The Effect of Surface Morphology of Tapered Rolling Bearings in High-Speed Train on Grease Lubrication

Abstract

:1. Introduction

- (a)

- The working conditions which tend to form mixed-lubrication are determined in high-speed trains. It is the phase of acceleration of starting or the process of braking at a low speed;

- (b)

- Mixed lubrication can be transitioned to full film lubrication by optimizing surface morphology of rolling element. A theoretical suggestion on surface morphology of rolling element is provided for surface machining. It is recommended that roughness is greater than 0.03 μm and less than 0.1 μm, kurtosis is 3, skewness is negative in a range of −1 to −0.5 and texture direction is parallel to rotation direction.

2. Governing Equations

2.1. Analysis of Motion and Geometry

2.2. Reynolds Equation

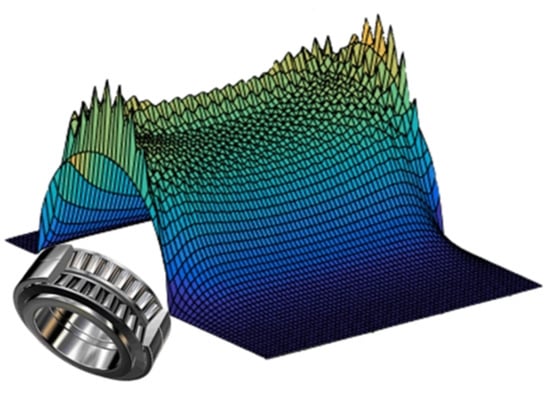

2.3. Film Thickness Equation

2.4. Pressure–Viscosity Relationship

2.5. Density–Pressure Model

2.6. Load Equation

2.7. Working Condition

2.8. Simulating Non-Gaussian Rough Surface by FFT

3. Numeric Procedure

4. Results and Discussion

4.1. Film Forming Characteristics in Actual Working Conditions

4.1.1. Effect of Velocity

4.1.2. Effect of Acceleration

4.2. Film Forming Characteristics on Micro Rough Surface

4.2.1. Effect of Texture Direction and Surface Roughness

4.2.2. Effect of Skewness Sk and Kurtosis Ku

5. Concluding Remarks

- On precondition of maximum-allowable axle load in high-speed trains, insufficient lubrication will occur when the temperature and acceleration increase and running speed of high-speed trains decreases. Therefore, considering of actual working conditions of high-speed trains, in this study, a certain working condition of simulation model was set as 70 °C ambient temperature and acceleration of 1.05 m/s2 and running speed of 25 km/h. As a result, mixed-lubrication is formed in that condition;

- When surface roughness was less than 0.1 μm, lubrication state could be transformed from mixed-lubrication to full film lubrication but it was less useful for improving lubrication when it was less than 0.03 μm. Texture-direction parallel to the rotation direction of rolling element was conducive to lubrication;

- When the surface of rolling element was nearly smooth, kurtosis less than three could reduce fluctuations of film thickness a bit. However, a negative value of skewness had little influence on film-forming of lubricant, it had some influence on reducing the maximum pressure of film.

Author Contributions

Funding

Conflicts of Interest

Appendix A

| E | = Integrated elastic modulus, 2.198e5Mpa | = Load, N | |

| = Pressure-viscosity exponent, m2/N | = X-coordinate (rolling direction), m | ||

| = Hertzian contact radius, m | = Y-coordinate, m | ||

| = Radius of Hertzian contact circle, m | = Viscosity of lubricant, Ns/m2 | ||

| = Film thickness, m | = Viscosity coefficient at an ambient temperature, Ns/m2 | ||

| = Shear layer thickness, m | = Film thickness ratio | ||

| = Rigid central film thickness, m | = Density, kg/m3 | ||

| = Average central film thickness, m | = Density in ambient condition, kg/m3 | ||

| = The maximum Hertzian contact pressure, Pa | = Effective radius in x-z plane, m | ||

| = Film pressure, Pa | = Effective radius in y-z plane, m | ||

| = Length of the rolling element, m | u1,u2 | = Velocities of surface1 and surface2, m/s |

References

- Di Puccio, F. Analytical Modeling of an Oblique Edge Crack in Rolling Contact Fatigue. Math. Probl. Eng. 2018, 2018, 1–12. [Google Scholar] [CrossRef] [Green Version]

- Dowson, D.; Higginson, G.R. A Numerical Solution to the Elasto-Hydrodynamic Problem. J. Mech. Eng. Sci. 1959, 1, 6–15. [Google Scholar] [CrossRef]

- Chao-Ho, H.; Rong-Tsong, L. Advanced multilevel solution for elastohydrodynamic lubrication circular contact problem. Wear 1994, 177, 117–127. [Google Scholar] [CrossRef]

- Lugt, P.M. Modern advancements in lubricating grease technology. Tribol. Int. 2016, 97, 467–477. [Google Scholar] [CrossRef]

- Vengudusamy, B.; Kuhn, M.; Rankl, M.; Spallek, R. Film forming behavior of greases under starved and fully flooded EHL conditions. Tribol. Trans. 2016, 59, 62–71. [Google Scholar] [CrossRef]

- Cousseau, T.; Björling, M.; Graça, B.; Campos, A.; Seabra, J.H.O.; Larsson, R. Film thickness in a ball-on-disc contact lubricated with greases, bleed oils and base oils. Tribol. Int. 2012, 53, 53–60. [Google Scholar] [CrossRef] [Green Version]

- Yoo, J.-G.; Kim, K.-W. Numerical analysis of grease thermal elastohydrodynamic lubrication problems using the Herschel-Bulkley model. Tribol. Int. 1997, 30, 401–408. [Google Scholar] [CrossRef]

- Pandey, R.K.; Ghosh, M.K. Thermal effects on film thickness and traction in rolling/sliding EHL line contacts—an accurate inlet zone analysis. Wear 1996, 192, 118–127. [Google Scholar] [CrossRef]

- Sountaree, R.; Mongkol, M. Analysis of Two Surfaces in Line Contact under TEHL with Non-Newtonian Lubricants. Appl. Mech. Mater. 2011, 148, 736–742. [Google Scholar] [CrossRef]

- Bonaventure, J.; Cayer-Barrioz, J.; Mazuyer, D. Transition Between Mixed Lubrication and Elastohydrodynamic Lubrication with Randomly Rough Surfaces. Tribol. Lett. 2016, 64, 2–13. [Google Scholar] [CrossRef]

- Choo, J.W.; Olver, A.V.; Spikes, H.A. The influence of transverse roughness in thin film, mixed elastohydrodynamic lubrication. Tribol. Int. 2007, 40, 220–232. [Google Scholar] [CrossRef]

- Torabi, A.; Akbarzadeh, S.; Salimpour, M.R.; Taei, M. Effect of surface roughness pattern on transient mixed elastohydrodynamic lubrication. Surf. Topogr. Metrol. Prop. 2015, 4, 15001. [Google Scholar] [CrossRef]

- Marian, M.; Tremmel, S.; Wartzack, S. Microtextured surfaces in higher loaded rolling-sliding EHL line-contacts. Tribol. Int. 2018, 127, 420–432. [Google Scholar] [CrossRef]

- Taee, M.; Torabi, A.; Akbarzadeh, S.; Khonsari, M.; Badrossamay, M. On the Performance of EHL Contacts with Textured Surfaces. Tribol. Lett. 2017, 65, 85. [Google Scholar] [CrossRef]

- Mo, S.; Zhang, T.; Jin, G.; Zhu, S.; Gong, J.; Bian, J. Elastohydrodynamic Lubrication Characteristics of Spiral Bevel Gear Subjected to Shot Peening Treatment. Math. Probl. Eng. 2018, 2018, 1–12. [Google Scholar] [CrossRef]

- Zhu, N.; Hu, Y.-Z. A Computer Program Package for the Prediction of EHL and Mixed Lubrication Characteristics, Friction, Subsurface Stresses and Flash Temperatures Based on Measured 3-D Surface Roughness. Tribol. Trans. 2001, 44, 383–390. [Google Scholar] [CrossRef]

- Yan, K.; Wang, N.; Zhai, Q.; Zhu, Y.; Zhang, J.; Niu, Q. Theoretical and experimental investigation on the thermal characteristics of double-row tapered roller bearings of high speed locomotive. Int. J. Heat Mass Transf. 2015, 84, 1119–1130. [Google Scholar] [CrossRef]

- Xu, H. Analysis of Hydrodynamic Lubrication of Oil Film between Elastic Rolling Elements. Master’s Thesis, Qingdao University of Technological, Qingdao, China, 2011. [Google Scholar]

- Kauzlarich, J.J.; Greenwood, J.A. Elastohydrodynamic Lubrication with Herschel-Bulkley Model Greases. ASLE Trans. 1972, 15, 269–277. [Google Scholar] [CrossRef]

- Peiran, Y.; Shizhu, W. A Generalized Reynolds Equation for Non-Newtonian Thermal Elastohydrodynamic Lubrication. J. Tribol. 1990, 112, 631–636. [Google Scholar] [CrossRef]

- Nelias, D.; Antaluca, E.; Boucly, V.; Creţu, S. A Three-Dimensional Semianalytical Model for Elastic-Plastic Sliding Contacts. J. Tribol. 2007, 129, 761–771. [Google Scholar] [CrossRef]

- Liu, S.; Wang, Q.; Liu, G. A versatile method of discrete convolution and FFT (DC-FFT) for contact analyses. Wear 2000, 243, 101–111. [Google Scholar] [CrossRef]

- Litvak, M.Y.; Malyugin, V.I. Poly-Gaussian models of a non-Gaussian randomly rough surface. Tech. Phys. 2012, 57, 524–533. [Google Scholar] [CrossRef]

- Deng, S.; Jia, Q. Design Principle of Rolling Bearing; China Standards Press: Beijing, China, 2008. [Google Scholar]

- Yang, X.; Pan, L.; Xiao, H. Research on the influence of radial clearance to the load of four-row conical roller bearing based on boundary element method. J. Eng. Des. 2014, 21, 191–197. [Google Scholar]

- Wang, Y.; Liu, Y.; Zhang, G.; Wang, Y. A Simulation Method for Non-Gaussian Rough Surfaces Using Fast Fourier Transform and Translation Process Theory. J. Tribol. 2017, 140, 021403. [Google Scholar] [CrossRef]

- Hu, Y.-Z.; Zhu, N. A Full Numerical Solution to the Mixed Lubrication in Point Contacts. J. Tribol. 1999, 122, 1–9. [Google Scholar] [CrossRef]

- Wang, B.M. High. Speed Motor Car Assembly and Bogie; AARSC: Chengdu, China, 2008. [Google Scholar]

- Wang, X.L.; Gui, C.L.; Zhu, Y.B. Determination and research of rheological parameters of homemade grease. J. Tribol. 1997, 17, 232–235. [Google Scholar]

- Wang, Z.; Shen, X.; Chen, X.; Tao, D.; Shi, L.; Liu, S. Experimental investigation of EHD grease lubrication in finite line contacts. Friction 2018, 7, 237–245. [Google Scholar] [CrossRef] [Green Version]

- Wilson, W.R.; Kalpakjian, S. Low-Speed Mixed Lubrication of Metal-Forming Processes. CIRP Ann. 1995, 44, 205–208. [Google Scholar] [CrossRef]

- Li, M.; Lyu, B.; Yuan, J.; Yao, W.; Zhou, F.; Zhong, M. Evolution and equivalent control law of surface roughness in shear-thickening polishing. Int. J. Mach. Tools Manuf. 2016, 108, 113–126. [Google Scholar] [CrossRef]

- Xie, X. The Study on Anti-Stick-Slip Phenonmenon and Reducing Friction of Sliding Machine Tool Guideways Based on Laser Composite Micro Textures. Doctoral Dissertation, Jiangsu University, Jiangsu, China, 2018. [Google Scholar]

| Parameters | Value | Parameters | Value |

|---|---|---|---|

| Length of rolling element, L (mm) | 48.9 | Angle of cone of outer raceway θ1 (°) | 9 |

| Average radius of rolling element R1 (mm) | 26.7 | Angle of cone of inner raceway θ2 (°) | 2 |

| Average radius of inner raceway R2 (mm) | 170.6 | Contact angle between rolling element and outer ring αo (°) | 11 |

| Arc radius of modified end Ry (mm) | 45.0 | Contact angle between rolling element and inner ring αi (°) | 8 |

| Parameter | Value | Parameter | Value |

|---|---|---|---|

| The yield stress in 10 °C, τy (Pa) | 556.79 | The yield stress in 70 °C, τy (Pa) | 348.3 |

| The plastic viscosity in 10 °C, ŋ0 (Pa.s) | 8.229 | The plastic viscosity in 70 °C, ŋ0 (Pa.s) | 0.899 |

| The plasticity index in 10 °C, α (Pa−1) | 0.696 | The plasticity index in 70 °C, α (Pa−1) | 0.929 |

| Environmental density of the grease ρ0 (kg.m−3) | 870 | The bulk density ρg (kg.m−3) | 7850 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, H.; Huang, H.; Yu, S.; Gu, W. The Effect of Surface Morphology of Tapered Rolling Bearings in High-Speed Train on Grease Lubrication. Lubricants 2020, 8, 76. https://doi.org/10.3390/lubricants8070076

Wang H, Huang H, Yu S, Gu W. The Effect of Surface Morphology of Tapered Rolling Bearings in High-Speed Train on Grease Lubrication. Lubricants. 2020; 8(7):76. https://doi.org/10.3390/lubricants8070076

Chicago/Turabian StyleWang, Heli, Haifeng Huang, Sibo Yu, and Weijie Gu. 2020. "The Effect of Surface Morphology of Tapered Rolling Bearings in High-Speed Train on Grease Lubrication" Lubricants 8, no. 7: 76. https://doi.org/10.3390/lubricants8070076

APA StyleWang, H., Huang, H., Yu, S., & Gu, W. (2020). The Effect of Surface Morphology of Tapered Rolling Bearings in High-Speed Train on Grease Lubrication. Lubricants, 8(7), 76. https://doi.org/10.3390/lubricants8070076