Temperature Dependent Solid Solution Strengthening in the High Entropy Alloy CrMnFeCoNi in Single Crystalline State

Abstract

:1. Introduction

2. Materials and Methods

2.1. Alloy Fabrication

2.2. Sample Preparation

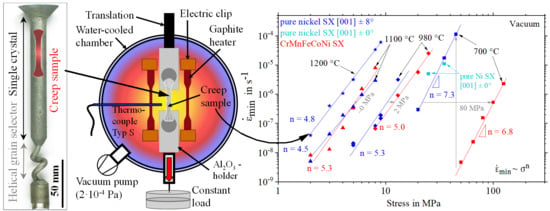

2.3. Mechanical Testing

3. Results and Discussion

4. Conclusions

- Creep testing of single crystals under vacuum allows a comparison of pure solid solution strengthening, excluding oxidation effects, grain size effects, grain boundary sliding, diffusion, and no precipitate effects.

- The 8° deviation from the [001] orientation for SX-Ni leads to an orientation sensitive primary creep behavior compared to [001] ± 0°, but there is no detected effect on the minimum creep rate.

- The SX CrMnFeCoNi alloy has a strong solid solution strengthening effect at 700 °C compared to SX pure nickel. The stress necessary to reach the same creep rate is 80 MPa higher in CrMnFeCoNi than in Ni.

- The solid solution strengthening effect due to high configurational entropy depends on the temperature and is strongly reduced at 980 °C and no longer present at 1100 °C.

Author Contributions

Funding

Conflicts of Interest

References

- Murty, B.C.; Yeh, J.W.; Ranganathan, S. High-Entropy Alloys; Elsevier: London, UK, 2014; ISBN 9780128002513. [Google Scholar]

- Zhang, W.; Liaw, P.K.; Zhang, Y. Science and technology in high-entropy alloys. Sci. China Mater. 2018, 61, 2–22. [Google Scholar] [CrossRef] [Green Version]

- George, E.P.; Raabe, D.; Ritchie, R.O. High-entropy alloys. Nat. Rev. Mater. 2019, 4, 515–534. [Google Scholar] [CrossRef]

- Miracle, D.B.; Senkov, O.N. A critical review of high entropy alloys and related concepts. Acta Mater. 2017, 122, 448–511. [Google Scholar] [CrossRef] [Green Version]

- Yeh, J.-W.; Chen, S.-K.; Lin, S.-J.; Gan, J.-Y.; Chin, T.-S.; Shun, T.-T.; Tsau, C.-H.; Chang, S.-Y. Nanostructured High-Entropy Alloys with Multiple Principal Elements: Novel Alloy Design Concepts and Outcomes. Adv. Eng. Mater. 2004, 6, 299–303. [Google Scholar] [CrossRef]

- Ye, Y.F.; Wang, Q.; Lu, J.; Liu, C.T.; Yang, Y. High-entropy alloy: Challenges and prospects. Mater. Today 2016, 19, 349–362. [Google Scholar] [CrossRef]

- Yeh, J.-W. Recent progress in high-entropy alloys. Ann. Chim. Sci. Mater. 2006, 31, 633–648. [Google Scholar] [CrossRef]

- Fantin, A.; Lepore, G.O.; Manzoni, A.M.; Kasatikov, S.; Scherb, T.; Huthwelker, T.; d’Acapito, F.; Schumacher, G. Short-range chemical order and local lattice distortion in a compositionally complex alloy. Acta Mater. 2020. [Google Scholar] [CrossRef]

- Okamoto, N.L.; Yuge, K.; Tanaka, K.; Inui, H.; George, E.P. Atomic displacement in the CrMnFeCoNi high-entropy alloy—A scaling factor to predict solid solution strengthening. AIP Adv. 2016. [Google Scholar] [CrossRef]

- Ma, D.; Friák, M.; Von Pezold, J.; Neugebauer, J.; Raabe, D. Ab initio study of compositional trends in solid solution strengthening in metals with low Peierls stresses. Acta Mater. 2015. [Google Scholar] [CrossRef]

- Ma, D.; Friák, M.; Von Pezold, J.; Raabe, D.; Neugebauer, J. Computationally efficient and quantitatively accurate multiscale simulation of solid-solution strengthening by ab initio calculation. Acta Mater. 2015. [Google Scholar] [CrossRef]

- Leyson, G.P.M.; Curtin, W.A.; Hector, L.G.; Woodward, C.F. Quantitative prediction of solute strengthening in aluminium alloys. Nat. Mater. 2010. [Google Scholar] [CrossRef]

- Nabarro, F.R.N. The mechanical properties of metallic solid solutions. Proc. Phys. Soc. 1946. [Google Scholar] [CrossRef]

- Otto, F.; Dlouhý, A.; Somsen, C.; Bei, H.; Eggeler, G.; George, E.P. The influences of temperature and microstructure on the tensile properties of a CoCrFeMnNi high-entropy alloy. Acta Mater. 2013, 61, 5743–5755. [Google Scholar] [CrossRef] [Green Version]

- Gali, A.; George, E.P. Tensile properties of high- and medium-entropy alloys. Intermetallics 2013, 39, 74–78. [Google Scholar] [CrossRef] [Green Version]

- Wu, Z.; Bei, H.; Otto, F.; Pharr, G.M.; George, E.P. Recovery, recrystallization, grain growth and phase stability of a family of FCC-structured multi-component equiatomic solid solution alloys. Intermetallics 2014, 46, 131–140. [Google Scholar] [CrossRef]

- Otto, F.; Hanold, N.L.; George, E.P. Microstructural evolution after thermomechanical processing in an equiatomic, single-phase CoCrFeMnNi high-entropy alloy with special focus on twin boundaries. Intermetallics 2014, 54, 39–48. [Google Scholar] [CrossRef]

- Bin Kang, Y.; Shim, S.H.; Lee, K.H.; Hong, S.I. Dislocation creep behavior of CoCrFeMnNi high entropy alloy at intermediate temperatures. Mater. Res. Lett. 2018, 6, 689–695. [Google Scholar] [CrossRef]

- Tirunilai, A.S.; Sas, J.; Weiss, K.-P.; Chen, H.; Szabó, D.V.; Schlabach, S.; Haas, S.; Geissler, D.; Freudenberger, J.; Heilmaier, M.; et al. Peculiarities of deformation of CoCrFeMnNi at cryogenic temperatures. J. Mater. Res. 2018, 33, 3287–3300. [Google Scholar] [CrossRef] [Green Version]

- Sun, S.J.; Tian, Y.Z.; Lin, H.R.; Dong, X.G.; Wang, Y.H.; Zhang, Z.J.; Zhang, Z.F. Enhanced strength and ductility of bulk CoCrFeMnNi high entropy alloy having fully recrystallized ultrafine-grained structure. Mater. Des. 2017. [Google Scholar] [CrossRef]

- Joseph, J.; Haghdadi, N.; Annasamy, M.; Kada, S.; Hodgson, P.D.; Barnett, M.R.; Fabijanic, D.M. On the enhanced wear resistance of CoCrFeMnNi high entropy alloy at intermediate temperature. Scr. Mater. 2020. [Google Scholar] [CrossRef]

- Otto, F.; Dlouhý, A.; Pradeep, K.G.; Kuběnová, M.; Raabe, D.; Eggeler, G.; George, E.P. Decomposition of the single-phase high-entropy alloy CrMnFeCoNi after prolonged anneals at intermediate temperatures. Acta Mater. 2016, 112, 40–52. [Google Scholar] [CrossRef] [Green Version]

- Vaidya, M.; Pradeep, K.G.; Murty, B.S.; Wilde, G.; Divinski, S.V. Bulk tracer diffusion in CoCrFeNi and CoCrFeMnNi high entropy alloys. Acta Mater. 2018. [Google Scholar] [CrossRef]

- Tsai, K.Y.; Tsai, M.H.; Yeh, J.W. Sluggish diffusion in Co-Cr-Fe-Mn-Ni high-entropy alloys. Acta Mater. 2013. [Google Scholar] [CrossRef]

- Kireeva, I.V.; Chumlyakov, Y.I.; Pobedennaya, Z.V.; Vyrodova, A.V.; Karaman, I. Twinning in [001]-oriented single crystals of CoCrFeMnNi high-entropy alloy at tensile deformation. Mater. Sci. Eng. A 2018, 713, 253–259. [Google Scholar] [CrossRef]

- Abuzaid, W.; Sehitoglu, H. Critical resolved shear stress for slip and twin nucleation in single crystalline FeNiCoCrMn high entropy alloy. Mater. Charact. 2017, 129, 288–299. [Google Scholar] [CrossRef]

- Patriarca, L.; Ojha, A.; Sehitoglu, H.; Chumlyakov, Y.I. Slip nucleation in single crystal FeNiCoCrMn high entropy alloy. Scr. Mater. 2016, 112, 54–57. [Google Scholar] [CrossRef]

- Fleischmann, E.; Konrad, C.; Preußner, J.; Völkl, R.; Affeldt, E.; Glatzel, U. Influence of Solid Solution Hardening on Creep Properties of Single-Crystal Nickel-Based Superalloys. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2015, 46, 1125–1130. [Google Scholar] [CrossRef]

- Haas, S.; Mosbacher, M.; Senkov, O.; Feuerbacher, M.; Freudenberger, J.; Gezgin, S.; Völkl, R.; Glatzel, U. Entropy Determination of Single-Phase High Entropy Alloys with Different Crystal Structures over a Wide Temperature Range. Entropy 2018, 20, 654. [Google Scholar] [CrossRef] [Green Version]

- Konrad, C.H.; Brunner, M.; Kyrgyzbaev, K.; Völkl, R.; Glatzel, U. Determination of heat transfer coefficient and ceramic mold material parameters for alloy IN738LC investment castings. J. Mater. Process. Technol. 2011, 211, 181–186. [Google Scholar] [CrossRef]

- Fleischmann, E.; Miller, M.K.; Affeldt, E.; Glatzel, U. Quantitative experimental determination of the solid solution hardening potential of rhenium, tungsten and molybdenum in single-crystal nickel-based superalloys. Acta Mater. 2015, 87, 350–356. [Google Scholar] [CrossRef] [Green Version]

- Mora-García, A.G.; Mosbacher, M.; Hastreiter, J.; Völkl, R.; Glatzel, U.; Muñoz-Saldaña, J. Creep behavior of polycrystalline and single crystal Ni-based superalloys coated with Ta-containing NiCoCrAlY by high-velocity oxy-fuel spraying. Scr. Mater. 2020, 178, 522–526. [Google Scholar] [CrossRef]

- Kellner, P.M.; Völkl, R.; Glatzel, U. Influence of Ingot and Powder Metallurgy Production Route on the Tensile Creep Behavior of Mo–9Si–8B Alloys with Additions of Al and Ge. Adv. Eng. Mater. 2018, 20. [Google Scholar] [CrossRef]

- Völkl, R.; Fischer, B.; Beschliesser, M.; Glatzel, U. Evaluating strength at ultra-high temperatures—Methods and results. Mater. Sci. Eng. A 2008, 483–484, 587–589. [Google Scholar] [CrossRef]

- Haas, S.; Manzoni, A.M.; Krieg, F.; Glatzel, U. Microstructure and mechanical properties of precipitate strengthened high entropy alloy Al10Co25Cr8Fe15Ni36Ti6 with additions of Hafnium and molybdenum. Entropy 2019, 169. [Google Scholar] [CrossRef] [Green Version]

- Rae, C.M.F.; Zhang, L. Primary creep in single crystal superalloys: Some comments on effects of composition and microstructure. Mater. Sci. Technol. 2009, 25, 228–235. [Google Scholar] [CrossRef]

- Tsuno, N.; Shimabayashi, S.; Kakehi, K.; Rae, C.M.F.; Reed, R.C. Tension/compression asymmetry in yield and creep strengths of ni-based superalloys. In Proceedings of the International Symposium on Superalloys, Champion, PA, USA, 14–18 September 2008; pp. 433–442. [Google Scholar]

- Mackay, R.A.; Maier, R.D. The influence of orientation on the stress rupture properties of nickel-base superalloy single crystals. Metall. Mater. Trans. A 1982, 13, 1747–1754. [Google Scholar] [CrossRef]

- Leverant, G.R.; Kear, B.H. The mechanism of creep in gamma prime precipitation-hardened nickel-base alloys at intermediate temperatures. Metall. Mater. Trans. B 1970, 1, 491–498. [Google Scholar] [CrossRef]

- Caillard, D.; Martin, J.L. New trends in creep microstructural models for pure metals. Rev. Phys. Appliquée 1987, 22, 169–183. [Google Scholar] [CrossRef]

- Ashby, M.F.; Frost, H.J. Deformation-Mechanism Maps; Pergamon Press: Oxford, UK, 1982. [Google Scholar]

- Cao, C.; Fu, J.; Tong, T.; Hao, Y.; Gu, P.; Hao, H.; Peng, L. Intermediate-temperature creep deformation and microstructural evolution of an equiatomic FCC-structured CoCrFeNiMn high-entropy alloy. Entropy 2018, 960. [Google Scholar] [CrossRef] [Green Version]

| Material | SX-Ni | SX-CrMnFeCoNi | |||||

|---|---|---|---|---|---|---|---|

| Temperature in °C | 700 | 980 | 1100 | 1200 | 700 | 980 | 1100 |

| Load in MPa | |||||||

| 2 | −8.2 | −7.4 | −8.1 | ||||

| 3 | −7.5 | −6.4 | −7.9 | ||||

| 4 | −6.7 | −6.0 | −7.1 | ||||

| 5 | −7.7 | −6.4 | −5.5 | −6.5 | |||

| 6 | −6.0 | −5.8 | |||||

| 8 | −7.1 | −5.5 | −4.5 | −7.2 | −5.1 | ||

| 9 | −6.8 | −4.2 | |||||

| 13 | −5.5 | −6.0 | |||||

| 20 | −6.5 | −5.2 | |||||

| 25 | −5.3 1 | −4.6 | |||||

| 35 | −4.8/–5.0 1 | ||||||

| 45 | −4.0 | ||||||

| 50 | −8.3 | ||||||

| 65 | −7.6 | ||||||

| 80 | −6.8 | ||||||

| 100 | −6.3 | ||||||

| 125 | −5.6 | ||||||

| Norton exp. n | 7.3 | 5.3 | 4.5 | 4.8 | 6.8 | 5.0 | 5.3 |

| t2% in h | |||||||

|---|---|---|---|---|---|---|---|

| Material | SX-Ni | SX-CrMnFeCoNi | |||||

| Temperature in °C | 700 | 980 | 1100 | 1200 | 700 | 980 | 1100 |

| Load in MPa | |||||||

| 2 | 740.7 | 28.4 2 | 564.4 2 | ||||

| 3 | 70.8 | 6.7 | 289.5 2 | ||||

| 4 | 9.5 | 1.5 | 72.0 2 | ||||

| 5 | 32.0 | 15.2 | |||||

| 8 | 1.5 | 72.0 | |||||

| 9 | 0.7 | ||||||

| 13 | 0.1 | 5.0 | |||||

| 20 | 3.1 | 1.0 | |||||

| 25 | 0.8 1 | 0.2 | |||||

| 35 | 0.1/0.2 1 | ||||||

| 45 | <0.1 | ||||||

| 50 | 830.0 2 | ||||||

| 65 | 130.0 | ||||||

| 80 | 35.0 | ||||||

| 100 | 3.5 | ||||||

| 125 | 0.3 | ||||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gadelmeier, C.; Haas, S.; Lienig, T.; Manzoni, A.; Feuerbacher, M.; Glatzel, U. Temperature Dependent Solid Solution Strengthening in the High Entropy Alloy CrMnFeCoNi in Single Crystalline State. Metals 2020, 10, 1412. https://doi.org/10.3390/met10111412

Gadelmeier C, Haas S, Lienig T, Manzoni A, Feuerbacher M, Glatzel U. Temperature Dependent Solid Solution Strengthening in the High Entropy Alloy CrMnFeCoNi in Single Crystalline State. Metals. 2020; 10(11):1412. https://doi.org/10.3390/met10111412

Chicago/Turabian StyleGadelmeier, Christian, Sebastian Haas, Tim Lienig, Anna Manzoni, Michael Feuerbacher, and Uwe Glatzel. 2020. "Temperature Dependent Solid Solution Strengthening in the High Entropy Alloy CrMnFeCoNi in Single Crystalline State" Metals 10, no. 11: 1412. https://doi.org/10.3390/met10111412

APA StyleGadelmeier, C., Haas, S., Lienig, T., Manzoni, A., Feuerbacher, M., & Glatzel, U. (2020). Temperature Dependent Solid Solution Strengthening in the High Entropy Alloy CrMnFeCoNi in Single Crystalline State. Metals, 10(11), 1412. https://doi.org/10.3390/met10111412