Experimental Investigation of the Mechanical and Surface Properties of Sub-Micron Carbon Spheres

Abstract

:1. Introduction

2. Experimental Methods

2.1. Material Synthesis

2.2. Characterization Techniques

3. Results and Discussion

3.1. Scanning Electron Microscopy and EDS

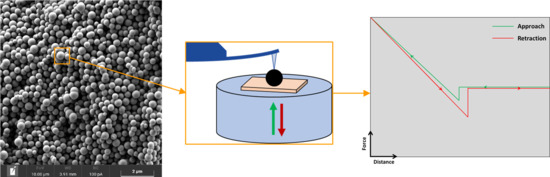

3.2. Atomic Force Microscopy

3.3. Nano-Indentation Experiments

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Cha, C.; Shin, S.R.; Annabi, N.; Dokmeci, M.R.; Khademhosseini, A. Carbon-Based Nanomaterials: Multifunctional Materials for Biomedical Engineering. ACS Nano 2013, 7, 2891–2897. [Google Scholar] [CrossRef] [PubMed]

- Zhai, W.; Srikanth, N.; Kong, L.B.; Zhou, K. Carbon nanomaterials in tribology. Carbon 2017, 119, 150–171. [Google Scholar] [CrossRef]

- Mauter, M.S.; Elimelech, M. Environmental applications of carbon-based nanomaterials. Environ. Sci. Technol. 2008, 42, 5843–5859. [Google Scholar] [CrossRef] [PubMed]

- Lu, G.; Lu, G.M.; Xiao, Z.M. Mechanical properties of porous materials. J. Porous Mater. 1999, 6, 359–368. [Google Scholar] [CrossRef]

- Yang, Y.H.; Li, W.Z. Radial elasticity of single-walled carbon nanotube measured by atomic force microscopy. Appl. Phys. Lett. 2011, 98, 041901. [Google Scholar] [CrossRef]

- Cesano, F.; Cravanzola, S.; Brunella, V.; Scarano, D. Porous carbon spheres from poly (4-ethylstyrene-co-divinylbenzene: Role of ZnCl2 and KOH agents in affecting porosity, surface area and mechanical properties. Microporous Mesoporous Mater. 2019, 288, 109605. [Google Scholar] [CrossRef]

- Trompeta, A.F.A.; Koumoulos, E.P.; Kartsonakis, I.A.; Charitidis, C.A. Advanced characterization of by-product carbon film obtained by thermal chemical vapor deposition during CNT manufacturing. Manuf. Rev. 2017, 4, 7. [Google Scholar] [CrossRef] [Green Version]

- Pol, S.V.; Pol, V.G.; Sherman, D.; Gedanken, A. A solvent free process for the generation of strong, conducting carbon spheres by the thermal degradation of waste polyethylene terephthalate. Green Chem. 2009, 11, 448–451. [Google Scholar] [CrossRef]

- Etacheri, V.; Wang, C.; O’Connell, M.J.; Chan, C.K.; Pol, V.G. Porous carbon sphere anodes for enhanced lithium-ion storage. J. Mater. Chem. A 2015, 3, 9861–9868. [Google Scholar] [CrossRef]

- Fan, X.; Li, W.; Fu, H.; Zhu, M.; Wang, L.; Cai, Z.; Liu, J.; Li, H. Probing the function of solid nanoparticle structure under boundary lubrication. ACS Sustain. Chem. Eng. 2017, 5, 4223–4233. [Google Scholar] [CrossRef]

- Alazemi, A.A.; Etacheri, V.; Dysart, A.D.; Stacke, L.E.; Pol, V.G.; Sadeghi, F. Ultrasmooth submicrometer carbon spheres as lubricant additives for friction and wear reduction. ACS Appl. Mater. Interfaces 2015, 7, 5514–5521. [Google Scholar] [CrossRef] [PubMed]

- Alazemi, A.A.; Dysart, A.D.; Phuah, X.L.; Pol, V.G.; Sadeghi, F. MoS2 nanolayer coated carbon spheres as an oil additive for enhanced tribological performance. Carbon 2016, 110, 367–377. [Google Scholar] [CrossRef]

- Ivanova, O.; Williams, C.; Campbell, T. Additive manufacturing (AM) and nanotechnology: Promises and challenges. Rapid Prototyp. J. 2013, 19, 353–364. [Google Scholar] [CrossRef] [Green Version]

- Holmberg, K.; Erdemir, A. Global impact of friction on energy consumption, economy and environment. Fme Trans. 2015, 43, 181–185. [Google Scholar]

- Ren, B.; Gao, L.; Li, M.; Zhang, S.; Ran, X. Tribological properties and anti-wear mechanism of ZnO@ graphene core-shell nanoparticles as lubricant additives. Tribol. Int. 2020, 144, 106114. [Google Scholar] [CrossRef]

- Kotia, A.; Ghosh, G.K.; Srivastava, I.; Deval, P.; Ghosh, S.K. Mechanism for improvement of friction/wear by using Al2O3 and SiO2/Gear oil nanolubricants. J. Alloy. Compd. 2019, 782, 592–599. [Google Scholar] [CrossRef]

- Zhang, F.; Zhang, X.; Zhang, F.; Tang, G.; Li, C.; Xu, J. 3D/1D heterostructure of flower-like MoS2 nanospheres anchored on carbon nanotubes for enhanced friction and wear properties as oil additives. Mater. Res. Express 2020, 6, 1250f9. [Google Scholar] [CrossRef]

- Beheshti, A.; Huang, Y.; Ohno, K.; Blakey, I.; Stokes, J.R. Improving tribological properties of oil-based lubricants using hybrid colloidal additives. Tribol. Int. 2020, 144, 106130. [Google Scholar] [CrossRef]

- Akbulut, M. Nanoparticle-based lubrication systems. J. Powder Metall. Min. 2012, 1, 1–3. [Google Scholar] [CrossRef]

- Butt, H.J.; Cappella, B.; Kappl, M. Force measurements with the atomic force microscope: Technique, interpretation and applications. Surf. Sci. Rep. 2005, 59, 1–152. [Google Scholar] [CrossRef] [Green Version]

- Wagner, R.; Moon, R.; Pratt, J.; Shaw, G.; Raman, A. Uncertainty quantification in nanomechanical measurements using the atomic force microscope. Nanotechnology 2011, 22, 455703. [Google Scholar] [CrossRef] [PubMed]

- Wagner, R.; Moon, R.; Pratt, J.; Shaw, G.; Raman, A. Radial elasticity of multiwalled carbon nanotubes. Phys. Rev. Lett. 2005, 94, 175502. [Google Scholar]

- Lee, C.; Wei, X.; Kysar, J.W.; Hone, J. Measurement of the elastic properties and intrinsic strength of monolayer graphene. Science 2008, 321, 385–388. [Google Scholar] [CrossRef] [PubMed]

- Pol, V.G.; Shrestha, L.K.; Ariga, K. Tunable, Functional Carbon Spheres Derived from Rapid Synthesis of Resorcinol-Formaldehyde Resins. ACS Appl. Mater. Interfaces 2014, 6, 10649–10655. [Google Scholar] [CrossRef] [PubMed]

- Tze, W.; Wang, S.; Rials, T.; Pharr, G.; Kelley, S. Nanoindentation of wood cell walls: Continuous stiffness and hardness measurements. Compos. Part A Appl. Sci. Manuf. 2007, 38, 945–953. [Google Scholar] [CrossRef]

- Konnerth, J.; Gierlinger, N.; Keckes, J.; Gindl, W.; Gindl-Altmutter, W. Actual versus apparent within cell wall variability of nanoindentation results from wood cell walls related to cellulose microfibril angle. J. Mater. Sci. 2009, 44, 4399–4406. [Google Scholar] [CrossRef] [Green Version]

- Alazemi, A.A. Experimental Investigation of Friction Fundamentals at the Microscale; Purdue University: West Lafayette, IN, USA, 2017. [Google Scholar]

- Hertz, H. Ueber die Berührung fester elastischer Körper. J. Reine Angew. Math. 1882, 1882, 156–171. [Google Scholar]

- Guo, D.; Li, J.; Xie, G.; Wang, Y.; Luo, J. Elastic Properties of Polystyrene Nanospheres Evaluated with Atomic Force Microscopy: Size Effect and Error Analysis. Langmuir 2014, 30, 7206–7212. [Google Scholar] [CrossRef] [PubMed]

- Johnson, K.L.; Johnson, K.L. Contact Mechanics; Cambridge University Press: Cambridge, UK, 1987. [Google Scholar]

- Chizhik, S.A.; Huang, Z.; Gorbunov, V.V.; Myshkin, N.K.; Tsukruk, V.V. Micromechanical Properties of Elastic Polymeric Materials As Probed by Scanning Force Microscopy. Langmuir 1998, 14, 2606–2609. [Google Scholar] [CrossRef]

- Leyland, A.; Matthews, A. Design criteria for wear-resistant nanostructured and glassy-metal coatings. Surf. Coat. Technol. 2004, 177, 317–324. [Google Scholar] [CrossRef]

- Ashby, M.F.; Cebon, D. Materials selection in mechanical design. MRS Bull. 2005, 30, 995. [Google Scholar] [CrossRef] [Green Version]

| Hardness, H (GPa) | Reduced Modulus, Er (GPa) | Elastic Modulus of CS, Ecs (GPa) | |

|---|---|---|---|

| Mean | 1.2 | 16.6 | 16.5 |

| Standard Deviation | 0.6 | 4.7 | 4.8 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alazemi, A.A.; Dysart, A.D.; Pol, V.G. Experimental Investigation of the Mechanical and Surface Properties of Sub-Micron Carbon Spheres. Lubricants 2020, 8, 77. https://doi.org/10.3390/lubricants8070077

Alazemi AA, Dysart AD, Pol VG. Experimental Investigation of the Mechanical and Surface Properties of Sub-Micron Carbon Spheres. Lubricants. 2020; 8(7):77. https://doi.org/10.3390/lubricants8070077

Chicago/Turabian StyleAlazemi, Abdullah A., Arthur D. Dysart, and Vilas G. Pol. 2020. "Experimental Investigation of the Mechanical and Surface Properties of Sub-Micron Carbon Spheres" Lubricants 8, no. 7: 77. https://doi.org/10.3390/lubricants8070077

APA StyleAlazemi, A. A., Dysart, A. D., & Pol, V. G. (2020). Experimental Investigation of the Mechanical and Surface Properties of Sub-Micron Carbon Spheres. Lubricants, 8(7), 77. https://doi.org/10.3390/lubricants8070077