Low Friction, Lubricity, and Durability of Polymer Brush Coatings, Characterized Using the Relaxation Tribometer Technique †

Abstract

:1. Introduction

2. Materials and Methods

2.1. Preparation of ILPBs

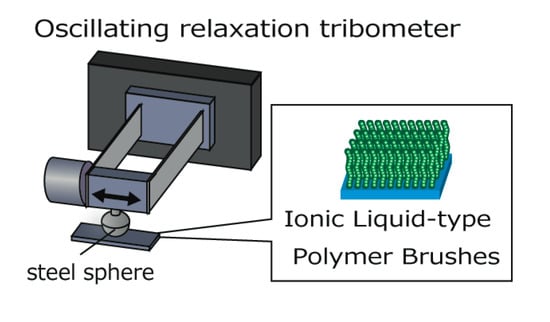

2.2. Testing with the Relaxation Tribometer

2.3. Identification of the Friction Laws

3. Operating Conditions

4. Results and Discussion

4.1. Thick ILPB Grafted on Silicon

4.2. Thin ILPB Grafted on Steel

4.3. A New Lubrication Process

4.4. Durability of the ILPB Coating

5. Conclusions

- -

- a thick layer of the PBs layer on the silicon was very resistant to high contact pressure, up to 540 MPa;

- -

- the friction behavior of the brushes was close to a Newtonian viscous behavior, even at the maximum normal loads;

- -

- the corresponding friction law was viscous-type, even at a very low sliding velocity;

- -

- poorer results were obtained on the thinner sample. The corresponding friction laws of such a tribosystem were shown to be viscous-type at low contact pressure, after which a Stribeck-like behavior was exhibited at a higher pressure;

- -

- repetition, of up to 5000 oscillations, on the same surface did not affect the friction damping of the contact, which showed the very good resistance of this film to friction under severe contact conditions;

- -

- the feasibility of grafting onto steel surfaces was demonstrated. Thus, these ILPBs’ coatings could act as a very good lubricant, providing a friction law that differs considerably from a classic Stribeck curve. The friction at near-zero velocity was found to be in the millirange and was even lower. In the case of low contact pressure testing, µ as low as 0.0008 could be determined. These ILPBs were found to be robust, even under repetitive testing;

- -

- finally, based on our results presented in this paper, the thicker polymer brushes were found to be more resilient under severe conditions. However, the thicker samples needed more time and more reagent for synthesis, which led to higher cost. We are now trying to ascertain the optimal conditions by cooperating with several companies, so as to utilize the polymer brushes for industrial usage.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Tannous, J.; Dassenoy, F.; Lahouij, I.; Le Mogne, T.; Vacher, B.; Bruhács, A.; Tremel, W. Understanding the Tribochemical Mechanisms of IF-MoS2 Nanoparticles Under Boundary Lubrication. Tribol. Lett. 2011, 41, 55–64. [Google Scholar] [CrossRef]

- Martin, J.M. Superlubricity of Molybdenum Disulfide. In Superlubricity; Springer: Berlin, Germany, 2007; pp. 207–225. ISBN 13-978-0-444-52772-1. [Google Scholar]

- Heeb, R.; Bielecki, R.M.; Lee, S.; Spencer, N.D. Room-Temperature, Aqueous-Phase Fabrication of Poly(methacrylic acid) Brushes by UV-LED-Induced, Controlled Radical Polymerization with High Selectivity for Surface-Bound Species. Macromolecules 2009, 42, 9124–9132. [Google Scholar] [CrossRef]

- Chen, M.; Briscoe, W.H.; Armes, S.P.; Klein, J. Lubrication at Physiological Pressures by Polyzwitterionic Brushes. Science 2009, 323, 1698–1701. [Google Scholar] [CrossRef] [PubMed]

- Nomura, A.; Goto, A.; Ohno, K.; Kayahara, E.; Yamago, S.; Tsujii, Y. Controlled synthesis of hydrophilic concentrated polymer brushes and their friction/lubrication properties in aqueous solutions. J. Polym. Sci. Part A Polym. Chem. 2011, 49, 5284–5292. [Google Scholar] [CrossRef]

- Tsujii, Y.; Nomura, A.; Okayasu, K.; Gao, W.; Ohno, K.; Fukuda, T. AFM studies on microtribology of concentrated polymer brushes in solvents. J. Phys. Conf. Ser. 2009, 184, 12031. [Google Scholar] [CrossRef]

- Nomura, A.; Ohno, K.; Fukuda, T.; Sato, T.; Tsujii, Y. Lubrication mechanism of concentrated polymer brushes in solvents: Effect of solvent viscosity. Polym. Chem. 2012, 3, 148. [Google Scholar] [CrossRef]

- Kaneko, D.; Tada, T.; Kurokawa, T.; Gong, J.P.; Osada, Y. Mechanically Strong Hydrogels with Ultra-Low Frictional Coefficients. Adv. Mater. 2005, 17, 535–538. [Google Scholar] [CrossRef]

- Torimoto, T.; Tsuda, T.; Okazaki, K.I.; Kuwabata, S. New frontiers in materials science opened by ionic liquids. Adv. Mater. 2010, 22, 1196–1221. [Google Scholar] [CrossRef] [PubMed]

- Minami, I. Ionic liquids in tribology. Molecules 2009, 14, 2286–2305. [Google Scholar] [CrossRef] [PubMed]

- Ishikawa, T.; Kobayashi, M.; Takahara, A. Macroscopic frictional properties of poly(1-(2-methacryloyloxy)ethyl-3-butyl imidazolium bis(trifluoromethanesulfonyl)-imide) brush surfaces in an ionic liquid. ACS Appl. Mater. Interfaces 2010, 2, 1120–1128. [Google Scholar] [CrossRef] [PubMed]

- Arafune, H.; Kamijo, T.; Morinaga, T.; Honma, S.; Sato, T.; Tsujii, Y. A Robust Lubrication System Using an Ionic Liquid Polymer Brush. Adv. Mater. Interfaces 2015, 2, 1500187. [Google Scholar] [CrossRef]

- Drobek, T.; Spencer, N.D. Nanotribology of Surface-Grafted PEG Layers in an Aqueous Environment. Langmuir 2008, 24, 1484–1488. [Google Scholar] [CrossRef] [PubMed]

- Brady, M.A.; Limpoco, F.T.; Perry, S.S. Solvent-dependent friction force response of poly(ethylenimine)-graft-poly(ethylene glycol) brushes investigated by atomic force microscopy. Langmuir 2009, 25, 7443–7449. [Google Scholar] [CrossRef] [PubMed]

- Kitano, K.; Inoue, Y.; Matsuno, R.; Takai, M.; Ishihara, K. Nanoscale evaluation of lubricity on well-defined polymer brush surfaces using QCM-D and AFM. Colloids Surf. B Biointerfaces 2009, 74, 350–357. [Google Scholar] [CrossRef] [PubMed]

- Ramakrishna, S.N.; Cirelli, M.; Divandari, M.; Benetti, E.M. Effects of Lateral Deformation by Thermoresponsive Polymer Brushes on the Measured Friction Forces. Langmuir 2017, 33, 4164–4171. [Google Scholar] [CrossRef] [PubMed]

- Banquy, X.; Burdyńska, J.; Lee, D.W.; Matyjaszewski, K.; Israelachvili, J. Bioinspired bottle-brush polymer exhibits low friction and amontons-like behavior. J. Am. Chem. Soc. 2014, 136, 6199–6202. [Google Scholar] [CrossRef] [PubMed]

- Zoppe, J.O.; Ataman, N.C.; Mocny, P.; Wang, J.; Moraes, J.; Klok, H.A. Surface-Initiated Controlled Radical Polymerization: State-of-the-Art, Opportunities, and Challenges in Surface and Interface Engineering with Polymer Brushes. Chem. Rev. 2017, 117, 1105–1318. [Google Scholar] [CrossRef] [PubMed]

- Majdoub, F.; Belin, M.; Martin, J.M.; Perret-Liaudet, J.; Kano, M.; Yoshida, K. Exploring low friction of lubricated DLC coatings in no-wear conditions with a new relaxation tribometer. Tribol. Int. 2013, 65, 278–285. [Google Scholar] [CrossRef]

- Majdoub, F.; Perret-Liaudet, J.; Belin, M.; Martin, J.M. Decaying law for the free oscillating response with a pseudo-polynomial friction law: Analysis of a superlow lubricated friction test. J. Sound Vib. 2015, 348, 263–281. [Google Scholar] [CrossRef]

- Belin, M.; Kakizawa, M.; Martin, J.M. Dual characterization of boundary friction thanks to the harmonic tribometer: Identification of viscous and solid friction contributions. J. Phys. Conf. Ser. 2010, 258, 012008. [Google Scholar] [CrossRef]

- Hriouech, A.; Belin, M.; Perret-Liaudet, J.; De Barros, M.I.; Diaby, M. An original tribometer coupling a free-oscillation dynamic tribotest with a conventional linear reciprocating tribometer. In Proceedings of the World Tribology Conference 2017, WTC’2017, Beijing, China, 18–22 September 2017. Poster ST-A-019. [Google Scholar]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Belin, M.; Arafune, H.; Kamijo, T.; Perret-Liaudet, J.; Morinaga, T.; Honma, S.; Sato, T. Low Friction, Lubricity, and Durability of Polymer Brush Coatings, Characterized Using the Relaxation Tribometer Technique †. Lubricants 2018, 6, 52. https://doi.org/10.3390/lubricants6020052

Belin M, Arafune H, Kamijo T, Perret-Liaudet J, Morinaga T, Honma S, Sato T. Low Friction, Lubricity, and Durability of Polymer Brush Coatings, Characterized Using the Relaxation Tribometer Technique †. Lubricants. 2018; 6(2):52. https://doi.org/10.3390/lubricants6020052

Chicago/Turabian StyleBelin, Michel, Hiroyuki Arafune, Toshio Kamijo, Joël Perret-Liaudet, Takashi Morinaga, Saika Honma, and Takaya Sato. 2018. "Low Friction, Lubricity, and Durability of Polymer Brush Coatings, Characterized Using the Relaxation Tribometer Technique †" Lubricants 6, no. 2: 52. https://doi.org/10.3390/lubricants6020052

APA StyleBelin, M., Arafune, H., Kamijo, T., Perret-Liaudet, J., Morinaga, T., Honma, S., & Sato, T. (2018). Low Friction, Lubricity, and Durability of Polymer Brush Coatings, Characterized Using the Relaxation Tribometer Technique †. Lubricants, 6(2), 52. https://doi.org/10.3390/lubricants6020052