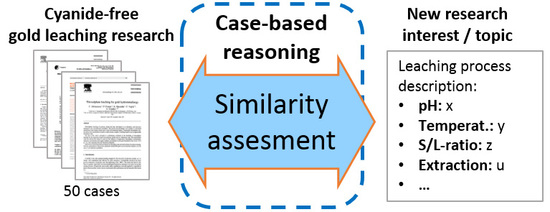

Assessing the Similarity of Cyanide-Free Gold Leaching Processes: A Case-Based Reasoning Application

Abstract

:1. Introduction

2. Methods

2.1. Utilized Software

2.2. Interviewing Technique

2.3. Testing the Improved Model

3. LeachSim Model

3.1. New Attributes

3.2. Case Base

3.3. Local Similarity Models

3.3.1. Method

- Overall method; possibility for several values;

- Complexant source; possibility for several values; and,

- Oxidant source; possibility for several values.

- Overall method: “Chloride”;

- Complexant source: “Sodium chloride NaCl”; and,

- Oxidant source: “Calcium hypochlorite Ca(OCl)2”.

- Overall method: “Thiourea”; “Thiocyanate”

- Overall method: “Dual”

3.3.2. Complexant and Oxidant Concentration

3.3.3. pH and Redox-Potential

3.3.4. Temperature

3.3.5. Extraction

3.3.6. Extraction Rate

3.3.7. Pretreatment

- hydrometallurgical vs. pyrometallurgical;

- suitability for refractory vs. mildly refractory ores;

- suitability for high sulfur content;

- suitability for high carbon content; and,

- pH: acid vs. neutral/alkaline.

3.3.8. Solid-Liquid Ratio

3.3.9. Pressure

3.3.10. Reagent Consumption

3.3.11. Materials of Construction

3.4. Attribute Weights

4. Testing the LeachSim Model

4.1. Preliminary Tests

4.2. Test Queries

- Similar Leaching Methods—A researcher has conducted chloride leaching tests on an ore and is now looking for articles that have used a similar leaching process [5].

- Similar Articles—A researcher has found a particularly interesting research article, in this case bromide leaching of gold. This article’s information is used as a query to find similar articles. [36].

- Pretreatment and Thiourea—A researcher is looking for articles where the gold ore has been pretreated and leached with a thiourea solution, leading to successful results in extraction percentage (equal weights were used for the attributes Pretreatment and Extraction).

- Dual Lixiviant—A researcher is looking for any dual lixiviant systems operating at an acidic pH and at room temperature.

- Industrially Attractive—A researcher wants to find the most industrially attractive thiosulfate articles by minimizing Reagent consumption and Temperature, and by maximizing Solid-liquid ratio, Extraction, and Extraction rate.

4.3. Results and Discussion

5. Conclusions

- Scientific articles in the specific field of cyanide-free gold leaching are suitable to be compared through narrow AI.

- Case-based reasoning is a viable methodology for constructing a knowledge model that compares the scientific articles in a very specific field.

- The LeachSim model is able to sort through and organize scientific articles that are based on the user’s interests/research problem in its given field.

- Similarity assessment and sorting is possible even with incomplete and not exactly matching input data.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A

| Reference to Case Source | No. of Cases |

| 1 |

| 3 |

| 1 |

| 1 |

| 1 |

| 2 |

| 1 |

| 1 |

| 1 |

| 2 |

| 1 |

| 1 |

| 1 |

| 1 |

| 1 |

| 1 |

| 1 |

| 1 |

| 1 |

| 3 |

| 1 |

| 2 |

| 2 |

| 1 |

| 1 |

| 2 |

| 1 |

| 2 |

| 2 |

| 1 |

| 1 |

| 2 |

| 1 |

| 1 |

| 2 |

| 1 |

| 1 |

Appendix B

- Imagine you were designing an experiment series for chloride leaching. If all information from previous research articles was thoroughly organized, what knowledge and parameters would you compare for:

- (i)

- free-milling ore?

- (ii)

- refractory ore?

- What parameters would you like to use for excluding cases from the comparison?

- If you were designing a thiosulfate experiment instead, would it change your answers to questions 1 and 2?

- There is a preliminary model that compares previous research cases based on attributes in this example:

Method Mineral 1 Mineral 2 Gold Content (g/t) Chloride Ankerite Muscovite 1.5 Thiosulfate Arsenopyrite Pyrite 56 Thiosulfate Pyrite 94.63

References

- Hilson, G.; Monhemius, A. Alternatives to cyanide in the gold mining industry: What prospects for the future? J. Clean. Prod. 2006, 14, 1158–1167. [Google Scholar] [CrossRef]

- Senanayake, G. Gold leaching in non-cyanide lixiviant systems: Critical issues on fundamentals and applications. Miner. Eng. 2004, 17, 785–801. [Google Scholar] [CrossRef]

- Choi, Y.; Baron, J.Y.; Wang, Q.; Langhans, J.; Kondos, P. Thiosulfate processing—From lab curiosity to commercial application. In Proceedings World Gold 2013; The Australasian Institute of Mining and Metallurgy: Melbourne, Australia, 2013; pp. 45–50. [Google Scholar]

- Fleming, C.; McMullen, J.; Thomas, K.; Wells, J. Recent advances in the development of an alternative to the cyanidation process: Thiosulfate leaching and resin in pulp. Miner. Metall. Process. 2003, 20, 1–9. [Google Scholar]

- Ghobeiti Hasab, M.; Rashchi, F.; Raygan, S. Chloride–hypochlorite leaching and hydrochloric acid washing in multi-stages for extraction of gold from a refractory concentrate. Hydrometallurgy 2014, 142, 56–59. [Google Scholar] [CrossRef]

- Lampinen, M.; Seisko, S.; Forsström, O.; Laari, A.; Aromaa, J.; Lundström, M.; Koiranen, T. Mechanism and kinetics of gold leaching by cupric chloride. Hydrometallurgy 2017, 169, 103–111. [Google Scholar] [CrossRef]

- Seisko, S.; Lampinen, M.; Aromaa, J.; Laari, A.; Koiranen, T.; Lundström, M. Kinetics and mechanisms of gold dissolution by ferric chloride leaching. Miner. Eng. 2018, 115, 131–141. [Google Scholar] [CrossRef]

- Li, J.; Miller, J.D. A review of gold leaching in acid thiourea solutions. Miner. Process. Extr. Metall. Rev. 2006, 27, 177–214. [Google Scholar] [CrossRef]

- Oraby, E.; Eksteen, J. The leaching of gold, silver and their alloys in alkaline glycine–peroxide solutions and their adsorption on carbon. Hydrometallurgy 2015, 152, 199–203. [Google Scholar] [CrossRef]

- Rintala, L.; Leikola, M.; Sauer, C.; Aromaa, J.; Roth-Berghofer, T.; Forsén, O.; Lundström, M. Designing gold extraction processes: Performance study of a case-based reasoning system. Miner. Eng. 2017, 109, 42–53. [Google Scholar] [CrossRef]

- Rintala, L.; Lillkung, K.; Aromaa, J. The use of decision and optimization methods in selection of hydrometallurgical unit process alternatives. Physicochem. Probl. Miner. Process. 2011, 46, 229–242. [Google Scholar]

- Liang, Y.; Wang, H.; Xu, A.; Tian, N. A Two-step Case-based Reasoning Method Based on Attributes Reduction for Predicting the Endpoint Phosphorus Content. ISIJ Int. 2015, 55, 1035–1043. [Google Scholar] [CrossRef] [Green Version]

- Feng, K.; He, D.; Xu, A.; Wang, H. End temperature prediction of molten steel in RH based on case-based reasoning with optimized case base. J. Iron Steel Res. Int. 2015, 22, 68–74. [Google Scholar] [CrossRef]

- Zhang, Z.; Chen, D.; Feng, Y.; Yuan, Z.; Chen, B.; Qin, W.; Zou, S.; Qin, S.; Han, J. A strategy for enhancing the operational agility of petroleum refinery plant using case based fuzzy reasoning method. Comput. Chem. Eng. 2018, 111, 27–36. [Google Scholar] [CrossRef]

- Qi, J.; Hu, J.; Peng, Y. A modularized case adaptation method of case-based reasoning in parametric machinery design. Eng. Appl. Artif. Intell. 2017, 64, 352–366. [Google Scholar] [CrossRef]

- Aamodt, A.; Plaza, E. Case-based reasoning: Foundational issues, methodological variations, and system approaches. AI Commun. 1994, 7, 39–59. [Google Scholar] [CrossRef]

- Stahl, A.; Roth-Berghofer, T.R. Rapid prototyping of CBR applications with the open source tool myCBR. In Advances in Case-Based Reasoning: Proceedings of the European Conference on Case-Based Reasoning, Trier, Germany, 1–4 September 2008; Althoff, K., Bergmann, R., Minor, M., Hanft, A., Eds.; Lecture Notes in Computer Science 5239; Springer: Berlin/Heidelberg, Germany, 2008; pp. 615–629. [Google Scholar]

- Leikola, M.; Rintala, L.; Sauer, C.; Roth-Berghofer, T.; Lundström, M. Applicability of Case-Based Reasoning for Selection of Cyanide-Free Gold Leaching Methods. In Case-Based Reasoning Research and Development, Proceedings of the 24th International Conference on Case-Based Reasoning (ICCBR 2016), Atlanta, GA, USA, 31 October–2 November 2016; Goel, A., Díaz-Agudo, M.B., Roth-Berghofer, T., Eds.; Lecture Notes in Computer Science 9969; Springer: Berlin/Heidelberg, Germany, 2016; pp. 249–264. [Google Scholar]

- myCBR 3 Workbench. Available online: http://mycbr-project.net/download.html (accessed on 3 May 2018).

- Sauer, C.S.; Rintala, L.; Roth-Berghofer, T. Two-phased Knowledge Formalisation for Hydrometallurgical Gold Ore process recommendation and validation. Künstliche Intell. 2014, 28, 283–295. [Google Scholar] [CrossRef]

- Rintala, L. Development of a Process Selection Method for Gold Ores Using Case-Based Reasoning; Aalto University Publication Series Doctoral Dissertations 161/2015; Aalto University: Helsinki, Finland, 2015; ISBN 978-952-60-6483-3. [Google Scholar]

- Rogers, Y.; Sharp, H.; Preece, J. Interaction Design: Beyond Human Computer Interaction; John Wiley & Sons: New York, NY, USA, 2002; pp. 392–395. ISBN 978-0-471-49278-8. [Google Scholar]

- Burgess, T.F. Guide to the Design of Questionnaires: A General Introduction to the Design of Questionnaires for Survey Research; Information System Services, University of Leeds: Leeds, UK, 2001. [Google Scholar]

- Guest, G.; Bunce, A.; Johnson, L. How many interviews are enough? An experiment with data saturation and variability. Field Methods 2006, 18, 59–82. [Google Scholar] [CrossRef]

- Glaser, B.; Strauss, A. The Discovery of Grounded Theory: Strategies for Qualitative Research; Aldine Transaction: New Brunswick, NJ, USA, 2006; pp. 61–62. ISBN 0-202-30260-1. [Google Scholar]

- Francis, J.J.; Johnston, M.; Robertson, C.; Glidewell, L.; Entwistle, V.; Eccles, M.P.; Grimshaw, J.M. What is an adequate sample size? Operationalising data saturation for theory-based interview studies. Psychol. Health 2010, 25, 1229–1245. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Baghalha, M. Leaching of an oxide gold ore with chloride/hypochlorite solutions. Int. J. Miner. Process. 2007, 82, 178–186. [Google Scholar] [CrossRef]

- Cheng, Y.; Shen, S.; Zhang, J.; Chen, S.; Xiong, L.; Liu, J. Fast and Effective Gold Leaching from a Desulfurized Gold Ore Using Acidic Sodium Chlorate Solution at Low Temperature. Ind. Eng. Chem. Res. 2013, 52, 16622–16629. [Google Scholar] [CrossRef]

- Zhang, J.; Shen, S.; Cheng, Y.; Lan, H.; Hu, X.; Wang, F. Dual lixiviant leaching process for extraction and recovery of gold from ores at room temperature. Hydrometallurgy 2014, 144–145, 114–123. [Google Scholar] [CrossRef]

- Marsden, J.; House, I. The Chemistry of Gold Extraction, 2nd ed.; Society for Mining, Metallurgy and Exploration, Inc.: Littleton, CO, USA, 2006; pp. 84, 113–121, 132, 147–224, 263, 270. ISBN 978-0-87335-240-6. [Google Scholar]

- Pourbaix, M. Atlas of Electrochemical Equilibria in Aqueous Solutions, 1st ed.; Pergamon Press: Oxford, UK, 1966. [Google Scholar]

- Aylmore, M.G. Alternative lixiviants to cyanide for leaching gold. In Advances in Gold Ore Processing; Adams, M.D., Wills, B.A., Eds.; Elsevier: Amsterdam, The Netherlands, 2005; Volume 15, pp. 501–539. ISBN 978-0-444-51730-2. [Google Scholar]

- Kim, E.; Kim, M.; Lee, J.; Pandey, B. Selective recovery of gold from waste mobile phone PCBs by hydrometallurgical process. J. Hazard. Mater. 2011, 198, 206–215. [Google Scholar] [CrossRef] [PubMed]

- Navarro, P.; Vargas, C.; Villarroel, A.; Alguacil, F. On the use of ammoniacal/ammonium thiosulphate for gold extraction from a concentrate. Hydrometallurgy 2002, 65, 37–42. [Google Scholar] [CrossRef]

- Ubaldini, S.; Fornari, P.; Massidda, R.; Abbruzzese, C. An innovative thiourea gold leaching process. Hydrometallurgy 1998, 48, 113–124. [Google Scholar] [CrossRef]

- Parga, J.R.; Valenzuela, J.L.; Francisco, C.T. Pressure cyanide leaching for precious metals recovery. JOM 2007, 59, 43–47. [Google Scholar] [CrossRef]

- Adams, M.D. Summary of gold plants and processes. In Advances in Gold Ore Processing; Adams, M.D., Wills, B.A., Eds.; Elsevier: Amsterdam, The Netherlands, 2005; Volume 15, pp. 994–1013. ISBN 978-0-444-51730-2. [Google Scholar]

| Included Process Attributes | Number of Mentions | Excluded Process Attributes | Number of Mentions |

|---|---|---|---|

| Complexant concentration | 13 | Price | 3 |

| Temperature | 11 | Time | 3 |

| Extraction percentage | 11 | Recovery after leaching | 3 |

| Oxidant concentration | 8 | Solution preparation method | 2 |

| Reagent consumption | 8 | Solution stability | 2 |

| Extraction rate | 6 | Environmental impact | 1 |

| Solution characteristics | 6 | Safety issues | 1 |

| Pretreatment | 6 | Energy consumption | 1 |

| Solid-liquid ratio | 6 | Possibility for in-situ | 1 |

| pH | 5 | Leaching completion | 1 |

| Redox-potential | 4 | Water balance | 1 |

| Pressure | 4 | Need for bleed treatment | 1 |

| Materials of construction | 4 | Simultaneous oxidation and leaching | 1 |

| Level of technological development, for example, lab/batch/pilot/industrial | 1 |

| Pretreatment | Preaeration | Acidic Pressure Oxidation | Pressure Oxidation | Acid Pretreatment | Chlorination | Biological Oxidation | Roasting | Any | None |

|---|---|---|---|---|---|---|---|---|---|

| Preaeration | 1.0 | 0.4 | 0.6 | 0.4 | 0.4 | 0.2 | 0.0 | 1.0 | 0.0 |

| Acidic Pressure Oxidation | 0.4 | 1.0 | 0.4 | 1.0 | 0.6 | 0.8 | 0.4 | 1.0 | 0.0 |

| Pressure Oxidation | 0.6 | 0.4 | 1.0 | 0.4 | 0.8 | 0.6 | 0.4 | 1.0 | 0.0 |

| Acid Pretreatment | 0.4 | 1.0 | 0.4 | 1.0 | 0.6 | 0.8 | 0.4 | 1.0 | 0.0 |

| Chlorination | 0.4 | 0.6 | 0.8 | 0.6 | 1.0 | 0.8 | 0.4 | 1.0 | 0.0 |

| Biological Oxidation | 0.2 | 0.8 | 0.6 | 0.8 | 0.8 | 1.0 | 0.6 | 1.0 | 0.0 |

| Roasting | 0.0 | 0.4 | 0.4 | 0.4 | 0.4 | 0.6 | 1.0 | 1.0 | 0.0 |

| Any | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 | 0.0 |

| None | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 1.0 |

| Attribute Value | Ambient/Mild Vacuum (atm) | High Pressure (pres) |

|---|---|---|

| Ambient/Mild Vacuum (atm) | 1 | 0 |

| High Pressure (pres) | 0 | 1 |

| Attribute | Query 1—Similar Leaching Methods | Query 2—Similar Articles | Query 3—Pretreatment and Thiourea | Query 4—Dual Lixiviant | Query 5—Industrially Attractive |

|---|---|---|---|---|---|

| Pretreatment | None | Preaeration | Any | ||

| Overall method | Chloride | Bromine-bromide | Thiourea | Dual | Thiosulfate |

| Complexant source | Sodium chloride NaCl | Sodium bromide NaBr | |||

| Oxidant source | Calcium hypochlorite Ca(OCl)2 | Bromine Br2 | |||

| Complexant concentration (M) | 1.6 | 0.02 | |||

| Oxidant concentration (M) | 1.3 | 0.04 | |||

| pH | 6.0 | 1.5 | |||

| Redox-potential (mV vs. SHE) | 650 | 1000 | |||

| Solid-liquid ratio (msolid/mslurry) | 0.15 | 0.3 | 0.6 | ||

| Reagent consumption (kg/t) | 2 | 0 | |||

| Pressure | atm | atm | |||

| Temperature (°C) | 25 | 25 | 25 | 0 | |

| Extraction (%) | 90 | 100 | 100 | ||

| Extraction rate (%/min) | 0.35 | 5 |

| Attribute | Query 1 | 1st | 2nd | 3rd | 5th |

|---|---|---|---|---|---|

| Similarity | 0.95 | 0.93 | 0.84 | 0.81 | |

| Pretreatment | None | None | None | None | None |

| Overall method | Chloride | Chloride | Chloride | Chloride | Chloride |

| Complexant source | Sodium chloride NaCl | Sodium chloride NaCl | Sodium chloride NaCl | Sodium chloride NaCl | Sodium chloride NaCl |

| Oxidant source | Calcium hypochlorite Ca(OCl)2 | Calcium hypochlorite Ca(OCl)2 | Calcium hypochlorite Ca(OCl)2 | Calcium hypochlorite Ca(OCl)2 | Calcium hypochlorite Ca(OCl)2 |

| Complexant concentration (M) | 1.6 | 1.711 | 3.422 | 1.71 | 1.71 |

| Oxidant concentration (M) | 1.3 | 1.399 | 1.399 | 1.749 | 1.749 |

| Redox-potential (mV vs. SHE) | 650 | 600 | 600 | Unknown | Unknown |

| Solid-liquid ratio (msolid/mslurry) | 0.15 | 0.167 | 0.167 | 0.048 | 0.048 |

| Pressure | atm | atm | atm | atm | atm |

| Temperature (°C) | 25 | 70 | 25 | 25 | 65 |

| Reference | Ghobeiti Hasab et al., 2014 ([10] in Appendix A) | Ghobeiti Hasab et al., 2013b ([9] in Appendix A) | Ghobeiti Hasab et al., 2013c ([11] in Appendix A) | Ghobeiti Hasab et al., 2013c ([11] in Appendix A) |

| Attribute | Query 2 | 1st | 2nd | 3rd |

|---|---|---|---|---|

| Similarity | 0.99 | 0.8 | 0.7 | |

| Pretreatment | Preaeration | Preaeration | None | Preaeration |

| Overall method | Bromine-bromide | Bromine-bromide | Bromine-bromide | Bromine-bromide |

| Complexant source | Sodium bromide NaBr | Sodium bromide NaBr | Sodium bromide NaBr | Sodium bromide NaBr |

| Oxidant source | Bromine Br2 | Bromine Br2 | Bromine Br2 | Bromine Br2 |

| Complexant concentration (M) | 0.04 | 0.053 | 0.100 | Unknown |

| Oxidant concentration (M) | 0.02 | 0.010 | 0.047 | Unknown |

| pH | 6.0 | 6.1 | 5.6 | 6 |

| Redox-potential (mV vs. SHE) | 1000 | 1 050 | 980 | 1 060 |

| Solid-liquid ratio (msolid/mslurry) | 0.3 | 0.29 | 0.17 | Unknown |

| Reagent consumption (kg/t) | 2 | 1.45 | 20.3 | 4 |

| Pressure | atm | atm | atm | atm |

| Temperature (°C) | 25 | 22 | 22 | 22 |

| Extraction (%) | 90 | 92.3 | 85.4 | 86.8 |

| Extraction rate (%/min) | 0.35 | 0.384583 | Unknown | 0.060278 |

| Reference | Melashvili et al., 2014 ([20] in Appendix A) | Melashvili et al., 2014 ([20] in Appendix A) | Melashvili et al., 2014 ([20] in Appendix A) |

| Attribute | Query 3 | 1st | 2nd | 3rd | 10th |

|---|---|---|---|---|---|

| Similarity | 0.96 | 0.86 | 0.83 | 0.00 | |

| Pretreatment | Any | Bio-oxidation | Acid leaching | Acid leaching | None |

| Overall method | Thiourea | Thiourea | Thiourea | Thiourea | Thiourea |

| Extraction (%) | 100 | 95 | 83 | 79 | Unknown |

| Reference | Guo et al., 2017 ([12] in Appendix A) | Lacoste-Bouchet et al., 1998 ([17] in Appendix A) | Tremblay et al., 1996 ([28] in Appendix A) | Whitehead et al., 2009 ([31] in Appendix A) |

| Attribute | Query 4 | 1st | 2nd | 3rd |

|---|---|---|---|---|

| Similarity | 0.99 | 0.99 | 0.63 | |

| Method | Dual | Thiourea; Thiocyanate; Dual | Thiourea; Thiocyanate; Dual | Chloride; Bromide; Dual |

| pH | 1.5 | 1.5 | 1.5 | Unknown |

| Temperature (°C) | 25 | 21 | 21 | 40 |

| Reference | Zhang et al., 2014 [29] ([35] in Appendix A) | Zhang et al., 2014 [29] ([35] in Appendix A) | De Michelis et al., 2013 ([5] in Appendix A) |

| Attribute | Query 5 | 1st | 2nd | 3rd | 20th |

|---|---|---|---|---|---|

| Similarity | 0.76 | 0.74 | 0.73 | 0.39 | |

| Overall method | Thiosulfate | Thiosulfate | Thiosulfate | Thiosulfate | Thiosulfate |

| Solid-liquid ratio (msolid/mslurry) | 0.6 | 0.286 | 0.61 | 0.5 | 0.2 |

| Reagent consumption (kg/t) | 0 | 0.03 | 17 | 0.4 | Unknown |

| Temperature (°C) | 0 | 25 | 22 | 22 | 40 |

| Extraction (%) | 100 | 100 | 90 | 83 | 56 |

| Extraction rate (%/min) | 5 | 0.069 | 0.063 | 0.108 | 0.467 |

| Reference | Feng and van Deventer, 2007 ([6] in Appendix A) | Xia et al., 2003 ([32] in Appendix A) | Langhans et al., 1992 ([19] in Appendix A) | Mohammadi et al., 2017 ([21] in Appendix A) |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Leikola, M.; Sauer, C.; Rintala, L.; Aromaa, J.; Lundström, M. Assessing the Similarity of Cyanide-Free Gold Leaching Processes: A Case-Based Reasoning Application. Minerals 2018, 8, 434. https://doi.org/10.3390/min8100434

Leikola M, Sauer C, Rintala L, Aromaa J, Lundström M. Assessing the Similarity of Cyanide-Free Gold Leaching Processes: A Case-Based Reasoning Application. Minerals. 2018; 8(10):434. https://doi.org/10.3390/min8100434

Chicago/Turabian StyleLeikola, Maria, Christian Sauer, Lotta Rintala, Jari Aromaa, and Mari Lundström. 2018. "Assessing the Similarity of Cyanide-Free Gold Leaching Processes: A Case-Based Reasoning Application" Minerals 8, no. 10: 434. https://doi.org/10.3390/min8100434

APA StyleLeikola, M., Sauer, C., Rintala, L., Aromaa, J., & Lundström, M. (2018). Assessing the Similarity of Cyanide-Free Gold Leaching Processes: A Case-Based Reasoning Application. Minerals, 8(10), 434. https://doi.org/10.3390/min8100434