Water Droplet Erosion Performance of Laser Shock Peened Ti-6Al-4V

Abstract

:1. Introduction

2. Experimental Procedure

2.1. Material and Sample Geometries

2.2. LSP Processing and Characterizations

2.2.1. LSP Processing

2.2.2. X-ray Diffraction (XRD) Pattern and Residual Stress Measurement

2.2.3. Microhardness

2.2.4. Microscopy

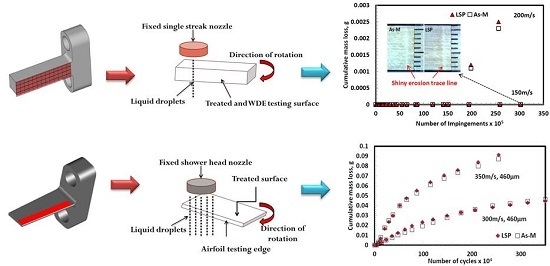

2.3. Water Droplet Erosion (WDE) Testing and Damage Analysis

2.3.1. WDE Tests

2.3.2. Damage Analysis and WDE Curves Characterizations

3. Results and Discussion

3.1. Effect of LSP on Surface and In-Depth Characteristics

3.1.1. XRD Pattern and Compressive Residual Stresses

3.1.2. Microstructure

3.1.3. Microhardness

3.2. Water Droplet Erosion Performance

3.2.1. WDE Performance of LSP and As-M T-Shaped Sample Conditions

3.2.2. WDE Performance of LSP and As-M Airfoil Sample Conditions

3.2.3. Effect of Sample Geometry and LSP on WDE Performance

3.3. WDE Damage Evolution

3.4. WDE and Fatigue Damage

4. Conclusions

- LSP treatment using 2 and 3 pulses per unit area induces significant levels of compressive residual stress. However, for the treatment approach and conditions used in this work, LSP shows little or no effect on the Ti-6Al-4V microstructure and microhardness.

- WDE results show similar WDE performance for the T-shaped flat LSP and As-M conditions at all tested speeds (150 to 350 m/s). At 150 m/s, both the LSP and As-M conditions show no erosion damage after 840 min (30 million impingements).

- Both LSP and As-M conditions show similar ERmax and a speed exponent value of 8.9. Hence, for the T-shaped flat geometry, the LSP treatment shows no beneficial effect in enhancing the WDE performance.

- Despite LSP inducing compressive residual stresses, the residual stresses reached in this work do not improve WDE performance. Since LSP is proven to improve fatigue behaviour of Ti-6Al-4V alloy, this indicates that the fatigue-like mechanism is not dominating in WDE.

- For the airfoil geometry, WDE curves show similar WDE performances for LSP and As-M conditions at 350 m/s. At 300 m/s, LSP shows little improvement in WDE resistance at the advanced erosion stage. The compressive residual stress through the sample thickness influences this behaviour.

- Synergy between surface hardening, microstructural refinement, and compressive residual stresses is necessary for significant improvement in water droplet impingement erosion resistance.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Meher-Homji, C.B.; Mee, T.R. Gas turbine power augmentation by fogging of inlet air. In Proceedings of the ASME International 28th Turbomachinery Symposium, Houston, TX, USA, 4 September 1999; pp. 93–114.

- Giampaolo, T. The Gas Turbine Handbook: Principles and Practice, 3rd ed.; Fairmont Press: New York, NY, USA, 2006. [Google Scholar]

- Khan, J.R. Fog Cooling, Wet Compression and Droplet Dynamics in Gas Turbine Compressors. Ph.D. Thesis, University of New Orleans, New Orleans, LA, USA, 2009. [Google Scholar]

- ASTM G40-15: Standard Terminology Relating to Wear and Erosion; ASTM International: West Conshohocken, PA, USA, 2015.

- Hammitt, F.G.; Heymann, F.J. Liquid-Erosion Failures, Failure Analysis and Prevention. In ASM Handbook; ASM International: Materials Park, OH, USA, 1986; Volume 11, pp. 163–171. [Google Scholar]

- Lesser, M.B.; Field, J.E. The impact of compressible liquids. Annu. Rev. Fluid Mech. 1983, 15, 97–122. [Google Scholar] [CrossRef]

- Mahdipoor, M.S.; Tarasi, F.; Moreau, C.; Dolatabadi, A.; Medraj, M. HVOF sprayed coatings of nano-agglomerated tungsten-carbide/cobalt powders for water droplet erosion application. Wear 2015, 330–331, 338–347. [Google Scholar] [CrossRef]

- Mann, B.S.; Arya, V. An experimental study to corelate water jet impingement erosion resistance and properties of metallic materials and coatings. Wear 2002, 253, 650–661. [Google Scholar] [CrossRef]

- Mann, B.S. Water droplet and cavitation erosion behavior of laser treated stainless steel and titanium alloy: Their similarities. J. Mater. Eng. Perform. 2013, 22, 3647–3656. [Google Scholar] [CrossRef]

- Gerdes, C.; Karimi, A.; Bieler, H. Water droplet erosion and microstructure of laser nitrided Ti-6A1-4V. Wear 1995, 186–187, 368–374. [Google Scholar] [CrossRef]

- Ma, D.; Mostafa, A.; Kevorkov, D.; Jedrzejowski, P.; Pugh, M.; Medraj, M. Water impingement erosion of deep-rolled Ti64. Metals 2015, 5, 1462–1486. [Google Scholar] [CrossRef]

- Gujba, A.K.; Ren, Z.; Dong, Y.; Ye, C.; Medraj, M. Effect of ultrasonic nanocrystalline surface modification on the water droplet erosion performance of Ti-6Al-4V. Surf. Coat. Technol. 2016, 307, 157–170. [Google Scholar] [CrossRef]

- Gujba, A.K.; Medraj, M. Laser peening process and its impact on materials properties in comparison with shot peening and ultrasonic impact peening. Materials 2014, 7, 7925–7974. [Google Scholar] [CrossRef]

- Zhang, X.C.; Zhang, Y.K.; Lu, J.Z.; Xuan, F.Z.; Wang, Z.D.; Tu, S.T. Improvement of fatigue life of Ti-6Al-4V alloy by laser shock peening. Mater. Sci. Eng. A 2010, 527, 3411–3415. [Google Scholar] [CrossRef]

- Ruschau, J.; John, R.; Thompson, S.R.; Nicholas, T. Fatigue crack nucleation and growth rate behavior of laser shock peened titanium. Int. J. Fatigue 1999, 21, 199–209. [Google Scholar] [CrossRef]

- Altenberger, I.; Nalla, R.K.; Sano, Y.; Wagner, L.; Ritchie, R.O. On the effect of deep-rolling and laser-peening on the stress-controlled low- and high-cycle fatigue behavior of Ti-6Al-4V at elevated temperatures up to 550 °C. Int. J. Fatigue 2012, 44, 292–302. [Google Scholar] [CrossRef]

- Liu, K.K.; Hill, M.R. The effects of laser peening and shot peening on fretting fatigue in Ti-6Al-4V coupons. Tribol. Int. 2009, 42, 1250–1262. [Google Scholar] [CrossRef]

- Srinivasan, S.; Garcia, D.B.; Gean, M.C.; Murthy, H.; Farris, T.N. Fretting fatigue of laser shock peened Ti-6Al-4V. Tribol. Int. 2009, 42, 1324–1329. [Google Scholar] [CrossRef]

- Gao, Y.K. Improvement of fatigue property in 7050–T7451 aluminum alloy by laser peening and shot peening. Mater. Sci. Eng. A 2011, 528, 3823–3828. [Google Scholar] [CrossRef]

- Kamkar, N. Water Droplet Erosion Mechanisms of Ti-6Al-4V. Ph.D. Thesis, École de Technologie Supérieure (ÉTS), Montreal, QC, Canada, 2014. [Google Scholar]

- Hattori, S.; Takinami, M. Comparison of cavitation erosion rate with liquid impingement erosion rate. Wear 2010, 269, 310–316. [Google Scholar] [CrossRef]

- Gujba, A.K.; Hackel, L.; Kevorkov, D.; Medraj, M. Water droplet erosion behaviour of Ti-6Al-4V and mechanisms of material removal at the early and advanced stages. Wear 2016, 358–359, 109–122. [Google Scholar] [CrossRef]

- ASM Aerospace Specification Metals: Titanium Ti-6Al-4V (Grade 5), ASM Material Data Sheet. Available online: www.aerospacemetals.com (accessed on 20 August 2016).

- Zhou, Z.; Bhamare, S.; Ramakrishnan, G.; Mannava, S.R.; Langer, K.; Wen, Y.; Qian, D.; Vasudevan, V.K. Thermal relaxation of residual stress in laser shock peened Ti-6Al-4V alloy. Surf. Coat. Technol. 2012, 206, 4619–4627. [Google Scholar] [CrossRef]

- Zabeen, S.; Preuss, M.; Withers, P.J. Residual stresses caused by head-on and 45° foreign object damage for a laser shock peened Ti-6Al-4V alloy aerofoil. Mater. Sci. Eng. A 2013, 560, 518–527. [Google Scholar] [CrossRef]

- Lin, B.; Lupton, C.; Spanrad, S.; Schofield, J.; Tong, J. Fatigue crack growth in laser-shock-peened Ti-6Al-4V aerofoil specimens due to foreign object damage. Int. J. Fatigue 2014, 59, 23–33. [Google Scholar] [CrossRef]

- Shepard, M.J.; Smith, P.R.; Amer, M.S. Introduction of compressive residual stresses in Ti-6Al-4V simulated airfoils via laser shock processing. J. Mater. Eng. Perform. 2001, 10, 670–678. [Google Scholar] [CrossRef]

- Spanrad, S.; Tong, J. Characterisation of foreign object damage (FOD) and early fatigue crack growth in laser shock peened Ti-6Al-4V aerofoil specimens. Mater. Sci. Eng. A 2011, 528, 2128–2136. [Google Scholar] [CrossRef]

- Zolotoyabko, E.; Rupp, J.L.M.; Gauckler, L.J. Interrelationship between grain size-induced and strain-induced broadening of X-ray diffraction profiles: What we can learn about nanostructured materials? Scr. Mater. 2012, 66, 190–193. [Google Scholar] [CrossRef]

- Gammon, L.M.; Briggs, R.D.; Packard, J.M.; Batson, K.W.; Boyer, R.; Domby, C.W. Metallography and microstructures of titanium and its alloys. In ASM Handbook; ASM International: Materials Park, OH, USA, 2004; Volume 9, pp. 899–917. [Google Scholar]

- ASTM G73-10: Standard Test Method for Liquid Impingement Erosion Using Rotating Apparatus; ASTM International: West Conshohocken, PA, USA, 2010.

- Ahmad, M.; Casey, M.; Sürken, N. Experimental assessment of droplet impact erosion resistance of steam turbine blade materials. Wear 2009, 267, 1605–1618. [Google Scholar] [CrossRef]

- Heymann, F. Liquid Impingement Erosion. In ASM Handbook; ASM International: Materials Park, OH, USA, 1992; Volume 18, pp. 221–232. [Google Scholar]

- Peyre, P.; Fabbro, R.; Merrien, P.; Lieurade, H. Laser shock processing of aluminium alloys. Application to high cycle fatigue behaviour. Mater. Sci. Eng. A 1996, 210, 102–113. [Google Scholar] [CrossRef]

- Peyre, P.; Sollier, A.; Chaieb, I.; Berthe, L.; Bartnicki, E.; Braham, C.; Fabbro, R. FEM simulation of residual stresses induced by laser Peening. Eur. Phys. J. Appl. Phys. 2003, 88, 83–88. [Google Scholar] [CrossRef]

- Prevey, P. Current Applications of X-ray Diffraction Residual Stress Measurement. In Developments in Materials Characterization Technologies; ASM International: Materials Park, OH, USA, 1996; pp. 103–110. [Google Scholar]

- Hackel, L.; Marley, S.; Rubenchik, A. Reduction of cavitation erosion by laser peening. In Proceedings of the SNAME Annual Maritime Convention (SMC), Houston, TX, USA, 22–24 October 2014; pp. 1–10.

- Prevéy, P.; Hornbach, D.; Mason, P. Thermal residual stress relaxation and distortion in surface enhanced gas turbine engine components. In Proceedings of the 17th Heat Treating Society Conference and Exposition and the 1st International Induction Heat Treating Symposium, Indianapolis, IN, USA, 16–18 September 1997; pp. 3–12.

- Feng, B.; Yang, G.; Mao, X.; Yu, L.; Wu, X. Research development of shot peening strengthening of titanium alloys. Titan. Ind. Prog. 2008, 3, 1–5. [Google Scholar]

- Hammersley, G.; Hackel, L.A.; Harris, F. Surface prestressing to improve fatigue strength of components by laser shot peening. Opt. Lasers Eng. 2000, 34, 327–337. [Google Scholar] [CrossRef]

- Zhao, Y. Effects of Laser Shock Peening on Residual Stress, Texture and Deformation Microstructure of Ti-6Al-4V Alloy. Ph.D. Thesis, University of Cincinnati, Cincinnati, OH, USA, 2012. [Google Scholar]

- Hatamleh, O. The effects of laser peening and shot peening on mechanical properties in friction stir welded 7075-T7351 aluminum. J. Mater. Eng. Perform. 2008, 17, 688–694. [Google Scholar] [CrossRef]

- Chávez, J.; Rodríguez, E.; Flores, M.; Ibarra-Montalvo, J.; Jiménez, O.; Gómez-Rosas, G. On the properties and resistance to abrasive wear of surface-modified Ti-6Al-4V alloy by laser shock processing. Superf. Vacio 2014, 27, 54–60. [Google Scholar]

- Rubio-González, C.; Felix-Martinez, C.; Gomez-Rosas, G.; Ocaña, J.L.; Morales, M.; Porro, J.A. Effect of laser shock processing on fatigue crack growth of duplex stainless steel. Mater. Sci. Eng. A 2011, 528, 914–919. [Google Scholar] [CrossRef]

- Clauer, A.H.; Fairand, B.P. Interaction of laser-induced stress waves with metals. In Proceedings of the ASM Conference Applications of Lasers in Materials Processing, Washington, DC, USA, 18–20 April 1979.

- Cellard, C.; Retraint, D.; François, M.; Rouhaud, E.; Le Saunier, D. Laser shock peening of Ti-17 titanium alloy: Influence of process parameters. Mater. Sci. Eng. A 2012, 532, 362–372. [Google Scholar] [CrossRef]

- Smith, P.R.; Shepard, M.J.; Prevey, P.S.; Clauer, A.H. Effect of power density and pulse repetition on laser shock peening of Ti-6AI-4V. J. Mater. Eng. Perform. 2000, 9, 33–37. [Google Scholar] [CrossRef]

- Petunlna, E.V.; Poplayskaya, V.L. Strength increase of titanium-base alloys by cold working. Met. Sci. Heat Treat. Met. 1959, 1, 24–27. [Google Scholar]

- Nagarjuna, S.; Balasubramanian, K.; Sarma, D.S. Effect of prior cold work on mechanical properties. J. Mater. Sci. 1997, 2, 3375–3385. [Google Scholar] [CrossRef]

- Baufeld, B.; van der Biest, O. Mechanical properties of Ti-6Al-4V specimens produced by shaped metal deposition. Sci. Technol. Adv. Mat. 2009, 10, 1–10. [Google Scholar] [CrossRef]

- Gupta, R.K.; Kumar, V.A.; Mathew, C.; Rao, G.S. Strain hardening of Titanium alloy Ti-6Al-4V sheets with prior heat treatment and cold working. Mater. Sci. Eng. A 2016, 662, 537–550. [Google Scholar] [CrossRef]

- Heymann, F. On the Time Dependence of the Rate of Erosion Due to Impingement or Cavitation; ASTM STP 408; American Society for Testing and Materials: West Conshohocken, PA, USA, 1967; pp. 70–110. [Google Scholar]

- Kirols, H.S.; Kevorkov, D.; Uihlein, A.; Medraj, M. The effect of initial surface roughness on water droplet erosion behaviour. Wear 2015, 342–343, 198–209. [Google Scholar] [CrossRef]

- Thiruvengadam, A.; Rudy, S.L. Experimental and Analytical Investigations on Multiple Liquid Impact Erosion; National Aeronautics and Space Administration (NASA): Moffett Field, CA, USA, 1969; pp. 1–93.

- Hoff, G.; Landbein, G.; Rieger, H. Material destruction due to liquid impact in Erosion by Cavitation or Impingement: A symposium. In Proceedings of the 6–9th Annual Meeting, American Society for Testing and Materials, Atlanta City, NJ, USA, 26 June–1 July 1966; pp. 42–69.

- Mahdipoor, M.S.; Kirols, H.S.; Kevorkov, D.; Jedrzejowski, P.; Medraj, M. Influence of impact speed on water droplet erosion of TiAl compared with Ti-6Al-4V. Sci. Rep. 2015, 5, 14182. [Google Scholar] [CrossRef] [PubMed]

- Fujisawa, N.; Yamagata, T.; Takano, S.; Saito, K.; Morita, R.; Fujiwara, K.; Inada, F. The influence of material hardness on liquid droplet impingement erosion. Nucl. Eng. Des. 2015, 288, 27–34. [Google Scholar] [CrossRef]

- Heymann, F.J. Erosion by liquids. Available online: http://users.encs.concordia.ca/~tmg/images/8/8b/Erosion_by_liquids.pdf (accessed on 20 August 2016).

- Robinson, J.I.; Reed, R.C. Water droplet erosion of laser surface treated Ti-6A1-4V. Wear 1995, 187, 360–367. [Google Scholar] [CrossRef]

- Yasugahira, N.; Namura, K.; Kaneko, R.; Satoh, T. Erosion resistance of titanium alloys for steam turbines blades as measured by water droplet impingement. In Proceedings of the Workshop on titanium steam turbine blading, PaloAlto, CA, USA, 9–10 November 1988; pp. 385–402.

| Sample Geometry | T-Shaped Flat | Airfoil |

|---|---|---|

| Surface treated | As-M | As-M |

| Laser type | Nd:Glass | Nd:Glass |

| Ablative layer | Aluminum | No layer |

| Intensity (GW/cm2) | 10 | 10 |

| Pulse time (ns) | 18 | 18 |

| Number of layers | 2 | 3 |

| Spot geometry | Square | Square |

| Spot size (mm) | 3 × 3 | 3 × 3 |

| WDE Parameters | Flat Sample | Airfoil Sample |

|---|---|---|

| Impact speed (m/s) | 150, 200, 250, 300, 325, 350 | 300, 350 |

| Rotational speed × 103 (rpm) | 6, 8, 10, 12, 13, 14 | 12, 14 |

| Flow rate (L/min) | 0.05 | 0.15, 0.20 * |

| Nozzle head type | Single streak | Shower head |

| Nozzle distance from sample (mm) | 5 | 5 |

| Average droplet size (µm) | 463 | 460, 200 |

| Impact angle (°) | 90 | 90 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gujba, A.K.; Hackel, L.; Medraj, M. Water Droplet Erosion Performance of Laser Shock Peened Ti-6Al-4V. Metals 2016, 6, 262. https://doi.org/10.3390/met6110262

Gujba AK, Hackel L, Medraj M. Water Droplet Erosion Performance of Laser Shock Peened Ti-6Al-4V. Metals. 2016; 6(11):262. https://doi.org/10.3390/met6110262

Chicago/Turabian StyleGujba, Abdullahi K., Lloyd Hackel, and Mamoun Medraj. 2016. "Water Droplet Erosion Performance of Laser Shock Peened Ti-6Al-4V" Metals 6, no. 11: 262. https://doi.org/10.3390/met6110262

APA StyleGujba, A. K., Hackel, L., & Medraj, M. (2016). Water Droplet Erosion Performance of Laser Shock Peened Ti-6Al-4V. Metals, 6(11), 262. https://doi.org/10.3390/met6110262