The Performance of SiO2 and TiO2 Nanoparticles as Lubricant Additives in Sunflower Oil

Abstract

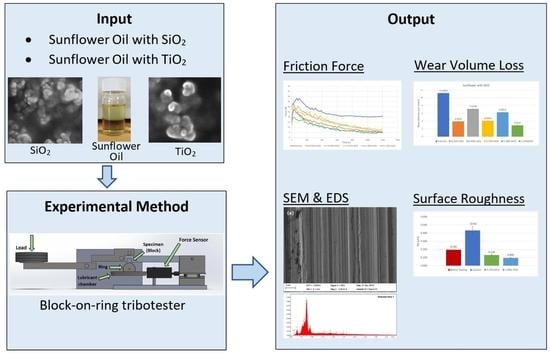

:1. Introduction

2. Materials and Methods

2.1. Formulation of the Nano-Lubricants

2.2. Rheological Measurements

2.3. Tribological Characterization

2.4. Surface Analysis

3. Results and Discussion

3.1. Rheological Characterization

3.2. Power Law and Cross-Equation Rheological Models

3.3. Tribological Results

3.4. SEM and EDS Analysis

3.5. Surface Roughness Analysis

4. Conclusions

- The rheological behavior of the sunflower nano-lubricant is dependent on the concentration and type of nanoparticles. For sunflower oil enhanced with SiO2 nanoparticles, the viscosity increased at higher concentrations, whereas for sunflower oil enhanced with TiO2 nanoparticles, the viscosity decreased as the concentration of TiO2 nanoparticles increased.

- Different rheological behaviors were observed by adding SiO2 and TiO2 into the sunflower oil. The sunflower oil enhanced with SiO2 nanoparticles presented a shear-thinning behavior, whereas the sunflower oil enhanced with TiO2 nanoparticles showed a shear thickening behavior.

- SiO2 and TiO2 nanoparticles were effective additives for incorporation into the sunflower oil; where they reduced the COF and wear volume loss by 77.7 and 74.1%, and 93.7 and 70.1%, respectively.

- The surface enhancement of the worn surfaces via the polishing effect produced by the nanoparticle additives was confirmed using SEM and profilometry analyses. The protective film lubrication mechanism was discovered using EDS elemental analysis on the worn surfaces.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Siniawski, M.T. Influence of fatty acid composition on the tribological performance of two vegetable-based lubricants. J. Synth. Lubr. 2007, 24, 101–110. Available online: https://onlinelibrary.wiley.com/doi/abs/10.1002/jsl.32 (accessed on 20 November 2019). [CrossRef]

- Quinchia, L.A.; Delgado, M.A.; Reddyhoff, T.; Gallegos, C.; Spikes, H.A. Tribological studies of potential vegetable oil-based lubricants containing environmentally friendly viscosity modifiers. Tribol. Int. 2014, 69, 110–117. [Google Scholar] [CrossRef]

- Darminesh, S.P.; Sidik, N.A.C.; Najafi, G.; Mamat, R.; Ken, T.L.; Asako, Y. Recent development on biodegradable nanolubricant: A review. Int. Commun. Heat Mass Transf. 2017, 86, 159–165. [Google Scholar] [CrossRef]

- Jayadas, N.H.; Nair, K.P. Coconut oil as base oil for industrial lubricants—Evaluation and modification of thermal, oxidative and low temperature properties. Tribol. Int. 2006, 39, 873–878. [Google Scholar] [CrossRef]

- Zareh-Desari, B.; Davoodi, B. Assessing the lubrication performance of vegetable oil-based nano-lubricants for environmentally conscious metal forming processes. J. Clean. Prod. 2016, 135, 1198–1209. [Google Scholar] [CrossRef]

- Fox, N.J.; Stachowiak, G.W. Vegetable oil-based lubricants—A review of oxidation. Tribol. Int. 2007, 40, 1035–1046. [Google Scholar] [CrossRef]

- Jabal, M.H.; Abdulmunem, A.R.; Abd, H.S. Experimental investigation of tribological characteristics and emissions with nonedible sunflower oil as a biolubricant. J. Air Waste Manag. Assoc. 2019, 69, 109–118. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Gnanasekaran, D.; Chavidi, V.P. Vegetable oil based bio-lubricants and transformer fluids. In Materials Forming, Machining and Tribology; Springer: Singapore, 2018. [Google Scholar] [CrossRef]

- Rudnick, L.R. (Ed.) Lubricant Additives: Chemistry and Applications, 3rd ed.; Chemical Industries; CRC Press Taylor & Francis Group: Boca Raton, FL, USA, 2017. [Google Scholar]

- Peng, D.X.; Kang, Y.; Hwang, R.M.; Shyr, S.S.; Chang, Y.P. Tribological properties of diamond and SiO2 nanoparticles added in paraffin. Tribol. Int. 2009, 42, 911–917. [Google Scholar] [CrossRef]

- Hernández Battez, A.; González, R.; Viesca, J.L.; Fernández, J.E.; Díaz Fernández, J.M.; Machado, A.; Chou, R.; Riba, J. CuO, ZrO2 and ZnO nanoparticles as antiwear additive in oil lubricants. Wear 2008, 265, 422–428. [Google Scholar] [CrossRef]

- Liu, G.; Li, X.; Qin, B.; Xing, D.; Guo, Y.; Fan, R. Investigation of the mending effect and mechanism of copper nano-particles on a tribologically stressed surface. Tribol. Lett. 2004, 17, 961–966. [Google Scholar] [CrossRef]

- Rapoport, L.; Leshchinsky, V.; Lvovsky, M.; Nepomnyashchy, O.; Volovik, Y.; Tenne, R. Mechanism of friction of fullerenes. Ind. Lubr. Tribol. 2002, 54, 171–176. [Google Scholar] [CrossRef]

- Wu, Y.Y.; Tsui, W.C.; Liu, T.C. Experimental analysis of tribological properties of lubricating oils with nanoparticle additives. Wear 2007, 262, 819–825. [Google Scholar] [CrossRef]

- Chiñas-Castillo, F.; Spikes, H.A. Mechanism of action of colloidal solid dispersions. J. Tribol. 2003, 125, 552–557. [Google Scholar] [CrossRef]

- Tao, X.; Jiazheng, Z.; Kang, X. The ball-bearing effect of diamond nanoparticles as an oil additive. J. Phys. D Appl. Phys. 1996, 29, 2932–2937. [Google Scholar] [CrossRef]

- Chang, L.; Zhang, Z.; Breidt, C.; Friedrich, K. Tribological properties of epoxy nanocomposites: I. Enhancement of the wear resistance by nano-TiO2 particles. Wear 2005, 258, 141–148. [Google Scholar] [CrossRef]

- Peng, D.-X.; Chen, C.-H.; Kang, Y.; Chang, Y.-P.; Chang, S.-Y. Size effects of SiO2 nanoparticles as oil additives on tribology of lubricant. Ind. Lubr. Tribol. 2010, 62, 111–120. [Google Scholar] [CrossRef]

- Peng, D.-X.; Kang, Y.; Chen, S.-K.; Shu, F.-C.; Chang, Y.-P. Dispersion and tribological properties of liquid paraffin with added aluminum nanoparticles. Ind. Lubr. Tribol. 2010, 62, 341–348. [Google Scholar] [CrossRef]

- Hu, Z.S.; Lai, R.; Lou, F.; Wang, L.G.; Chen, Z.L.; Chen, G.X.; Dong, J.X. Preparation and tribological properties of nanometer magnesium borate as lubricating oil additive. Wear 2002, 252, 370–374. [Google Scholar] [CrossRef]

- Xiaodong, Z.; Xun, F.; Huaqiang, S.; Zhengshui, H. Lubricating properties of Cyanex 302-modified MoS2 microspheres in base oil 500SN. Lubr. Sci. 2007, 19, 71–79. [Google Scholar] [CrossRef]

- Rastogi, R.B.; Yadav, M.; Bhattacharya, A. Application of molybdenum complexes of 1-Aryl-2,5-dithiohydrazodicarbonamides as extreme pressure lubricant additives. Wear 2002, 252, 686–692. [Google Scholar] [CrossRef]

- Gulzar, M.; Masjuki, H.H.; Kalam, M.A.; Varman, M.; Zulkifli, N.W.M.; Mufti, R.A.; Zahid, R.; Yunus, R. Dispersion stability and tribological characteristics of TiO2/SiO2 nanocomposite-enriched biobased lubricant. Tribol. Trans. 2017, 60, 670–680. [Google Scholar] [CrossRef]

- Lee, M.; Alcoutlabi, M.; Magda, J.J.; Dibble, C.; Solomon, M.J.; Shi, X.; McKenna, G.B. The effect of the shear-thickening transition of model colloidal spheres on the sign of N1 and on the radial pressure profile in torsional shear flows. J. Rheol. 2006, 50, 293–311. [Google Scholar] [CrossRef] [Green Version]

- Alcoutlabi, M.; Baek, S.G.; Magda, J.J.; Shi, X.; Hutcheson, S.A.; McKenna, G.B. A comparison of three different methods for measuring both normal stress differences of viscoelastic liquids in torsional rheometers. Rheol. Acta 2009, 48, 191–200. [Google Scholar] [CrossRef]

- G02 Committee. Test Method for Ranking Resistance of Materials to Sliding Wear Using Block-on-Ring Wear Test; ASTM International: West Conshohocken, PA, USA, 2017. [Google Scholar]

- Sanukrishna, S.S.; Vishnu, S.; Jose Prakash, M. Experimental investigation on thermal and rheological behaviour of PAG lubricant modified with SiO2 nanoparticles. J. Mol. Liq. 2018, 261, 411–422. [Google Scholar] [CrossRef]

- Ghasemi, R.; Fazlali, A.; Mohammadi, A.H. Effects of TiO2 nanoparticles and oleic acid surfactant on the rheological behavior of engine lubricant oil. J. Mol. Liq. 2018, 268, 925–930. [Google Scholar] [CrossRef]

- Saravanakumar, N.; Jothi Saravanan, M.L.; Barathkumar, K.E.; Gokula Kannan, K.; Karthikeyan, R. Development and testing of nano particulate lubricant for worm gear application. J. Mech. Sci. Technol. 2019, 33, 1785–1791. [Google Scholar] [CrossRef]

- Gulzar, M.; Masjuki, H.; Varman, M.; Kalam, M.; Mufti, R.A.; Zulkifli, N.; Yunus, R.; Zahid, R. Improving the AW/EP ability of chemically modified palm oil by adding CuO and MoS2 nanoparticles. Tribol. Int. 2015, 88, 271–279. [Google Scholar] [CrossRef]

- Lee, C.-G.; Hwang, Y.-J.; Choi, Y.-M.; Lee, J.-K.; Choi, C.; Oh, J.-M. A study on the tribological characteristics of graphite nano lubricants. Int. J. Precis. Eng. Manuf. 2009, 10, 85–90. [Google Scholar] [CrossRef]

- Arumugam, S.; Sriram, G. Synthesis and characterization of rapeseed oil bio-lubricant dispersed with nano copper oxide: Its effect on wear and frictional behavior of piston ring–cylinder liner combination. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2014, 228, 1308–1318. [Google Scholar] [CrossRef]

| Material | Properties |

|---|---|

| Lubricant | |

| Sunflower oil | Density (40 °C): 0.90 g/cm3 |

| Viscosity (40 °C): 35 mPas | |

| Nanoparticles | |

| Silicon dioxide | Chemical Formula: SiO2, Purity: 99.5% |

| Particle size: 20–30 nm | |

| Titanium oxide | Chemical Formula: TiO2 (anatase), Purity: 99.9% |

| Particle size: 18 nm | |

| Specimens | |

| Blocks | AISI 304 steel, dimensions: 14 × 6.35 × 6.35 mm, hardness: 128 HRB |

| Rings | AISI 52100 steel, d = 40 mm, hardness: 60 HRC |

| Model | Configuration | K | n | R2 | η0 | η∞ | SSE |

|---|---|---|---|---|---|---|---|

| Power Law | Sunflower Oil w/1.25% SiO2 | 180.4 | 0.8547 | 0.8516 | N/A | N/A | 110.3 |

| Cross Equation | Sunflower Oil w/1.25% SiO2 | 0.1134 | 0.9874 | 0.8877 | 190 | 84.49 | 8.347 |

| Power Law | Sunflower Oil w/1.00% TiO2 | 50.92 | 1.0320 | 0.7395 | N/A | N/A | 27.16 |

| Cross Equation | Sunflower Oil w/1.00% TiO2 | 0.0175 | 3.3032 | 0.8245 | 55.91 | 59.99 | 18.3 |

| Element | Sunflower Oil (SO) Conc. (wt. %) | SO with SiO2 1.25% Conc. (wt. %) | SO with TiO2 1.0% Conc. (wt. %) |

|---|---|---|---|

| C K | 9.66 | 9.70 | 7.46 |

| O K | 3.04 | 3.44 | 5.54 |

| Cr L | 12.08 | 11.19 | 8.65 |

| Mn L | 2.92 | 2.81 | 4.54 |

| Fe L | 56.22 | 57.20 | 51.58 |

| Ni L | 11.44 | 11.44 | 10.77 |

| Al K | 0.49 | 0.56 | 0.10 |

| Si K | 1.53 | 1.61 | 0.69 |

| P K | 0.98 | 0.79 | 0.20 |

| S K | 1.66 | 1.25 | 1.14 |

| Ti L | 0 | 0 | 9.31 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cortes, V.; Sanchez, K.; Gonzalez, R.; Alcoutlabi, M.; Ortega, J.A. The Performance of SiO2 and TiO2 Nanoparticles as Lubricant Additives in Sunflower Oil. Lubricants 2020, 8, 10. https://doi.org/10.3390/lubricants8010010

Cortes V, Sanchez K, Gonzalez R, Alcoutlabi M, Ortega JA. The Performance of SiO2 and TiO2 Nanoparticles as Lubricant Additives in Sunflower Oil. Lubricants. 2020; 8(1):10. https://doi.org/10.3390/lubricants8010010

Chicago/Turabian StyleCortes, Vicente, Karen Sanchez, Ramiro Gonzalez, Mataz Alcoutlabi, and Javier A. Ortega. 2020. "The Performance of SiO2 and TiO2 Nanoparticles as Lubricant Additives in Sunflower Oil" Lubricants 8, no. 1: 10. https://doi.org/10.3390/lubricants8010010

APA StyleCortes, V., Sanchez, K., Gonzalez, R., Alcoutlabi, M., & Ortega, J. A. (2020). The Performance of SiO2 and TiO2 Nanoparticles as Lubricant Additives in Sunflower Oil. Lubricants, 8(1), 10. https://doi.org/10.3390/lubricants8010010