Effect of Hygrothermal Ageing on Tribological Behaviour of PTFE-Based Composites

Abstract

:1. Introduction

2. Experimental Work

2.1. Materials

2.2. Test Specimens

2.3. Hygrothermal Ageing Calculations

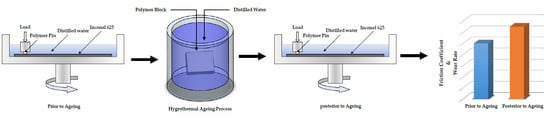

2.4. Experimental Setup and Material Characterisations

2.4.1. Tribo-Test

2.4.2. Fourier Transform Infrared Spectroscopy (FTIR)

2.4.3. Differential Scanning Calorimetry (DSC)

2.4.4. Contact Angle and Surface Energy Measurements

2.4.5. SEM and EDS Analysis

3. Results and Discussion

3.1. Water Absorption

3.2. FTIR Measurements

3.3. Friction and Wear

3.3.1. Unfilled PTFE

Dry Condition

- Higher heat generated as a consequence of the PTFE’s low thermal conductivity and the absence of cooling lubricant [30]. Therefore, the matrix loses its integrity due to the reduction of bulk material strength and hardness [31] which is proceeded by less stable flake separation, as demonstrated in Figure 6B,C.

- Severe operating condition along with the nature of the counter-surface (Inconel 625) can result in the formation of no or discontinuous tribofilm [29,32]. It has been suggested that flaky wear debris could be generated from the delamination wear initiated because of operating in wear peak conditions at (~10−1 m/s and 23 °C) [29].

Water-Lubricated Condition

- Better dissipation of generated heat in the friction interface

- Lubricous behaviour of water facilitating the sliding contact

Hygrothermal Ageing

3.3.2. PTFE Filled with 25% Glass Fibre

Dry Condition

Water-Lubricated Condition

Hygrothermal Ageing

3.3.3. PTFE Filled with 20% Glass Fibre and 5% MoS2

Dry Condition

Water-Lubricated Condition

Hygrothermal Ageing

3.3.4. PTFE Filled with 40% Bronze

Dry Condition

Water-lubricated Condition

Hygrothermal Ageing

3.4. Thermal Characterisation

3.5. Wettability and Surface Free Energy Analysis

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Golchin, A.; Simmons, G.F.; Glavatskih, S.; Prakash, B. Tribological behaviour of polymeric materials in water-lubricated contacts. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2013, 227, 811–825. [Google Scholar] [CrossRef]

- Brostow, W.; Hagg Lobland, H.E. Materials: Introduction and Applications; John Wiley & Sons: Hoboken, NJ, USA, 2017. [Google Scholar]

- Ginzburg, B.M.; Tochil’nikov, D.G.; Bakhareva, V.E.; Anisimov, A.V.; Kireenko, O.F. Polymeric materials for water-lubricated plain bearings. Russ. J. Appl. Chem. 2006, 79, 695–706. [Google Scholar] [CrossRef]

- Ray, B.C. Temperature effect during humid ageing on interfaces of glass and carbon fibers reinforced epoxy composites. J. Colloid Interface Sci. 2006, 298, 111–117. [Google Scholar] [CrossRef] [PubMed]

- Taktak, R.; Guermazi, N.; Derbeli, J.; Haddar, N. Effect of hygrothermal aging on the mechanical properties and ductile fracture of polyamide 6: Experimental and numerical approaches. Eng. Fract. Mech. 2015, 148, 122–133. [Google Scholar] [CrossRef]

- Eftekhari, M.; Fatemi, A. Tensile behavior of thermoplastic composites including temperature, moisture, and hygrothermal effects. Polym. Test. 2016, 51, 151–164. [Google Scholar] [CrossRef]

- Bárány, T.; Földes, E.; Czigány, T. Effect of thermal and hygrothermal aging on the plane stress fracture toughness of poly(ethylene terephthalate) sheets. Express Polym. Lett. 2007, 1, 180–187. [Google Scholar] [CrossRef]

- Barraza, H.J.; Aktas, L.; Hamidi, Y.K.; Long, J.; O’Rear, E.A.; Altan, M.C. Moisture absorption and wet-adhesion properties of resin transfer molded (RTM) composites containing elastomer-coated glass fibers. J. Adhes. Sci. Technol. 2003, 17, 217–242. [Google Scholar] [CrossRef]

- Mortazavian, S.; Fatemi, A.; Khosrovaneh, A. Effect of Water Absorption on Tensile and Fatigue Behaviors of Two Short Glass Fiber Reinforced Thermoplastics. SAE Int. J. Mater. Manuf. 2015, 8, 435–443. [Google Scholar] [CrossRef]

- Illing, T.; Schoßig, M.; Bierögel, C.; Grellmann, W. Influence of hygrothermal aging on dimensional stability of thin injection-molded short glass fiber reinforced PA6 materials. J. Appl. Polym. Sci. 2015, 132. [Google Scholar] [CrossRef]

- Valentin, D.; Paray, F.; Guetta, B. The hygrothermal behaviour of glass fibre reinforced Pa66 composites: A study of the effect of water absorption on their mechanical properties. J. Mater. Sci. 1987, 22, 46–56. [Google Scholar] [CrossRef]

- Foulc, M.P.; Bergeret, A.; Ferry, L.; Ienny, P.; Crespy, A. Study of hygrothermal ageing of glass fibre reinforced PET composites. Polym. Degrad. Stab. 2005, 89, 461–470. [Google Scholar] [CrossRef]

- Evans, D.C. Polymer-fluid interaction in relation to wear. In Proceedings of the Third Leeds–Lyon Symposium Tribology Wear Non-Metallic Materials; Mechanical Engineering Publications Limited for the Institute of Tribology: Leeds, London, 1978; pp. 47–55. [Google Scholar]

- Autay, R.; Njeh, A.; Dammak, F. Effect of hygrothermal aging on mechanical and tribological behaviors of short glass-fiber-reinforced PA66. J. Thermoplast. Compos. Mater. 2018. [Google Scholar] [CrossRef]

- Yousif, B.F.; Nirmal, U. Wear and frictional performance of polymeric composites aged in various solutions. Wear 2011, 272, 97–104. [Google Scholar] [CrossRef]

- Palmeira Belotti, L. Tribological Performance of Hygrothermally Aged UHMWPE Hybrid Composites 2018. Available online: http://www.diva-portal.org/smash/record.jsf?pid=diva2%3A1243332&dswid=5262 (accessed on 22 November 2018).

- Wang, J.; Chen, J.; Chen, B.; Yan, F.; Xue, Q. Wear behaviors and wear mechanisms of several alloys under simulated deep-sea environment covering seawater hydrostatic pressure. Tribol. Int. 2012, 56, 38–46. [Google Scholar] [CrossRef]

- Shen, C.-H.; Springer, G.S. Moisture Absorption and Desorption of Composite Materials. J. Compos. Mater. 1976, 10, 2–20. [Google Scholar] [CrossRef]

- Wingard, D. Use of DSC and DMA Techniques to Help Investigate a Material Anomaly for PTFE Used in Processing a Piston Cup for the Urine Processor Assembly (UPA) on International Space Station (ISS). In Proceedings of the 2010 North American Thermal Analysis Society (NATAS) Conference, Philadelphia, PA, USA, 16–18 August 2010. [Google Scholar]

- Owens, D.K.; Wendt, R.C. Estimation of the surface free energy of polymers. J. Appl. Polym. Sci. 1969, 13, 1741–1747. [Google Scholar] [CrossRef]

- Dortwegt, R.; Maughan, E.V. The chemistry of copper in water and related studies planned at the Advanced Photon Source. In Proceedings of the PACS2001, 2001 Part Accel Conf (Cat No01CH37268), Chicago, IL, USA, 18–22 June 2001; Volume 2, pp. 1456–1458. [Google Scholar] [CrossRef]

- Miroshnikov, V.N.; Fedorchenko, I.M. Oxidation kinetics of bronze-graphite materials in boiling water and steam in the laboratory. Powder Metall. Met. Ceram. 1968, 7, 43–47. [Google Scholar] [CrossRef]

- Holinski, R.; Gänsheimer, J. A study of the lubricating mechanism of molybdenum disulfide. Wear 1972, 19, 329–342. [Google Scholar] [CrossRef]

- Ignat’eva, L.N.; Buznik, V.M. IR-Spectroscopic Examination of Polytetrafluoroethylene and Its Modified Forms. Russ. J. Gen. Chem. 2009, 52, 677–685. [Google Scholar] [CrossRef]

- Dubal, D.P.; Dhawale, D.S.; Salunkhe, R.R.; Jamdade, V.S.; Lokhande, C.D. Fabrication of copper oxide multilayer nanosheets for supercapacitor application. J. Alloys Compd. 2010, 492, 26–30. [Google Scholar] [CrossRef]

- Pusawale, S.N.; Deshmukh, P.R.; Lokhande, C.D. Chemical synthesis and characterization of hydrous tin oxide (SnO2:H2O) thin films. Bull. Mater. Sci. Indian Acad. Sci. 2011, 34, 1179–1183. [Google Scholar] [CrossRef]

- Tanaka, K.; Kawakami, S. Effect of various fillers on the friction and wear of polytetrafluoroethylene-based composites. Wear 1982, 79, 221–234. [Google Scholar] [CrossRef]

- Lancaster, J.K. Polymer-based bearing materials. The role of fillers and fibre reinforcement. Tribology 1972, 5, 249–255. [Google Scholar] [CrossRef]

- Blanchet, T.A.; Kennedy, F.E. Sliding wear mechanism of polytetrafluoroethylene (PTFE) and PTFE composites. Wear 1992, 153, 229–243. [Google Scholar] [CrossRef]

- Conte, M.; Pinedo, B.; Igartua, A. Role of crystallinity on wear behavior of PTFE composites. Wear 2013, 307, 81–86. [Google Scholar] [CrossRef]

- Li, D.; Celestin, A. TEFLON MECHANICAL PROPERTIES AT HIGH TEMPERATURE BY NANOINDENTATION. 2016. Available online: https://nanovea.com/App-Notes/temperature-nanoindentation.pdf (accessed on 22 November 2018).

- Chen, Y.K.; Modi, O.P.; Mhay, A.S.; Chrysanthou, A.; O’Sullivan, J.M. The effect of different metallic counterface materials and different surface treatments on the wear and friction of polyamide 66 and its composite in rolling-sliding contact. Wear 2003, 255, 714–721. [Google Scholar] [CrossRef]

- Sebastian, R.; Noll, A.; Zhang, G.; Burkhart, T.; Wetzel, B. Friction and wear of PPS/CNT nanocomposites with formation of electrically isolating transfer films. Tribol. Int. 2013, 64, 187–195. [Google Scholar] [CrossRef]

- Ye, S.; Zeng, X. Tribological Properties of PTFE and PTFE Composites at Different Temperatures. Tribol. Trans. 2014, 57, 382–386. [Google Scholar] [CrossRef]

- Lancaster, J.K. Lubrication of carbon fibre-reinforced polymers part I—Water and aqueous solutions. Wear 1972, 20, 315–333. [Google Scholar] [CrossRef]

- Farr, J.P.G. Molybdenum disulphide in lubrication. A review. Wear 1975, 35, 1–22. [Google Scholar] [CrossRef]

- Khare, H.S.; Burris, D.L. The effects of environmental water and oxygen on the temperature-dependent friction of sputtered molybdenum disulfide. Tribol. Lett. 2013, 52, 485–493. [Google Scholar] [CrossRef]

- Jia, J.; Chen, J.; Wang, J.; Zhou, H. Friction and wear properties of bronze–graphite composite under water lubrication. Tribol. Int. 2004, 37, 423–429. [Google Scholar] [CrossRef]

- Lai, S.Q.; Yue, L.; Li, T.S. Mechanism of filler action in reducing the wear of PTFE polymer by differential scanning calorimetry. J. Appl. Polym. Sci. 2007, 106, 3091–3097. [Google Scholar] [CrossRef]

- Borruto, A.; Crivellone, G.; Marani, F. Influence of surface wettability on friction and wear tests. Wear 1998, 222, 57–65. [Google Scholar] [CrossRef]

- Vadivel, H.S.; Golchin, A.; Emami, N. Tribological behaviour of carbon filled hybrid UHMWPE composites in water. Tribol. Int. 2018, 124, 169–177. [Google Scholar] [CrossRef]

| Specimen | Filler | Filler Content (wt %) | Shape and Size of the Filler |

|---|---|---|---|

| PTFE | Unfilled | - | - |

| Bronze PTFE (PB) | Bronze | 40 | Irregular shape particle; 2–28 µm in size |

| Black glass fibre PTFE (PGF) | Glass Fibre | 25 | Fibre; mean diameter of the cross-section, 17 µm |

| MoS2+Black glass fibre PTFE (PGFM) | Glass Fibre MoS2 | 20 5 | Fibre; mean diameter of the cross-section, 17 µm; Powder (crushed); 4–74 µm in size |

| Room Temperature | ||

|---|---|---|

| Mm (%) | D (mm2/day) | |

| Unfilled PTFE | 4.89 × 10−3 | 2.06 × 10−9 |

| Glass fibre-filled PTFE (PGF) | 4.09 × 10−1 | 2.80 × 10−7 |

| Bronze-filled PTFE (PB) | 3.82 × 10−1 | 4.63 × 10−8 |

| Glass fibre and MoS2 (PGFM) | 1.79 × 10−1 | 8.83 × 10−8 |

| 80 °C | ||

| Mm (%) | D (mm2/day) | |

| Unfilled PTFE | 6.70 × 10−3 | 5.47 × 10−9 |

| Glass fibre-filled PTFE (PGF) | 4.60 × 10−1 | 1.44 × 10−6 |

| Bronze-filled PTFE (PB) | 4.33 × 10−1 | 9.68 × 10−8 |

| Glass fibre and MoS2 (PGFM) | 1.06 × 100 | 1.22 × 10−7 |

| Sample | Melting Temperature (°C) | Degree of Crystallinity (%) | ||||

|---|---|---|---|---|---|---|

| Non-Aged Samples | Two Months Aged, Room Temperature | Two Months Aged, 80 °C | 132 Days Aged, Room Temperature | 132 Days Aged, 80 °C | ||

| Unfilled PTFE | 329 | 30.46 | 30.42 | 30.43 | 30.47 | 30.41 |

| PB | 330 | 27.48 | 25.98 | 23.46 | 23.53 | 23.22 |

| PGF | 329 | 37.34 | 37.23 | 36.80 | 36.43 | 35.93 |

| PGFM | 328 | 38.97 | 38.56 | 38.51 | 37.88 | 37.49 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Homayoun, M.-R.; Golchin, A.; Emami, N. Effect of Hygrothermal Ageing on Tribological Behaviour of PTFE-Based Composites. Lubricants 2018, 6, 103. https://doi.org/10.3390/lubricants6040103

Homayoun M-R, Golchin A, Emami N. Effect of Hygrothermal Ageing on Tribological Behaviour of PTFE-Based Composites. Lubricants. 2018; 6(4):103. https://doi.org/10.3390/lubricants6040103

Chicago/Turabian StyleHomayoun, Mohammad-Reza, Arash Golchin, and Nazanin Emami. 2018. "Effect of Hygrothermal Ageing on Tribological Behaviour of PTFE-Based Composites" Lubricants 6, no. 4: 103. https://doi.org/10.3390/lubricants6040103

APA StyleHomayoun, M. -R., Golchin, A., & Emami, N. (2018). Effect of Hygrothermal Ageing on Tribological Behaviour of PTFE-Based Composites. Lubricants, 6(4), 103. https://doi.org/10.3390/lubricants6040103