A Fluid-Structure Interaction Method for the Elastohydrodynamic Lubrication Characteristics of Rubber-Plastic Double-Layer Water-Lubricated Journal Bearings

Abstract

:1. Introduction

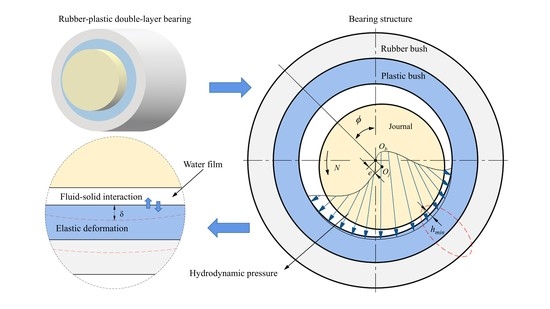

2. Geometry

3. Numerical Analysis

3.1. Water Film Fluid Model

3.2. Bearing Bush Solid Model

3.3. Fluid–Solid Coupling Calculation

4. Results and Discussion

4.1. Performance Comparison

4.2. Effect of Rotational Speed on Bearing Performance

4.3. Effect of Length-to-Diameter Ratio on Bearing Performance

4.4. Effect of Relative Clearance on Bearing Performance

4.5. Effect of Plastic Layer Elastic Modulus on Bearing Performance

4.6. Effect of Plastic Layer Thickness on Bearing Performance

5. Conclusions

- (1)

- The bush deformation of the rubber-plastic double-layer bearing is between those of the rubber bearing and the plastic bearing, and its distribution area is close to that of the rubber bearing. However, the shape change of the double-layer bearing is smaller than that of the rubber bearing due to the larger stiffness of the plastic layer bush.

- (2)

- The maximum pressure, the maximum bush deformation, the load-carrying capacity and friction torque increase noticeably with N, and the variation increases with ε. The load-carrying capacity increases almost linearly with N for small ε values. When ε is more than 0.8, the influence of bush deformation on the minimum water film thickness becomes more significant, and the increase in load-carrying capacity with N slows down.

- (3)

- Under the influence of side leakage, the maximum water film pressure increases significantly with L/D for small L/D values, but as L/D increases, the maximum pressure increases to a certain value. L/D affects the load-carrying capacity and friction torque significantly.

- (4)

- With the increase in ψ, the load-carrying capacity and frictional torque decrease, the maximum bush deformation decreases, and the attitude angle has little changes. The bearing lubrication performance is greatly affected by the bush deformation for small ψ values.

- (5)

- The elastic modulus and thickness of the plastic layer bush mainly affect the bearing lubrication performance under heavy load conditions (ε > 0.8). As E1 and t1 increase, the maximum bush deformation and the minimum water film thickness decrease, and the load-carrying capacity increase. The friction torque and the attitude angle change little.

- (6)

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ouyang, W.; Liu, Q.; Xiao, J.; Huang, J.; Zhang, Z.; Wang, L. Experimental study on the distributed lubrication characteristics of full-size water-lubricated stern bearings under hull deformation. Ocean Eng. 2023, 267, 113226. [Google Scholar] [CrossRef]

- Szlapczynski, R.; Krata, P. Determining and visualizing safe motion parameters of a ship navigating in severe weather conditions. Ocean Eng. 2018, 158, 263–274. [Google Scholar] [CrossRef]

- Xie, Z.; Jiao, J.; Yang, K. Theoretical and experimental study on the fluid-structure-acoustic coupling dynamics of a new water lubricated bearing. Tribol. Int. 2023, 177, 107982. [Google Scholar] [CrossRef]

- Michalec, M.; Svoboda, P.; Křupka, I.; Hartl, M. A review of the design and optimization of large-scale hydrostatic bearing systems. Eng. Sci. Technol. Int. J. 2021, 24, 936–958. [Google Scholar] [CrossRef]

- Nijssen, J.; Faludi, J.; van Ostayen, R. An eco-impact design metric for water lubricated bearings based on anticipatory Life Cycle Assessment. J. Clean. Prod. 2021, 321, 128874. [Google Scholar] [CrossRef]

- Xie, Z.; Jiao, J.; Yang, K.; Zhang, H. A State-of-Art Review on the Water-Lubricated Bearing. Tribol. Int. 2023, 180, 108276. [Google Scholar] [CrossRef]

- Yamajo, S.; Kikkawa, F. PTFE Compound Bearing for Water Lubricated Shaft Systems. In Proceedings of the SNAME 10th Propeller and Shafting Symposium, Virginia Beach, VA, USA, 12–13 September 2003. [Google Scholar] [CrossRef]

- Litwin, W. Experimental research on water lubricated three layer sliding bearing with lubrication grooves in the upper part of the bush and its comparison with a rubber bearing. Tribol. Int. 2015, 82, 153–161. [Google Scholar] [CrossRef]

- Litwin, W. Properties comparison of rubber and three layer PTFE-NBR-bronze water lubricated bearings with lubricating grooves along entire bush circumference based on experimental tests. Tribol. Int. 2015, 90, 404–411. [Google Scholar] [CrossRef]

- Shi, Y.; Li, M.; Zhu, G.; Yu, Y. Dynamics of a rotor system coupled with water-lubricated rubber bearings. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2018, 232, 4263–4277. [Google Scholar] [CrossRef]

- Liu, G.; Li, M. Experimental study on the lubrication characteristics of water-lubricated rubber bearings at high rotating speeds. Tribol. Int. 2021, 157, 106868. [Google Scholar] [CrossRef]

- Qiao, J.; Zhou, G.; Pu, W.; Li, R.; He, M. Coupling analysis of turbulent and mixed lubrication of water-lubricated rubber bearings. Tribol. Int. 2022, 172, 107644. [Google Scholar] [CrossRef]

- Kuznetsov, E.; Glavatskih, S.; Fillon, M. THD analysis of compliant journal bearings considering liner deformation. Tribol. Int. 2011, 4, 1629–1641. [Google Scholar] [CrossRef]

- Wang, Y.; Yin, Z.; Jiang, D.; Gao, G.; Zhang, X. Study of the lubrication performance of water-lubricated journal bearings with CFD and FSI method. Ind. Lubr. Tribol. 2016, 8, 341–348. [Google Scholar] [CrossRef]

- Yang, Z.; Guo, Z.; Yang, Z.; Wang, C.; Yuan, C. Study on tribological properties of a novel composite by filling microcapsules into UHMWPE matrix for water lubrication. Tribol. Int. 2021, 153, 106629. [Google Scholar] [CrossRef]

- Cheng, B.; Duan, H.; Chen, Q.; Shang, H.; Zhang, Y.; Li, J.; Shao, T. Effect of laser treatment on the tribological performance of polyetheretherketone (PEEK) under seawater lubrication. Appl. Surf. Sci. 2021, 566, 150668. [Google Scholar] [CrossRef]

- Balmus, M.; Massing, A.; Hoffman, J.; Razavi, R.; Nordsletten, D.A. A partition of unity approach to fluid mechanics and fluid–structure interaction. Comput. Methods Appl. Mech. Eng. 2020, 362, 112842. [Google Scholar] [CrossRef]

- Burman, E.; Fernández, M.A.; Frei, S.; Gerosa, F.M. A mechanically consistent model for fluid–structure interactions with contact including seepage. Comput. Methods Appl. Mech. Eng. 2022, 392, 114637. [Google Scholar] [CrossRef]

- Tang, D.; Han, Y.; Yin, L.; Chen, Y. Numerical Analysis of the Mixed-Lubrication Performance of Staved Stern Tube Bearings Lubricated with Water. Lubricants 2023, 11, 168. [Google Scholar] [CrossRef]

- Yang, Z.; Zhang, X.; Wang, Y.; Zhao, Y. Study on elastohydrodynamic lubrication performance of double-layer composite water-lubricated bearings. Mech. Ind. 2023, 24, 3. [Google Scholar] [CrossRef]

- Thomsen, K.; Klit, P. A study on compliant layers and its influence on dynamic response of a hydrodynamic journal bearing. Tribol. Int. 2011, 44, 1872–1877. [Google Scholar] [CrossRef]

- Xiang, G.; Yang, T.; Guo, J.; Wang, J.; Liu, B.; Chen, S. Optimization transient wear and contact performances of water-lubricated bearings under fluid-solid-thermal coupling condition using profile modification. Wear 2022, 502, 204379. [Google Scholar] [CrossRef]

- Chen, S.; Xiang, G.; Fillon, M.; Guo, J.; Wang, J.; Cai, J. On the tribo-dynamic behaviors during start-up of water lubricated bearing considering imperfect journal. Tribol. Int. 2022, 174, 107685. [Google Scholar] [CrossRef]

- Cai, J.; Xiang, G.; Li, S.; Guo, J.; Wang, J.; Chen, S.; Yang, T. Mathematical modeling for nonlinear dynamic mixed friction behaviors of novel coupled bearing lubricated with low-viscosity fluid. Phys. Fluids 2022, 34, 093612. [Google Scholar] [CrossRef]

- Gong, J.; Jin, Y.; Liu, Z.; Jiang, H.; Xiao, M. Study on influencing factors of lubrication performance of water-lubricated micro-groove bearing. Tribol. Int. 2019, 129, 390–397. [Google Scholar] [CrossRef]

- Du, Y.; Lan, J.; Quan, H.; Sun, C.; Liu, X.; Yang, X. Effect of different turbulent lubrication models on the lubrication characteristics of water-lubricated rubber bearings at a high Reynolds number. Phys. Fluids 2021, 33, 065118. [Google Scholar] [CrossRef]

- Xie, Z.; Song, P.; Hao, L.; Shen, N.; Zhu, W.; Liu, H.; Shi, J.; Wang, Y.; Tian, W. Investigation on effects of Fluid-Structure-Interaction (FSI) on the lubrication performances of water lubricated bearing in primary circuit loop system of nuclear power plant. Ann. Nucl. Energy 2020, 141, 107355. [Google Scholar] [CrossRef]

- Xie, Z.; Wang, X.; Zhu, W. Theoretical and experimental exploration into the fluid structure coupling dynamic behaviors towards water-lubricated bearing with axial asymmetric grooves. Mech. Syst. Signal Process. 2022, 168, 108624. [Google Scholar] [CrossRef]

- Wang, Y.; Yin, Z.; Gao, G.; Zhang, X. Analysis of the performance of worn hydrodynamic water-lubricated plain journal bearings considering cavitation and elastic deformation. Mech. Ind. 2017, 18, 508. [Google Scholar] [CrossRef]

- Hili, M.A.; Bouaziz, S.; Maatar, M.; Fakhfakh, T.; Haddar, M. Hydrodynamic and Elastohydrodynamic Studies of a Cylindrical Journal Bearing. J. Hydrodyn. 2010, 22, 155–163. [Google Scholar] [CrossRef]

- Rohilla, P.K.; Verma, R.; Verma, S. Performance analysis of couple stress fluid operated elastic hydrodynamic journal bearing. Tribol. Online 2019, 14, 143–154. [Google Scholar] [CrossRef]

- Linjamaa, A.; Lehtovaara, A.; Larsson, R.; Kallio, M.; Söchting, S. Modelling and analysis of elastic and thermal deformations of a hybrid journal bearing. Tribol. Int. 2018, 118, 451–457. [Google Scholar] [CrossRef]

- Huang, B.; Wang, L.-Q.; Guo, J. Performance comparison of circular, two-lobe and elliptical journal bearings based on TEHD analysis. Ind. Lubr. Tribol. 2014, 66, 184–193. [Google Scholar] [CrossRef]

- Smith, E.H. On the Design and Lubrication of Water-Lubricated, Rubber, Cutlass Bearings Operating in the Soft EHL Regime. Lubricants 2020, 8, 75. [Google Scholar] [CrossRef]

- Xiang, G.; Han, Y. Study on the tribo-dynamic performances of water-lubricated microgroove bearings during start-up. Tribol. Int. 2020, 151, 106395. [Google Scholar] [CrossRef]

- Ma, J.; Fu, C.; Zhang, H.; Chu, F.; Shi, Z.; Gu, F.; Ball, A.D. Modelling non-Gaussian surfaces and misalignment for condition monitoring of journal bearings. Measurement 2021, 174, 108983. [Google Scholar] [CrossRef]

- Zienkiewicz, O.C.; Taylor, R.L.; Zhu, J.Z. The Finite Element Method: Its Basis and Fundamentals, 7th ed.; Butterworth Heinemann: Oxford, UK, 2013. [Google Scholar] [CrossRef]

- Litwin, W.; Olszewski, A. Water-Lubricated Sintered Bronze Journal Bearings—Theoretical and Experimental Research. Tribol. Trans. 2014, 57, 114–122. [Google Scholar] [CrossRef]

| Parameter | Symbol | Value |

|---|---|---|

| Bearing diameter (mm) | D | 100 |

| Relative clearance (%) | ψ | 0.4 |

| Length-to-diameter ratio | L/D | 2 |

| Total bush thickness (mm) | t | 10 |

| Plastic bush thickness (mm) | t1 | 5 |

| Rubber bush thickness (mm) | t2 | 5 |

| Plastic bush elastic modulus (MPa) | E1 | 700 |

| Rubber bush elastic modulus (MPa) | E2 | 40 |

| Plastic bush Poisson’s ratio | ν1 | 0.46 |

| Rubber bush Poisson’s ratio | ν2 | 0.497 |

| Eccentricity ratio | ε | 0.9 |

| Journal rotational speed (r/min) | N | 1000 |

| Dynamic viscosity (Pa·s) | μ | 0.001 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shen, Y.; Zhang, Y.; Zhang, X.; Zheng, H.; Wei, G.; Wang, M. A Fluid-Structure Interaction Method for the Elastohydrodynamic Lubrication Characteristics of Rubber-Plastic Double-Layer Water-Lubricated Journal Bearings. Lubricants 2023, 11, 240. https://doi.org/10.3390/lubricants11060240

Shen Y, Zhang Y, Zhang X, Zheng H, Wei G, Wang M. A Fluid-Structure Interaction Method for the Elastohydrodynamic Lubrication Characteristics of Rubber-Plastic Double-Layer Water-Lubricated Journal Bearings. Lubricants. 2023; 11(6):240. https://doi.org/10.3390/lubricants11060240

Chicago/Turabian StyleShen, Yuankang, Yao Zhang, Xiuli Zhang, Hongyu Zheng, Guorui Wei, and Mingyang Wang. 2023. "A Fluid-Structure Interaction Method for the Elastohydrodynamic Lubrication Characteristics of Rubber-Plastic Double-Layer Water-Lubricated Journal Bearings" Lubricants 11, no. 6: 240. https://doi.org/10.3390/lubricants11060240

APA StyleShen, Y., Zhang, Y., Zhang, X., Zheng, H., Wei, G., & Wang, M. (2023). A Fluid-Structure Interaction Method for the Elastohydrodynamic Lubrication Characteristics of Rubber-Plastic Double-Layer Water-Lubricated Journal Bearings. Lubricants, 11(6), 240. https://doi.org/10.3390/lubricants11060240