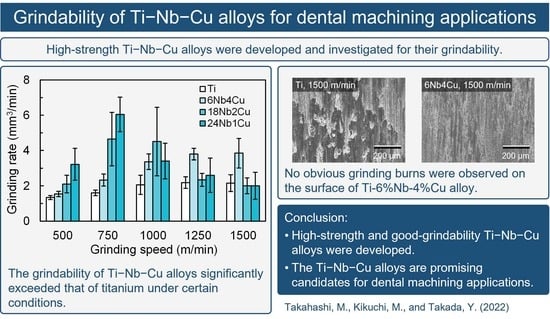

Grindability of Ti−Nb−Cu Alloys for Dental Machining Applications

Abstract

:1. Introduction

2. Materials and Methods

2.1. Preparation of Specimens

2.2. X-ray Diffractometry

2.3. Hardness Tests

2.4. Grinding Test

3. Results

3.1. X-ray Diffractometry

3.2. Hardness

3.3. Grindability

3.4. Observation of Metal Chips, Wheels, and Ground Surfaces after Grinding

4. Discussion

4.1. Alloy Phases and Hardness

4.2. Grindability

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chandler, H.E. Machining of Reactive Metals. In Machining; ASM Handbook, ASM Handbook Committee; ASM International: Materials Park, OH, USA, 1989; Volume 16, pp. 844–857. [Google Scholar] [CrossRef]

- Machado, A.R.; Wallbank, J. Machining of titanium and its alloys—a review. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 1990, 204, 53–60. [Google Scholar] [CrossRef]

- Ezugwu, E.O.; Wang, Z.M. Titanium alloys and their machinability—A review. J. Mater. Process. Technol. 1997, 68, 262–274. [Google Scholar] [CrossRef]

- Okabe, T.; Ohkubo, C.; Watanabe, I.; Okuno, O.; Takada, Y. The present status of dental titanium casting. JOM 1998, 50, 24–29. [Google Scholar] [CrossRef]

- Kikuchi, M.; Takahashi, M.; Okabe, T.; Okuno, O. Grindability of dental cast Ti-Ag and Ti-Cu Alloys. Dent. Mater. J. 2003, 22, 191–205. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kikuchi, M.; Takahashi, M.; Okuno, O. Mechanical properties and grindability of dental cast Ti-Nb alloys. Dent. Mater. J. 2003, 22, 328–342. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Takahashi, M.; Kikuchi, M.; Okuno, O. Grindability of dental cast Ti-Zr alloys. Mater. Trans. 2009, 50, 859–863. [Google Scholar] [CrossRef] [Green Version]

- Kikuchi, M.; Takahashi, M.; Sato, H.; Okuno, O.; Nunn, M.E.; Okabe, T. Grindability of cast Ti-Hf alloys. J. Biomed. Mater. Res. B Appl. Biomater. 2006, 77, 34–38. [Google Scholar] [CrossRef]

- Takahashi, M.; Kikuchi, M.; Okuno, O. Mechanical properties and grindability of experimental Ti-Au alloys. Dent. Mater. J. 2004, 23, 203–210. [Google Scholar] [CrossRef] [Green Version]

- Hsu, H.C.; Wu, S.C.; Chiang, T.Y.; Ho, W.F. Structure and grindability of dental Ti-Cr alloys. J. Alloys Compd. 2009, 476, 817–825. [Google Scholar] [CrossRef]

- Lim, H.S.; Hwang, M.J.; Jeong, H.N.; Lee, W.Y.; Song, H.J.; Park, Y.J. Evaluation of surface mechanical properties and grindability of binary Ti alloys containing 5 wt% Al, Cr, Sn, and V. Metals 2017, 7, 487. [Google Scholar] [CrossRef] [Green Version]

- Davis, J.R. (Ed.) ASM Materials Engineering Dictionary; ASM Press International: Materials Park, OH, USA, 1992; p. 175. [Google Scholar]

- Takahashi, M.; Kikuchi, M.; Takada, Y. Mechanical properties and microstructures of dental cast Ti-6Nb-4Cu, Ti-18Nb-2Cu, and Ti-24Nb-1Cu alloys. Dent. Mater. J. 2016, 35, 564–570. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- ISO 22674:2016; Dentistry—Metallic Materials for Fixed and Removable Restorations and Appliances. ISO: Geneva, Switzerland, 2016; pp. 1–26. [CrossRef]

- Takahashi, M.; Kikuchi, M.; Takada, Y.; Okuno, O. Mechanical properties and microstructures of dental cast Ti-Ag and Ti-Cu alloys. Dent. Mater. J. 2002, 21, 270–280. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Sato, K.; Takahashi, M.; Takada, Y. Construction of Ti-Nb-Ti2Cu pseudo-ternary phase diagram. Dent. Mater. J. 2020, 39, 422–428. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Holden, F.C.; Watts, A.A.; Ogden, H.R.; Jaffee, R.I. Heat treatment and mechanical properties of Ti-Cu alloys. JOM 1955, 7, 117–125. [Google Scholar] [CrossRef]

- Taguchi, O.; Iijima, Y. Diffusion of copper, silver and gold in α-titanium. Philos. Mag. A 1995, 72, 1649–1655. [Google Scholar] [CrossRef]

- Collings, E.W.; Water, J.L.; Jackson, M.R.; Sims, C.T. (Eds.) Introduction to Titanium Alloy Design, Alloying; ASM International: Metals Park, OH, USA, 1988; pp. 257–370. [Google Scholar]

- Murray, J.L. The Nb-Ti (Niobium–Titanium) System, Phase Diagrams of Binary Titanium Alloys; ASM International: Metals Park, OH, USA, 1990; pp. 188–194. [Google Scholar]

- Hanada, S.; Ozeki, M.; Izumi, O. Deformation characteristics in β phase Ti-Nb alloys. Metall. Trans. A 1985, 16, 789–795. [Google Scholar] [CrossRef]

- López de lacalle, L.N.; Pérez, J.; Llorente, J.I.; Sánchez, J.A. Advanced cutting conditions for the milling of aeronautical alloys. J. Mater. Process. Technol. 2000, 100, 1–11. [Google Scholar] [CrossRef]

- Okamoto, H.; Massalski, T.B. Binary Alloy Phase Diagrams, 2nd ed.; Okamoto, H., Schlesinger, M.E., Mueller, E.M., Eds.; ASM International: Materials Park, OH, USA, 1990; Volume 2, p. 12. [Google Scholar]

- Kikuchi, M.; Takahashi, M.; Okuno, O. Machinability of experimental Ti-Ag alloys. Dent. Mater. J. 2008, 27, 216–220. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Inagaki, R.; Kikuchi, M.; Takahashi, M.; Takada, Y.; Sasaki, K. Machinability of an experimental Ti-Ag alloy in terms of tool life in a dental CAD/CAM system. Dent. Mater. J. 2015, 34, 679–685. [Google Scholar] [CrossRef] [Green Version]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Takahashi, M.; Kikuchi, M.; Takada, Y. Grindability of Ti−Nb−Cu Alloys for Dental Machining Applications. Metals 2022, 12, 861. https://doi.org/10.3390/met12050861

Takahashi M, Kikuchi M, Takada Y. Grindability of Ti−Nb−Cu Alloys for Dental Machining Applications. Metals. 2022; 12(5):861. https://doi.org/10.3390/met12050861

Chicago/Turabian StyleTakahashi, Masatoshi, Masafumi Kikuchi, and Yukyo Takada. 2022. "Grindability of Ti−Nb−Cu Alloys for Dental Machining Applications" Metals 12, no. 5: 861. https://doi.org/10.3390/met12050861

APA StyleTakahashi, M., Kikuchi, M., & Takada, Y. (2022). Grindability of Ti−Nb−Cu Alloys for Dental Machining Applications. Metals, 12(5), 861. https://doi.org/10.3390/met12050861