Development and Characterization of Multi-Scale Carbon Reinforced PPS Composites for Tribological Applications

Abstract

:1. Introduction

2. Materials and Methods

2.1. Sample Preparation

2.2. Characterization Methods

2.2.1. Morphological Characterization

2.2.2. Thermogravimetric Analysis (TGA)

2.2.3. Differential Scanning Calorimetry (DSC)

2.2.4. Micro Hardness Measurements

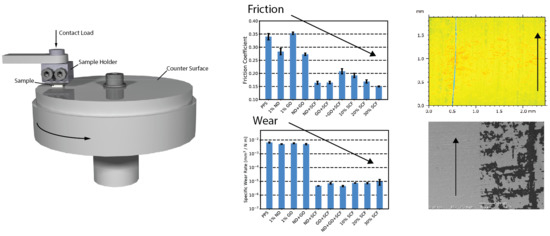

2.2.5. Tribological Characterization

2.2.6. SEM/EDS and Optical Profilometry Observations

2.2.7. Wettability

2.2.8. Dilatometry

3. Results and Discussion

3.1. Morphological Characterization

3.2. Thermogravimetric Analysis (TGA)

3.3. Differential Scanning Calorimetry (DSC)

3.4. Micro Hardness

3.5. Tribological Characterization

3.5.1. Friction and Wear

3.5.2. SEM/EDS and Optical Profilometry Observations

3.6. Wettability

3.7. Dilatometry

4. Conclusions

- The used sample preparation processes did not negatively influence the polymer powder morphology and a good reinforcement dispersion was evident.

- The addition of the carbon based reinforcements increased the thermal stability of the polymer by delaying the thermal degradation.

- SCF and ND were effective in reducing friction and wear in water lubricated conditions. A synergistic effect was observed by combining both reinforcements, reducing the friction coefficient by over 50% and the specific wear rate in the order of ∼103.

- Under dry sliding conditions, the addition of ND and SCF allowed for a reduction in friction but an increase in specific wear rate was observed.

- The addition of PTFE reduced both friction and wear in water lubricated conditions while under dry sliding conditions only the friction coefficient was reduced by over 67%.

Author Contributions

Funding

Conflicts of Interest

References

- Nicolais, L.; Meo, M.; Milella, E. Composite Materials: A Vision for the Future; Bücher, Springer: London, UK, 2011. [Google Scholar] [CrossRef]

- Brostow, W.; Lobland, H.E.H. Materials: Introduction and Applications; John Wiley & Sons: Hoboken, NJ, USA, 2016. [Google Scholar]

- Briscoe, B.J.; Sinha, S.K. Chapter 1—Tribological applications of polymers and their composites—Past, present and future prospects. In Tribology of Polymeric Nanocomposites, 2nd ed.; Friedrich, K., Schlarb, A.K., Eds.; Butterworth-Heinemann: Oxford, UK, 2013; pp. 1–22. [Google Scholar] [CrossRef]

- Frlic, S. Tribological Behaviour of Polymer Materials for Gear Applications. Master’s Thesis, Luleå University of Technology, Luleå, Sweden, 2016. [Google Scholar]

- Golchin, A.; Friedrich, K.; Noll, A.; Prakash, B. Tribological behavior of carbon-filled PPS composites in water lubricated contacts. Wear 2015, 328–329, 456–463. [Google Scholar] [CrossRef]

- Yamamoto, Y.; Hashimoto, M. Friction and wear of water lubricated PEEK and PPS sliding contacts Part 2. Composites with carbon or glass fibre. Wear 2004, 257, 181–189. [Google Scholar] [CrossRef]

- Chukov, D.I.; Stepashkin, A.A.; Maksimkin, A.V.; Tcherdyntsev, V.V.; Kaloshkin, S.D.; Kuskov, K.V.; Bugakov, V.I. Investigation of structure, mechanical and tribological properties of short carbon fiber reinforced UHMWPE-matrix composites. Compos. Part B Eng. 2015, 76, 79–88. [Google Scholar] [CrossRef]

- Zhang, D.; Qi, H.; Zhao, F.; Zhang, G.; Wang, T.; Wang, Q. Tribological performance of PPS composites under diesel lubrication conditions. Tribol. Int. 2017, 115, 338–347. [Google Scholar] [CrossRef]

- Xu, H.; Feng, Z.; Chen, J.; Zhou, H. Tribological behavior of the carbon fiber reinforced polyphenylene sulfide (PPS) composite coating under dry sliding and water lubrication. Mater. Sci. Eng. A 2006, 416, 66–73. [Google Scholar] [CrossRef]

- Luo, W.; Liu, Q.; Li, Y.; Zhou, S.; Zou, H.; Liang, M. Enhanced mechanical and tribological properties in polyphenylene sulfide/polytetrafluoroethylene composites reinforced by short carbon fiber. Compos. Part B Eng. 2016, 91, 579–588. [Google Scholar] [CrossRef]

- Golchin, A.; Wikner, A.; Emami, N. An investigation into tribological behaviour of multi-walled carbon nanotube/graphene oxide reinforced UHMWPE in water lubricated contacts. Tribol. Int. 2016, 95, 156–161. [Google Scholar] [CrossRef]

- Ayatollahi, M.R.; Alishahi, E.; Doagou-R, S.; Shadlou, S. Tribological and mechanical properties of low content nanodiamond/epoxy nanocomposites. Compos. Part B Eng. 2012, 43, 3425–3430. [Google Scholar] [CrossRef]

- Neitzel, I.; Mochalin, V.; Bares, J.A.; Carpick, R.W.; Erdemir, A.; Gogotsi, Y. Tribological Properties of Nanodiamond-Epoxy Composites. Tribol. Lett. 2012, 47, 195–202. [Google Scholar] [CrossRef]

- Lee, J.Y.; Lim, D.S. Tribological behavior of PTFE film with nanodiamond. Surf. Coat. Technol. 2004, 188, 534–538. [Google Scholar] [CrossRef]

- Vadivel, H.S. Tribological Behaviour of Hybrid Carbon Filled UHMWPE Composites in Water. Master’s Thesis, Luleå University of Technology, Luleå, Sweden, 2016. [Google Scholar]

- Friedrich, K. Microstructural efficiency and fracture toughness of short fiber/thermoplastic matrix composites. Compos. Sci. Technol. 1985, 22, 43–74. [Google Scholar] [CrossRef]

- Lin, G.M.; Lai, J.K. Fracture mechanism in short fibre reinforced thermoplastic resin composites. J. Mater. Sci. 1993, 28, 5240–5246. [Google Scholar] [CrossRef]

- Biswas, S.; Vijayan, K. Friction and wear of PTFE—A review. Wear 1992, 158, 193–211. [Google Scholar] [CrossRef]

- Ashby, M.F. Materials Selection in Mechanical Design; Elsevier Science: Amsterdam, The Netherlands, 2004. [Google Scholar]

- Hay, J.N.; Luck, D.A. The conformation of crystalline poly(phenylene sulphide). Polymer 2001, 42, 8297–8301. [Google Scholar] [CrossRef]

- Owens, D.K.; Wendt, R.C. Estimation of the surface free energy of polymers. J. Appl. Polym. Sci. 1969, 13, 1741–1747. [Google Scholar] [CrossRef]

- Melk, L.; Emami, N. Mechanical and thermal performances of UHMWPE blended vitamin E reinforced carbon nanoparticle composites. Compos. Part B Eng. 2018, 146, 20–27. [Google Scholar] [CrossRef]

- Rezaei, F.; Yunus, R.; Ibrahim, N.A. Effect of fiber length on thermomechanical properties of short carbon fiber reinforced polypropylene composites. Mater. Des. 2009, 30, 260–263. [Google Scholar] [CrossRef]

- Chang, L.; Zhang, Z. Tribological properties of epoxy nanocomposites. Part II. A combinative effect of short carbon fibre with nano-TiO2. Wear 2006, 260, 869–878. [Google Scholar] [CrossRef]

- Friedrich, K.; Schlarb, A.K.; Bahadur, S.; Schwartz, C. The effect of nanoparticle fillers on transfer film formation and the tribological behavior of polymers. Tribol. Polym. Nanocompos. 2013, 23–48. [Google Scholar] [CrossRef]

- Zhai, W.; Srikanth, N.; Kong, L.B.; Zhou, K. Carbon nanomaterials in tribology. Carbon 2017, 119, 150–171. [Google Scholar] [CrossRef]

- Friedrich, K. Polymer composites for tribological applications. Adv. Ind. Eng. Polym. Res. 2018, 1, 3–39. [Google Scholar] [CrossRef]

- Borruto, A.; Crivellone, G.; Marani, F. Influence of Surface Energy on Friction and Wear Phenomena. J. Appl. Phys. 1961, 32, 1440–1444. [Google Scholar] [CrossRef]

| (a) | |||

|---|---|---|---|

| Series 1 | |||

| Label | Reinforcement [%] | ||

| ND | GO | SCF | |

| PPS | – | – | – |

| 1% ND | 1 | – | – |

| 1% GO | – | 1 | – |

| ND/GO | 1 | 1 | – |

| ND/SCF | 0.5 | – | 10 |

| GO/SCF | – | 0.5 | 10 |

| ND/GO/SCF | 0.5 | 0.5 | 10 |

| 10% SCF | – | – | 10 |

| 20% SCF | – | – | 20 |

| 30% SCF | – | – | 30 |

| (b) | |||

| Series 2 | |||

| Label | Reinforcement [%] | ||

| ND | SCF | PTFE | |

| PPS | – | – | – |

| 0.5% ND | 0.5 | – | – |

| 1% ND | 1 | – | – |

| 10% SCF | – | 10 | – |

| 10% PTFE | – | – | 10 |

| Sample | t [C] | t [C] | t [C] |

|---|---|---|---|

| PPS | 504.7 | 678.1 | 706.0 |

| 1% ND | 500.6 | 667.0 | 682.0 |

| 1% GO | 503.0 | 658.0 | 717.0 |

| ND+GO | 504.9 | 672.5 | 708.8 |

| ND+SCF | 505.4 | 678.5 | 758.0 |

| GO+SCF | 513.7 | 664.6 | 776.8 |

| ND+GO+SCF | 512.0 | 621.0 | 771.9 |

| 10% SCF | 505.7 | 622.0 | 753.0 |

| 20% SCF | 505.3 | 605.0 | 769.0 |

| 30% SCF | 513.2 | 618.9 | 769.0 |

| Sample | CA Water [] | CA Dio [] | [mJ/m] | [m/m K] |

|---|---|---|---|---|

| PPS | 83. 8 ± 3. 1 | 34. 3 ± 2. 1 | 44. 2 | |

| 0.5% ND | 84. 7 ± 3. 4 | 43. 7 ± 2. 2 | 40. 1 | |

| 1% ND | 85. 6 ± 0. 9 | 45. 6 ± 1. 5 | 39. 0 | |

| 10% SCF | 90. 0 ± 1. 6 | 46. 1 ± 3. 5 | 37. 7 | |

| 10% PTFE | 88. 6 ± 1. 5 | 46. 3 ± 2. 2 | 37. 7 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jain, A.; Somberg, J.; Emami, N. Development and Characterization of Multi-Scale Carbon Reinforced PPS Composites for Tribological Applications. Lubricants 2019, 7, 34. https://doi.org/10.3390/lubricants7040034

Jain A, Somberg J, Emami N. Development and Characterization of Multi-Scale Carbon Reinforced PPS Composites for Tribological Applications. Lubricants. 2019; 7(4):34. https://doi.org/10.3390/lubricants7040034

Chicago/Turabian StyleJain, Ayush, Julian Somberg, and Nazanin Emami. 2019. "Development and Characterization of Multi-Scale Carbon Reinforced PPS Composites for Tribological Applications" Lubricants 7, no. 4: 34. https://doi.org/10.3390/lubricants7040034

APA StyleJain, A., Somberg, J., & Emami, N. (2019). Development and Characterization of Multi-Scale Carbon Reinforced PPS Composites for Tribological Applications. Lubricants, 7(4), 34. https://doi.org/10.3390/lubricants7040034