Novel α + β Type Ti-Fe-Cu Alloys Containing Sn with Pertinent Mechanical Properties

Abstract

:1. Introduction

2. Materials and Methods

2.1. Alloy Preparation

2.2. Analysis of the Crystalline Structure

2.3. Dual-Axial Forging Procedure and Mechanical Testing

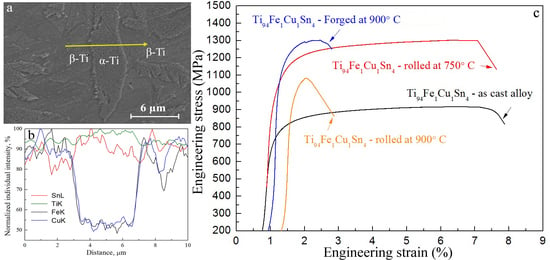

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Ilyin, A.A.; Kolachev, B.A.; Polkin, I.S. Titanium Alloys. In Composition, Structure, Properties, Reference Book; VILS-MATI Publishing: Moscow, Russia, 2009. [Google Scholar]

- Donachie, M.J., Jr. Titanium: A Technical Guide, 2nd ed.; ASM International: Materials Park, OH, USA, 2000. [Google Scholar]

- Helth, A.; Siegel, U.; Kühn, U.; Gemming, T.; Gruner, W.; Oswald, S.; Marr, T.; Freudenberger, J.; Scharnweber, J.; Oertel, C.-G.; et al. Influence of boron and oxygen on the microstructure and mechanical properties of high-strength Ti66Nb13Cu8Ni6.8Al6.2 alloys. Acta Mater. 2013, 61, 3324–3334. [Google Scholar] [CrossRef]

- Niinomi, M.; Nakai, M.; Hieda, J. Development of new metallic alloys for biomedical applications. Acta Biomater. 2012, 8, 3888–3903. [Google Scholar] [CrossRef] [PubMed]

- Niinomi, M. Recent research and development in titanium alloys for biomedical applications and healthcare goods. Sci. Technol. Adv. Mater. 2003, 4, 445–454. [Google Scholar] [CrossRef] [Green Version]

- Long, M.; Rack, H.J. Titanium alloys in total joint replacement-a materials science perspective. Biomaterials 1998, 19, 1621–1639. [Google Scholar] [CrossRef]

- Atapour, M.; Pilchak, A.L.; Frankel, G.S.; Williams, J.C. Corrosion behavior of β titanium alloys for biomedical applications. Mater. Sci. Eng. C 2011, 31, 885–891. [Google Scholar] [CrossRef]

- Rack, H.J.; Qazi, J.I. Titanium alloys for biomedical applications. Mater. Sci. Eng. C 2006, 26, 1269–1277. [Google Scholar] [CrossRef]

- Wang, K. The use of titanium for medical applications in the USA. Mater. Sci. Eng. A 1996, 213, 134–137. [Google Scholar] [CrossRef]

- Miura, K.; Yamada, N.; Hanada, S.; Jung, T.K.; Itoi, E. The bone tissue compatibility of a new Ti-Nb-Sn alloy with a low Young’s modulus. Acta Biomater. 2011, 7, 2320–2326. [Google Scholar] [CrossRef]

- Liua, H.; Niinomi, M.; Nakai, M.; Obara, S.; Fuji, H. Improved fatigue properties with maintaining low Young’s modulus achieved in biomedical beta-type titanium alloy by oxygen addition. Mater. Sci. Eng. A 2017, 704, 10–17. [Google Scholar] [CrossRef]

- Liu, H.H.; Niinomi, M.; Nakai, M.; Cho, K.; Narita, K.; Sen, M.; Shiku, H.; Matsue, T. Mechanical properties and cytocompatibility of oxygen-modified β-type Ti-Cr alloys for spinal fixation devices. Acta Biomater. 2015, 12, 352–361. [Google Scholar] [CrossRef]

- Liu, H.H.; Niinomi, M.; Nakai, M.; Hieda, J.; Cho, K. Changeable Young’s modulus with large elongation-to-failure in β-type titanium alloys for spinal fixation applications. Scr. Mater. 2014, 82, 29–32. [Google Scholar] [CrossRef]

- Niinomi, M. Design and development of metallic biomaterials with biological and mechanical biocompatibility. J. Biomed. Mater. Res. A 2019, 107, 944–954. [Google Scholar] [CrossRef] [PubMed]

- Pilliar, R.M. Modern metal processing for improved load-bearing surgical implants. Biomaterials 1991, 12, 95–100. [Google Scholar] [CrossRef]

- Rho, J.Y.; Tsui, T.Y.; Pharr, G.M. Elastic properties of human cortical and trabecular lamellar bone measured by nanoindentation. Biomaterials 1997, 18, 1325–1330. [Google Scholar] [CrossRef]

- Li, Q.; Ma, G.; Li, J.; Niinomi, M.; Nakai, M.; Koizumi, Y.; Wei, D.-X.; Kakeshita, T.; Nakano, T.; Chiba, A.; et al. Development of low-Young’s modulus Ti–Nb-based alloys with Cr addition. J. Mater. Sci. 2019, 54, 8675–8683. [Google Scholar] [CrossRef]

- Homma, T.; Arafah, A.; Haley, D.; Nakai, M.; Niinomi, M.; Moody, M.P. Effect of alloying elements on microstructural evolution in oxygen content controlled Ti-29Nb-13Ta-4.6Zr (wt%) alloys for biomedical applications during aging. Mater. Sci. Eng. A 2018, 709, 312–321. [Google Scholar] [CrossRef]

- Tahara, M.; Kim, H.Y.; Hosoda, H.; Miyazaki, S. Shape memory effect and cyclic deformation behavior of Ti-Nb-N alloys. Funct. Mater. Lett. 2009, 2, 79–82. [Google Scholar] [CrossRef]

- Ramarolahy, A.; Castany, P.; Prima, F.; Laheurte, P.; Peron, I.; Gloriant, T. Microstructure and mechanical behavior of superelastic Ti-24Nb-0.5O and Ti-24Nb-0.5N biomedical alloys. J. Mech. Behav. Biomed. Mater. 2012, 9, 83–90. [Google Scholar] [CrossRef] [Green Version]

- Bars, J.-P.; David, D.; Etchessahar, E.; Debuigne, J. Titanium α- nitrogen solid solution formed by high temperature nitriding: Diffusion of nitrogen, hardness, and crystallographic parameters. Metall. Trans. A 1983, 14, 1537–1543. [Google Scholar] [CrossRef]

- Tahara, M.; Kim, H.Y.; Inamura, T.; Hosoda, H.; Miyazaki, S. Role of interstitial atoms in the microstructure and non-linear elastic deformation behavior of Ti–Nb alloy. J. Alloys Compd. 2013, 577, S404–S407. [Google Scholar] [CrossRef]

- Tahara, M.; Kim, H.Y.; Inamura, T.; Hosoda, H.; Miyazaki, S. Lattice modulation and superelasticity in oxygen-added β-Ti alloys. Acta Mater. 2001, 59, 6208–6218. [Google Scholar] [CrossRef]

- Zadorozhnyy, V.; Kopylov, A.; Gorshenkov, M.; Shabanova, E.; Zadorozhnyy, M.; Novikov, A.; Maksimkin, A.; Wada, T.; Louzguine-Luzgin, D.; Kato, H. Structure and mechanical properties of Ti-Based alloys containing Ag subjected to a thermomechanical treatment. J. Alloys Compd. 2019, 781, 1182–1188. [Google Scholar] [CrossRef]

- Ozaki, T.; Matsumoto, H.; Watanabe, S.; Hanada, S. Beta Ti Alloys with Low Young’s Modulus. Mater. Trans. 2004, 45, 2776–2779. [Google Scholar] [CrossRef] [Green Version]

- Zheng, H.C.Y.; Xu, X.; Xu, Z.; Wang, J. Metallic Biomaterials; Wiley-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2017. [Google Scholar]

- Kuroda, D.; Niinomi, M.; Morinaga, M.; Kato, Y.; Yashiro, T. Design and mechanical properties of new β type titanium alloys for implant materials. Mater. Sci. Eng. A 1998, 243, 244–249. [Google Scholar] [CrossRef]

- Tane, M.; Akita, S.; Nakano, T.; Hagihara, K.; Umakoshi, Y.; Niinomi, M.; Nakajima, H. Peculiar elastic behavior of Ti–Nb–Ta–Zr single crystals. Acta Mater. 2008, 56, 2856–2863. [Google Scholar] [CrossRef]

- Zhao, G.-H.; Ketov, S.V.; Mao, H.; Borgenstam, A.; Louzguine-Luzgin, D.V. Ti-Fe-Sn-Nb hypoeutectic alloys with superb yield strength and significant strain-hardening. Scr. Mater. 2017, 135, 59–62. [Google Scholar] [CrossRef]

- Zhao, G.-H.; Ketov, S.V.; Jiang, J.; Mao, H.; Borgenstam, A.; Louzguine-Luzgin, D.V. New beta-type Ti-Fe-Sn-Nb alloys with superior mechanical strength. Mater. Sci. Eng. A 2017, 705, 348–351. [Google Scholar] [CrossRef]

- Zadorozhnyy, V.Y.; Inoue, A.; Louzguine-Luzgin, D.V. Ti-based nanostructured low-alloy with high strength and ductility. Mater. Sci. Eng. A 2012, 551, 82–86. [Google Scholar] [CrossRef]

- Zadorozhnyy, V.Y.; Shchetinin, I.V.; Chirikov, N.V.; Louzguine-Luzgin, D.V. Tensile properties of a dual-axial forged Ti-Fe-Cu alloy containing Boron. Mater. Sci. Eng. A 2014, 614, 238–242. [Google Scholar] [CrossRef]

- Zadorozhnyy, V.Y.; Shchetinin, I.V.; Zheleznyi, M.V.; Chirikov, N.V.; Wada, T.; Kato, H.; Louzguine-Luzgin, D.V. Investigation of structure—Mechanical properties relations of dual-axial forged Ti-based low-alloys. Mater. Sci. Eng. A 2015, 632, 88–95. [Google Scholar] [CrossRef]

- Zadorozhnyy, V.Y.; Shi, X.; Kozak, D.S.; Wada, T.; Wang, J.Q.; Kato, H.; Louzguine-Luzgin, D.V. Electrochemical behavior and biocompatibility of Ti-Fe-Cu alloy with high strength and ductility. J. Alloys Compd. 2017, 707, 291–297. [Google Scholar] [CrossRef]

- Zadorozhnyy, V.Y.; Kozak, D.S.; Shi, X.; Wada, T.; Louzguine-Luzgin, D.V.; Kato, H. Mechanical properties, electrochemical behavior and biocompatibility of the Ti-based low-alloys containing a minor fraction of noble metals. J. Alloys Compd. 2018, 732, 915–921. [Google Scholar] [CrossRef]

- Zadorozhnyy, V.Y.; Shi, X.; Kopylov, A.N.; Shchetinin, I.V.; Wada, T.; Louzguine-Luzgin, D.V.; Kato, H. Mechanical properties, structure, and biocompatibility of dual-axially forged Ti94Fe3Au3, Ti94Fe3Nb3 and Ti94Au3Nb3 alloys. J. Alloys Compd. 2017, 707, 269–274. [Google Scholar] [CrossRef]

- Zadorozhnyy, V.Y.; Shi, X.; Wada, T.; Kato, H.; Louzguine-Luzgin, D.V. Mechanical properties and biocompatibility of the Ti-based low-alloys minor alloying by the noble metals. Nano Hybrids Compos. 2017, 13, 63–68. [Google Scholar] [CrossRef]

- Zadorozhnyy, V.Y.; Shi, X.; Gorshenkov, M.V.; Kozak, D.S.; Wada, T.; Louzguine, D.V.; Inoue, A.; Kato, H. Ti-Ag-Pd alloy with good mechanical properties and high potential for biological applications. Sci. Rep. 2016, 6, 25142. [Google Scholar] [CrossRef] [Green Version]

- Yang, H.; Su, Y.; Luo, L.; Chen, H.; Guo, J.; Fu, H. Influences of Fe and B on the Columnar Structure of Ti-46Al Alloys. Rare Met. Mater. Eng. 2012, 41, 570–574. [Google Scholar] [CrossRef]

- Louzguine-Luzgin, D.V. High-Strength Ti-Based Alloys Containing Fe as One of the Main Alloying Elements. Mater. Trans. 2018, 59, 1537–1544. [Google Scholar] [CrossRef] [Green Version]

- Nishikiori, S.; Takahash, S.; Satou, S.; Tanaka, T.; Matsuo, T. Microstructure and creep strength of fully-lamellar TiAl alloys containing beta-phase. Mater. Sci. Eng. A 2002, 329–331, 802–809. [Google Scholar] [CrossRef]

- Palm, M.; Lacaze, J. Assessment of the Al–Fe–Ti system. Intermetallics 2016, 14, 1291–1303. [Google Scholar] [CrossRef] [Green Version]

- Mazdiyasni, S.; Miracle, D.B.; Dimiduk, D.M.; Mendiratta, M.G.; Subramanian, P.R. High temperature phase equilibria of the lip composition in the Ai-Ti-Ni, Ai-Ti-Fe and Ai-Ti-Cu systems. Scripta Metall. 1989, 23, 327–331. [Google Scholar] [CrossRef]

- Liu, J.; Li, F.; Liu, C.; Wang, H.; Ren, B.; Yang, K.; Zhang, E. Effect of Cu content on the antibacterial activity of titanium–copper sintered alloys. Mater. Sci. Eng. C 2014, 35, 392–400. [Google Scholar] [CrossRef] [PubMed]

- Kikuchi, M.; Takada, Y.; Kiyosue, S.; Yoda, M.; Woldu, M.; Cai, Z.; Okuno, O.; Okabe, T. Mechanical properties and microstructures of cast Ti–Cu alloys. Dent. Mater. 2003, 19, 174–181. [Google Scholar] [CrossRef]

- Ohkubo, C.; Shimura, I.; Aoki, T.; Hanatani, S.; Hosoi, T.; Hattori, M.; Oda, Y.; Okabe, T. Wear resistance of experimental Ti–Cu alloys. Biomaterials 2003, 24, 3377–3381. [Google Scholar] [CrossRef]

- Takahashi, M.; Kikuchi, M.; Takada, Y. Mechanical properties and microstructure of dental cast Ti–Ag and Ti–Cu alloy. Dent. Mater. J. 2002, 21, 270–280. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhang, E.; Zheng, L.; Liu, J.; Bai, B.; Liu, C. Influence of Cu content on the cell biocompatibility of Ti–Cu sintered alloys. Mater. Sci. Eng. C 2015, 46, 148–157. [Google Scholar] [CrossRef] [PubMed]

- Wan, Y.Z.; Xiong, G.Y.; Liang, H.; Raman, S.; He, F.; Huang, Y. Modification of medical metals by ion implantation of copper. Appl. Surf. Sci. 2007, 253, 9426–9429. [Google Scholar] [CrossRef]

- Tian, X.B.; Wang, Z.M.; Yang, S.Q.; Luo, Z.J.; Fu, R.K.Y.; Chu, P.K. Antibacterial copper containing titanium nitride films produced by dual magnetron sputtering. Surf. Coat. Technol. 2007, 201, 8606–8609. [Google Scholar] [CrossRef]

- Shelekhov, E.V.; Sviridova, T.A. Programs for X-ray analysis of polycrystals. Met. Sci. Heat Treat. 2000, 42, 309–313. [Google Scholar] [CrossRef]

- Brandes, E.A.; Brook, G.B. (Eds.) Equilibrium Diagrams. In Smithells Metals Reference Book, 7th ed.; Reed Educational and Professional Publishing Ltd.: Oxford, UK, 1992. [Google Scholar]

- Bowen, A.W. Omega phase embrittlement in aged Ti-15%Mo. Scr. Met. 1971, 5, 709–716. [Google Scholar] [CrossRef]

- Wang, Y.B.; Zhao, Y.H.; Lian, Q.; Liao, X.Z.; Valiev, R.Z.; Ringer, S.P.; Zhu, Y.T.; Lavernia, E.J. Grain size and reversible beta-to-omega phase transformation in a Ti alloy. Scr. Mater. 2010, 63, 613–616. [Google Scholar] [CrossRef]

- Gonzalez, M.; Pena, J.; Gil, F.J.; Manero, J.M. Low modulus Ti-Nb-Hf alloy for biomedical applications. Mater. Sci. Eng. C 2014, 42, 691–695. [Google Scholar] [CrossRef] [PubMed]

- Mishra, R.; Balasubramaniam, R. Effect of nanocrystalline grain size on the electrochemical and corrosion behavior of nickel. Corr. Sci. 2004, 46, 3019–3029. [Google Scholar] [CrossRef]

- American Society for Testing, Materials. In Annual Book of ASTM Standard; ASTM: Philadelphia, PA, USA, 1978; Volume 817.

- Schiøtz, J.; Di Tolla, F.D.; Jacobsen, K.W. Softening of nanocrystalline metals at very small grain sizes. Nature 1998, 391, 561–563. [Google Scholar] [CrossRef]

- Hao, Y.L.; Li, S.J.; Sun, Y.; Zheng, C.Y.; Hu, Q.M.; Yang, R. Super-elastic titanium alloy with unstable plastic deformation. Appl. Phys. Lett. 2005, 87, 091906. [Google Scholar] [CrossRef]

- Mello, M.G.; Taipina, M.O.; Rabelo, G.; Cremasco, A.; Caram, R. Production and characterization of TiO2 nanotubes on Ti-Nb-Mo-Sn system for biomedical applications. Surf. Coat. Technol. 2017, 326, 126–133. [Google Scholar] [CrossRef]

- De Mello, M.G.; Salvador, C.F.; Cremasco, A.; Caram, R. The effect of Sn addition on phase stability and phase evolution during aging heat treatment in Ti–Mo alloys employed as biomaterials. Mater. Charact. 2015, 110, 5–13. [Google Scholar] [CrossRef]

- Moraes, P.E.L.; Contieri, R.J.; Lopes, E.S.N.; Robin, A.; Caram, R. Effects of Sn addition on the microstructure, mechanical properties and corrosion behavior of Ti–Nb–Sn alloys. Mater. Charact. 2014, 96, 273–281. [Google Scholar] [CrossRef]

- Tsao, L.C. Effect of Sn addition on the corrosion behavior of Ti–7Cu–Sn cast alloys for biomedical applications. Mater. Sci. Eng. C 2015, 46, 246–252. [Google Scholar] [CrossRef]

- Niinomi, M. Recent metallic materials for biomedical applications. Metall. Mater. Trans. A 2002, 33, 477–486. [Google Scholar] [CrossRef]

- Gosheger, G.; Hardes, J.; Ahrens, H.; Streitburger, A.; Buerger, H.; Erren, M.; Gunsel, A.; Kemperd, F.H.; Winkelmann, W.; Eiff, C. Silver-coated megaendoprostheses in a rabbit model-ananalysis of the infection rate and toxicological side effects. Biomaterials 2004, 25, 5547–5556. [Google Scholar] [CrossRef]

- Hardes, J.; Ahrens, H.; Gebert, C.; Streitbuerger, A.; Buerger, H.; Erren, M.; Gunsel, A.; Wedemeyer, C.; Saxler, G.; Winkelmann, W.; et al. Lack of toxicological side-effects in silver-coated megaprostheses in humans. Biomaterials 2007, 28, 2869–2875. [Google Scholar] [CrossRef] [PubMed]

| Alloy Composition | Treatment | σuts, MPa | σ0.2, MPa | δ,% | E, GPa | HV |

|---|---|---|---|---|---|---|

| Ti90Fe3Cu3Sn4 | As cast | 520 ± 20 | - | 0 | 98 ± 10 | 492 ± 30 |

| Rolled at 900 °C | 750 ± 20 | - | 0 | 501 ± 30 | ||

| Forged at 900 °C for 15 times | 460 ± 20 | - | 0 | 513 ± 20 | ||

| Ti92Fe2Cu2Sn4 | As-cast | 1000 ± 30 | 950 ± 20 | 0.3 ± 0.2 | 93 ± 10 | 440 ± 20 |

| Forged at 900 °C for 15 times | 880 ± 20 | - | 0 | 562 ± 30 | ||

| Rolled at 900 °C | 720 ± 20 | - | 0 | 558 ± 20 | ||

| Ti94Fe1Cu1Sn4 | As-cast | 920 ± 20 | 860 ± 40 | 7 ± 1 | 75 ± 10 | 326 ± 15 |

| Rolled at 750 °C | 1300 ± 30 | 1070 ± 30 | 6 ± 1 | 70 ± 10 | 416 ± 30 | |

| Rolled at 900 °C | 1080 ± 30 | 900 ± 20 | 0.7 ± 0.5 | 95 ± 10 | 440 ± 20 | |

| Forged 900 °C for 15 times | 1300 ± 30 | 1070 ± 30 | 1.5 ± 1 | 513 ± 40 | ||

| Ti94Fe2Cu2Sn2 | As-cast | 800 ± 20 | - | 0 | 100 ± 10 | 437 ± 15 |

| Forged at 900 °C for 15 times | 740 ± 20 | - | 0 | 587 ± 30 | ||

| Rolled at 900 °C | 1000 ± 30 | - | 0 | 555 ± 40 | ||

| Ti92Fe3Cu3Sn2 | As-cast | 290 ± 50 | 280 ± 40 | 0.5 ± 0.5 | 90 ± 10 | 323 ± 20 |

| Forged at 900 °C for 15 times | 400 ± 20 | - | 0 | 523 ± 30 | ||

| Rolled at 900 °C | 540 ± 20 | - | 0 | 446 ± 30 | ||

| Ti94Fe3Cu3 (large amount of β-Ti phase) [31] | 1200 ± 30 | 1050 ± 20 | 8 ± 2 | 70 ± 10 | 430 ± 20 | |

| Pure Ti (for comparison, as-cast state [38]) | 400 ± 50 | 320 ± 40 | 50 ± 5 | 110 ± 10 | 145 ± 15 | |

| Alloys Composition | Phase Composition, vol. % | Lattice Parameter, nm | Coherent-Scattering Region Size, nm | Root-Mean Square Microstrain, % |

|---|---|---|---|---|

| As cast | α-Ti, 80 | a: 0.2899 | ˃500 | 0.218 |

| (type A3) | c: 0.4615 | - | - | |

| β-Ti, 20 | - | - | - | |

| (type A2) | a: 0.3195 | ˃500 | 0.042 | |

| Rolled at 900 °C | α-Ti, 98 | a: 0.2905 | 20 | 0.292 |

| (type A3) | c: 0.4618 | - | - | |

| β-Ti, 2 | - | - | - | |

| (type A2) | a: 0.3260 | 15 | 0.013 | |

| Rolled at 750 °C | α-Ti, 70 | a: 0.2916 | 35 | 0.381 |

| (type A3) | c: 0.4667 | - | - | |

| β-Ti, 30 | - | - | - | |

| (type A2) | a: 0.3204 | 10 | 0.248 | |

| Forged at 900 °C | α-Ti, 98 | a: 0.2986 | 15 | 0.31 |

| (type A3) | c: 0.4651 | - | - | |

| β-Ti, 2 | - | - | - | |

| (type A2) | a: 0.3304 | 10 | 0.331 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zadorozhnyy, V.; Ketov, S.V.; Wada, T.; Wurster, S.; Nayak, V.; Louzguine-Luzgin, D.V.; Eckert, J.; Kato, H. Novel α + β Type Ti-Fe-Cu Alloys Containing Sn with Pertinent Mechanical Properties. Metals 2020, 10, 34. https://doi.org/10.3390/met10010034

Zadorozhnyy V, Ketov SV, Wada T, Wurster S, Nayak V, Louzguine-Luzgin DV, Eckert J, Kato H. Novel α + β Type Ti-Fe-Cu Alloys Containing Sn with Pertinent Mechanical Properties. Metals. 2020; 10(1):34. https://doi.org/10.3390/met10010034

Chicago/Turabian StyleZadorozhnyy, Vladislav, Sergey V. Ketov, Takeshi Wada, Stefan Wurster, Vignesh Nayak, Dmitri V. Louzguine-Luzgin, Jürgen Eckert, and Hidemi Kato. 2020. "Novel α + β Type Ti-Fe-Cu Alloys Containing Sn with Pertinent Mechanical Properties" Metals 10, no. 1: 34. https://doi.org/10.3390/met10010034

APA StyleZadorozhnyy, V., Ketov, S. V., Wada, T., Wurster, S., Nayak, V., Louzguine-Luzgin, D. V., Eckert, J., & Kato, H. (2020). Novel α + β Type Ti-Fe-Cu Alloys Containing Sn with Pertinent Mechanical Properties. Metals, 10(1), 34. https://doi.org/10.3390/met10010034