A Novel Approach for Modeling Surface Effects in Hydrodynamic Lubrication

Abstract

:1. Introduction

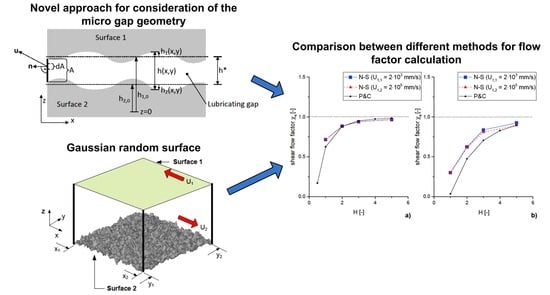

2. Mathematical Background

3. Numerical Method

3.1. Geometry and Mesh

3.2. Boundary Conditions

3.3. Numerical Schemes

3.4. Post Processing

4. Simulation Results and Discussion

4.1. Influence of Orientation and Pressure/Shear Gradient

4.2. Influence of the Numerical Method on the Shear Flow Factor

5. Conclusions and Outlook

Acknowledgments

Author Contributions

Conflicts of Interest

Nomenclature

| Variable | Name |

| velocity vector | |

| ∇ | Nabla operator |

| t | time |

| p | fluid pressure |

| fluid density | |

| kinematic viscosity | |

| normal vector | |

| b | width of the control volume |

| Q | volume flow rate |

| pressure flow factor | |

| shear flow factor | |

| H | non-dimensional height factor () |

| Peklenik (orientation) factor () | |

| correlation length | |

| relative velocity | |

| standard deviation of the combined surface profile | |

| coordinates of the three-dimensional space | |

| h | local gap height |

| nominal gap height | |

| height changes of one surface measured from its mean level |

References

- Ramesh, A.; Akram, W.; Mishra, S.P.; Cannon, A.H.; Polycarpou, A.A.; King, W.P. Friction characteristics of microtexured surfaces under mixed and hydrodynamic lubrication. Tribol. Int. 2013, 57, 170–176. [Google Scholar] [CrossRef]

- Grün, F.; Gódor, I.; Gärtner, W.; Eichlseder, W. Tribological performance of thin overlays for journal bearings. Tribol. Int. 2011, 44, 1271–1280. [Google Scholar] [CrossRef]

- Summer, F.; Grün, F.; Schiffer, J.; Gódor, I.; Papadimitriou, I. Tribological study of crankshaft bearing systems: Comparison of forged steel and cast iron counterparts under start-stop operation. Wear 2015, 338–339, 232–241. [Google Scholar] [CrossRef]

- Bergmann, P.; Grün, F.; Summer, F.; Gódor, I.; Stadler, G. Expansion of the metrological visualization capability by the implementation of acoustic emission analysis. Adv. Tribol. 2017, 2017. [Google Scholar] [CrossRef]

- Moder, J.; Grün, F.; Stoschka, M.; Gódor, I. A Novel Two-Disc Machine for High Precision Friction Assessment. Adv. Tribol. 2017, 2017. [Google Scholar] [CrossRef]

- Chunxing, G.; Xianghui, M.; Youbai, X.; Di, Z. Mixed lubrication problems in the presence of textures: An efficient solution to the cavitation problem with consideration of roughness effects. Tribol. Int. 2016, 103, 516–528. [Google Scholar]

- Quinonez, A.F.; Morales-Espejel, G.E. Surface roughness effects in hydrodynamic bearings. Tribol. Int. 2016, 98, 212–219. [Google Scholar] [CrossRef]

- Ruggiero, A.; Gomez, E.; D’Amato, R. Approximate Analytical Model for the Speeze-Film Lubrication of the Human Ankle Joint with Synovial Fluid Filtrated by Articular Cartilage. Tribol. Lett. 2011, 41, 337–343. [Google Scholar] [CrossRef] [Green Version]

- Ruggiero, A.; Gomez, E.; D’Amato, R. Approximate closed-form solution of the synovial fluid film force in the human ankle joint with non-Newtonian lubricant. Tribol. Int. 2013, 57, 156–161. [Google Scholar] [CrossRef]

- D’Amato, R.; Calvo, R.; Gomez, E. Sensitivity study of the morphometric fitting on the pressure field inside ankle joints. Case Stud. Mech. Syst. Signal Process. 2015, 1, 8–14. [Google Scholar] [CrossRef]

- Reynolds, O. On the Theory of Lubrication and its Application to Mr. Beauchamp Tower’s Experiments, including an Experimental Determination of the Viscosity of Olive Oil. Philos. Trans. R. Soc. Lond. 1886, 177, 157–234. [Google Scholar] [CrossRef]

- Patir, N.; Cheng, H.S. An average flow model for determining effects of three-dimensional roughness on partial hydrodynamic lubrication. J. Lubr. Technol. 1978, 100, 12–17. [Google Scholar] [CrossRef]

- Xu, G.; Sadeghi, F. Thermal EHL analysis of circular contacts with measured surface roughness. J. Tribol. 1989, 118, 473–482. [Google Scholar] [CrossRef]

- Chang, L.; Farnum, C. A thermal model for elastohydrodynamic lubrication of rough surfaces. Tribol. Trans. 1992, 35, 281–286. [Google Scholar] [CrossRef]

- Dobrica, M.B.; Fillon, M.; Maspeyrot, P. Influence of mixed-lubrication and rough elastic-plastic contact on the performance of small fluid film bearings. Tribol. Trans. 2008, 51, 699–717. [Google Scholar] [CrossRef]

- Patir, N.; Cheng, H.S. Application of average flow model to lubrication between rough sliding surfaces. J. Lubr. Technol. 1979, 101, 220–230. [Google Scholar] [CrossRef]

- Wilson, W.R.D.; Marsault, N. Partial hydrodynamic lubrication with large fractional contact areas. J. Tribol. 1998, 120, 16–20. [Google Scholar] [CrossRef]

- Offner, G.; Knaus, O. A Generic Friction Model for Radial Slider Bearing Simulation Considering Elastic and Plastic Deformation. Lubricants 2015, 3, 522–538. [Google Scholar] [CrossRef]

- Knoll, G. Elastohydrodynamische Simulationstechnik mit integriertem Mischreibungskontkat. Materialwissenschaft und Werkstofftechnik 2003, 34, 946–952. [Google Scholar] [CrossRef]

- Brenner, G.; Al-Zoubi, A.; Mukinovic, M.; Schwarze, H.; Swoboda, S. Numerical simulation of surface roughness effects in laminar lubrication using the Lattice-Boltzmann Method. J. Tribol. 2007, 129, 603–610. [Google Scholar] [CrossRef]

- Sahlin, F.; Almqvist, A.; Larsson, R.; Glavatskih, S.B. Rough surface flow factors in full film lubrication based on a homogenization technique. Tribol. Int. 2007, 40, 1025–1034. [Google Scholar] [CrossRef]

- Meng, F.M.; Cen, S.Q.; Hu, Y.Z.; Wang, H. On elastic deformation, inter-asperity cavitation and lubricant thermal effects on flow factors. Tribol. Int. 2009, 42, 260–274. [Google Scholar] [CrossRef]

- Chengwei, W.; Linqing, Z. An average Reynold Equation for partial film lubrication with a contact factor. J. Tribol. 1989, 111, 188–191. [Google Scholar]

- Lunde, L.; Tonder, K. Pressure and shear flow in a rough hydrodynamic bearing, flow factor calculation. J. Tribol. 1997, 119, 549–555. [Google Scholar] [CrossRef]

- Almqvist, A.; Fabricius, J.; Spencer, A.; Wall, P. Similarities and differences between the flow factor method by Patir and Cheng and homogenization. J. Tribol. 2011, 133. [Google Scholar] [CrossRef]

- Sahlin, F.; Glavatskih, S.B.; Almqvist, T.; Larsson, R. Two-dimensional CFD-Analysis of micro-patterned surfaces in hydrodynamic lubrication. J. Lubr. Technol. 2005, 127, 96–102. [Google Scholar] [CrossRef]

- Brajdic-Mitidieri, P.; Gosman, A.D.; Ioannides, E.; Spikes, H.A. CFD analysis of a low friction pocketed pad bearing. J. Tribol. 2005, 127, 803–812. [Google Scholar] [CrossRef]

- Arghir, M.; Roucou, N.; Helene, M.; Frene, J. Theoretical analysis of the incompressible laminar flow in a macro-roughness cell. J. Tribol. 2003, 125, 309–318. [Google Scholar] [CrossRef]

- Dobrica, M.B.; Fillon, M. About the validity of Reynolds equation and inerta effects in textured sliders of infinite width. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2009, 223, 69–78. [Google Scholar] [CrossRef]

- Bayada, G.; Chambat, M. New Models in the Theory of the Hydrodynamic Lubrication of Rough Surfaces. J. Tribol. 1988, 110, 402–407. [Google Scholar] [CrossRef]

- De Kraker, A.; van Ostayen, R.A.J.; Rixen, D.J. A Multiscale Method Modeling Surface Texture Effects. J. Tribol. 2006, 129, 221–230. [Google Scholar] [CrossRef]

- De Kraker, A.; van Ostayen, R.A.J.; Rixen, D.J. Development of a texture averaged Reynolds equation. Tribol. Int. 2010, 43, 2100–2109. [Google Scholar] [CrossRef]

- Yildiran, I.N.; Temizer, I.; Cetin, B. Homogenization in Hydrodynamic Lubrication: Microscopic Regimes and Re-Entrant Textures. J. Tribol. 2017, 140. [Google Scholar] [CrossRef]

- Bestehorn, M. Hydrodynamik und Strukturbildung; Springer: Berlin/Heidelberg, Germany, 2006. [Google Scholar]

- Fröhlich, J. Large Eddy Simulation Turbuleter Strömungen; Teubner Verlag: Wiesbaden, Germany, 2006. [Google Scholar]

- Lesieur, M.; Metais, O.; Comte, P. Large-Eddy Simulations of Turbulence; Cambridge University Press: Cambridge, UK, 2005. [Google Scholar]

- Deardorff, J.W. The use of subgrid transport equations in a three-dimensional model of athmospheric turbulence. J. Fluids Eng. 1973, 95, 429–438. [Google Scholar] [CrossRef]

- Yoshizawa, A. Statistical theory for compressible turbulent shear flows, with the application to subgrid modeling. Phys. Fluids 1986, 29, 2152–2164. [Google Scholar] [CrossRef]

- Peklenik, J. New Developments in Surface Characterization and Measurement by Means of Random Process Analysis. Proc. Inst. Mech. Eng. 1967, 182, 108–126. [Google Scholar] [CrossRef]

- Knoll, G.; Boucke, A.; Winijsart, A.; Stapelmann, A.; Auerbach, P. Reduction of Friction Losses in Journal Bearings of Valve Train Shaft by Application of Running-in Profile. Tribologie und Schmierungstechnik 2016, 63, 14–21. [Google Scholar]

- Vogelpohl, G. Betriebssichere Gleitlager; Springer: Berlin/Heidelberg, Germany; New York, NY, USA, 1967. [Google Scholar]

- Tripp, J.H. Surface roughness effects in hydrodynamic lubrication: The flow factor method. J. Lubr. Technol. 1983, 105, 458–463. [Google Scholar] [CrossRef]

- Harp, S.; Salant, R. An Average Flow Model of Rough Surface Lubrication with Inter-Asperity Cavitation. J. Tribol. 2001, 123, 134–143. [Google Scholar] [CrossRef]

- Peeken, H.; Knoll, G.; Rienäcker, A.; Lang, J.; Schönen, R. On the Numerical Determination of Flow Factors. J. Tribol. 1997, 119, 259–264. [Google Scholar] [CrossRef]

- Bakolas, V. Numerical generation of arbitrarily oriented non-gaussian three-dimensional rough surfaces. Wear 2003, 254, 546–554. [Google Scholar] [CrossRef]

- Dietrich, C.R.; Newsam, G.N. Fast and exact simulation of stationary gaussian processes through circulant embedding of the covariance matrix. SIAM J. Sci. Comput. 1997, 18, 1088–1107. [Google Scholar] [CrossRef]

- Sykulski, A.M.; Percival, D.B. Exact simulation of noncircular or improper complex-valued stationary Gaussian processes using circulant embedding. In Proceedings of the IEEE 26th International Workshop on Machine Learning for Signal Processing, Salerno, Italy, 13–16 September 2016; pp. 1–6. [Google Scholar]

- Kroese, D.P.; Botev, Z.I. Spatial Process Generation. arXiv, 2013; arXiv:1308.0399. [Google Scholar]

- Elrod, H.G. A general theory for laminar lubrication with Reynolds roughness. J. Tribol. 1979, 101, 8–14. [Google Scholar] [CrossRef]

| C | r | |||||

|---|---|---|---|---|---|---|

| 1/9 | 1.48 | 0.42 | 2.046 | 1.12 | 0.78 | 0.03 |

| 9 | 0.87 | 1.5 | 1.011 | 0.54 | 1.07 | 0.08 |

| Position | Boundary Condition |

|---|---|

| Surface 1 | |

| Surface 2 |

| Position | Boundary Condition |

|---|---|

| Surface 1 | |

| Surface 2 |

| Patir & Cheng | Mapping | Moving Mesh | |

|---|---|---|---|

| Normalized gap height H (-) | 5.2 | 5.2 | 5.2 |

| Orientation (-) | 9 | 9 | 9 |

| Surface velocity (mm/s) | |||

| Shear flow factor (-) | 0.984 | 0.968 | 0.967 |

| Patir & Cheng | Moving Mesh | |

|---|---|---|

| Normalized gap height H (-) | 5.2 | 5.2 |

| Orientation (-) | 9 | 9 |

| Surface velocity (mm/s) | ||

| Shear flow factor (-) | 1.097 | 1.086 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pusterhofer, M.; Bergmann, P.; Summer, F.; Grün, F.; Brand, C. A Novel Approach for Modeling Surface Effects in Hydrodynamic Lubrication. Lubricants 2018, 6, 27. https://doi.org/10.3390/lubricants6010027

Pusterhofer M, Bergmann P, Summer F, Grün F, Brand C. A Novel Approach for Modeling Surface Effects in Hydrodynamic Lubrication. Lubricants. 2018; 6(1):27. https://doi.org/10.3390/lubricants6010027

Chicago/Turabian StylePusterhofer, Michael, Philipp Bergmann, Florian Summer, Florian Grün, and Clemens Brand. 2018. "A Novel Approach for Modeling Surface Effects in Hydrodynamic Lubrication" Lubricants 6, no. 1: 27. https://doi.org/10.3390/lubricants6010027

APA StylePusterhofer, M., Bergmann, P., Summer, F., Grün, F., & Brand, C. (2018). A Novel Approach for Modeling Surface Effects in Hydrodynamic Lubrication. Lubricants, 6(1), 27. https://doi.org/10.3390/lubricants6010027