Reduction of CO2 Emissions and Cost Analysis of Ultra-Low Viscosity Engine Oil

Abstract

:1. Introduction

2. Experimental

2.1. System Boundary and Analysis Method

2.2. The Method of Analyzing the Effect of Improving Fuel Efficiency

2.3. Specifications of Analyzed Engine Oils

2.4. Cost Analysis Method

3. Results and Discussion

3.1. Result of Analysis for Improving the Fuel Efficiency

3.2. CO2 Emissions from Oil Production

3.3. The Effect of Reducing LCCO2 Emissions

3.4. Cost Analysis

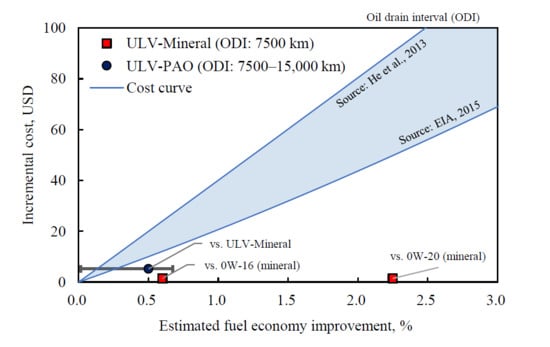

3.5. Cost-Effectiven ess (Breakeven Cost Analysis)

4. Conclusions

- When the upper limit of the Noack volatility was set to 15 wt %, the lower limit of KV100 mineral engine oil with Group-III base-stock and synthetic engine oil with PAO base-stock were estimated at 5.3 and 4.5 mm2/s, respectively.

- Compared with the conventional 0W-16 engine oil (KV100 6.2 mm2/s), ULV-Mineral (KV100 5.3 mm2/s) and ULV-PAO (KV100 4.5 mm2/s) were designed to improve vehicle fuel efficiency by 0.6 and 1.1%, respectively, considering 1.5–1.8 L gasoline engines in NEDC mode.

- As vehicle fuel efficiency improves, the ratio of CO2 emissions from engine oil production to CO2 emissions during vehicle operation increases. Regarding the mineral engine oils, when the ODI was set to 7500 km, CO2 emissions during vehicle operation using 2030 standards (assuming a vehicle fuel efficiency of 66.5 g-CO2/km) increased to 0.8% by CO2 emissions for the production of mineral engine oils. Meanwhile, when synthetic engine oil was used, CO2 emissions in vehicle operation significantly increased to 1.3% under the same conditions.

- Compared with the conventional 0W-16 mineral engine oil, the reduction of LCCO2 emissions associated with ULV-Mineral using a Group-III base-stock was estimated at 0.6% while maintaining a constant cost. In other words, the viscosity of mineral engine oil is expected to continually decrease in the future.

- Compared with ULV-Mineral, ULV-PAO improves the fuel efficiency of the vehicle by 0.5%. However, considering the CO2 emissions during engine oil production, the reduction of LCCO2 emissions of ULV-PAO compared with ULV-Mineral will be of 0.1% or less in 2030 (assuming a vehicle fuel efficiency of 66.5 g-CO2/km) when the ODI is set equivalent to mineral engine oil (7500 km). Consequently, ULV-PAO loses the cost-effectiveness based on the increased cost of PAO base-stock. On the other hand, when utilizing the characteristics of PAO base-stock with higher oxidation stability in comparison with the mineral base-stock, and extending the ODI to 15,000 km, the effect of reduction of LCCO2 emissions of ULV-PAO is estimated to be 0.7% in 2030, thus making ULV-PAO a competitive and cost-effectiveness alternative. In other words, the popularization of synthetic engine oil as we move toward 2030 will require the consideration of both the reduction in viscosity and the extension of the ODI.

Author Contributions

Funding

Conflicts of Interest

References

- Proposal for Post-2020 CO2 Targets for Cars and Vans. Available online: https://ec.europa.eu/clima/policies/transport/vehicles/proposal_en (accessed on 4 January 2018).

- Toyota Aims for Sales of More Than 5.5 Million Electrified Vehicles Including 1 Million Zero-Emission Vehicles per Year by 2030. Available online: https://newsroom.toyota.co.jp/en/corporate/20353243.html (accessed on 2 January 2018).

- Worldwide Sales of Toyota Hybrids Surpass 10 Million Units. Available online: https://newsroom.toyota.co.jp/en/detail/14940871 (accessed on 2 January 2018).

- Correspondence for Structural Change of the Automobile Industry. Available online: www.meti.go.jp/policy/economy/keiei_innovation/sangyokinyu/GB/04.pdf (accessed on 2 January 2018). (In Japanese)

- Osawa, H.; Yamashita, Y. Trends of R&D Investment. Finance 2017, 53, 52–53. (In Japanese) [Google Scholar]

- Mang, T.; Dresel, W. Lubricants and Lubrication; Wiley: Weinheim, Germany, 2007. [Google Scholar]

- Forecast of Demand of Petroleum Products from 2017 to 2021 (Plan). Available online: www.meti.go.jp/committee/sougouenergy/shigen_nenryo/sekiyu_gas/sekiyu_doukou_wg/pdf/004_02_00.pdf (accessed on 18 March 2018). (In Japanese)

- Statistical Information, Conversion Factor List. Available online: www.paj.gr.jp/statis/kansan/ (accessed on 18 March 2018). (In Japanese).

- Survey the World Market Related to Lubricants. Available online: www.group.fuji-keizai.co.jp/press/pdf/161018_16083.pdf (accessed on 9 December 2017). (In Japanese).

- Kanari, S.; Kii, M.; Suehiro, S. Reduction of CO2 and cost-effectiveness analysis by future technology of Automobile. J. Jpn. Soc. Energy Resour. 2009, 31, 4. (In Japanese) [Google Scholar]

- US Energy Information Administration (EIA). Assumptions to the Annual Energy Outlook 2015. Available online: https://www.eia.gov/outlooks/aeo/assumptions/pdf/0554%282015%29.pdf (accessed on 16 November 2018).

- U.S. EPA; NHTSA. Joint Technical Support Document: Final Rulemaking for 2017-2025 Light-Duty Vehicle Greenhouse Gas Emission Standards and Corporate Average Fuel Economy Standards. Joint Technical Support Document (EPA-420-R-12-901). Available online: https://www.nhtsa.gov/sites/nhtsa.dot.gov/files/joint_final_tsd.pdf (accessed on 16 November 2018).

- Girotti, G.; Raimondi, A.; Blengini, G.A.; Fino, D. The contribution of lube additives to the life cycle impacts of fully formulated petroleum-based lubricants. Am. J. Appl. Sci. 2011, 8, 1232–1240. [Google Scholar] [CrossRef]

- Sagawa, T.; Nakano, S.; Bito, Y.; Koike, Y.; Okuda, S.; Suzuki, R. Development of Low Viscosity API SN 0W-16 Fuel-Saving Engine Oil Considering Chain Wear Performance (2017-01-0881). SAE Int. J. Fuels Lubr. 2017, 10, 469–477. [Google Scholar] [CrossRef]

- Fuel Saving Engine Oil Available Models List. Available online: http://toyota.jp/pages/contents/after_service/car_care/yohin/engine_room/engine_oil/image/engine_oil_list_201503.pdf (accessed on 9 December 2017). (In Japanese).

- Daily Vehicle Check. Available online: http://qa.jaf.or.jp/check/daily/10.htm (accessed on 9 December 2017). (In Japanese).

- Actual Usage of Vehicles in Japan. Available online: http://www.mlit.go.jp/jidosha/iinkai/seibi/5th/5-2.pdf (accessed on 9 December 2017). (In Japanese)

- He, H.; Bandivadekar, A. Passenger Car Fuel-Effiency 2020–2025 (No.2013-3). Available online: https://www.theicct.org/sites/default/files/publications/ICCT_PVfe-feasibility_201308.pdf (accessed on 9 December 2017).

- Holmberg, K.; Andersson, P.; Erdemir, A. Global energy consumption due to friction in passenger cars. Tribol. Int. 2012, 47, 221–234. [Google Scholar] [CrossRef]

- Okuyama, Y.; Shimokoji, D.; Kawauchi, S.; Hatta, T.; Maruyama, M. Effects of Low-viscosity Engine Oil on Fuel Economy and Wear. Honda R&D Tech. Rev. 2010, 22, 158–165. [Google Scholar]

- Mo, Y.; Wang, J.; Wang, J.; Dong, T.; Zhou, W. Experimental Research on the Impact of Lubricating Oils on Engine Friction and Vehicle Fuel Economy. In Proceedings of the 3rd International Conference on Material, Mechanical and Manufacturing Engineering (IC3ME 2015), Guangzhou, China, 27–28 June 2015. [Google Scholar]

- Fujimoto, K.; Yamashita, M.; Kaneko, T.; Hirano, S.; Ito, Y.; Nemoto, S.; Onodera, K. Development of ILSAC GF-5 0W-20 fuel economy gasoline engine oil (No. 2012-01-1614). SAE Tech. Pap. 2012. [Google Scholar] [CrossRef]

- Kaneko, T.; Yamamori, K.; Suzuki, H.; Onodera, K. Development of Low Viscosity Engine Oil Compatible with LSPI Prevention Performance (No. 20176327). In Proceedings of the 2017 Society of Automotive Engineers of Japan (JSAE) Annual Congress (Autumn), Osaka, Japan, 11–13 October 2017. (In Japanese). [Google Scholar]

- Liu, H.; Jin, J.; Li, H.; Yamamori, K.; Kaneko, T.; Yamashita, M.; Zhang, L. 0W-16 Fuel Economy Gasoline Engine Oil Compatible with Low Speed Pre-Ignition Performance (2017-01-2346). SAE Int. J. Fuels Lubr. 2017, 10. [Google Scholar] [CrossRef]

- Tamoto, Y.; Kido, M.; Murata, H. Possibilities of ultra-low viscosity fuel saving gasoline engine oil (No. 2004-01-1936). SAE Tech. Pap. 2004. [Google Scholar] [CrossRef]

- Ishizaki, K.; Nakano, M. Low viscosity lubricant contribution to reduce life cycle CO2 emissions on passenger vehicle. J. Jpn. Soc. Tribol. 2018, 63, 563–572. (In Japanese) [Google Scholar]

- Covitch, M.J.; Brown, M.; May, C.; Selby, T.; Goldmints, I.; George, D. Extending SAE J300 to viscosity grades below SAE 20 (2010-01-2286). SAE Int. J. Fuels Lubr. 2010, 3, 1030–1040. [Google Scholar] [CrossRef]

- Carvalho, M.; Richard, K.; Goldmints, I.; Tomanik, E. Impact of lubricant viscosity and additives on engine fuel economy (No. 2014-36-0507). SAE Tech. Pap. 2014. [Google Scholar] [CrossRef]

- Vinci, J.N.; Grisso, B.A.; Schenkenberger, C.; Qureshi, F.S.; Gahagan, M.P.; Hasegawa, H. Systematic formulation of efficient and durable axle lubricants for light trucks and sport utility vehicles (No. 2004-01-3030). SAE Tech. Pap. 2004. [Google Scholar] [CrossRef]

- Rudnick, L.R. Synthetics, Mineral Oils, and Bio-Based Lubricants: Chemistry and Technology; CRC Press: Boca Raton, FL, USA, 2013. [Google Scholar]

- Masuko, M. Trends of Lubricants. J. Jpn. Soc. Tribol. 2016, 61, 35–38. (In Japanese) [Google Scholar]

- Wu, M.M.; Ho, S.C.; Forbus, T.R. Synthetic lubricant base stock processes and products. In Practical Advances in Petroleum Processing; Springer: New York, NY, USA, 2006; pp. 553–577. [Google Scholar]

- Brewer, M.L.; Smith, S.J. Liquid Fuel Compositions. United States Patent Application Publication US 2014/0338624 A1, 20 November 2014. [Google Scholar]

- Kimura, Y.; Kato, N.; Kataoka, T.; Takahashi, K.; Kikuchi, T. Bubble behavior in engine lubricant. Int. J. Automot. Eng. 2011, 2, 149–153. [Google Scholar]

- Product Data Sheet of HiTEC® 9858. Available online: www.neochemical.kz/File/HiTEC_9858_PDS.pdf (accessed on 26 May 2018).

- Product Data Sheet of HiTEC® 9890. Available online: http://www.oil-club.ru/forum/index.php?app=core&module=attach§ion=attach&attach_id=96390 (accessed on 26 May 2018).

- Product Data Sheet of HiTEC® 11170. Available online: https://www.ashdowneoil.co.uk/wp-content/uploads/2017/07/HiTEC-11170_PDS.pdf (accessed on 26 May 2018).

- Treat Rates. Available online: https://passenger.lubrizoladditives360.com/treat-rates/ (accessed on 26 May 2018).

- Sloan, T. A Strategic Analysis of Bestline Lubricants’diesel Engine Treatment. Available online: http://summit.sfu.ca/item/15858 (accessed on 16 November 2018).

- Erhan, S.Z.; Sharma, B.K.; Doll, K.M. Opportunities for industrial uses of agricultural products. Chem. Today 2009, 27, 38–41. [Google Scholar]

- Base Oil Market Prices, News and Analysis in 2012. Available online: https://www.argusmedia.com/DataFiles/BASEOILS/2012-08-31/ufsaks20120831baseoils.pdf (accessed on 26 May 2018).

- Base Oil Market Prices, News and Analysis in 2016. Available online: http://view.argusmedia.com/rs/584-BUW-606/images/Argus%20Base%20Oils%20Review%20Preview%202016-17.pdf (accessed on 26 May 2018).

- Base Oil Market Prices, News and Analysis in 2017. Available online: https://www.argusmedia.com/-/media/Files/brochures/argus-base-oils-annual-review-2017.ashx?la=en&hash=861F41CD4F925DE138B7D3DE0C1D3E837177894B (accessed on 26 May 2018).

- Base Oil Report. Available online: http://machinerylubricationindia.com/magazine/105-2015/mar-apr/271-base-oil-report (accessed on 13 January 2018).

- Market Trend of Base-Stocks for Lubricants. Available online: https://www.juntsu.co.jp/tribology-doc/baseoil-markettrend.php (accessed on 13 January 2018). (In Japanese).

- Koyamaishi, N.; Suzuki, T.; Kamioka, R.; Murakami, M.; Yamashita, M.; Ogawa, T.; Komiya, K.; Moritani, H. Study of future engine oil (first report): Future engine oil scenario (No. 2007-01-1977). SAE Tech. Pap. 2007. [Google Scholar] [CrossRef]

- Akiyama, K.; Ueda, F.; Miyake, J.; Tasaka, K.; Sugiyama, S. Fuel economy performance of the highly efficient fuel economy oils using chassis dynamometer test (No. 932690). SAE Tech. Pap. 1993, 932690. [Google Scholar] [CrossRef]

- Zacharof, N.; Fontaras, G.; Ciuffo, B.; Tsiakmakis, S.; Anagnostopoulos, K.; Marotta, A.; Pavlovic, J. Review of in Use Factors Affecting the Fuel Consumption and CO2 Emissions of Passenger Cars; European Commission: Luxembourg, 2016. [Google Scholar]

- Spot Prices for Crude Oil and Petroleum Products. Available online: https://www.eia.gov/dnav/pet/hist/LeafHandler.ashx?n=PET&s=RWTC&f=M (accessed on 13 January 2018).

- Poly Alpha Olefin (PAO) Market Forecast by 2025. Available online: https://allindustryresearch.com/poly-alpha-olefin-pao-market-forecast-by-2025-qy-research/113298/ (accessed on 4 November 2018).

- Arezki, M.R.; Jakab, Z.; Laxton, M.D.; Matsumoto, M.A.; Nurbekyan, A.; Wang, H.; Yao, J. Oil Prices and the Global Economy; International Monetary Fund: Washington, DC, USA, 2017. [Google Scholar]

| Property | 0W-16 | ULV-Mineral | ULV-PAO |

|---|---|---|---|

| Finished fluid KV100 | 6.2 mm2/s | 5.3 mm2/s | 4.5 mm2/s |

| Base-stock KV100 (type) | n/a (Gr-III) | 4.3 mm2/s (Gr-III) | 3.6 mm2/s (PAO) |

| Add Pack KV100 | n/a | 80 mm2/s | 80 mm2/s |

| Noack volatility | n/a | 15 wt % | 15 wt.% |

| Mineral base-stock | Yes | 89.0 wt % | – |

| PAO base-stock | No | – | 89.0 wt % |

| Add Pack | n/a | 11.0 wt % | 11.0 wt % |

| Detergent (Det) | n/a | 2.0 wt % | 2.0 wt % |

| Dispersant (Dis) | n/a | 6.0 wt % | 6.0 wt % |

| Antioxidant (AO) | n/a | 1.0 wt % | 1.0 wt % |

| Antiwear (AW) | n/a | 2.0 wt % | 2.0 wt % |

| Oil amount | 4.0 L | 4.0 L | 4.0 L |

| Density | n/a | 0.84 kg/L | 0.84 kg/L |

| ODI | 7500 km | 7500 km | 7500, 15,000, and 25,000 km |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ishizaki, K.; Nakano, M. Reduction of CO2 Emissions and Cost Analysis of Ultra-Low Viscosity Engine Oil. Lubricants 2018, 6, 102. https://doi.org/10.3390/lubricants6040102

Ishizaki K, Nakano M. Reduction of CO2 Emissions and Cost Analysis of Ultra-Low Viscosity Engine Oil. Lubricants. 2018; 6(4):102. https://doi.org/10.3390/lubricants6040102

Chicago/Turabian StyleIshizaki, Keita, and Masaru Nakano. 2018. "Reduction of CO2 Emissions and Cost Analysis of Ultra-Low Viscosity Engine Oil" Lubricants 6, no. 4: 102. https://doi.org/10.3390/lubricants6040102

APA StyleIshizaki, K., & Nakano, M. (2018). Reduction of CO2 Emissions and Cost Analysis of Ultra-Low Viscosity Engine Oil. Lubricants, 6(4), 102. https://doi.org/10.3390/lubricants6040102