Synthetic and Natural Insecticides: Gas, Liquid, Gel and Solid Formulations for Stored-Product and Food-Industry Pest Control

Abstract

:Simple Summary

Abstract

1. Formulations Are Adapted According to Specific Routes of Insect Body Entry, Arthropod Diversity, and Various Environmental Conditions

2. Gas and Vapor Insecticide Application Formulations

2.1. Vaporization and Sublimation

2.1.1. Thermal Vaporization

2.1.2. Cold Vaporization or Sublimation (“Residual Fumigation”)

2.1.3. Preventive vs. Repressive Application Methods of Insecticide Evaporators

2.1.4. Injection/Infusion into and Evaporation Inside Bags (“In-Bag Fumigation”)

2.2. Fumigation—Toxic Gas Release from Solid, Liquid, and Gas Formulations

2.2.1. Fumigants Released from Solid Formulations

2.2.2. Fumigants Released from Liquid or Liquidized Gas Formulations (Compressed in Cylinders, Soaked in Porous Materials)

2.3. Application of Inert Gases as Modified Atmospheres (i.e., Pest Asphyxiation by Hypoxic/Anoxic Atmospheres)

2.3.1. Hermetic Airtight Storage (Bags, Cocoons, Bunkers, Underground Stores and Pits, Under-Sheets)

2.3.2. Controlled Atmospheres in Food Packages, Chambers, Silos, Horizontal Stores, and Flexible Enclosures (Normal/Changed Atmospheric Pressure)

3. Delivery of Insecticides as Liquids (Admixtures, Liquid Baits, Aerosols, Sprays, etc.)

3.1. Grain Protectants—Spray, Drip, Cob-Dip, and Aerosol Treatments (Insecticide Admixture, Top-Dressing)

3.2. Dip and Spray Insecticide Coatings for the Protection of Dried or Smoked Fishes and Animal Skins

3.3. Liquid or Aqueous Baits (Traditional Toxic Baits or “Smart Baits” Based on RNA Interference)

3.4. Insecticide Dipping, Impregnation, and Spraying of Bags and Packages

3.5. Liquid Insecticide Aerosols and Mists: Thermal Fogs and Cold Aerosols (“ULV”, “LV”, “HV”)

3.6. Surface Spray, Brush or Sponge Applications, Leaving Residual Insecticide Deposits

3.6.1. Formulations and Active Compounds Used as Surface-Residual Sprays

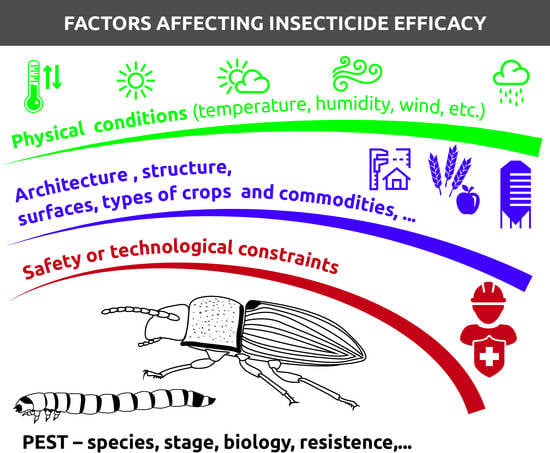

3.6.2. Biotic and Abiotic Factors Influencing the Efficacy of Insecticide Deposits

3.6.3. Equipment and Types of Spray or Brush Applications (Broadcast, Spot, Crack-And-Crevice, Barrier, Direct, and Special Treatments)

4. Insecticide Gel and Foam Application Formulations

4.1. Gel and Paste Baits

4.2. Expandable Insecticide Foams (Baits and Contact Insecticides)

4.3. Acaricide Gels and Coatings (Films, Nets) for Ham Protection

4.4. Gels, Gelatines, Starch Pastes, and Wax Polish Used for Residual Insecticide Pre-Treatment or Co-Treatment

5. Insecticide Delivery in Solid Forms

5.1. Smoke-Generating Formulations (Chemically Activated or Ignition-Activated Pyrotechnic Smoke Generators, Cartridges, Tablets, and Canisters)

5.2. Baits Applied as Solid Dusts, Granules, or Semi-Solid Slurries

5.3. Application of Synthetic or Natural Organic and Inorganic Insecticide Dusts (Structural, Grain Admixture)

5.3.1. Dusts Applied as Surface and Structural Treatments

5.3.2. Dusts Applied as Commodity Admixture Protectants

5.4. Botanical Ash, Dust, Powders, Particles, Leaves, Phyto-Tablets, and Sachets

5.5. Incorporated Insecticides: Seed Dressings, Toxic and Edible Coatings and Films

5.6. Insecticide Incorporated/Impregnated Bags, Packaging Foils and Packages (“Active Packaging”)

5.7. Insecticides Incorporated in Nets and Nettings

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Acknowledgments

Conflicts of Interest

References

- Athanassiou, C.G.; Arthur, F.H. Recent Advances in Stored Product Protection; Springer: Berlin, Germany, 2018; p. 273. [Google Scholar]

- Stejskal, V.; Vendl, T.; Li, Z.; Aulicky, R. Efficacy of visual evaluation of insect-damaged kernels of malting barley by Sitophilus granarius from various observation perspectives. J. Stored Prod. Res. 2020, 89, 101711. [Google Scholar] [CrossRef]

- Stejskal, V.; Hubert, J.; Aulicky, R.; Kucerova, Z. Overview of present and past and pest-associated risks in stored food and feed products: European perspective. J. Stored Prod. Res. 2015, 64, 122–132. [Google Scholar] [CrossRef]

- Hubert, J.; Erban, T.; Nesvorna, M.; Stejskal, V. Emerging risk of infestation and contamination of dried fruits by mites in the Czech Republic. Food Addit. Contam. Part A 2011, 28, 1129–1135. [Google Scholar] [CrossRef] [Green Version]

- Hubert, J.; Stejskal, V.; Athanassiou, C.G.; Throne, J.E. Health hazards associated with arthropod infestation of stored products. Annu. Rev. Entomol. 2018, 63, 553–573. [Google Scholar] [CrossRef] [PubMed]

- Stejskal, V.; Vendl, T.; Kolar, V.; Li, Z.; Aulicky, R. First population quantification of the infestation of legumes by stored-product bruchids imported in freight containers into Europe. Bull. Insectol. 2020, 73, 233–239. [Google Scholar]

- Nopsa, J.F.H.; Daglish, G.J.; Hagstrum, D.W.; Leslie, J.F.; Phillips, T.W.; Scoglio, C.; Thomas-Sharma, S.; Walter, G.H.; Garrett, K.A. Ecological networks in stored grain: Key postharvest nodes for emerging pests, pathogens, and mycotoxins. Bioscience 2015, 65, 985–1002. [Google Scholar] [CrossRef] [Green Version]

- Fardisi, M.; Gondhalekar, A.D.; Ashbrook, A.R.; Scharf, M.E. Rapid evolutionary responses to insecticide resistance management interventions by the German cockroach (Blattella germanica L.). Sci. Rep. 2019, 9, 1–10. [Google Scholar] [CrossRef] [Green Version]

- Opit, G.P.; Phillips, T.W.; Aikins, M.J.; Hasan, M.M. Phosphine resistance in Tribolium castaneum and Rhyzopertha dominica from stored wheat in Oklahoma. J. Econ. Entomol. 2012, 105, 1107–1114. [Google Scholar] [CrossRef] [Green Version]

- Nayak, M.K.; Daglish, G.J.; Phillips, T.W.; Ebert, P.R. Resistance to the fumigant phosphine and its management in insect pests of stored products: A global perspective. Annu. Rev. Entomol. 2020, 65, 333–350. [Google Scholar] [CrossRef] [Green Version]

- Sparks, T.C.; Storer, N.; Porter, A.; Slater, R.; Nauen, R. Insecticide resistance management and industry–The origins and evolution of the Insecticide Resistance Action Committee (IRAC) and the mode of action classification scheme. Pest Manag. Sci. 2021, 77, 2609–2619. [Google Scholar] [CrossRef]

- Zhu, F.; Lavine, L.; O’Neal, S.; Lavine, M.; Foss, C.; Walsh, D. Insecticide resistance and management strategies in urban ecosystems. Insects 2016, 7, 2. [Google Scholar] [CrossRef]

- Capinera, J.L. Encyclopedia of Entomology; Springer: New York, NY, USA, 2008. [Google Scholar]

- Ebeling, W.; Pence, R.J. Pesticide formulation. Influence of formulation on effectiveness. J. Agric. Food Chem. 1953, 1, 386–397. [Google Scholar] [CrossRef]

- Guedes, R.N.C.; Smagghe, G.; Stark, J.D.; Desneux, N. Pesticide-induced stress in arthropod pests for optimized integrated pest management programs. Annu. Rev. Entomol. 2016, 61, 43–62. [Google Scholar] [CrossRef] [Green Version]

- Busvine, J.R. A Critical Review of the Techniques for Testing Insecticides, 2nd ed.; Commonwealth Agricultural Bureaux: Slough, UK, 1971; p. 345. [Google Scholar]

- Wardle, R.A. The Problems of Applied Entomology; Manchester University Press: Manchester, UK, 1929; p. 587. [Google Scholar]

- Gerolt, P. Insecticides—their route of entry, mechanism of transport and mode of action. Biol. Rev. Camb. Philos. Soc. 1983, 58, 233–274. [Google Scholar] [CrossRef]

- Najar-Rodriguez, A.J.; Lavidis, N.A.; Mensah, R.K.; Choy, P.T.; Walter, G.H. The toxicological effects of petroleum spray oils on insects–Evidence for an alternative mode of action and possible new control options. Food Chem. Toxicol. 2008, 46, 3003–3014. [Google Scholar] [CrossRef] [PubMed]

- Webb, J.E.; Green, R.A. On the penetration of insecticides through the insect cuticle. J. Exp. Biol. 1945, 22, 8–20. [Google Scholar] [CrossRef] [PubMed]

- Busvine, J.R. Arthropod Vectors of Disease. In Studies in Biology; No. 55; Edward Arnold: London, UK, 1975; p. 67. [Google Scholar]

- Hagstrum, D.W.; Phillips, T.W. Evolution of stored-product entomology: Protecting the world food supply. Annu. Rev. Entomol. 2017, 62, 379–397. [Google Scholar] [CrossRef]

- Maier, D.E. Advances in Postharvest Management of Cereals and Grains; Burleigh Dodds Science Publishing: Cambridge, UK, 2020; p. 300. [Google Scholar]

- Stejskal, V.; Vendl, T.; Li, Z.; Aulicky, R. Minimal thermal requirements for development and activity of stored product and food industry pests (Acari, Coleoptera, Lepidoptera, Psocoptera, Diptera and Blattodea): A review. Insects 2019, 10, 149. [Google Scholar] [CrossRef] [Green Version]

- Jian, F. Influences of stored product insect movements on integrated pest management decisions. Insects 2019, 10, 100. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Munro, J.W. Pests of Stored Products; The Rentokil Library, Hutchinson: London, UK, 1966. [Google Scholar]

- Snell, E.J. Future trends in pesticide applications. In Proceedings of the 3rd International Conference Urban Pest, Prague, Czech Republic, 19–22 July 1999; pp. 35–41. [Google Scholar]

- Robinson, W.H. The Service Technician’s Application and Equipment Manual: A Practical Guide for Pest Control Professionals; Lupo, L.J., Ed.; PCT—Pest Control Technology: Valley View, OH, USA, 2015; p. 128. [Google Scholar]

- Murdock, L.L.; Seck, D.; Ntoukam, G.; Kitch, L.; Shade, R.E. Preservation of cowpea grain in sub-Saharan Africa—Bean/Cowpea CRSP contributions. Field Crops Res. 2003, 82, 169–178. [Google Scholar] [CrossRef]

- Stathers, T.; Holcroft, D.K.L.; Mvumi, B.; English, A.; Omotilewa, O.; Kocher, M.; Ault, J.; Torero, M. A scoping review of interventions for crop postharvest loss reduction in sub-Saharan Africa and South Asia. Nat. Sustain. 2020, 3, 821–835. [Google Scholar] [CrossRef]

- Sparks, T.C.; Wessels, F.J.; Lorsbach, B.A.; Nugent, B.M.; Watson, G.B. The new age of insecticide discovery-the crop protection industry and the impact of natural products. Pestic. Biochem. Physiol. 2019, 161, 12–22. [Google Scholar] [CrossRef]

- Freeman, J.A. Pest infestation control in breweries and maltings. J. Inst. Brew. 1951, 57, 326–337. [Google Scholar] [CrossRef]

- Hill, D.S. Pests of Stored Foodstuffs and Their Control; Kluwer Academic Publishers: Boston, MA, USA, 2002. [Google Scholar]

- Peckman, P.S.; Arthur, F.H. Insecticide space treatments in food plants. In Insect Management for Food Storage and Processing; Heaps, J., Ed.; AACC: Minneapolis, MN, USA, 2006; pp. 175–182. [Google Scholar]

- Arthur, F.H. Structural Pest Management for Stored Product Insects. In Recent Advances in Stored Product Protection; Athanassiou, C., Arthur, F., Eds.; Springer: Berlin/Heidelberg, Germany, 2018; Chapter 4; pp. 65–81. [Google Scholar]

- Matthews, G.; Bateman, R.; Miller, P. Pesticide Application Methods, 4th ed.; John Wiley & Sons: Hoboken, NJ, USA, 2014. [Google Scholar]

- Golob, P.; Farrell, G.; Orchard, J.E. Crop Post-harvest: Principles and practice. In Crop Post-Harvest: Science and Technology; Golob, P., Farrell, G., Orchard, J.E., Eds.; John Wiley & Sons: Hoboken, NJ, USA, 2002. [Google Scholar]

- Rust, M.K.; Owens, J.M.; Reierson, D.A. Understanding and Controlling the German Cockroach; Oxford University Press: New York, NY, USA, 1995. [Google Scholar]

- Rust, M.K. The Changing Role of Insecticides in Structural Pest Control. In Hayes’ Handbook of Pesticide Toxicology; Academic Press: Cambridge, MA, USA, 2010; pp. 257–270. [Google Scholar]

- Daglish, G.J.; Nayak, M.K.; Arthur, F.H.; Athanassiou, C.G. Insect Pest Management in Stored Grain. In Recent Advances in Stored Product Protection; Athanassiou, C., Arthur, F., Eds.; Springer: Berlin, Germany, 2018. [Google Scholar]

- Robinson, W. Urban Insects and Arachnids: A Handbook of Urban Entomology; Cambridge University Press: Cambridge, UK, 2005. [Google Scholar]

- Hagstrum, D.W.; Subramanyam, B. Stored-Product Insect Resource; AACC International: Saint Paul, MN, USA, 2009; p. 509. [Google Scholar]

- Sutar, S.A.; Thirumdas, R.; Chaudhari, B.B.; Deshmukh, R.K.; Annapure, U.A. Effect of cold plasma on insect infestation and keeping quality of stored wheat flour. J. Stored Prod. Res. 2021, 92, 101774. [Google Scholar] [CrossRef]

- Plimmer, J. Pesticides for Stored Products. In Biodegradation of Pesticides; Mastumura, F., Krishma, C., Eds.; Plenum Press: New York, NY, USA, 1982; pp. 239–255. [Google Scholar]

- Thoms, E.M.; Busacca, J.D. Fumigants. In Encyclopedia of Food and Health; Caballero, B., Finglas, P.M., Toldrá, F., Eds.; Academic Press: Cambridge, MA, USA, 2015; pp. 150–156. [Google Scholar]

- Bond, E.J. 1984: Manual of Fumigation for Insect Control; FAO: Rome, Italy, 1984; Volume 54, p. 432. [Google Scholar]

- Baur, F.J. Insect Management for Food Storage and Processing; ACCC International: St. Paul, MN, USA, 1984; p. 384. [Google Scholar]

- Stejskal, V.; Kocourek, V.; Aulicky, R.; Hajslova, J. Insecticide Aerosols in Storage IPM: Biological Efficacy and Residues in Air and Food. In Proceedings of the 11th International Working Conference on Stored Product Prot., Chiang Mai, Thailand, 24–28 November 2014; Arthur, F.H., Kengkanpanich, R., Chayaprasert, W., Suthisut, D., Eds.; Julius-Kühn-Archiv: Berlin, Germany, 2014; p. 903. [Google Scholar]

- Roark, R.C.; Nelson, O.A. Maximum weights of various fumigants which can exist in vapor form in a 1,000 cubic foot fumigating chamber. J. Econ. Entomol. 1929, 22, 381–387. [Google Scholar] [CrossRef]

- Jian, F.; Jayas, D.S. Engineering considerations for creating uniform distribution of applied gas during controlled atmospheres and fumigation. In Proceedings of the 10th International Conference on Controlled Atmosphere and Fumigation in Stored Products, New Dehli, India, 6–11 November 2016; pp. 1–11. [Google Scholar]

- Jiang, X.; Huang, L.F.; Zheng, S.H.; Chen, S.L. Sulfur fumigation, a better or worse choice in preservation of traditional Chinese medicine? Phytomedicine 2013, 20, 97–105. [Google Scholar] [CrossRef]

- Monro, H.A.U. Manual of Fumigation for Insect Control, 2nd ed.; St. Paul’s Press, Malta for United Nations FAO: Rome, Italy, 1969; p. 381. [Google Scholar]

- Bell, C.H. Fumigation in the 21st century. Crop Prot. 2000, 19, 563–569. [Google Scholar] [CrossRef]

- Aulicky, R.; Stejskal, V.; Frydova, B.; Athanassiou, C.G. Susceptibility of two strains of the confused flour beetle (Coleoptera: Tenebrionidae) following phosphine structural mill fumigation: Effects of concentration, temperature, and flour deposits. J. Econ. Entomol. 2015, 108, 2823–2830. [Google Scholar] [CrossRef]

- Mahroof, R.M.; Amoah, B.A.; Wrighton, J. Efficacy of ozone against the life stages of Oryzaephilus mercator (Coleoptera: Silvanidae). J. Econ. Entomol. 2018, 111, 470–481. [Google Scholar] [CrossRef]

- Navarro, S.; Navarro, H. Advances in insect pest management in postharvest storage of cereals: Use of controlled atmosphere and temperature control. In Advances in Postharvest Management of Cereals and Grains; Maier, D.E., Ed.; Burleigh Dodds Science Publishing Limited: Cambridge, UK, 2020; p. 478. [Google Scholar]

- Rajendran, S. Insect pest management in stored products. Outlooks Pest. Manag. 2020, 31, 24–35. [Google Scholar] [CrossRef]

- Liu, Y.B. Comparison of efficacy of nitric oxide fumigation under nitrogen and carbon dioxide atmospheres in controlling granary weevil (Sitophilus granaries) and confused flour beetle (Tribolium confusum). J. Stored Prod. Res. 2020, 88, 101672. [Google Scholar] [CrossRef]

- Phillips, T.; Thoms, E.; DeMark, J.; Walse, S. Fumigation. In Stored Product Protection, Circular S156; Hagstrum, D.H., Phillips, T.W., Cuperus, G.W., Eds.; Kansas State University: Manhattan, KS, USA, 2012; pp. 157–178. [Google Scholar]

- Arthur, F.H.; Johnson, J.A.; Neven, L.G.; Hallman, G.J.; Follett, P.A. Insect pest management in postharvest ecosystems in the United States of America. Outlooks Pest. Manag. 2009, 20, 279–284. [Google Scholar] [CrossRef]

- Douda, O.; Stejskal, V.; Manasova, M.; Zouhar, M.; Hnatek, J. Inexpensive screening method to validate the efficacy of ethanedinitrile fumigant on the forest invasive nematode pest Bursaphelenchus xylophilus. Sustainability 2020, 12, 4765. [Google Scholar] [CrossRef]

- Douda, O.; Manasova, M.; Zouhar, M.; Hnatek, J.; Stejskal, V. Field validation of the effect of soil fumigation of ethanedinitrile (EDN) on the mortality of Meloidogyne hapla and carrot yield parameters. Agronomy 2021, 11, 208. [Google Scholar] [CrossRef]

- Armstrong, J.W.; Brash, D.W.; Waddell, B.C. Comprehensive literature review of fumigants and disinfestation strategies, methods and techniques pertinent to potential use as quarantine treatments for New Zealand export logs. Plant Food Res. SPTS 2014, 10678, 1–184. [Google Scholar]

- Stejskal, V.; Douda, O.; Zouhar, M.; Manasova, M.; Dlouhy, M.; Simbera, J.; Aulicky, R. Wood penetration ability of hydrogen cyanide and its efficacy for fumigation of Anoplophora glabripennis, Hylotrupes bajulus (Coleoptera), and Bursaphelenchus xylophilus (Nematoda). Int. Biodeter. Biodegr. 2014, 86, 189–195. [Google Scholar] [CrossRef]

- Neven, L.G. Postharvest management of insects in horticultural products by conventional and organic means, primarily for quarantine purposes. Stewart Postharvest Rev. 2010, 6, 1–11. [Google Scholar]

- Rajendran, S.; Sriranjini, V. Plant products as fumigants for stored-product insect control. J. Stored Prod. Res. 2008, 44, 126–135. [Google Scholar] [CrossRef]

- Ajesh, G.; Jayaprakas, C.A.; Krishnan, J.U.; Rajeswari, L.S. Fumigant activity of insecticidal principles isolated from cassava (Manihot esculenta Crantz) against Tribolium castaneum and Rhyzopertha dominica. J. Entomol. Zool. Stud. 2018, 6, 220–225. [Google Scholar]

- Mora, C.A.; Halter, J.G.; Adler, C.; Hund, A.; Anders, H.; Yu, K.; Stark, W.J. Application of the Prunus spp. cyanide seed defense system onto wheat: Reduced insect feeding and field growth tests. J. Agric. Food Chem. 2016, 64, 3501–3507. [Google Scholar] [CrossRef]

- Campolo, O.; Giunti, G.; Russo, A.; Palmeri, V.; Zappalà, L. Essential oils in stored product insect pest control. J. Food Qual. 2018, 2018, 1–18. [Google Scholar] [CrossRef] [Green Version]

- Follett, P.A.; Rivera-Leong, K.; Myers, R.Y. Rice weevil response to basil oil fumigation. J. Asia Pac. Entomol. 2013, 17, 119–121. [Google Scholar] [CrossRef]

- Yang, X.; Liu, Y.-B.; Feng, Y.; Zhang, A. Methyl benzoate fumigation for control of post-harvest pests and its effects on apple quality. J. Appl. Entomol. 2020, 144, 191–200. [Google Scholar] [CrossRef]

- Morrison, W.R.; Larson, N.L.; Brabec, D.; Zhang, A. Methyl benzoate as a putative alternative, environmentally friendly fumigant for the control of stored-product insects. J. Econ. Entomol. 2019, 112, 2458–2468. [Google Scholar] [CrossRef]

- Chen, J.; Rashid, T.; Feng, G.; Feng, Y.; Zhang, A.; Grodowitz, M.J. Insecticidal activity of methyl benzoate analogs against red imported fire ants, Solenopsis invicta (Hymenoptera: Formicidae). J. Econ. Entomol. 2019, 112, 691–698. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Mostafiz, M.M.; Hassan, E.; Acharya, R.; Shim, J.K.; Lee, K.Y. Methyl benzoate is superior to other natural fumigants for controlling the Indian meal moth (Plodia interpunctella). Insects 2021, 12, 23. [Google Scholar] [CrossRef] [PubMed]

- Larson, N.R.; Zhang, A.; Feldlaufer, M.F. Fumigation activities of ethyl benzoate and its derivatives against the common bed bug (Hemiptera: Cimicidae). J. Med. Entomol. 2020, 57, 187–191. [Google Scholar] [CrossRef]

- Feng, Y.; Zhang, A. A floral fragrance methyl benzoate is an efficient green pesticide. Sci. Rep. 2017, 7, 1–9. [Google Scholar] [CrossRef]

- Panagiotakopulu, E.; Buckland, P.C.; Day, P.M.; Sarpaki, A.A.; Doumas, C. Natural insecticides and insect repellents in antiquity: A review of the evidence. J. Archaeol. Sci. 1995, 22, 705–710. [Google Scholar] [CrossRef]

- Hartzell, A. Naphthalene fumigation of greenhouses. J. Econ. Entomol. 1926, 19, 780–786. [Google Scholar] [CrossRef]

- Bourcart, E. Insecticides, Fungicides and Weedkillers: A Practical Manual on the Diseases of Plants and Their Remedies for the Use of Manufacturing Chemists, Agriculturists, Arborculturists, and Horticulturists, 1st ed.; Scott, Greenwood and Son: London, UK, 1913; p. 431. [Google Scholar]

- Gnadinger, C.B. Pyrethrum Flowers, 2nd ed.; McLaughlin Gormley King Co.: Minneapolis, MN, USA, 1936; pp. 281–284. [Google Scholar]

- Frear, D.E.H. Chemistry of Insecticides, Fungicides and Herbicides; D. Van Nostrand Company, Inc.: New York, NY, USA, 1942; p. 300. [Google Scholar]

- Spear, P.J. Laboratory Tests with Insecticides Dispersed from the American Aerovap. Master’s Thesis, University of Massachusetts, Amherst, MA, USA, 1950. [Google Scholar]

- Siakotos, A.N. Contamination of Food and Air by Lindane Vapor. Master’s Thesis, University of Massachusetts, Amherst, MA, USA, 1954. [Google Scholar]

- Stammers, F.M.; Whitfield, F.G. The toxicity of DDT to man and animals. Bull. Entomol. Res. 1947, 38, 1–73. [Google Scholar] [CrossRef] [PubMed]

- Spear, P.J. Continuous Vaporization of Insecticides. Ph.D. Thesis, University of Massachusetts, Amherst, MA, USA, 1952. [Google Scholar]

- Braid, P.E.; LeBoeuf, J. Determination of trace amounts of lindane in air by infrared spectrophotometry. Anal.Chem. 1957, 29, 1625–1627. [Google Scholar] [CrossRef]

- Spear, P.J.; Sweetman, H.L. Continuous vaporization of insecticides with special reference to DDT. J. Econ. Entomol. 1952, 45, 869–873. [Google Scholar] [CrossRef]

- Diptyanusa, A.; Satoto, T.B.T.; Hadianto, T. Trial of neem oil (Azadirachta indica) as basic compound of electric liquid vaporizer against Aedes aegypti mortality. YARSI Med. J. 2017, 25, 23–32. [Google Scholar]

- Valecha, N.; Ansari, M.A.; Prabhu, S.; Razdan, R.K. Preliminary evaluation of safety aspects of neem oil in kerosene lamp. Indian J. Malariol. 1996, 33, 139–143. [Google Scholar] [PubMed]

- Ansari, M.A.; Razdan, R.K. Operational feasibility of malaria control by burning neem oil in kerosene lamp in Beel Akbarpur village, District Ghaziabad, India. Indian J. Malariol. 1996, 33, 81–87. [Google Scholar]

- Busvine, J.R. Insects and Hygiene: The Biology and Control of Insect Pests of Medical and Domestic Importance in Britain, 2nd ed.; Methuen & Co.: London, UK, 1966; p. 467. [Google Scholar]

- Wright, D. Mercury as a control for stored grain pests. Bull. Entomol. Res. 1944, 35, 143–160. [Google Scholar] [CrossRef]

- Gough, H.C. Toxicity of mercury vapour to insects. Nature 1938, 141, 922–923. [Google Scholar] [CrossRef]

- Larson, A.O. Metallic mercury as an insecticide. J. Econ. Entomol. 1922, 15, 391–395. [Google Scholar] [CrossRef]

- Herrick, G.W.; Griswold, G.H. Naphthalene as a fumigant for the immature stages of clothes moths and carpet beetles. J. Econ. Entomol. 1933, 26, 446–451. [Google Scholar] [CrossRef]

- Batth, S.S. Influence of temperature on the effectiveness of paradichlorobenzene fumigation of black carpet beetle larvae. J. Econ. Entomol. 1969, 62, 747–748. [Google Scholar] [CrossRef]

- Ryckman, R.E. Vapona for the control of museum pests. J. Med. Entomol. 1969, 6, 98. [Google Scholar] [CrossRef]

- Batth, S.S. Influence of temperature on the effectiveness of paradichlorobenzene fumigation of webbing clothes moth larvae. J. Econ. Entomol. 1971, 64, 989–990. [Google Scholar] [CrossRef]

- Jay, E.G.; Gillenwater, H.B.; Harein, P.K. The toxicity of several dichlorvos (DDVP) and nailed formulations to the adult confused flour beetle. J. Econ. Entomol. 1964, 57, 415–416. [Google Scholar] [CrossRef]

- Harein, P.K.; Gillenwater, H.B.; Eason, G. Dichlorvos space treatment for protection of packaged flour against insect infestation. J. Stored Prod. Res. 1971, 7, 57–62. [Google Scholar] [CrossRef]

- Harein, P.K.; Gillenwater, H.B.; Jay, E.G. Dichlorvos: Methods of dispensing, estimates of concentration in air, toxicity to stored-product insects. J. Econ. Entomol. 1970, 63, 1263–1268. [Google Scholar] [CrossRef]

- Lehnert, M.P.; Pereira, R.M.; Koehler, P.G.; Walker, W.; Lehnert, M.S. Control of Cimex lectularius using heat combined with dichlorvos resin strips. Med. Vet. Entomol. 2011, 25, 460–464. [Google Scholar] [CrossRef]

- Ujihara, K.; Sugano, M.; Nakada, K.; Iwakura, K.; Nishihara, K.; Katoh, H. Discovery and development of profluthrin (Fairytale), a new active ingredient of moth proofer. Sumitomo Kagaku 2010, 2, 13–23. [Google Scholar]

- Abdel-Mohdy, F.A.; Fouda, M.M.; Rehan, M.F.; Aly, A.S. Repellency of controlled-release treated cotton fabrics based on cypermethrin and prallethrin. Carbohydr. Polym. 2008, 73, 92–97. [Google Scholar] [CrossRef]

- Ansari, M.A.; Sharma, V.P.; Razdan, R.K. Esbiothrin-impregnated ropes as mosquito repellent. Indian J. Malariol. 1992, 29, 203–210. [Google Scholar]

- Bullington, S.W.; Pienkowski, R.L. Dichlorvos and plastic covers affect insects infesting stored cocoa beans in dockside warehouses. J. Econ. Entomol. 1993, 86, 1151–1156. [Google Scholar] [CrossRef]

- Peters, L. EC78-1534 Insect Prevention and Control in Farm Stored Grain; Historical Materials from University of Nebraska-Lincoln Extension; University of Nebraska: Lincoln, USA, 1978. [Google Scholar]

- Gillenwater, G.B.; Harein, P.K.; Loy, E.W.; Thompson, J.F.; Laudani, H.; Gerald Eason, G. Dichlorvos applied as a vapor in a warehouse containing packaged foods. J. Stored Prod. Res. 1971, 7, 45–56. [Google Scholar] [CrossRef]

- Wohlgemuth, R. Verfahren zur Untersuchung der Wirkungs abhängigkeit bei Dichlorvos (DDVP-) abgebenden Strips auf die Mortalität vorratsschädlicher Insekten am Beispiel von Plodia interpunctella (Dörrobstmotte). Nachr. Dtsch. Pflanzenschutzd. 1992, 44, 152–156. [Google Scholar]

- Boina, D.R.; Subramanyam, B. Insect management with aerosols in food processing facilities. In Insecticides: Advances in Integrated Pest Management; Perveen, F.K., Ed.; InTech Europe: Rijeka, Croatia, 2012; pp. 195–212. [Google Scholar]

- Boles, H.P.; Bry, R.E.; Mc Donald, L.L. Dichlorvos vapours: Toxicity to larvae of the furniture carpet beetle. J. Econ. Entomol. 1974, 67, 308–309. [Google Scholar] [CrossRef]

- Endrödy-Younga, S.; Baunok, I. Efficiency and health hazards tests on Vapona used in insect collections. Entomol. Gen. 1984, 10, 47–51. [Google Scholar] [CrossRef]

- Linnie, M.J.; Keatinge, M.J. Pest control in museums: Toxicity of para-dichlorobenzene, ‘Vapona’™, and naphthalene against all stages in the life-cycle of museum pests, Dermestes maculatus Degeer, and Anthrenus verbasci (L.) (Coleoptera: Dermestidae). Int. Biodeterior. Biodegradation 2000, 45, 1–13. [Google Scholar] [CrossRef]

- Kumar, R.; Tiwari, S.N. Fumigant toxicity of essential oils against four major storage insect pests. Indian J. Entomol. 2017, 79, 156–159. [Google Scholar] [CrossRef]

- Bengston, M. Timed daily emission of dichlorvos for control of Ephestia cautella (Walker) infesting stored wheat. J. Stored Prod. Res. 1976, 12, 157–164. [Google Scholar] [CrossRef]

- Aulicky, R.; Stejskal, V.; Opit, G. Short-exposure biological activity of dichlorvos insecticide strips on coleopteran storage pests under two evaporation regimes: Can slow-release dichlorvos formulations replace aerosols? Pak. J. Zool. 2019, 51, 475–482. [Google Scholar] [CrossRef]

- Taylor, R.W.D. Fumigation of individual sacks of grain using methallyl chloride for control of maize weevil. Int. Pest Control. 1975, 17, 4–8. [Google Scholar]

- Green, A.A.; Wilkin, D.R. The control of insects in bagged grain by the injection of dichlorvos. J. Stored Prod. Res. 1969, 5, 11–19. [Google Scholar] [CrossRef]

- Webley, D.J.; Hams, A.H. A comparison of fumigants for in-bag fumigation. Trop. Stored Prod. Inf. 1977, 33, 9–17. [Google Scholar]

- Peirrot, R.; Ducom, P. Efficacy of carbon tetrachloride in sealed sacks compared with contact insecticides. In Proceedings of the GASCA Seminar on Appropriate Use of Pesticides for the Control of Stored Product Pests in Developing Countries; Central Science Laboratory (CSL): Slough, UK, 1981; pp. 149–152. [Google Scholar]

- Knight, K.L. Fumigation of sacked grain with chloropicrin. J. Econ. Entomol. 1940, 33, 536–539. [Google Scholar] [CrossRef]

- Tola, B.Y.; Muleta, D.O.; Werner, C.H. Selection, characterization and identification of smokes from different biomass materials as a medium for modifying the atmosphere for stored grain. J. Stored Prod. Postharvest Res. 2018, 9, 104–114. [Google Scholar]

- Hole, B.D.; Bell, C.H.; Mills, K.A.; Goodship, G. The toxicity of phosphine to all developmental stages of thirteen species of stored product beetles. J. Stored Prod. Res. 1976, 12, 235–244. [Google Scholar] [CrossRef]

- Athanassiou, C.G.; Phillips, T.W.; Arthur, F.H.; Aikins, M.J.; Agrafioti, P.; Hartzer, K.L. Efficacy of phosphine fumigation for different life stages of Trogoderma inclusum and Dermestes maculatus (Coleoptera: Dermestidae). J. Stored Prod. Res. 2020, 86, 101556. [Google Scholar] [CrossRef]

- Banks, H.J. Behaviour of gases in grain storages. In Fumigation and Controlled Atmosphere Storage of Grain, Proceedings of the International Conference, Singapore, 14–18 February 1989; Champ, B.R., Highley, E., Banks, H.J., Eds.; ACIAR Proceedings No. 25; PageCraft Publishing Pty Ltd.: Canberra, Australia, 1989; pp. 96–107. [Google Scholar]

- Berck, B. Analysis of fumigants and fumigant residues. J. Chromatogr. Sci. 1975, 13, 256–267. [Google Scholar] [CrossRef]

- Daglish, G.J. Opportunities and barriers to the adoption of potential new grain protectants and fumigants. In Proceedings of the 9th International Working Confonference on Stored Product Protection, Campinas, Brazil, 15–18 October 2006; pp. 209–216. [Google Scholar]

- Anonymous. Fumigation with the Liquid Fumigants Carbon Tetrachloride, Ethylene Dichloride and Ethylene Dibromide—Precautionary Measures; Ministry of Agriculture, Fisheries and Food: London, UK, 1966; p. 9.

- Dean, G.A.; Cotton, R.T.; Wagner, G.B. Flour-Mill Insects and Their Control; U.S. Department of Agriculture: Washington, DC, USA, 1936; p. 360.

- Walkden, H.H.; Schwitzgebel, R.B. Evaluations of Fumigations for Control of Insects Attacking Wheat and Corn in Steel Bins; U.S. Department of Agriculture Technical Bulletin No. 1045: Washington, DC, USA, 1951; p. 20.

- Ramey, C.A.; Schafer, E.W., Jr. The evolution of APHIS two gas cartridges. Proc. Vertebr. Pest Conf. 1996, 17, 219–224. [Google Scholar]

- Lemay, A.; Hall, T. The use of carbon monoxide in wildlife damage management. In Human Health and Ecological Risk Assessment for the Use of Wildlife Damage Management Methods by USDA-APHIS-Wildlife Services; Hall, T., Algeo, T., Green, M., Lemay, A., Wang-Cahill, F., Warren, J., Wimberly, R., Eds.; U.S. Department of Agriculture: Washington, DC, USA, 2017; pp. 1–41. [Google Scholar]

- Chittenden, F.H. Control of the Mediterranean Flour Moth by Hydrocyanic-Acid Gas Fumigation; U.S. Department of Agriculture, Bureau of Entomology: Washington, DC, USA, 1910; p. 22.

- Lindgren, D.L.; Vincent, L.E.; Strong, R.G. Studies on hydrogen phosphide as a fumigant. J. Econ. Entomol. 1958, 51, 900–903. [Google Scholar] [CrossRef]

- Reichmuth, C. Phosphine fumigation-new aspects in stored products protection. Gesunde Pflanz. 1975, 37, 417–420. [Google Scholar]

- Ryan, R.F.; Nicolson, J. UltraPhos: High purity phosphine—Revisited. In Proceedings of the 11th International Working Conference on Stored Product Protection, Chaing Mai, Thailand, 24–28 November 2014; Arthur, F.H., Kengkanpanich, R., Chayaprasert, W., Suthisut, D., Eds.; Julius-Kühn-Archiv: Berlin, Germany, 2014; pp. 510–522. [Google Scholar]

- Anonymous. Cyanamid, Patent Appeal No. 2315-2315—California Cyanide Co. v. Am. Cyanamid Co., Patent Appeal No-40 F.2d 1003, 17 C.C.P.A. 1198 (C.C.P.A. 1930). 1930. Available online: https://case-law.vlex.com/vid/40-f-2d-1003-602840598 (accessed on 24 June 2021).

- Reichmuth, C.h. Silozellenbegasung mit Phosphorwasserstoff aus Beutelrollen (Bag Blankets) [Silo bin fumigation with phosphine from bag blankets]. Muhle Mischfuttertech. 1983, 120, 503–504. [Google Scholar]

- Dieterich, W.H.; Mayr, G.; Hild, K.; Sullivan, J.B.; Murphy, J. Hydrogen phosphide as a fumigant for foods, feeds and processed food products. Residue Rev. 1967, 19, 135–149. [Google Scholar] [PubMed]

- Reichmuth, C. Uptake of phosphine by stored-product pest insects during fumigation. In Proceedings of the 6th International Working Conference on Stored-product Protection, Canderra, Australia, 17–23 April 1994; pp. 157–162. [Google Scholar]

- Chadda, I.C. Fumigation with phosphine-a perspective. Indian J. Entomol. 2016, 78, 39–44. [Google Scholar] [CrossRef]

- Agrafioti, P.; Sotiroudas, V.; Kaloudis, E.; Bantas, S.; Athanassiou, C.G. Real time monitoring of phosphine and insect mortality in different storage facilities. J. Stored Prod. Res. 2020, 89, 101726. [Google Scholar] [CrossRef]

- Aulicky, R.; Stejskal, V. Efficacy and limitations of phosphine “spot-fumigation” against five Coleoptera species of stored product pests in wheat in a grain store—Short note. Plant Prot. Sci. 2015, 51, 33–38. [Google Scholar] [CrossRef] [Green Version]

- Feja, F.H.; Reichmuth, C.U.S. Patent No. 6, 315,965; Patent and Trademark Office: Washington, DC, USA, 2001. [Google Scholar]

- Ryan, R.F.; Shore, W.; Newman, C. Phosphine generator trial using external air dilution. In Proceedings of the 10th International Working Conference on Stored Product Protection, Estoril, Portugal, 27 June–2 July 2010; Julius-Kühn-Archiv: Berlin, Germany, 2010; pp. 430–432. [Google Scholar]

- Liu, Y.B. Low-Temperature fumigation of harvested lettuce using a phosphine generator. J. Econ. Entomol. 2018, 111, 1171–1176. [Google Scholar] [CrossRef]

- Kostyukovsky, M.; Trostanetsky, A.; Yasinov, G.; Menasherov, M.; Hazan, T. Improvement of phosphine fumigation by the use of Speedbox. Julius-Kühn-Archiv 2010, 425, 377–380. [Google Scholar]

- Waterford, C.J.; Asher, P.P. Trials of two phosphine generators based on a new formulation of aluminium phosphide. In Proceedings of the International Conference on Controlled Atmosphere and Fumigation in Stored Products, Fresno, CA, USA, 29 October–3 November 2000; Executive Printing Services: Clovis, CA, USA, 2001; pp. 327–333. [Google Scholar]

- Formato, A.; Naviglio, D.; Pucillo, D.P.; Nota, G. Improved fumigation process for stored foodstuffs by using phosphine in sealed chambers. J. Agric. Food Chem. 2012, 60, 331–338. [Google Scholar] [CrossRef] [Green Version]

- Collins, D.L.; Glasgow, R.D. DDT thermal aerosol fogs to control clothes moths in a wool storage warehouse. J. Econ. Entomol. 1946, 39, 241–245. [Google Scholar] [CrossRef] [PubMed]

- Aulicky, R.; Stejskal, V.; Dlouhy, M.; Liskova, J. Validation of hydrogen cyanide fumigation in flourmills to control the confused flour beetle. Czech J. Food Sci. 2015, 33, 174–179. [Google Scholar] [CrossRef] [Green Version]

- Stejskal, V.; Adler, C. Fumigation and Controlled Atmospheres; (Fumigace a řízené atmosféry); Sdružení DDD: Prague, Czech Republic, 1997; p. 128. [Google Scholar]

- Loucks, M.F. Composition of Grain Fumigants. J. AOAC Int. 1965, 48, 576–579. [Google Scholar] [CrossRef]

- Quinlan, J.K.; McGaughey, W.H. Fumigation of empty grain drying bins with chloropicrin, phosphine, and liquid fumigant mixtures. J. Econ. Entomol. 1983, 76, 184–187. [Google Scholar] [CrossRef]

- Ren, Y.; Lee, B.; Mahon, D.; Xin, N.; Head, M.; Reid, R. Fumigation of wheat using liquid ethyl formate plus methyl isothiocyanate in 50-tonne farm bins. J. Econ. Entomol. 2008, 101, 623–630. [Google Scholar] [CrossRef]

- Li, Y.; Agarwal, M.; Cao, Y.; Li, F.; Ren, Y. Field trials using ethyl formate as grain surface and empty silo treatments. In Proceedings of the 10th International Conference on Controlled Atmosphere and Fumigation in Stored Products, New Delhi, India, 6–11 November 2016; Navarro, S., Jayas, D.S., Alagusundaram, K., Eds.; CAF Permanent Committee Secretariat: Winnipeg, MB, Canada, 2016; pp. 244–251. [Google Scholar]

- Bridgeman, B.; Ryan, R.; Gock, D.; Collins, P. High dose phosphine fumigation using on-site mixing. In Proceedings of the International Conference Controlled Atmosphere and Fumigation in Stored Products, Fresno, CA, USA, 29 October–3 November 2000; Donahaye, E.J., Navarro, S., Leesch, J.G., Eds.; Executive Printing Services: Clovis, CA, USA, 2001; pp. 379–389. [Google Scholar]

- Ryan, R.F. Gaseous Phosphine—A revitalised fumigant. In Proceedings of the International Conference on Controlled Atmosphere and Fumigation in Stored Products, Nicosia, Cyprus, 21–26 April 1996; Donahaye, E.J., Navarro, S., Varnava, A., Eds.; Printco Ltd.: Nicosia, Cyprus, 1997; pp. 305–310. [Google Scholar]

- Ryan, R.F.; Latif, S. Fumigant System. US Patent 4 1989, 889,708, 26 December 1989. [Google Scholar]

- Ryan, R.F.; Shore, W.P. Pre-mix and on-site mixing of fumigants. Julius-Kühn-Archiv 2010, 425, 419. [Google Scholar]

- Ryan, R.; Krishna, H.; Bishop, S.R.; Fontinha, M.; Grant, N.; van Epenhuijsen, C.W.; Page, B.; Zhang, Z.; Brash, D.; Mitcham, E.J. Disinfestation and quarantine fumigation. In Proceedings of the Australian Postharvest Horticulture Conference, Brisbane, Australia, 1–3 October 2003; Queensland Government, Department of Primary Industries: Brisbane City, QLD, Australia, 2003; pp. 102–104. [Google Scholar]

- Mueller, D.K. Patent on Phosphine, Carbon Dioxide and Heat against Stored Product Pest Insects; Quoted in Mueller, K.D. Stored Product Protection A Period of Transition; Insects Limited, Inc.: Indianapolis, IN, USA, 1998; p. 352. [Google Scholar]

- Adler, C.; Corinth, H.G.; Reichmuth, C. Modified atmospheres. In Alternatives to Pesticides in Stored-Product IPM; Subramanyam, B., Hagstrum, D.W., Eds.; Kluwer: Boston, MA, USA, 2000; pp. 105–146. [Google Scholar]

- Dendy, A. Report on the effect of air-tight storage upon grain insects. Part I. Rep. Grain Pests (War) Comm. 1918, 1, 6–24. [Google Scholar]

- Dendy, A.; Elkington, H. Report on the effect of airtight storage upon grain insects. Part III. Rep. Grain Pests (War) Comm. 1920, 6, 51. [Google Scholar]

- Froggatt, W.W. Fumigation maize with carbon dioxide. Agric. Gaz. 1921, 32, 472. [Google Scholar]

- Winterbottom, D.C. Weevil in Wheat Storage of Grain in Bags: A Record of Australian Experience during the War Period. (1915–1919); Government: Adelaide, Australia, 1920; p. 122.

- Navarro, S. Modified atmospheres for the control of stored-product insects and mites. In Insect Management for Food Storage and Processing, 2nd ed.; Heaps, J.W., Ed.; ACCC International: St. Paul, MN, USA, 2006; pp. 105–146. [Google Scholar]

- White, N.D.G.; Jayas, D.S.; Muir, W.E. Toxicity of carbon dioxide at biologically producible levels to stored-product beetles. Environ. Entomol. 1995, 24, 640–647. [Google Scholar] [CrossRef]

- Lessard, F.F.; LeTorch, J.M. Practical approach to purging grain with low oxygen atmosphere for disinfestation of large wheat bins against the granary weevil, Sitophilus granarius. In Proceedings of the 4nd International Work. Confonference Stored-Product Prot, Tel Aviv, Israel, 21–26 September 1986; pp. 208–217. [Google Scholar]

- Storey, C.L. Exothermic inert atmosphere generator for control of insects in stored wheat. J. Econ. Entomol. 1973, 66, 511–514. [Google Scholar] [CrossRef]

- Mohammed, M.E.; El-Shafie, H.A.; Alhajhoj, M.R. Design and efficacy evaluation of a modern automated controlled atmosphere system for pest management in stored dates. J. Stored Prod. Res. 2020, 89, 101719. [Google Scholar] [CrossRef]

- Catling, D.; Zahnle, K. Evolution of atmospheric oxygen. In Encyclopedia of Atmospheric Sciences; North, G.R., Pyle, J.A., Zhang, F., Eds.; Academic Press: Cambridge, MA, USA, 2003; pp. 754–761. [Google Scholar]

- Cao, Y.; Gao, S.; Qu, G.; Li, Y.; Li, G.; Carvalho, M.O. Study on the mortality of the stored-grain insects adults in different concentrations of low oxygen. In Proceedings of the 10th International Work. Confonfernece on Stored Product Prot, Estoril, Portugal, 27 June–2 July 2010; Julius Kühn-Archiv: Berlin, Germany, 2010; pp. 476–478. [Google Scholar]

- Bond, E.J.; Buckland, C.T. Development of resistance to carbon dioxide in the granary weevil. J. Econ. Entomol. 1979, 7, 770–771. [Google Scholar] [CrossRef]

- Donahaye, E. Laboratory selection of resistance by the red flour beetle Tribolium castaneum (Herbst) to an atmosphere of low oxygen concentration. Phytoparasitica 1990, 18, 189–202. [Google Scholar] [CrossRef]

- Wang, J.J.; Zhao, Z.M.; Tsai, J.H. Resistance and some enzyme activities in Liposcelis bostrychophila Badonnel (Psocoptera: Liposcelididae) in relation to carbon dioxide enriched atmospheres. J. Stored Prod. Res. 2020, 36, 297–308. [Google Scholar] [CrossRef]

- Cao, Y.; Xu, K.; Zhu, X.; Bai, Y.; Yang, W.; Li, C. Role of modified atmosphere in pest control and mechanism of its effect on insects. Front. Physiol. 2019, 10, 206. [Google Scholar] [CrossRef] [Green Version]

- Buckland, P.C. Granaries, stores and insects. The archeology of insect synanthropy. In La Préparation Alimentaire des Céréales; Fournier, D., Sigaut, F., Eds.; PACT: Rixensart, Belgium, 1990; pp. 69–81. [Google Scholar]

- Lavigne, R. Stored grain insects in underground storage pits in Somalia and their control. Int. J. Trop. Insect Sci. 1991, 12, 571–578. [Google Scholar] [CrossRef]

- Bailey, S.W. Air-tight storage of grain; its effects on insect pests-I. Calandra granaria L. (Coleoptera, Curculionidae). Aust. J. Agric. Res. 1955, 6, 33–51. [Google Scholar] [CrossRef]

- Bailey, S.W. Air-tight storage of grain; its effects on insect pests-IV. Rhyzopertha dominica (F.) and some other Coleoptera that infest stored grain. J. Stored Prod. Res. 1965, 1, 25–33. [Google Scholar]

- Adhikarinayake, T.B.; Palipane, K.B.; Müller, J. Quality change and mass loss of paddy during airtight storage in a ferro-cement bin in Sri Lanka. J. Stored Prod. Res. 2006, 42, 377–390. [Google Scholar] [CrossRef]

- Prasantha, B.D.R.; Kumarasinha, K.M.H.; Emitiyagoda, G.A.M.S. Storage of mungbean in hermetic PVC tank. In Proceedings of the 12th International Work, Conference on Stored Product Prot, Berlin, Germany, 7–11 October 2018; Julius Kühn-Archiv: Berlin, Germany, 2018; pp. 441–447. [Google Scholar]

- Tivana, L.D.; Nguenha, R.J.; Viola, P.; Monjane, I.; Lungu, I.O.; Kafwamfwa, N. Effectiveness of high-density polyethylene container and Super Grain Bag for the storage system of cowpea grain for smallholder farmers. Legum. Sci. 2020, 3e67, 1–12. [Google Scholar]

- Villers, P.; Navarro, S.; Bruin, T. New applications of hermetic storage for grain storage and transport. In Proceedings of the 10th International Work. Conference on Stored Product Protect, Estoril, Portugal, 27 June–2 July 2010; Julius-Kühn-Archiv: Berlin, Germany, 2010; pp. 446–452. [Google Scholar]

- Ochandio, D.C.; Cardoso, L.M.; Bartosik, R.E.; De la Torre, D.A.; Rodríguez, J.C.; Massigoge, J. Storage of quality malting barley in hermetic plastic bags. In Proceedings of the 10th International Working Conference on Stored Product Protection, Estoril, Portugal, 27 June–2 July 2010; Julius-Kühn-Archiv: Berlin, Germany, 2010; pp. 331–337. [Google Scholar]

- Murdock, L.L.; Baoua, I.B. On Purdue improved cowpea storage (PICS) technology: Background, mode of action, future prospects. J. Stored Prod. Res. 2014, 58, 3–11. [Google Scholar] [CrossRef]

- Wilkin, D.R.; Green, A.A. Polythene sacks for the control of insects in bagged grain. J. Stored Prod. Res. 1970, 6, 97–101. [Google Scholar] [CrossRef]

- Guenha, R.; das Virtuedes Salvador, B.; Rickman, J.; Goulao, L.F.; Muocha, I.M.; Carvalho, M.O. Hermetic storage with plastic sealing to reduce insect infestation and secure paddy seed quality: A powerful strategy for rice farmers in Mozambique. J. Stored Prod. Res. 2014, 59, 275–281. [Google Scholar] [CrossRef]

- Sanon, A.; Dabiré-Binso, L.C.; Ba, N.M. Triple-bagging of cowpeas within high density polyethylene bags to control the cowpea beetle Callosobruchus maculatus F. (Coleoptera: Bruchidae). J. Stored Prod. Res. 2011, 47, 210–215. [Google Scholar] [CrossRef]

- Mubayiwa, M.; Mvumi, B.M.; Stathers, T.; Mlambo, S.; Nyabako, T. Field evaluation of hermetic and synthetic pesticide-based technologies in smallholder sorghum grain storage in hot and arid climates. Sci. Rep. 2021, 11, 3692. [Google Scholar] [CrossRef] [PubMed]

- Paudyal, S.; Opit, G.P.; Arthur, F.H.; Bingham, G.V.; Payton, M.E.; Gautam, S.G.; Noden, B.H. Effectiveness of the ZeroFly® storage bag fabric against stored-product insects. J. Stored Prod. Res. 2017, 73, 87–97. [Google Scholar] [CrossRef]

- Ngwenyama, P.; Mvumi, B.; Nyanga, L.; Stathers, T.; Siziba, S. Comparative performance of five hermetic bag brands during on-farm smallholder cowpea (Vigna unguiculata L. Walp) storage. J. Stored Prod. Res. 2020, 88, 101658. [Google Scholar] [CrossRef]

- Mutambuki, K.; Affognon, H.; Likhayo, P.; Baributsa, D. Evaluation of Purdue improved crop storage triple layer hermetic storage bag against Prostephanus truncatus (Horn) (Coleoptera: Bostrichidae) and Sitophilus zeamais (Motsch.) (Coleoptera: Curculionidae). Insects 2019, 10, 204. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- García-Lara, S.; Ortíz-Islas, S.; Villers, P. Portable hermetic storage bag resistant to Prostephanus truncatus, Rhyzopertha dominica, and Callosobruchus maculatus. J. Stored Prod. Res. 2013, 54, 23–25. [Google Scholar] [CrossRef]

- Otitodun, G.O.; Ogundare, M.O.; Ajao, S.K.; Nwaubani, S.I.; Abel, G.I.; Opit, G.P.; Bingham, G.; Omobowale, M.O. Efficacy of phosphine and insect penetration ability in ZeroFly® bags. J. Stored Prod. Res. 2019, 82, 81–90. [Google Scholar] [CrossRef]

- Riudavets, J.; Castane, C.; Alomar, O.; Pons, M.J.; Gabarra, R. Modified atmosphere packaging (MAP) as an alternative measure for controlling ten pests that attack processed food products. J. Stored Prod. Res. 2009, 45, 91–96. [Google Scholar] [CrossRef]

- Kucerova, Z.; Kyhos, K.; Aulicky, R.; Stejskal, V. Low pressure treatment to control food-infesting pests (Tribolium castaneum, Sitophilus granarius) using a vacuum packing machine. Czech J. Food Sci. 2013, 31, 94–98. [Google Scholar] [CrossRef] [Green Version]

- Kucerova, Z.; Kyhos, K.; Aulicky, R.; Lukas, J.; Stejskal, V. Laboratory experiments of vacuum treatment in combination with an O2 absorber for the suppression of Sitophilus granarius infestations in stored grain samples. Crop Prot. 2014, 61, 79–83. [Google Scholar] [CrossRef]

- Aulicky, R.; Kolar, V.; Plachy, J.; Stejskal, V. Field efficacy of brief exposure of adults of six storage pests to nitrogen-controlled atmospheres. Plant Protect. Sci. 2017, 53, 169–176. [Google Scholar]

- Williams, P.; Minett, W.; Navarro, S.; Amos, T.G. Sealing a farm silo for insect control by nitrogen swamping for fumigation. Aust. J. Exp. Anim. Husb. 1980, 20, 108–114. [Google Scholar] [CrossRef]

- Carvalho, M.O.; Pires, I.; Barbosa, A.; Barros, G.; Riudavets, J.; Garcia, A.C.; Navarro, S. The use of modified atmospheres to control Sitophilus zeamais and Sitophilus oryzae on stored rice in Portugal. J. Stored Prod. Res. 2012, 50, 49–56. [Google Scholar] [CrossRef]

- Morrison, W.R.; Arthur, F.H.; Wilson, L.T.; Yang, Y.; Wang, J.; Athanassiou, C.G. Aeration to manage insects in wheat stored in the Balkan peninsula: Computer simulations using historical weather data. Agronomy 2020, 10, 1927. [Google Scholar] [CrossRef]

- Hagstrum, D.W.; Reed, C.; Kenkel, P. Management of stored wheat insect pests in the USA. Integrated Pest Manag. Rev. 1999, 4, 127–143. [Google Scholar] [CrossRef]

- Sthong, R.G.; Sbur, D.E. Protective sprays against internal infestations of grain beetles in wheat. J. Econ. Entomol. 1964, 57, 544–548. [Google Scholar] [CrossRef]

- Cotton, R.T.; Walkden, H.H.; White, G.D.; Wilbur, D.A. Causes of outbreaks of stored-grain insects. In Bulletin 416; Agricultural Experiment Station, Kansas State University of Agriculture and Apllied Science: Manhattan, KS, USA, 1960; p. 35. [Google Scholar]

- Cotton, R.T. Pests of Stored Grain and Stored Products; Burgess Publishing Co.: Minneapolis, MN, USA, 1963. [Google Scholar]

- Arthur, F.H. Grain protectants: Current status and prospect for the future. J. Stored Prod. Res. 1996, 32, 293–302. [Google Scholar] [CrossRef]

- Rahman, K.; Sohi, G. Mercury as a preventive against stored grain pests. Bull. Entomol. Res. 1946, 37, 131–141. [Google Scholar] [CrossRef] [PubMed]

- Shepard, H.H. Insects Infesting Stored Grain and Seeds. In Bulletin 340; University of Minnesota Agricultural Experiment Station: Saint Paul, MN, USA, 1947; p. 31. [Google Scholar]

- White, N.D.G.; Leesch, J.G. Chemical control. In Integrated Management of Insects in Stored Products; Subramanyam, B., Hagstrum, D.W., Eds.; Marcel Dekker: New York, NY, USA, 1996; pp. 287–330. [Google Scholar]

- Desmarchelier, J.M.; Banks, H.J.; Williams, P.; Minetta, W. Toxicity of dichlorvos. J. Stored Prod. Res. 1977, 13, 1–12. [Google Scholar] [CrossRef]

- Arthur, F.H. Efficacy of Combinations of methoprene and deltamethrin as long-term commodity protectants. Insects 2019, 10, 50. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Haddi, K.; Valbon, W.R.; Jumbo, L.O.V.; de Oliveira, L.O.; Guedes, R.N.; Oliveira, E.E. Diversity and convergence of mechanisms involved in pyrethroid resistance in the stored grain weevils. Sitophilus spp. Sci. Rep. 2018, 8, 1–15. [Google Scholar] [CrossRef] [PubMed]

- Ortega, D.S.; Bacca, T.; Silva, A.P.N.; Canal, N.A.; Haddi, K. Control failure and insecticides resistance in populations of Rhyzopertha dominica (Coleoptera: Bostrichidae) from Colombia. J. Stored Prod. Res. 2021, 92, 101802. [Google Scholar] [CrossRef]

- Yue, B.; Wilde, G.E.; Arthur, F. Evaluation of thiamethoxam and imidacloprid as seed treatments to control European corn borer and Indianmeal moth (Lepidoptera: Pyralidae) larvae. J. Econ. Entomol. 2003, 96, 503–509. [Google Scholar] [CrossRef]

- Boukouvala, M.; Kavallieratos, N. Evaluation of two formulations of chlorantraniliprole as maize protectants for the management of Prostephanus truncatus (Horn) (Coleoptera: Bostrychidae). Insects 2021, 12, 194. [Google Scholar] [CrossRef]

- Hertlein, M.B.; Thompson, G.D.; Subramanyam, B.; Athanassiou, C.G. Spinosad: A new natural product for stored grain protection. J. Stored Prod. Res. 2011, 47, 131–146. [Google Scholar] [CrossRef]

- Athanassiou, C.G.; Arthur, F.H.; Throne, J.E. Effects of short exposures to spinosad-treated wheat or maize on four stored-grain insects. J. Econ. Entomol. 2010, 103, 197–202. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Vassilakos, T.N.; Athanassiou, C.G. Effect of short exposures to spinetoram against three stored-product beetle species. J. Econ. Entomol. 2012, 105, 1088–1094. [Google Scholar] [CrossRef]

- Weaver, D.K.; Subramanyam, B. Botanicals. In Alternatives to Pesticides in Stored-Product IPM; Subramanyam, B., Hagstrum, D., Eds.; Kluwer Academic Publishers: Boston, MA, USA, 2000; pp. 303–320. [Google Scholar]

- Athanassiou, C.G.; Kontodimas, D.C.; Kavallieratos, N.G.; Veroniki, M.A. Insecticidal effect of NeemAzal against three stored-product beetle species on rye and oats. J. Econ. Entomol. 2005, 98, 1733–1738. [Google Scholar] [CrossRef]

- Kavallieratos, N.G.; Nika, E.P.; Skourti, A.; Ntalli, N.; Boukouvala, M.C.; Ntalaka, C.T.; Maggi, F.; Rakotosaona, R.; Cespi, M.; Perinelli, D.R.; et al. Developing a Hazomalania voyronii essential oil nanoemulsion for the eco-friendly management of Tribolium confusum, Tribolium castaneum and Tenebrio molitor larvae and adults on stored wheat. Molecules 2021, 26, 1812. [Google Scholar] [CrossRef]

- Dougoud, J.; Toepfer, S.; Bateman, M.; Jenner, W.D. Efficacy of homemade botanical insecticides based on traditional knowledge. A review. Agron. Sustain. Dev. 2019, 39, 1–22. [Google Scholar] [CrossRef] [Green Version]

- Sujatha, A.; Punnaiah, K.C. Effect of coating stored seed of greengram with vegetable oils on the development of pulse beetle. Indian J. Agric. Sci. 1985, 55, 475–477. [Google Scholar]

- Reed, C.; Pedersen, J.R.; Cuperus, G.W. Efficacy and cost effectiveness of grain protectants applied to farm-stored wheat at harvest and later. J. Econ. Entomol. 1993, 86, 1590–1598. [Google Scholar] [CrossRef]

- Pozidi-Metaxa, E.; Athanassiou, C.G. Comparison of spinosad with three traditional grain protectants against Prostephanus truncatus (Horn) and Ephestia kuehniella (Zeller) at different temperatures. J. Pest Sci. 2013, 86, 203–210. [Google Scholar] [CrossRef]

- Subramanyam, B.; Hagstrum, D.W. Resistance measurement and management. In Integrated Management of Insects in Stored Products; Subramanyam, B., Hagstrum, D.W., Eds.; Marcel Dekker: New York, NY, USA, 1996; pp. 331–399. [Google Scholar]

- Daglish, G.J.; Eeklema, M.; Harrison, M. Control of Sitophilus oryzae (L.) (Coleoptera: Curculionidae) in paddy rice using chlorpyrifos-methyl or fenitrotion in combination with several other protectants. J. Stored Prod. Res. 1996, 32, 247–253. [Google Scholar] [CrossRef]

- Dauguet, S.; Fleurat-Lessard, F.; Loison, J. Cross-contamination of oilseeds by insecticide residues during storage. In Proceedings of the 10th International Working Conference on Stored Product Protection, Estoril, Portugal, 27 June–2 July 2010; Carvalho, M.O., Ed.; Julius Kühn-Archiv: Berlin, Germany, 2010; pp. 827–832. [Google Scholar]

- Williams, C.M. Third-generation pesticides. Sci. Am. 1967, 217, 13–17. [Google Scholar] [CrossRef] [PubMed]

- Pener, M.P.; Dhadialla, T.S. Chapter One—An overview of insect growth disruptors; applied aspects. In Advances in Insect Physiology; Dhadialla, T.S., Ed.; Insect Growth Disruptors; Academic Press: Cambridge, MA, USA, 2012; Volume 43, pp. 1–162. [Google Scholar]

- Wijayaratne, L.K.W.; Fields, P.G.; Arthur, F.H. Residual efficacy of methoprene for control of Tribolium castaneum (Coleoptera: Tenebrionidae) larvae at different temperatures on varnished wood, concrete, and wheat. J. Econ. Entomol. 2012, 105, 718–725. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Daglish, G.J.; Pulvirenti, C. Reduced fecundity of Rhyzopertha dominica (F.) (Coleoptera: Bostrichidae) following exposure of adults to methoprene. J. Stored Prod. Res. 1997, 34, 201–206. [Google Scholar] [CrossRef]

- Kavallieratos, N.G.; Athanassiou, C.G.; Vayias, B.J.; Tomanovic, Z. Efficacy of insect growth regulators as grain protectants against two stored-product pestsin wheat and maize. J. Food Prot. 2012, 75, 942–950. [Google Scholar] [CrossRef]

- Phillips, T.W.; Throne, J.E. Biorational approaches to managing stored-product insects. Annu. Rev. Entomol. 2010, 55, 375–397. [Google Scholar] [CrossRef]

- Daglish, G.J.; Nayak, M.K. Uneven application can influence the efficacy of S-methoprene against Rhyzopertha dominica on wheat. J. Stored Prod. Res. 2010, 46, 250–253. [Google Scholar] [CrossRef]

- Edde, P.A. Review of the biology and control of Rhyzopertha dominica (F.) the lesser grain borer. J. Stored Prod. Res. 2012, 48, 1–18. [Google Scholar] [CrossRef]

- Arthur, F.H. Efficacy of methoprene for multi-year protection of stored wheat, brown rice, rough rice and corn. J. Stored Prod. Res. 2016, 68, 85–92. [Google Scholar] [CrossRef] [Green Version]

- Daglish, G.J. Efficacy of six grain protectants applied alone or in combination against three species of Coleoptera. J. Stored Prod. Res. 1998, 34, 263–268. [Google Scholar] [CrossRef]

- Athanassiou, C.G.; Kavallieratos, N.G.; Arthur, F.H.; Throne, J.E. Efficacy of spinosad and methoprene, applied alone or in combination, against six stored product insect species. J. Pest Sci. 2011, 84, 61–67. [Google Scholar] [CrossRef]

- Lui, S.; Arthur, F.H.; Van Gundy, D.; Phillips, T.W. Combination of methoprene and controlled aeration to manage insects in stored wheat. Insects 2016, 7, 25. [Google Scholar]

- Reed, C. Managing Stored Grain to Preserve Quality and Value; American Association of Cereal Chemists, ACCC International: St. Paul, MN, USA, 2006. [Google Scholar]

- Minett, W.; Williams, P. Influence of malathion distribution on the protection of wheat grain against insect infestation. J. Stored Prod. Res. 1971, 7, 233–242. [Google Scholar] [CrossRef]

- Subramanyam, B.; Boina, D.R.; Sehgal, B.; Lazzari, F. Efficacy of partial treatment of wheat with spinosad against Rhyzopertha dominica (F.) adults. J. Stored Prod. Res. 2014, 59, 197–203. [Google Scholar] [CrossRef] [Green Version]

- Kavallieratos, N.G.; Athanassiou, C.G.; Arthur, F.H. Efficacy of deltamethrin against stored-product beetles at short exposure intervals or on a partially treated rice mass. J. Econ. Entomol. 2015, 108, 1416–1421. [Google Scholar] [CrossRef] [Green Version]

- Scully, E.D.; Gerken, A.R.; Fifield, A.; Nguyen, V.; Van Pelt, N.; Arthur, F.H. Impacts of Storicide II on internal feeders of Brown rice. J. Stored Prod. Res. 2021, 90, 101758. [Google Scholar] [CrossRef]

- Singh, S.K.; Fan, L.T. A biopolymer-based pesticide delivery system for insect suppression in stored grains. Pestic. Sci. 1989, 25, 273–288. [Google Scholar] [CrossRef]

- Rumbos, C.I.; Dutton, A.C.; Athanassiou, C.G. Insecticidal efficacy of two pirimiphos-methyl formulations for the control of three stored-product beetle species: Effect of commodity. Crop Protect. 2016, 80, 94–100. [Google Scholar] [CrossRef]

- Kavallieratos, N.G.; Athanassiou, C.G.; Nika, E.P.; Boukouvala, M.C. Efficacy of alpha-cypermethrin, chlorfenapyr and pirimiphos-methyl applied on polypropylene bags for the control of Prostephanus truncatus (Horn), Rhyzopertha dominica (F.) and Sitophilus oryzae (L.). J. Stored Prod. Res. 2017, 73, 54–61. [Google Scholar] [CrossRef]

- Szilagyi, J. NovIGRain project aims to cut losses of stored grain. Int. Pest Control 2021, 63, 102–103. [Google Scholar]

- Athanassiou, C.G.; Arthur, F.H.; Throne, J.E. Efficacy of spinosad in layer-treated wheat against five stored-product insect species. J. Stored Prod. Res. 2009, 45, 236–240. [Google Scholar] [CrossRef]

- Golob, P.; Hanks, C. Protection of farm stored maize against infestation by Prostephanus truncatus (Horn) and Sitophilus species in Tanzania. J. Stored Prod. Res. 1990, 26, 187–198. [Google Scholar] [CrossRef]

- Hodges, R.J.; Meik, J. Infestation of maize cobs by Prostephanus truncatus (Horn) (Coleoptera: Bostrichidae) Aspects of biology and control. J. Stored Prod. Res. 1984, 20, 205–213. [Google Scholar] [CrossRef]

- Khan, M.A.A.; Khan, Y.S.A. Insects infestation and preventive measures in dry fish storage of Chittagong, Bangladesh. Int. J. Biol. Sci. 2001, 1, 963–965. [Google Scholar]

- Rajendran, S.; Parveen, K.M.H. Insect infestation in stored animal products. J. Stored Prod. Res. 2005, 41, 1–30. [Google Scholar] [CrossRef]

- MacQuillan, M.J.; Shipp, E. Evaluation of chlorpyrifos and chlorpyriphos-methyl for control of Dermestes maculatus Deg. (Coleoptera: Dermestidae) on sheepskins. J. Stored Prod. Res. 1976, 12, 93–96. [Google Scholar] [CrossRef]

- Golob, P.; Cox, J.R.; Kilminster, K. Evaluation of insecticide dips as protectants of stored dried fish from dermestid beetle infestation. J. Stored Prod. Res. 1987, 23, 47–56. [Google Scholar] [CrossRef]

- Don-Pedro, K.N. Toxicity of some citrus peels to Dermestes maculatus Deg. and Callosobruchus maculatus (F). J. Stored Prod. Res. 1985, 21, 31–34. [Google Scholar] [CrossRef]

- Onu, I.; Baba, G.O. Evaluation of Neem products for the control of Dermestid beetle on dried fish. Niger. J. Entomol. Soc. 2003, 20, 105–115. [Google Scholar]

- Nowsad, A.K.M.; Mondal, R.; Islam, M.R. Effectiveness of neem, garlic and red chili against adult dermestid beetle in sun dried fish. Progress. Agric. 2013, 20, 133–142. [Google Scholar] [CrossRef] [Green Version]

- Golob, P.; Gueye-Ndiaye, A.; Johnson, S. Prevention of beetle infestation of dried fish. In Proceedings of the 6th International Working Conference on Stored-Product Protection, Canberra, Australia, 17–23 April 1994; Highley, E., Wright, E.J., Banks, H.J., Champ, B.R., Eds.; CAB International: Wallingford, UK, 1994; pp. 777–781. [Google Scholar]

- Pretoru, E.G. Studies on Control of Dermestes maculatus Degeer on Dried Fish Treated by ULV Application. Ph.D. Thesis, Imperial College London, Silwood Park, UK, 1988. [Google Scholar]

- Khan, Y.S.A.; Khan, M.A.A. Study on the use of DDT as preservative practiced in stored dried fishes of Bangladesh. Poll. Res. 1998, 17, 363–365. [Google Scholar]

- Islam, M.N.; Kabir, M.A. Application of organic preservatives for sustainable storage of dried fishes. Int. J. Fish. Aquat. 2019, 7, 40–43. [Google Scholar]

- Adebote, D.A.; Abolude, D.S.; Oniye, S.J.; Olododo, S.S.; Hassan, M.M. Larvicidal and repellent actions of Detarium microcarpum seed oil against the larvae of Dermestes lardarius (Coleoptera: Dermestidae) in dried Clarias gariepinus fish. J. Entomol. 2006, 3, 248–253. [Google Scholar]

- Don-Pedro, K.N. Insecticidal activity of some vegetable oils against Dermestes maculatus Degeer (Coleoptera: Dermestidae) on dried fish. J. Stored Prod. Res. 1989, 25, 81–86. [Google Scholar] [CrossRef]

- Idris, G.L.; Omojowo, F.S. Comparative study of groundnut oil and sodium chloride as protectants against insect infestation of smoked dried fish in Kainji lake areas. J. Fish. Aquat. Sci. 2013, 8, 238–242. [Google Scholar] [CrossRef] [Green Version]

- Rust, M.K.; Reierson, D.A.; Klotz, J.H. Delayed toxicity as a critical factor in the efficacy of aqueous baits for controlling Argentine ants (Hymenoptera: Formicidae). J. Econ. Entomol. 2004, 97, 1017–1024. [Google Scholar] [CrossRef]

- Rust, M.K.; Choe, D.H.; Wilson-Rankin, E.; Campbell, K.; Kabashima, J.; Dimson, M. Controlling yellow jackets with fipronil-based protein baits in urban recreational areas. Int. J. Pest Manag. 2017, 63, 234–241. [Google Scholar] [CrossRef] [Green Version]

- Wongthangsiri, D.; Pereira, R.M.; Bangs, M.J.; Koehler, P.G.; Chareonviriyaphap, T. Potential of attractive toxic sugar baits for controlling Musca domestica L., Drosophila melanogaster Meigen, and Megaselia scalaris Loew adult flies. Agric. Nat. Res. 2018, 52, 393–398. [Google Scholar] [CrossRef]

- Gore, J.C.; Schal, C. Laboratory evaluation of boric acid-sugar solutions as baits for management of German cockroach infestations. J. Econ. Entomol. 2004, 97, 581–587. [Google Scholar] [CrossRef] [PubMed]

- Choe, D.H.; Campbell, K.; Hoddle, M.S.; Kabashima, J.; Dimson, M.; Rust, M.K. Evaluation of a hydrogel matrix for baiting western yellowjacket (Vespidae: Hymenoptera). J. Econ. Entomol. 2018, 111, 1799–1805. [Google Scholar] [CrossRef]

- Kikuta, S. Deployment of an attractive toxic sugar bait system (ATSB) with insecticide, for adult Tribolium castaneum (Coleoptera: Tenebrionidae). J. Stored Prod. Res. 2019, 83, 97–102. [Google Scholar] [CrossRef]

- Lee, S.H.; Choe, D.H.; Lee, C.Y. The impact of artificial sweeteners on insects. J. Econ. Entomol. 2021, 114, 1–13. [Google Scholar] [CrossRef]

- Baudier, K.M.; Kaschock-Marenda, S.D.; Patel, N.; Diangelus, K.L.; O’Donnell, S.; Marenda, D.R. Erythritol, a non-nutritive sugar alcohol sweetener and the main component of Truvia®, is a palatable ingested insecticide. PLoS ONE 2014, 9, e98949. [Google Scholar]

- Barrett, M.; Caponera, V.; McNair, C.; O’Donnell, S.; Marenda, D.R. Potential for use of erythritol as a socially transferrable ingested insecticide for ants (Hymenoptera: Formicidae). J. Econ. Entomol. 2020, 113, 1382. [Google Scholar] [CrossRef]

- Díaz-Fleischer, F.; Arredondo, J.; Lasa, R.; Bonilla, C.; Debernardi, D.; Pérez-Staples, D.; Williams, T. Sickly sweet: Insecticidal polyols induce lethal regurgitation in dipteran pests. Insects 2019, 10, 53. [Google Scholar] [CrossRef] [Green Version]

- Perkin, L.C.; Adrianos, S.L.; Oppert, B. Gene disruption technologies have the potential to transform stored product insect pest control. Insects 2016, 7, 46. [Google Scholar] [CrossRef] [Green Version]

- Silver, K.; Cooper, A.M.; Zhu, K.Y. Strategies for enhancing the efficiency of RNA interference in insects. Pest Manag. Sci. 2021, 77, 2645–2658. [Google Scholar] [CrossRef]

- Yan, S.; Ren, B.Y.; Shen, J. Nanoparticle-mediated double-stranded RNA delivery system: A promising approach for sustainable pest management. Insect Sci. 2021, 28, 21–34. [Google Scholar] [CrossRef]

- Huang, J.H.; Liu, Y.; Lin, Y.H.; Belles, X.; Lee, H.J. Practical use of RNA interference: Oral delivery of double-stranded RNA in liposome carriers for cockroaches. J. Vis. Exp. 2018, 135, e57385. [Google Scholar] [CrossRef] [Green Version]

- Wang, S.; Miao, S.; Yang, B.; Wang, Z.; Liu, Q.; Wang, R.; Du, X.; Ren, Y.; Lu, Y. Initial characterization of the vitellogenin receptor from a Psocoptera insect: Function analysis and RNA interference in Liposcelis entomophila (Enderlein). J. Stored Prod. Res. 2021, 92, 101803. [Google Scholar] [CrossRef]

- Stejskal, V.; Aulicky, R.; Kucerova, Z. Pest control strategies and damage potential of seed-infesting pests in the Czech stores—a review. Plant Protect. Sci. 2014, 50, 165–173. [Google Scholar] [CrossRef] [Green Version]

- Athanassiou, C.G.; Riudavets, J.; Kavallieratos, N.G. Preventing stored-product insect infestations in packaged-food products. Stewart Postharvest Rev. 2011, 3, 1–5. [Google Scholar]

- Yadav, T.D. Evaluation of deltamethrin as fabric treatment in storage of wheat seed at farm level. Indian J. Entomol. 1997, 59, 103–109. [Google Scholar]

- Cotton, R.T.; Balzer, A.I.; Young, H.D. Possible utility of DDT for insect-proofing paper bags. J. Econ. Entomol. 1944, 37, 140. [Google Scholar] [CrossRef]

- Hayhurst, H. The action on certain insects of fabrics impregnated with DDT. J. Soc. Chem. Ind. 1945, 64, 296. [Google Scholar] [CrossRef]

- Parkin, E.A. D.D.T. impregnation of sacks for the protection of stored cereals against insect infestation. Ann. Appl. Biol. 1948, 35, 233–242. [Google Scholar] [CrossRef]

- Atkins, W.G. Storage of flour in jute bags treated with insecticides. J. Sci. Food Agric. 1953, 4, 155–160. [Google Scholar] [CrossRef]

- Prevett, P.F. Treatment of rice stored in jute bags against insect pests. Trop. Stored Prod. Info. 1960, 1, 4–9. [Google Scholar]

- Pali, N.S. Studies on jute bag impregnation for the control of graminivorous insects. J. Entomol. 1961, 22, 211–213. [Google Scholar]

- Webley, D.J.; Kilminster, K.M. The persistence of insecticide spray deposits on woven polypropylene and jute sacking. Pestic. Sci. 1980, 11, 667–673. [Google Scholar] [CrossRef]

- Rai, R.S.; Lal, P.; Srivastava, P.K. Impregnation of jute bags with insecticide for protecting stored food grains. III. Comparative efficacy of impregnation method vis-a-vis existing method of prophylactic chemical treatment against cross infestation of different stored grain insect pests. Pesticides 1987, 21, 39–42. [Google Scholar]

- Yadav, T.D.; Singh, S. Persistence toxicity and efficacy of four insecticides as jute fabric treatment to protect cereal and legume seeds. Indian J. Entomol. 1994, 56, 146–155. [Google Scholar]

- Pathak, K.A.; Jha, A.N.; Singh, J.P. Effect of fabric treatment of jute and polypropylene bags with some insecticides on maize and paddy stored at Delhi and Meghalaya. Shashpa 2002, 9, 61–70. [Google Scholar]

- Morallo-Rejesus, B.; Varca, L.M.; Nerona, E.H. Insecticide impregnation of sacks and use of plastic lining for the protection of stored corn against insect damage. Philipp. Agric. 1975, 59, 196–204. [Google Scholar]

- Webley, D.J.; Kilminster, K.M. The persistence and activity of insecticide spray deposits on woven polypropylene fabric. Pestic. Sci. 1981, 12, 74–78. [Google Scholar] [CrossRef]

- Barakat, A.A.; Khan, P.; Karim, A.A. The persistence and activity of permethrin and chlorpyrifos-methyl sprays on jute and woven polypropylene bags. J. Stored Prod. Res. 1987, 23, 85–90. [Google Scholar] [CrossRef]

- Scheff, D.S.; Subramanyam, B.; Arthur, F.H. Susceptibility of Tribolium castaneum and Trogoderma variabile larvae and adults exposed to methoprene-treated woven packaging material. J. Stored Prod. Res. 2017, 73, 142–150. [Google Scholar] [CrossRef]

- Papanikolaou, N.E.; Kavallieratos, N.G.; Boukouvala, M.C.; Malesios, C. (Quasi)-binomial vs. gaussian models to evaluate thiamethoxam, pirimiphos-methyl, alpha-cypermethrin and deltamethrin on different types of storage bag materials against Ephestia kuehniella Zeller (Lepidoptera: Pyralidae) and Tribolium confusum Jacquelin du Val (Coleoptera: Tenebrionidae). Insects 2021, 12, 182. [Google Scholar]

- Himel, C.M. The optimum size for insecticide spray droplets. J. Econ. Entomol. 1969, 62, 919–925. [Google Scholar] [CrossRef]

- WHO. Equipment for Vector Control; WHO: Geneva, Switzerland, 1964. [Google Scholar]

- Sugiura, M.; Horibe, Y.; Kawada, H.; Takagi, M. Effect of different droplet size on the knockdown efficacy of directly sprayed insecticides. Pest. Manag. Sci. 2011, 67, 1115–1123. [Google Scholar] [CrossRef]

- Hewlett, P.S. A direct spray technique for the biological evaluation of pyrethrum-in-oil insecticides for use against stored product insects in warehouses. Ann. Appl. Biol. 1947, 34, 357–375. [Google Scholar] [CrossRef] [PubMed]

- Stadler, T.; Buteler, M. Modes of entry of petroleum distilled spray-oils into insects: A review. Bull. Insectol. 2009, 62, 169–177. [Google Scholar]

- Sugiura, M.; Horibe, Y.; Kawada, H.; Takagi, M. Insect spiracle as the main penetration route of pyrethroids. Pestic. Biochem. Physiol. 2008, 91, 135–140. [Google Scholar] [CrossRef] [Green Version]

- David, W.A.L. The quantity and distribution of spray collected by insects flying through insecticidal mists. Ann. Appl. Biol. 1946, 33, 133–141. [Google Scholar] [CrossRef] [PubMed]

- Marcombe, S.; Carron, A.; Darriet, F.; Etienne, M.; Agnew, P.; Tolosa, M.; Yp-Tcha, M.M.; Lagneau, C.; Yébakima, A.; Corbel, V. Reduced efficacy of pyrethroid space sprays for dengue control in an area of Martinique with pyrethroid resistance. Am. J. Trop. Med. Hyg. 2009, 80, 745–751. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Bonds, J.A.S. Ultra-low-volume space sprays in mosquito control: A critical review. Med. Vet. Entomol. 2012, 26, 121–130. [Google Scholar] [CrossRef]

- David, W.A.L. Factors influencing the interaction of insecticidal mists and flying insects. Part II. The production and behaviour of kerosene base insecticidal spray mists and their relation to flying insects. Bull. Entomol. Res. 1946, 37, 1–28. [Google Scholar] [CrossRef]

- Webley, D. Manual of Pest Control for Food Security Reserve Grain Stocks. In FAO Plant Production and Protection Paper No. 63; Food & Agriculture Org: Rome, Italy, 1988; p. 160. [Google Scholar]

- Matthews, G. Space spray fundamentals. Int. Pest Control 2013, 55, 78–80. [Google Scholar]

- Childs, D.P.; Phillips, G.L.; Press, A.R. Control of the cigarette beetle in tobacco warehouses with automatic dichlorvos aerosol treatments. J. Econ. Entomol. 1966, 59, 261–264. [Google Scholar] [CrossRef]

- Suss, L. A new method for the control of insects in warehouses and food industries. In Proceedings of the 7th International Work. Conference on Stored-Product Protection, Beijing, China, 14–19 October 1998; Jin, Z., Liang, Q., Liang, Y., Tan, X., Guan, L., Eds.; Sichuan Publishing House of Science and Technology: Chengdu, China, 1998; pp. 950–954. [Google Scholar]

- Lofgren, C.S. Ultralow volume applications of concentrated insecticides in medical and veterinary entomology. Ann. Rev. Entomol. 1970, 15, 321–342. [Google Scholar] [CrossRef]

- LaMer, V.K.; Hochberg, S.; Hodges, K.; Wilson, I.; Fales, J.A.; Latta, R. The influence of the particle size of homogeneous insecticidal aerosols on the mortality of mosquitoes in confined atmospheres. J. Colloid. Sci. 1947, 2, 539–549. [Google Scholar] [CrossRef]

- Rickett, F.E.; Chadwick, P.R. Measurements of temperature and degradation of pyrethroids in two thermal fogging machines, the Swingfog and TIFA. Pestic. Sci. 1972, 3, 263–269. [Google Scholar] [CrossRef]

- Hoffmann, W.C.; Walker, T.W.; Fritz, B.K.; Gwinn, T.; Smith, V.L.; Szumlas, D.; Quinn, B.; Lan, Y.; Huang, Y.; Sykes, D. Spray characterization of thermal fogging equipment typically used in vector control. J. Am. Mosq. Control Assoc. 2008, 24, 550–559. [Google Scholar] [CrossRef]

- Asuncion, F.X.B.; Brabec, D.L.; Casada, M.E.; Maghirang, R.G.; Arthur, F.H.; Campbell, J.F.; Zhu, K.Y.; Daniel, E.; Martin, D.E. Spray Characterization of aerosol delivery systems for use in stored product facilities. Trans. ASABE 2020, 63, 1925–1937. [Google Scholar] [CrossRef]

- Potter, C. An account of the constitution and use of an atomized white oil-pyrethrum fluid to control Plodia interpunctella and Ephestia elutella in warehouses. Ann. Appl. Biol. 1935, 22, 769–805. [Google Scholar] [CrossRef]

- Potter, C.; Graham-Bryce, I.J. An Appreciation. Ann. Appl. Biol. 1990, 117, 233–235. [Google Scholar] [CrossRef]

- Cornwell, P.B. The Cockroach. Vol. Ii. Insecticides and Cockroach Control; St. Martin’s Press: New York, NY, USA, 1976. [Google Scholar]

- Cogburn, R.R.; Simonaitis, R.A. Dichlorvos for control of stored-product insects in port warehouses: Low-volume aerosols and commodity residues. J. Econ. Entomol. 1975, 68, 361–365. [Google Scholar] [CrossRef] [PubMed]

- Bell, C. Pest control: Insects and mites. In Hygiene in Food Processing; Lelieveld, H.L.M., Ed.; Woodhead Publishing Limited: Cambridge, UK, 2003; pp. 335–379. [Google Scholar]

- Scheff, D.S.; Brabec, D.; Campbell, J.F.; Arthur, H.F. Case study: A practical application of an aerosol treatment in a commercial mill. Insects 2019, 10, 150. [Google Scholar] [CrossRef] [Green Version]

- Arthur, F.H.; Scheff, D.S.; Brabec, D.; Bindel, J. Aerosol concentration, deposition, particle size, and exposure interval as mortality factors Tribolium confusum Jacquelin du Val (Coleoptera: Tenebrionidae). J. Stored Prod. Res. 2019, 83, 191–199. [Google Scholar] [CrossRef]

- Arthur, F.H.; Campbell, J.F.; Ducatte, G.R. Susceptibility of Tribolium confusum (Coleoptera: Tenebrionidae) to pyrethrin aerosol: Effects of aerosol particle size, concentration, and exposure conditions. J. Econ. Entomol. 2014, 107, 2239–2251. [Google Scholar] [CrossRef]

- Arthur, F.H.; Campbell, J.F.; Brabec, D.L.; Ducatte, G.R.; Donaldson, J.E. Aerosol insecticide distribution inside a flour mill: Assessment using droplet measurements and bioassays. J. Stored Prod. Res. 2018, 77, 26–33. [Google Scholar] [CrossRef]

- Arthur, F.H.; Subramanyam, B.H. Chemical control in stored products. In Stored Product Protection; Hagstrum, D.W., Phillips, T.W., Cuperus, G., Eds.; Kansas State University Agricultural Experiment Station and Cooperative Extension Service: Manhattan, NY, USA, 2012; pp. 95–100. [Google Scholar]

- Arthur, F.H. Aerosols and contact insecticides as alternatives to methyl bromide in flour mills food production facilities and food warehouses. J. Pest Sci. 2012, 85, 323–329. [Google Scholar] [CrossRef]

- David, W.A.L. Insecticidal sprays and flying insects. Nature 1945, 155, 204. [Google Scholar] [CrossRef]

- David, W.A.L.; Bracey, P. Factors influencing the interaction of insecticidal mists on flying insects: Part III. Biological Factors. Bull. Entomol. Res. 1946, 37, 177–190. [Google Scholar] [CrossRef]

- Opit, G.P.; Arthur, F.H.; Throne, J.E.; Payton, M.E. Susceptibility of stored-product psocids to aerosol insecticides. J. Insect Sci. 2012, 12, 139. [Google Scholar] [CrossRef] [PubMed]

- Athanassiou, C.G.; Arthur, F.H.; Campbell, J.F.; Donaldson, J.E. Particle size matters: Efficacy of aerosols for the control of stored product psocids. J. Stored Prod. Res. 2019, 83, 148–152. [Google Scholar] [CrossRef]

- Jenson, E.A.; Arthur, F.H.; Nechols, J.R. Efficacy of methoprene applied at different temperatures and rates to different surface substrates to control eggs and fifth instars of Plodia interpunctella Hübner. J. Econ. Entomol. 2009, 102, 1992–2002. [Google Scholar] [CrossRef]

- Jenson, E.A.; Arthur, F.H.; Nechols, J.R. Efficacy of an esfenvalerate plus methoprene aerosol for the control of eggs and fifth instars of Plodia interpunctela (Lepidoptera: Pyralidae). Insect Sci. 2010, 17, 21–28. [Google Scholar] [CrossRef]

- Fontenot, E.A.; Arthur, F.H.; Nechols, J.R.; Throne, J.E. Using a population growth model to simulate response of Plodia interpunctella Hübner populations to timing and frequency of insecticide treatments. J. Pest Sci. 2012, 85, 469–476. [Google Scholar] [CrossRef]

- Reierson, D.A. Field tests to control German cockroaches with ULV aerosol generators. Pest Control 1973, 41, 26–32. [Google Scholar]

- Moore, R.C. Field tests of pyrethrins and resmethrin applied with ULV generators or total release aerosols to control the German cockroach. J. Econ. Entomol. 1977, 70, 86–88. [Google Scholar] [CrossRef]

- Chadwick, P.R.; Shaw, R.D. Cockroach control in sewers in Singapore using bioresmethrin and piperonyl butoxide as a thermal fog. Pestic. Sci. 1974, 5, 691–701. [Google Scholar] [CrossRef]

- DeVries, Z.C.; Santangelo, R.G.; Crissman, J.; Mick, R.; Schal, C. Exposure risks and ineffectiveness of total release foggers (TRFs) used for cockroach control in residential settings. BMC Public Health 2019, 19, 96. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kaakeh, W.; Bennett, G.W. Evaluation of trapping and vacuuming compared with low-impact insecticide tactics for managing German cockroaches in residences. J. Econ. Entomol. 1997, 90, 976–982. [Google Scholar] [CrossRef]

- Wang, C.; Bennett, G.W. Comparative study of integrated pest management and baiting for German cockroach management in public housing. J. Econ. Entomol. 2006, 99, 879–885. [Google Scholar] [CrossRef]