

Chicago/Turabian StyleFerrarese, Giacomo, and Stefano Malavasi. 2020. "Perspectives of Water Distribution Networks with the GreenValve System" Water 12, no. 6: 1579. https://doi.org/10.3390/w12061579

APA StyleFerrarese, G., & Malavasi, S. (2020). Perspectives of Water Distribution Networks with the GreenValve System. Water, 12(6), 1579. https://doi.org/10.3390/w12061579