Effect of Aluminum, Iron and Chromium Alloying on the Structure and Mechanical Properties of (Ti-Ni)-(Cu-Zr) Crystalline/Amorphous Composite Materials

Abstract

:1. Introduction

2. Materials and Methods

3. Results

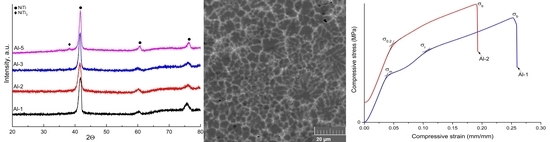

3.1. Structure

3.2. Mechanical Behavior

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Inoue, A. Stabilization of metallic supercooled liquid and bulk amorphous alloys. Acta Mater. 2000, 48, 279–306. [Google Scholar] [CrossRef]

- Inoue, A.; Shen, B.; Takeuchi, A. Fabrication, properties and applications of bulk glassy alloys in late transition metal-based systems. Mater. Sci. Eng. A 2006, 441, 18–25. [Google Scholar] [CrossRef]

- Inaekyan, K.; Brailovski, V.; Prokoshkin, S.; Korotitskiy, A.; Glezer, A. Characterization of amorphous and nanocrystalline Ti–Ni-based shape memory alloys. J. Alloys Compd. 2009, 473, 71–78. [Google Scholar] [CrossRef]

- Louzguine-Luzgin, D.; Vinogradov, A.; Xie, G.; Li, S.; Lazarev, A.; Hashimoto, S.; Inoue, A. High-strength and ductile glassy-crystal Ni–Cu–Zr–Ti composite exhibiting stress-induced martensitic transformation. Philos. Mag. 2009, 89, 2887–2901. [Google Scholar] [CrossRef]

- Surikova, N.S.; Klopotov, A.A.; Korznikova, E. Mechanisms of plastic deformation in microcrystalline and nanocrystalline TiNi-based alloys. Phys. Met. Met. 2010, 110, 269–278. [Google Scholar] [CrossRef]

- Zadorozhnyy, V.Y.; Inoue, A.; Louzguine-Luzgin, D. Formation and investigation of the structure and mechanical properties of bulk metallic glassy composite (Ti–Zr)–(Cu–Ni–Co) alloys with the addition of Boron. Mater. Sci. Eng. A 2012, 558, 472–477. [Google Scholar] [CrossRef]

- Madge, S.; Luzguine-Luzgin, D.V.; Inoue, A.; Greer, A.L. Large compressive plasticity in a la-based glass-crystal composite. Metals 2012, 3, 41–48. [Google Scholar] [CrossRef]

- Louzguine-Luzgin, D.V.; Jiang, J. On long-term stability of metallic glasses. Metals 2019, 9, 1076. [Google Scholar] [CrossRef] [Green Version]

- Golovin, I.; Zadorozhnyy, V.Y.; Churyumov, A.; Louzguine-Luzgin, D.; Louzguine-Luzgin, D. Internal friction in a Ni–Ti-based glassy-crystal alloy. J. Alloys Compd. 2013, 579, 633–637. [Google Scholar] [CrossRef]

- Jiang, J.; Wei, D.; Wada, T.; Louzguine-Luzgin, D.; Kato, H. The mechanical cycling behavior of TiNi based crystal/glassy alloy in the superelastic mode. J. Alloys Compd. 2018, 768, 176–180. [Google Scholar] [CrossRef]

- Hong, S.H.; Kim, J.; Park, J.; Song, G.; Wang, W.; Kim, K.B. Mechanical, deformation and fracture behaviors of bulk metallic glass composites reinforced by spherical B2 particles. Prog. Nat. Sci. Mater. Int. 2018, 28, 704–710. [Google Scholar] [CrossRef]

- Gargarella, P.; Pauly, S.; Song, K.; Hu, J.; Barekar, N.; Khoshkhoo, M.S.; Teresiak, A.; Wendrock, H.; Kühn, U.; Ruffing, C.; et al. Ti–Cu–Ni shape memory bulk metallic glass composites. Acta Mater. 2013, 61, 151–162. [Google Scholar] [CrossRef]

- Xue, P.; Huang, Y.; Pauly, S.; Jiang, S.; Guo, S.; Fan, H.; Ning, Z.; Cao, F.; Sun, J. Quantitatively determining the martensitic transformation in a CuZr-based bulk metallic glass composite. J. Alloys Compd. 2019, 782, 961–966. [Google Scholar] [CrossRef]

- Jhou, W.; Wang, C.; Ii, S.; Hsueh, C. Nanoscaled superelastic behavior of shape memory alloy/metallic glass multilayered films. Compos. Part B Eng. 2018, 142, 193–199. [Google Scholar] [CrossRef]

- Sun, F.; Zhang, J.; Marteleur, M.; Gloriant, T.; Vermaut, P.; Laillé, D.; Castany, P.; Curfs, C.; Jacques, P.; Prima, F. Investigation of early stage deformation mechanisms in a metastable β titanium alloy showing combined twinning-induced plasticity and transformation-induced plasticity effects. Acta Mater. 2013, 61, 6406–6417. [Google Scholar] [CrossRef] [Green Version]

- Bignon, M.; Bertrand, E.; Tancret, F.; Rivera-Díaz-Del-Castillo, P.E. Modelling martensitic transformation in titanium alloys: The influence of temperature and deformation. Materialia 2019, 7, 100382. [Google Scholar] [CrossRef]

- Fischer, F.D.; Reisner, G.; Werner, E.; Tanaka, K.; Cailletaud, G.; Antretter, T. A new view on transformation induced plasticity (TRIP). Int. J. Plast. 2000, 16, 723–748. [Google Scholar] [CrossRef]

- Pereloma, E.; Gazder, A.; Timokhina, I. Retained austenite: Transformation-Induced plasticity. In Encyclopedia of Iron, Steel, and Their Alloys; CRC Press: New York, NY, USA, 2016; pp. 3088–3103. [Google Scholar]

- Zackay, V.F.; Bhandarkar, M.D.; Parker, E.R. The role of deformation-induced phase transformations in the plasticity of some iron-base alloys. In Advances in Deformation Processing; Springer Science and Business Media LLC: Boston, MA, USA, 1978; pp. 351–404. [Google Scholar]

- Wang, M.M.; Tasan, C.C.; Ponge, D.; Raabe, D. Spectral TRIP enables ductile 1.1 GPa martensite. Acta Mater. 2016, 111, 262–272. [Google Scholar] [CrossRef]

- Kato, H.; Sasaki, K. Transformation-induced plasticity as the origin of serrated flow in an NiTi shape memory alloy. Int. J. Plast. 2013, 50, 37–48. [Google Scholar] [CrossRef]

- Hong, S.H.; Kim, J.; Park, H.; Kim, Y.; Suh, J.-Y.; Na, Y.-S.; Lim, K.; Park, J.M.; Kim, K.B. Gradual martensitic transformation of B2 phase on TiCu-based bulk metallic glass composite during deformation. Intermetallics 2016, 75, 1–7. [Google Scholar] [CrossRef]

- Gao, W.; Yi, X.; Meng, X.; Song, G.; Cai, W.; Zhao, L. Stress-Induced martensitic transformation of Zr50Cu25Ni10Co15 nanocrystals embedded in an amorphous matrix. J. Mater. Sci. Technol. 2017, 33, 276–280. [Google Scholar] [CrossRef]

- Song, K.; Pauly, S.; Zhang, Y.; Li, R.; Gorantla, S.; Narayanan, N.; Kühn, U.; Gemming, T.; Eckert, J. Triple yielding and deformation mechanisms in metastable Cu47.5Zr47.5Al5 composites. Acta Mater. 2012, 60, 6000–6012. [Google Scholar] [CrossRef]

- Wang, H.; Park, E.; Oak, J.; Setyawan, A.D.; Zhu, S.; Wada, T.; Wang, X.; Takeuchi, A.; Kato, H. Effect of cobalt microalloying on the glass forming ability of Ti–Cu–Pd–Zr metallic glass. J. Non-Crystalline Solids 2013, 379, 155–160. [Google Scholar] [CrossRef]

- Zhai, H.; Wang, H.; Liu, F. A strategy for designing bulk metallic glass composites with excellent work-hardening and large tensile ductility. J. Alloys Compd. 2016, 685, 322–330. [Google Scholar] [CrossRef]

- Tsarkov, A.; Churyumov, A.Y.; Zadorozhnyy, V.Y.; Louzguine-Luzgin, D. High-strength and ductile (Ti–Ni)-(Cu–Zr) crystalline/amorphous composite materials with superelasticity and TRIP effect. J. Alloys Compd. 2016, 658, 402–407. [Google Scholar] [CrossRef]

- Prokoshkin, S.; Brailovski, V.; Inaekyan, K.; Demers, V.; Kreitcberg, A. Nanostructured Ti–Ni shape memory alloys produced by thermomechanical processing. Shape Mem. Superelasticity 2015, 1, 191–203. [Google Scholar] [CrossRef] [Green Version]

- Miyazaki, S.; Otsuka, K. Development of shape memory alloys. ISIJ Int. 1989, 29, 353–377. [Google Scholar] [CrossRef]

- Brailovski, V.; Prokoshkin, S.; Terriault, P. Shape Memory Alloys: Fundamentals, Modeling and Applications; École de technologie supérieure: Montreal, QC, Canada, 2003. [Google Scholar]

- Hofmann, U.C.; Suh, J.-Y.; Wiest, A.; Duan, G.; Lind, M.-L.; Demetriou, M.D.; Johnson, W.L. Designing metallic glass matrix composites with high toughness and tensile ductility. Nature 2008, 451, 1085–1089. [Google Scholar] [CrossRef]

- Jiang, S.-S.; Huang, Y.; Wu, F.-F.; Xue, P.; Sun, J.-F. A CuZr-based bulk metallic glass composite with excellent mechanical properties by optimizing microstructure. J. Non-Cryst. Solids 2018, 483, 94–98. [Google Scholar] [CrossRef]

- Kim, W.-C.; Kim, Y.-J.; Kim, Y.-S.; Hyun, J.-I.; Hong, S.H.; Kim, W.-T.; Kim, D. Enhancement of superelastic property in Ti–Zr–Ni–Cu alloy by using glass alloy precursor with high glass forming ability. Acta Mater. 2019, 173, 130–141. [Google Scholar] [CrossRef]

- Qiao, J.-W.; Jia, H.; Liaw, P. Metallic glass matrix composites. Mater. Sci. Eng. R Rep. 2016, 100, 1–69. [Google Scholar] [CrossRef] [Green Version]

- Gargarella, P.; Pauly, S.; Khoshkhoo, M.S.; Kühn, U.; Eckert, J. Phase formation and mechanical properties of Ti–Cu–Ni–Zr bulk metallic glass composites. Acta Mater. 2014, 65, 259–269. [Google Scholar] [CrossRef]

- Isomäki, I.; Hämäläinen, M.; Gasik, M. Thermodynamic assessment of the ternary Ni–Ti–Cr system. J. Alloys Compd. 2012, 543, 12–18. [Google Scholar] [CrossRef]

- Young, K.; Ouchi, T.; Nei, J.; Meng, T. Effects of Cr, Zr, V, Mn, Fe, and Co to the hydride properties of Laves phase-related body-centered-cubic solid solution alloys. J. Power Sources 2015, 281, 164–172. [Google Scholar] [CrossRef] [Green Version]

- Liu, F.; Li, Y.; Li, Y.; Xu, H. A study on TiNi(Fe,Mo) shape memory alloy. Mater. Sci. Eng. A 2006, 438, 896–899. [Google Scholar] [CrossRef]

- Nakata, Y.; Tadaki, T.; Shimizu, K. Composition dependence of the atom location of the third element in Ti–Ni–X shape memory alloys. Mater. Trans. JIM 1991, 32, 1120–1127. [Google Scholar] [CrossRef] [Green Version]

- Nakata, Y.; Tadaki, T.; Shimizu, K. Atom location of the third element in Ti–Ni–X shape memory alloys determined by the electron channelling enhanced microanalysis. Mater. Trans. JIM 1991, 32, 580–586. [Google Scholar] [CrossRef] [Green Version]

- Zadorozhnyy, V.Y.; Inoue, A.; Louzguine-Luzgin, D. Formation and investigation of the structure and mechanical properties of bulk metallic glassy composite (Ti–Zr)–(Cu–Ni–Co) alloys. Intermetallics 2012, 31, 173–176. [Google Scholar] [CrossRef]

- Zadorozhnyy, V.Y.; Inoue, A.; Louzguine-Luzgin, D. Investigation of the structure and mechanical properties of as-cast Ti-Cu-based alloys. Mater. Sci. Eng. A 2013, 573, 175–182. [Google Scholar] [CrossRef]

- Jiang, J.; Ketov, S.; Kato, H.; Louzguine-Luzgin, D. Effect of the cooling rate on the mechanical properties of Ti-Ni-Cu-Zr-based crystal/glassy alloys. Mater. Sci. Eng. A 2017, 704, 147–153. [Google Scholar] [CrossRef]

- Khalil-Allafi, J.; Schmahl, W.W.; Toebbens, D. Space group and crystal structure of the r-phase in binary NiTi shape memory alloys. Acta Mater. 2006, 54, 3171–3175. [Google Scholar] [CrossRef]

- Ling, H.C.; Roy, K. Stress-Induced shape changes and shape memory in the r and martensite transformations in equiatomic NiTi. Met. Mater. Trans. A 1981, 12, 2101–2111. [Google Scholar] [CrossRef]

- Miyazaki, S.; Otsuka, K. Deformation and transition behavior associated with the r-phase in Ti-Ni alloys. Met. Mater. Trans. A 1986, 17, 53–63. [Google Scholar] [CrossRef]

- Santos, L.A.; Resende, P.D.; Bahia, M.G.D.A.; Buono, V. Effects of r-phase on mechanical responses of a nickel-titanium endodontic instrument: Structural characterization and finite element analysis. Sci. World J. 2016, 2016, 1–11. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Duerig, T.W.; Bhattacharya, K. The Influence of the r-phase on the superelastic behavior of NiTi. Shape Mem. Superelasticity 2015, 1, 153–161. [Google Scholar] [CrossRef]

- Frenzel, J.; Wieczorek, A.; Opahle, I.; Maas, B.; Drautz, R.; Eggeler, G. On the effect of alloy composition on martensite start temperatures and latent heats in Ni–Ti-based shape memory alloys. Acta Mater. 2015, 90, 213–231. [Google Scholar] [CrossRef]

- Miyazaki, S.; Kimura, S.; Otsuka, K. Shape-memory effect and pseudoelasticity associated with the r-phase transition in Ti-50·5 at.% Ni single crystals. Philos. Mag. A 1988, 57, 467–478. [Google Scholar] [CrossRef]

- Niu, J.; Geng, W.-T. Anti-precursor effect of Fe on martensitic transformation in TiNi alloys. Acta Mater. 2016, 104, 18–24. [Google Scholar] [CrossRef]

- Belyaev, S.; Resnina, N.; Iaparova, E.; Ivanova, A.; Rakhimov, T.; Andreev, V.; Belayev, S. Influence of chemical composition of NiTi alloy on the martensite stabilization effect. J. Alloys Compd. 2019, 787, 1365–1371. [Google Scholar] [CrossRef]

- Zhang, F.; Zheng, L.; Wang, Y.; Zhang, H. Effect of Ni content and Hf addition on the unlubricated wear performance of Ni-rich NiTi alloys. Intermetallics 2019, 112, 106548. [Google Scholar] [CrossRef]

- Chen, S.; Wu, J.; Tu, J.; Li, X.; Zou, J.; Hu, Q.; Zeng, X. Enhanced plasticity in a Ti-Ni-Nb-Zr shape memory bulk metallic glass composite with high Nb addition. Mater. Sci. Eng. A 2017, 704, 192–198. [Google Scholar] [CrossRef]

- De Keyzer, J.; Cacciamani, G.; Dupin, N.; Wollants, P. Thermodynamic modeling and optimization of the Fe–Ni–Ti system. Calphad 2009, 33, 109–123. [Google Scholar] [CrossRef]

- Fukunaga, T.; Hayashi, N.; Kai, K.; Watanabe, N.; Suzuki, K. Chemical short-range structure of NixTi1−x (x = 0.26−0.40) alloy glasses. Phys. B+C 1983, 120, 352–356. [Google Scholar] [CrossRef]

- Fan, Q.; Zhang, Y.; Wang, Y.; Sun, M.; Meng, Y.; Huang, S.; Wen, Y. Influences of transformation behavior and precipitates on the deformation behavior of Ni-rich NiTi alloys. Mater. Sci. Eng. A 2017, 700, 269–280. [Google Scholar] [CrossRef]

- Hashem, A.; Abuzeid, H.M.; Kaus, M.; Indris, S.; Ehrenberg, H.; Mauger, A.; Julien, C. Green synthesis of nanosized manganese dioxide as positive electrode for lithium-ion batteries using lemon juice and citrus peel. Electrochim. Acta 2018, 262, 74–81. [Google Scholar] [CrossRef]

- Chen, G.; Liss, K.-D.; Cao, P. An in situ study of NiTi powder sintering using neutron diffraction. Metals 2015, 5, 530–546. [Google Scholar] [CrossRef] [Green Version]

- Li, Q.; Liu, S.; Wang, X.; Yang, T.; Dong, C.; Hu, J.; Jiang, Y. Mechanical and corrosion properties of Ti-Ni-Cu-Zr metallic glass matrix composites. J. Alloys Compd. 2017, 727, 1344–1350. [Google Scholar] [CrossRef]

- Churyumov, A.; Bazlov, A.I.; Solonin, A.; Zadorozhnyi, V.Y.; Xie, G.Q.; Li, S.; Louzguine-Luzgin, D. Structure and mechanical properties of Ni-Cu-Ti-Zr composite materials with amorphous phase. Phys. Met. Met. 2013, 114, 773–778. [Google Scholar] [CrossRef]

- Desroches, R.; McCormick, J.; Delemont, M. Cyclic properties of superelastic shape memory alloy wires and bars. J. Struct. Eng. 2004, 130, 38–46. [Google Scholar] [CrossRef]

- Hurley, J.; Ortega, A.M.; Lechniak, J.; Gall, K.; Maier, H.J. Structural evolution during the cycling of NiTi shape memory alloys. Z. Met. 2003, 94, 547–552. [Google Scholar] [CrossRef]

- Pauly, S.; Das, J.; Bednarcik, J.; Mattern, N.; Kim, K.; Kim, D.; Eckert, J. Deformation-induced martensitic transformation in Cu–Zr–(Al,Ti) bulk metallic glass composites. Scr. Mater. 2009, 60, 431–434. [Google Scholar] [CrossRef] [Green Version]

| Alloy | Ti | Ni | Cu | Zr | Co | Y | Al/Fe/Cr |

|---|---|---|---|---|---|---|---|

| Al-1 | 40.25 | 40.25 | 8 | 8 | 2 | 0.5 | Al 1 |

| Al-2 | 39.75 | 39.75 | 8 | 8 | 2 | 0.5 | Al 2 |

| Al-3 | 39.25 | 39.25 | 8 | 8 | 2 | 0.5 | Al 3 |

| Al-5 | 38.25 | 38.25 | 8 | 8 | 2 | 0.5 | Al 5 |

| Cr-1 | 40.75 | 39.75 | 8 | 8 | 2 | 0.5 | Cr 1 |

| Cr-2 | 40.75 | 38.75 | 8 | 8 | 2 | 0.5 | Cr 2 |

| Cr-3 | 40.75 | 37.75 | 8 | 8 | 2 | 0.5 | Cr 3 |

| Cr-5 | 40.75 | 35.75 | 8 | 8 | 2 | 0.5 | Cr 5 |

| Fe-1 | 40.75 | 39.75 | 8 | 8 | 2 | 0.5 | Fe 1 |

| Fe-2 | 40.75 | 38.75 | 8 | 8 | 2 | 0.5 | Fe 2 |

| Fe-3 | 40.75 | 37.75 | 8 | 8 | 2 | 0.5 | Fe 3 |

| Fe-5 | 40.75 | 35.75 | 8 | 8 | 2 | 0.5 | Fe 5 |

| Fe-8 | 40.75 | 32.75 | 8 | 8 | 2 | 0.5 | Fe 8 |

| Alloy | Phase | Ti | Ni | Cu | Zr | Co | Y | Al |

|---|---|---|---|---|---|---|---|---|

| Al-1 | Amorphous | 38.1 | 36.5 | 9.9 | 11.9 | 1.4 | 0.1 | 2.2 |

| Al-2 | 36.4 | 34.7 | 10.3 | 13.2 | 1.2 | 0.5 | 3.7 | |

| Al-3 | 36.8 | 34.9 | 9.9 | 12.0 | 1.3 | 0.7 | 4.4 | |

| Al-5 | 36.6 | 34.2 | 10.7 | 13.0 | 1.2 | 0.9 | 3.3 | |

| Al-1 | cP2 | 43.7 | 40.3 | 5.9 | 6.5 | 2.7 | 0.1 | 0.9 |

| Al-2 | 44.7 | 40.7 | 4.9 | 4.8 | 3.3 | 0.0 | 1.6 | |

| Al-3 | 42.9 | 40.1 | 5.9 | 6.0 | 2.6 | 0.0 | 2.6 | |

| Al-5 | 44.3 | 40.5 | 5.0 | 5.4 | 3.1 | 0.0 | 1.7 |

| Alloy | σ0.2, MPa | σb, MPa | ε, % |

|---|---|---|---|

| Al-1 | here σM 1175; σR 1750 | 2650 | 25.2 |

| Al-2 | 1575 | 2490 | 18.9 |

| Al-3 | 1790 | 2190 | 10.1 |

| Al-5 | 1670 | 1830 | 9.1 |

| Cr-1 | 1590 | 2390 | 17.9 |

| Cr-2 | 1635 | 2360 | 15.2 |

| Cr-3 | 1520 | 2070 | 13.5 |

| Cr-5 | 1970 | 2330 | 11.9 |

| Fe-1 | 1390 | 2060 | 15.9 |

| Fe-2 | 1550 | 2110 | 15.2 |

| Fe-3 | 1580 | 2120 | 13.5 |

| Fe-5 | 1810 | 2510 | 18.7 |

| Fe-8 | 2030 | 2410 | 13.9 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tsarkov, A.A.; Zadorozhnyy, V.Y.; Solonin, A.N.; Louzguine-Luzgin, D.V. Effect of Aluminum, Iron and Chromium Alloying on the Structure and Mechanical Properties of (Ti-Ni)-(Cu-Zr) Crystalline/Amorphous Composite Materials. Metals 2020, 10, 874. https://doi.org/10.3390/met10070874

Tsarkov AA, Zadorozhnyy VY, Solonin AN, Louzguine-Luzgin DV. Effect of Aluminum, Iron and Chromium Alloying on the Structure and Mechanical Properties of (Ti-Ni)-(Cu-Zr) Crystalline/Amorphous Composite Materials. Metals. 2020; 10(7):874. https://doi.org/10.3390/met10070874

Chicago/Turabian StyleTsarkov, Andrey A., Vladislav Yu. Zadorozhnyy, Alexey N. Solonin, and Dmitri V. Louzguine-Luzgin. 2020. "Effect of Aluminum, Iron and Chromium Alloying on the Structure and Mechanical Properties of (Ti-Ni)-(Cu-Zr) Crystalline/Amorphous Composite Materials" Metals 10, no. 7: 874. https://doi.org/10.3390/met10070874

APA StyleTsarkov, A. A., Zadorozhnyy, V. Y., Solonin, A. N., & Louzguine-Luzgin, D. V. (2020). Effect of Aluminum, Iron and Chromium Alloying on the Structure and Mechanical Properties of (Ti-Ni)-(Cu-Zr) Crystalline/Amorphous Composite Materials. Metals, 10(7), 874. https://doi.org/10.3390/met10070874