1. Introduction

Due to the increasing need for irrigation worldwide aimed at enhancing crop yields, the importance of sustainable water use is attracting ever-increasing attention. Moreover, this trend is gradually moving from dry to relatively wet regions. One potentially applicable, and at the same time constantly available, source of water comprises treated wastewater (WW). While in dry areas the main driver for WW reuse comprises a lack of fresh water [

1,

2], in wet areas environmental concerns related to WW discharge into the environment predominate [

3]. The reclamation of WW is considered a sustainable practice towards a circular water economy and has the potential to solve several problems simultaneously. Moreover, wastewater is favorably regarded in terms of its nutritious value which allows its use as an alternative type of fertilizer able to enhance crop productivity [

4]. However, WW reuse in agriculture also presents a number of significant risks linked principally to the presence of pathogenic microorganisms and their potential spread to crops and the environment [

5], an increase in bacteria antibiotic resistance in irrigated soil [

6,

7] and the presence of various organic pollutants such as pharmaceuticals [

8] and per- and polyfluoroalkyl substances (PFAS) [

9] in the WW even following treatment. Therefore, a well-proved WW treatment approach must be in place prior to its use for field irrigation purposes.

Due to the high level of the removal efficiency of organic pollutants, nutrients, pathogenic bacteria [

10] and micropollutants, hybrid constructed wetlands (HCW) have the potential to offer an attractive solution to the treatment of WW for reclamation purposes [

11]. HCW are a nature-based solution for wastewater management and are generally characterized as sustainable systems that provide effective treatment combined with a minimum environmental footprint and a series of ecosystem services [

12]. The use of HCW for the treatment of various types of complex wastewaters commenced at the end of the 20th century [

13]. The main principle of hybrid systems is that they combine various types of constructed wetlands placed in series, thus enabling them to effectively treat several types of wastewater, e.g., domestic wastewater [

14], livestock production wastewater [

15,

16], mixed domestic and agro-industrial wastewater [

17], grey water [

18] and agricultural runoff polluted with pesticides [

19]. They have also proved effective in the successful treatment of WW containing organic micropollutants [

20] and pharmaceutical and personal care products (PPCPs) [

21]. In addition, the nutrients that remain following the treatment of WW have the potential to serve for the fertilization of crops [

4,

22].

This study focused on the operational efficiency of a full-scale HCW that is intermittently loaded with high volumes of moderately-polluted mixed WW discharged from a hotel, a restaurant and a brewery and the sequential reuse of the treated WW for the irrigation of various types of crops. The aim of the research was to determine whether such hybrid systems can be used as the final stage of the WW treatment procedure for the reclamation of water in the agricultural sector, fully respecting the various inherent risks (primarily microbial contamination) and taking into account the potential to make use of the nutritious value of the treated WW.

2. Materials and Methods

2.1. Hybrid System Description

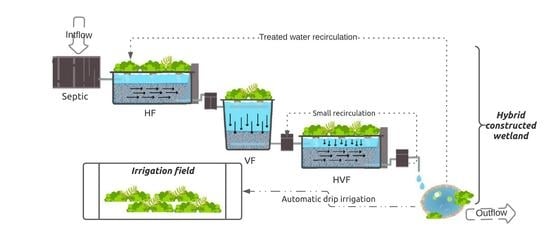

The investigated hybrid system is located at Kostelec nad Ohří in the North Bohemia region of the Czech Republic. The HCW receives high volumes of moderately-polluted mixed WW from a hotel, a restaurant and a brewery. The system consists of 5 treatment stages: (i) a septic tank, (ii) a horizontal filter (HF), (iii) a vertical filter (VF), (iv) a combined filter consisting of an unsaturated vertically-flowed part and a saturated horizontally flowed part (HVF) and (v) stabilization pond (SP). The layout of the study location is in

Figure 1.

At the beginning of the operation of the HCW (hereafter start-up), the VF and HVF were operated in a fully saturated regime and thus anaerobic processes in the whole HCW were prevailing. The reconstruction of the hybrid system was performed at the end of 2017 and consisted of the introduction of the recirculation system and a change of the water filling regime at the VF and HVF. The newly introduced recirculation pump pumps the water from the SP to the HF with approximately 2 L·s−1 flow to prolong water retention in the whole system and also to retain the water under the anaerobic conditions of the HF for a longer time. The VF was equipped with a control shaft with a special dosing device that discontinuously doses ~1.5 m3 of the WW each time the shaft becomes full. WW level in the VF was also decreased so the aerobic conditions could take place. Finally, the HVF was also equipped with the control shaft with a special dosing device that discontinuously doses ~1.5 m3 of the WW onto the surface of the filter. The outlet pipe of the HVF is located approximately in the middle of the depth of the filter, thus resulting in the upper half of the filter being unsaturated (aerobic conditions) and the lower half being saturated (anaerobic conditions). Moreover, a small recirculation pump was installed in the outlet shaft for the recycling of a part of the water (~0.5 L·s−1) back into the dosing shaft. The HCW has been in “full operation” since the beginning of 2018.

The calculated maximal treatment capacity of the system is 150 population equivalent (PE) with a maximal daily wastewater inflow of 16.5 m

3·d

−1. The wetland surface area of the hybrid system is 2.2 m

2·PE

−1. The HCW basins are planted with common reed (

Phragmites australis), reed canary grass (

Phalaris arundinacea), common cattail (

Typha latifolia), purple loosestrife (

Lythrum salicaria) and yellow iris (

Iris pseudacorus). More details on the treatment system are provided in

Table 1.

Table 2 shows the limits for the quality of discharged wastewater. These limits are stricter in comparison with national legislation (Government Regulation No. 401/2015 Coll.) due to the permission to spray treated water on the operator’s land. However, no limits are set for microbiological indicators and no national legislation imposes such limits.

2.2. Design of the Experimental Irrigation System

The experimental irrigation system was constructed and put into operation at the beginning of 2018 following the commencement of the full operation of the HCW. Two sources of water were used for the experiments—fresh water from a well (hereinafter fresh water) and treated wastewater (treated WW) from the HCW collected in the SP.

The experimental field has an area of 49 m

2 (7 × 7 m) and is built so that it is a waterproofed tub using plastic PVC foil with a depth of 0.7 m. The original rendzina soil is located in this area. The initial quality of the soil is summarized in

Table 3.

The experimental area was divided into four 1.5 m-wide plots, of which two were planted with various model crops and two remained unplanted (control). Treated WW and fresh water were each applied to one of the planted and one of the unplanted plots, thus creating four differing treatment areas. Four drainage pipes connected to the sampling shafts were positioned so as to collect any excess water that collected beneath the plots. An irrigation control system fitted with a Hunter I-Core (Hunter Industries Inc., San Marcos, CA, USA) control unit was installed in the service building adjacent to the field so as to ensure the automatic application of the irrigation water to the plots independently. The control system was equipped with a rain sensor that automatically shut down the irrigation system in the event of rainfall (sensors lower limit >3 mm), the aim of which was to prevent the leakage of nutrients and, potentially, pathogenic microorganisms and hazardous substances into the drainage system and, further, to the surface water. The control system was connected to two water pumps (DAB Pumps, Mestrino, Italy) intended for the pumping of the water sources into the drip irrigation system. The pumps were equipped with 1″ disk filters so as to prevent the clogging of the drippers. Drip irrigation hoses were installed in each section of the irrigation field in the form of three parallel lines. The spacing of the drippers was set at 40 cm, which also determined the distance between the planted crops in the 2 planted plots. The plants were irrigated between June and October in both seasons.

The experimental field was planted with common garden crops, one variety of each. In 2018 tomatoes (Solanum lycopersicum L.), the TORO F1 variety, were planted, whereas in 2019, three crops were planted; tomatoes (Solanum lycopersicum L.), the Tornado variety; potatoes (Solanum tuberosum), the Rosara variety; and lettuces (Lactuca sativa L.), the Capitate variety.

2.3. Crop Sampling and Harvesting

Each crop was harvested and sampled according to its maturation characteristics. The tomatoes were harvested at the fully red stage of maturity between August and September, following which they were transported in a cooling box to the laboratory. The harvesting procedure included a mixture of the mature tomatoes, and the weight of the harvest and number of tomatoes were recorded. After each harvest, three mixed samples (replicas) per treatment, each containing at least 3 randomly-picked tomatoes and each collected from different plants were analysed in terms of the pre-determined parameters. During seasons 2018 and 2019, 12 mixed samples (72 tomatoes) and 24 mixed samples (135 tomatoes), respectively were analysed for the selected parameters.

The potatoes were harvested in September 2019. The whole harvest of potatoes was mechanically cleaned of soil and three mixed samples from each variant containing five potatoes from randomly-selected plants were dispatched for microbial contamination testing. The number of potatoes and the weight of the harvest were calculated following cleaning with tap water. The weight of the previously collected samples was then added to the sum. A further three mixed samples were then prepared from randomly-picked potatoes from each variant for the completion of the analysis.

The lettuces from each treatment were harvested in June 2019. The above-ground biomass was weighed and three samples per treatment were prepared for analysis in the form of three mixed samples containing randomly picked parts from each plant.

2.4. Laboratory Analysis

2.4.1. Water Source Quality

The performance of the HCW system was evaluated based on samples extracted regularly every two months from three sampling points—the inlet to the septic tank (In), the outlet from the HVF (Out) and a mixed sample from the stabilization pond (SP). No inlet samples were taken at the start of operation. Fresh water from the well was collected from the pumping reservoir. Composite water samples collected over two hours were stored at 10 °C prior to the analysis. The chemical oxygen demand (COD, mg·L

−1) was measured using the dichromate method following ISO guideline 6060 [

23]. The biochemical oxygen demand (BOD

5, mg·L

−1) was measured following ISO guidelines 5815-1 [

24] and 5815-2 [

25]. The total phosphorus (TP, mg·L

−1) was measured using the ammonium molybdate spectrometric method following ISO guideline 6878 [

26]. The total nitrogen (TN, mg·L

−1) was measured following European norm EN 12,260 [

27]. The ammonia nitrogen (NH

4+–N, mg·L

−1) was measured by means of the manual spectrometric method following ISO guideline 7150 [

28]. The suspended solids (TSS, mg·L

−1) were measured via filtration through glass-fibre filters with pore size 1.5 µm following ISO guideline 11923:1997 [

29]. The following parameters were evaluated in order to describe the microbial contamination of the water sources: total coliforms (TC, CFU·mL

−1), thermotolerant coliforms (TTC, CFU·mL

−1) and

Escherichia coli (EC, CFU·mL

−1), each determined following Czech norm ČSN 75 7837 [

30]. Intestinal enterococci (IE, CFU·mL

−1) was determined following ISO guideline 7899-2 [

31].

2.4.2. Plant Analysis

The harvested plants and fruit were cut on a sterile surface under a laminar airflow hood. The following parameters were determined for all the collected samples: the number of plants/fruit, the weight of the harvest, the weight of the plants/fruit and the dry matter content (DM, %) using the gravimetric method following drying at 60 °C to a constant weight. Some of the samples were tested for microbial contamination; the total coliforms (TC, CFU·g

−1DM), thermotolerant coliforms (TTC, CFU·g

−1DM),

Escherichia coli (EC, CFU·g

−1DM) and intestinal enterococci (IE, CFU·g

−1DM) were determined using a modified version of the determination method in water mentioned above. The modification of the method comprised the preparation of a leachate from 90 mL of sterile physiological solution in tap water and 10 ± 0.5 g of the sample. The resulting suspension was shaken intensively, allowed to settle for 5 min and then analysed. The results took into account the dilution ratios. The rest of the biomass samples were tested for total nitrogen (TN, mg·kg

−1) via the determination of the TN content by means of combustion according to the Dumas principle (ISO guideline 16634:2) [

32], and total phosphorus (TP, mg·kg

−1) and potassium (TK, mg·kg

−1) via the determination of selected elements by means of inductively coupled plasma optical emission spectrometry following ISO guideline 11885 [

33] following homogenization and mineralization in hydrogen peroxide and acids.

2.5. Statistical Analysis

The results were statistically evaluated using R software, version 4.0.2. The comparison of the HCW removal efficiency was tested by means of non-parametric Kruskall–Wallis tests with evaluation at the p = 0.05 level.

4. Discussion

The main aim of this study was to describe the potential of hybrid constructed wetlands for the non-potable reuse of treated wastewater in the agriculture sector. The inlet and outlet concentrations of six chemical parameters and three microbiological parameters were studied for the assessment of the efficiency of an HCW in terms of purifying wastewater to the stage at which it can be used for irrigation purposes. Hence, an experimental field was established and used for the irrigation of selected crops (tomatoes, potatoes and lettuce), the results of which allowed for the description of both the fertilizing effect of the treated WW and the potential hygiene risks.

Wastewater reclamation is one of a number of non-conventional solutions being considered worldwide aimed at easing water scarcity issues caused by climate change [

37]. In decentralized semi-arid and arid areas particularly, where wastewater makes up a considerable percentage of irrigation water [

38], it is important that simple but effective wastewater treatment technologies are developed. Responsible treatment approaches assist in mitigating the risks associated with the application of WW to the soil [

39] and, moreover, the reuse of wastewater effluents helps in the recycling of nutrients and the protection of water bodies [

40]. It is very important to carefully consider the irrigation method applied. In this study, the drip irrigation approach was applied, which is both efficient and uses only around half the water required by other conventional methods [

41].

While many countries worldwide are adopting diverse legal limits for the minimum quality of water used for irrigation [

42], the European Commission is proposing to harmonize the rules applied within the EU via the implementation of Regulation of the European Parliament and of the Council on minimum requirements for water reuse 2018/0169/COD [

43]. According to this regulatory proposal, minimum reclaimed water quality will be divided into classes defined by crop category and based on the form of consumption (raw, boiled) as well as the potential for direct contact with the wastewater (Table 1 of the regulation proposal [

43]). The existing Czech standard [

36], which regulates the quality of irrigation water, does not consider the use of treated wastewater. For this reason this study assessed the performance of the HCW according to the proposed EU regulation.

The studied hybrid constructed wetland evinced a high level of organic pollution removal efficiency. The removal of BOD

5 and COD amounted to 99.0 ± 0.9% and 91.4 ± 6.4%, respectively, which is comparable to other hybrid systems with horizontal and vertical filters in series with reported [

44] removal efficiency levels of BOD

5 of 92.7 ± 10.3% and of COD 88.8 ± 10.2%. The high organic pollution removal rate was ensured by employing unsaturated vertical filters and the simple recirculation of the wastewater; however, the separate effects of these two factors were difficult to distinguish. Total suspended solids were removed at a very high removal rate of 96.0 ± 2.3% and the outlet concentrations corresponded to the results of other studies [

14]. However, the effluent water was observed to be very sensitive to changes in the TSS. We observed a significant increase in TSS concentrations in the stabilization pond due to the growth of algae. This factor thus plays an important role in terms of choosing the most suitable location for the pumping of irrigation water aimed at preventing the clogging of the irrigation distribution system. The outlet BOD

5 and TSS concentrations with respect to full operation were 5.6 ± 5.0 and 7.9 ± 3.8 mg·L

−1, which means that the water quality met A class reclaimed water quality requirements as set out in the relevant regulation [

43]. However, the irrigation water considered in the study was pumped from the SP, where the BOD

5 and TSS concentrations were 23.3 ± 27.4 and 101.0 ± 109.1 mg·L

−1, respectively. In this case, the WW met the requirements of the C-D quality class, concerning which limits are set according to EU Council directive 91/271/EEC: a limit value for BOD

5 of <25 mg·L

−1 and for TSS 35–60 mg·L

−1. Thus, we recommend the extraction of irrigation water directly from the outflow and not from the stabilization pond.

The removal of nitrogen comprises one of the most important advantages of hybrid systems. Moreover, this parameter is not limited solely to reclamation. Ammonia nitrogen, which made up 85% of TN, was removed at a 97.4 ± 2.0% efficiency rate, while the TN removal was just 86.3 ± 11.2%. At the same time, N–NH

4+ made up just 26% of TN at the outlet. Our findings in this respect are higher than those determined in other published hybrid system studies [

45,

46], in which removals of 83–89% and 78–83% for N–NH

4+ and TN, respectively have been reported. The results remain, however, significantly higher than those obtained from traditional horizontal sub-surface flow CWs with reported removals of N–NH

4+ and of TN of just 40.4% and 33.9%, respectively [

47]. Our results clearly show that unsaturated filters with aerobic conditions comprise the most important factor in terms of the efficient removal of nitrogen [

11]. Moreover, the oxidation of the N–NH

4+ in the HCW led to the creation of other nitrogen forms that provided mixtures of nitrate and ammonia that are more beneficial to plant growth [

48].

Generally, the removal of TP by constructed wetlands is limited. Vymazal (2013) [

44] reported the removal of TP in similar hybrid systems of 74 ± 13%, while our study determined a removal of TP of 86.3 ± 11.2%. Moreover, the removal of TP was independent of the configuration of the components of the HCW. The outlet concentrations of TP were determined at 4.5 ± 4.3 mg·L

−1 which, if limited, do not fulfil the required standards for the discharge of wastewater. However, for the purpose of the reuse of non-potable wastewater, the remaining nutrient concentrations provide a number of benefits, especially if one considers WW reclamation as an alternative to other biological and chemical resource recovery technologies such as microalgae, macrophyte, struvite, etc. [

49].

An important parameter that points to the advantage of this technology is the low acquisition and operating costs compared to conventional systems. As part of the evaluation of the operation of the HCW system, the costs for the acquisition and operation of the treatment plant were calculated. With an estimated useful life of 30 years, the total annual cost (capital and O&M) is 4026 €. This corresponds to an annual cost of 26.8 € per PE or 0.67 € per m

3 of treated water. These are operating costs comparable to other CW systems. Tsihrintzis et al. (2007) [

50], for example, states the operating costs of the free water surface system at 22.7 € per PE, while for the vertical subsurface flow CW it states a cost of 36.8 € per PE. Thus, implementation of modern hybrid CWs do not represent significantly higher operating costs.

The removal of pathogens comprises one of the most important factors in terms of reclamation. Many authors have reported removal rates for pathogens in constructed wetlands of as high as 99.99% [

51]. This study revealed a removal efficiency of 99.5% at the outlet, with similar results in the stabilization pond for

Escherichia coli, i.e., 95.4%, for intestinal enterococci, 95.7%, and 99.4% and 97.8% for the thermotolerant coliforms. The outlet concentrations of EC, IE and TTC were determined at 44.09, 1.55 and 73.00 CFU·mL

−1, respectively and the SP concentrations of EC, IE and TTC at 47.36, 1.45 and 277.55 CFU·mL

−1, respectively. According to [

43] the HCW effluent fulfils the quality requirements of class C reclaimed water (crops consumed raw, the above-ground edible parts of which are not in direct contact with the reclaimed water when using only the drip irrigation method). Similar or even higher concentrations of pathogens were observed in the reclaimed wastewater studied in [

52], which employed a drip system to irrigate tomatoes, lettuce and fennel with treated municipal wastewater.

The yields of the crops were significantly higher following irrigation with the reclaimed WW, particularly in the second season for the tomato plants. As evinced by other similar studies [

4,

40,

52], the weight of the harvested plants was higher following irrigation with reclaimed WW than with fresh water. Moreover, the yields would probably have been even higher if fertilizers had been used in addition to the nutrients added by the wastewater [

40]. The fact that the amount of nutrients available for the plants did not exceed typical doses of nutrients provided by fertilizers was evident from the content of N, P and K in the crop tissues. In particular, the content of N was at least one order lower than reported in other studies [

40,

53]. Moreover, no significant differences were observed in the N, P and K contents between the plants irrigated with wastewater and those with fresh water. The fecal contamination of the plants was reflected by the content of

E. coli, intestinal enterococci and thermotolerant coliforms on the surface of the plants.

E. coli contamination was proven only in the case of the lettuce plants. However, EC contamination was also detected on the plants irrigated with fresh water. Similarly, we observed the plant surface contamination of the tomatoes, potatoes and lettuce by intestinal enterococci even following irrigation by fresh water. Similar findings for tomatoes and lettuce were reported in [

52,

54] also following the fresh water irrigation of the plants. Such findings thus serve to contextualize the risks associated with the microbial contamination of plants irrigated by wastewater. Nevertheless, it is important to note that these findings also indicate that such plants should not be used without proper washing and cooking, and that reclaimed wastewater should not be used for irrigation purposes when the edible part of the plant may come into contact with the water [

55].