Investigation on the Case-Hardening Behavior of Additively Manufactured 16MnCr5

Abstract

:1. Introduction

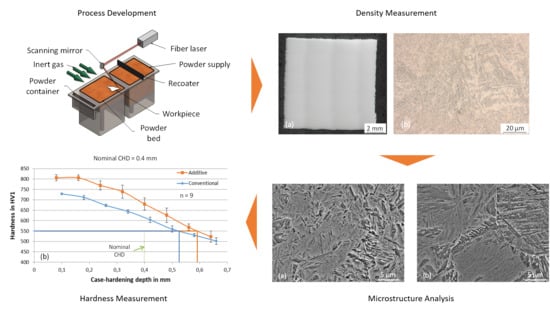

1.1. PBF-LB/M

1.2. Case-Hardening Steel 16MnCr5-1.7131

1.3. Additive Manufacturing of 16MnCr5

2. Materials and Methods

3. Results and Discussion

3.1. Identification of Suitable Parameter Range

3.2. Determination of Mechanical Hardness and Case-Hardening Depth

3.3. Evaluation of the Influence of Different Heat Treatment Strategies

4. Conclusions and Outlook

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Riecke, M.; Teipel, F. Econsense Resource Efficiency Challenge; Econsense–Forum for Sustainable Development of German Business: Berlin, Germany, 2012. [Google Scholar]

- Gibson, I.; Rosen, D.W.; Stucker, B. Additive Manufacturing Technologies; Springer: Boston, MA, USA, 2010; ISBN 978-1-4419-1119-3. [Google Scholar]

- Emmelmann, C.; Sander, P.; Kranz, J.; Wycisk, E. Laser additive manufacturing and bionics: Redefining lightweight design. Phys. Procedia 2011, 12, 364–368. [Google Scholar] [CrossRef] [Green Version]

- Hooper, P.A. Melt pool temperature and cooling rates in laser powder bed fusion. Addit. Manuf. 2018, 22, 548–559. [Google Scholar] [CrossRef]

- Tian, L.; Guo, Y.; Li, J.; Xia, F.; Liang, M.; Bai, Y. Effects of solidification cooling rate on the microstructure and mechanical properties of a cast Al-Si-Cu-Mg-Ni piston alloy. Materials 2018, 11, 1230. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Gorsse, S.; Hutchinson, C.; Gouné, M.; Banerjee, R. Additive manufacturing of metals: A brief review of the characteristic microstructures and properties of steels, Ti-6Al-4V and high-entropy alloys. Sci. Technol. Adv. Mater. 2017, 18, 584–610. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Morris, J.W. The Influence of Grain Size on the Mechanical Properties of Steel; Lawrence Berkeley National Laboratory: Berkeley, CA, USA, 2001. [Google Scholar]

- Qiao, Z.X.; Liu, Y.C.; Yu, L.M.; Gao, Z.M. Effect of cooling rate on microstructural formation and hardness of 30CrNi3Mo steel. Appl. Phys. A Mater. Sci. Process. 2009, 95, 917–922. [Google Scholar] [CrossRef]

- Van Bohemen, S.M.C.; Sietsma, J. The kinetics of bainite and martensite formation in steels during cooling. Mater. Sci. Eng. A 2010, 527, 6672–6676. [Google Scholar] [CrossRef]

- Liedtke, D. Merkblatt 452“Einsatzhärten”; Wirtschaftsvereinigung Stahl: Düsseldorf, Germany, 2008. [Google Scholar]

- Deutsches Institut für Normung. Einsatzstähle—Technische Lieferbedingungen; Deutsches Institut für Normung : Berlin, Germany, 2008; DIN EN 10084:2008-06. [Google Scholar]

- Sobottka, G. Case-Hardening Steels; Edelstahl Witten-Krefeld GmbH: Krefeld, Germany, 1999. [Google Scholar]

- International Organization for Standardization. Steel—Determination of the Thickness of Surface-Hardened Layers; ISO 18203:2016(en); International Organization for Standardization: Geneva, Switzerland, 2016. [Google Scholar]

- Song, B.; Zhao, X.; Li, S.; Han, C.; Wei, Q.; Wen, S.; Liu, J.; Shi, Y. Differences in microstructure and properties between selective laser melting and traditional manufacturing for fabrication of metal parts: A review. Front. Mech. Eng. 2015, 10, 111–125. [Google Scholar] [CrossRef]

- Deutsche Edelstahlwerke GmbH. Lieferzustand, Technische Bezeichnungen, Normen-1.7131 Datasheet; Deutsche Edelstahlwerke GmbH: Krefeld, Germany, 2016. [Google Scholar]

- Schmitt, M.; Schlick, G.; Seidel, C.; Reinhart, G. Examination of the processability of 16MnCr5 by means of laser powder bed fusion. Procedia CIRP 2018, 74, 76–81. [Google Scholar] [CrossRef]

- Kamps, T. Leichtbau von Stirnzahnrädern aus Edelstahl Mittels Laserstrahlschmelzen. Ph.D. Thesis, Technische Universität München, München, Germay, 2018. [Google Scholar]

- Liverani, E.; Toschi, S.; Ceschini, L.; Fortunato, A. Effect of selective laser melting (SLM) process parameters on microstructure and mechanical properties of 316L austenitic stainless steel. J. Mater. Process. Technol. 2017, 249, 255–263. [Google Scholar] [CrossRef]

- Koutiri, I.; Pessard, E.; Peyre, P.; Amlou, O.; De Terris, T. Influence of SLM process parameters on the surface finish, porosity rate and fatigue behavior of as-built Inconel 625 parts. J. Mater. Process. Technol. 2018, 255, 536–546. [Google Scholar] [CrossRef]

- Muszka, K.; Majta, J.; Bienias, Ł. Effect of grain refinement on mechanical properties of microalloyed steels. Metall. Foundry Eng. 2006, 32, 87. [Google Scholar] [CrossRef] [Green Version]

| Elemental Range | Elemental Composition | |||||

|---|---|---|---|---|---|---|

| C | Si | Mn | Cr | S | P | |

| Min. | 0.14 | - | 1.0 | 0.8 | - | - |

| Max. | 0.19 | 0.14 | 1.3 | 1.1 | 0.04 | 0.025 |

| EDX | Not detectable | 0.17 ± 0.02 | 1.33 ± 0.03 | 1.03 ± 0.01 | 0 | 0 |

| Parameter | Parameter Range |

|---|---|

| Laser power (PL) [W] | 250–300 |

| Scanning speed (vs) [mm/s] | 600–1000 |

| Hatch distance (h) [µm] | 120–160 |

| Heat Treatment Strategy | Temperature [°C] | Holding Time [h] | Heating Rate [K/min] | Cooling |

|---|---|---|---|---|

| HTS0 | Resembles the as-built state | |||

| HTS1 | 680 | 2 | 5 | Oven cooling |

| HTS2 | 1050 | 6 | 5 | Oven cooling |

| Case-Hardening Strategy | Temperature [°C] | Austenitizing Temperature [°C] | Nominal CHD [mm] | Annealing |

|---|---|---|---|---|

| CHS3 | 900–950 | 820–860 | 0.3 | 180 °C, 2 h |

| CHS4 | 900–950 | 820–860 | 0.4 | 180 °C, 2 h |

| CHS10 | 900–950 | 820–860 | 1.0 | 180 °C, 2 h |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bartels, D.; Klaffki, J.; Pitz, I.; Merklein, C.; Kostrewa, F.; Schmidt, M. Investigation on the Case-Hardening Behavior of Additively Manufactured 16MnCr5. Metals 2020, 10, 536. https://doi.org/10.3390/met10040536

Bartels D, Klaffki J, Pitz I, Merklein C, Kostrewa F, Schmidt M. Investigation on the Case-Hardening Behavior of Additively Manufactured 16MnCr5. Metals. 2020; 10(4):536. https://doi.org/10.3390/met10040536

Chicago/Turabian StyleBartels, Dominic, Julian Klaffki, Indra Pitz, Carsten Merklein, Florian Kostrewa, and Michael Schmidt. 2020. "Investigation on the Case-Hardening Behavior of Additively Manufactured 16MnCr5" Metals 10, no. 4: 536. https://doi.org/10.3390/met10040536

APA StyleBartels, D., Klaffki, J., Pitz, I., Merklein, C., Kostrewa, F., & Schmidt, M. (2020). Investigation on the Case-Hardening Behavior of Additively Manufactured 16MnCr5. Metals, 10(4), 536. https://doi.org/10.3390/met10040536