Microstructure and Mechanical Properties of Friction Welding Joints with Dissimilar Titanium Alloys

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

3.1. Macro and Microstructure

3.2. Compositional Analysis

3.3. Microhardness

3.4. Tensile Properties

3.5. Impact Toughness

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Mvola, B.; Kah, P.; Martikainen, J. Dissimilar ferrous metal welding using advanced gas metal arc welding processes. Rev. Adv. Mater. Sci. 2014, 38, 125–137. [Google Scholar]

- Martinsen, K.; Hu, S.J.; Carlson, B.E. Joining of dissimilar materials. CIRP Ann.-Manuf. Technol. 2015, 64, 526–533. [Google Scholar] [CrossRef]

- Chen, Y.C.; Nakata, K. Microstructural characterization and mechanical properties in friction stir welding of aluminum and titanium dissimilar alloys. Mater. Des. 2009, 30, 469–474. [Google Scholar] [CrossRef]

- Zhang, C.Q.; Robson, J.D.; Prangnell, P.B. Dissimilar ultrasonic spot welding of aerospace aluminum alloy AA2139 to titanium alloy TiAl6V4. J. Mater. Process. Technol. 2016, 231, 382–388. [Google Scholar] [CrossRef]

- Tao, B.H.; Li, Q.; Zhang, Y.H.; Zhang, T.C.; Liu, Y. Effects of post-weld heat treatment on fracture toughness of linear friction welded joint for dissimilar titanium alloys. Mater. Sci. Eng. A 2015, 634, 141–146. [Google Scholar] [CrossRef]

- Zhao, P.; Fu, L.; Chen, H. Low cycle fatigue properties of linear friction welded joint of TC11 and TC17 titanium alloys. J. Alloy. Compd. 2016, 675, 248–256. [Google Scholar] [CrossRef]

- Xu, C.; Sheng, G.; Wang, H.; Feng, K.; Yuan, X. Tungsten Inert Gas Welding-Brazing of AZ31B Magnesium Alloy to TC4 Titanium alloy. J. Mater. Process. Technol. 2016, 32, 167–171. [Google Scholar] [CrossRef]

- Wang, S.Q.; Li, W.Y.; Zhou, Y.; Li, X.; Chen, D.L. Tensile and fatigue behavior of electron beam welded dissimilar joints of Ti-6Al-4V and IMI834 titanium alloys. Mater. Sci. Eng. A 2016, 649, 146–152. [Google Scholar] [CrossRef]

- Vairis, A.; Frost, M. High frequency linear friction welding of a titanium alloy. Wear 1998, 217, 117–131. [Google Scholar] [CrossRef]

- Guo, Y.; Chiu, Y.; Attallah, M.M.; Li, H.; Bray, S.; Bowen, P. Characterization of Dissimilar Linear Friction Welds of α-β Titanium Alloys. J. Mater. Eng. Perform. 2012, 21, 770–776. [Google Scholar] [CrossRef]

- Wanjara, P.; Jahazi, M. Linear friction welding of Ti-6Al-4V: Processing, microstructure, and mechanical-property inter-relationships. Metall. Mater. Trans. A 2005, 36, 2148–2164. [Google Scholar] [CrossRef]

- Li, W.Y.; Ma, T.J.; Yang, S.Q. Microstructure evolution and mechanical properties of linear friction welded Ti-5Al-2Sn-2Zr-4Mo-4Cr (Ti17) titanium alloy joints. Adv. Eng. Mater. 2010, 12, 35–43. [Google Scholar] [CrossRef]

- Ma, T.; Yan, M.; Yang, X.; Li, W.; Chao, Y.J. Microstructure evolution in a single crystal nickel-based superalloy joint by linear friction welding. Mater. Des. 2015, 85, 613–617. [Google Scholar] [CrossRef]

- Chamanfar, A.; Jahazi, M.; Gholipour, J.; Wanjara, P.; Yue, S. Analysis of integrity and microstructure of linear friction welded Waspaloy. Mater. Charact. 2015, 104, 148–161. [Google Scholar] [CrossRef]

- Astarita, A.; Curioni, M.; Squillace, A.; Zhou, X.; Bellucci, F.; Thompson, G.E.; Beamish, K.A. Corrosion behaviour of stainless steel-titanium alloy linear friction welded joints: Galvanic coupling. Mater. Corros. 2015, 66, 111–117. [Google Scholar] [CrossRef]

- Grujicic, M.; Yavari, R.; Snipes, J.S.; Ramaswami, S. A linear friction welding process model for Carpenter Custom 465 precipitation-hardened martensitic stainless steel: A weld microstructure-evolution analysis. J. Eng. Manuf. 2015, 228, 1887–2020. [Google Scholar] [CrossRef]

- Rotundo, F.; Marconi, A.; Morri, A.; Ceschini, A. Dissimilar linear friction welding between a SiC particle reinforced aluminum composite and a monolithic aluminum alloy: Microstructural, tensile and fatigue properties. Mater. Sci. Eng. A 2013, 558, 852–860. [Google Scholar] [CrossRef]

- Bhamji, I.; Moat, R.J.; Preuss, M.; Threadgill, P.L.; Addison, A.C. Linear friction welding of aluminium to copper. Sci. Technol. Weld. Join. 2012, 17, 314–320. [Google Scholar] [CrossRef]

- Bhamji, I.; Preuss, M.; Moat, R.J.; Threadgill, P.L.; Addison, A.C. Linear friction welding of aluminium to magnesium. Sci. Technol. Weld. Join. 2012, 17, 368–374. [Google Scholar] [CrossRef]

- Ma, T.J.; Zhong, B.; Li, W.-Y.; Zhang, Y.; Yang, S.Q.; Yang, C.L. On microstructure and mechanical properties of linear friction welded dissimilar Ti-6Al-4V and Ti-6.5Al-3.5Mo-1.5Zr-0.3Si joint. Sci. Technol. Weld. Join. 2012, 17, 9–12. [Google Scholar] [CrossRef]

- Wen, G.D.; Ma, T.J.; Li, W.Y.; Wang, S.Q.; Guo, H.Z.; Chen, D.L. Strain-controlled fatigue properties of linear friction welded dissimilar joints between Ti-6Al-4V and Ti-6.5Al-3.5Mo-1.5Zr-0.3Si alloys. Mater. Sci. Eng. A 2014, 612, 80–88. [Google Scholar] [CrossRef]

- Zhao, P.; Fu, L. Strain hardening behavior of linear friction welded joints between TC11 and TC17 dissimilar titanium alloys. Mater. Sci. Eng. A 2015, 621, 149–156. [Google Scholar] [CrossRef]

- Frankel, P.; Preuss, M.; Steuwer, A.; Withers, P.J.; Bray, S. Comparison of residual stresses in Ti-6Al-4V and Ti-6Al-2Sn-4Zr-2Mo linear friction welds. Mater. Sci. Technol. 2009, 25, 640–650. [Google Scholar] [CrossRef]

- Karadge, M.; Preuss, M.; Lovell, C.; Withers, P.J.; Bray, S. Texture development in Ti-6Al-4V linear friction welds. Mater. Sci. Eng. A 2007, 458, 182–181. [Google Scholar] [CrossRef]

- Lang, B.; Zhang, T.C.; Li, X.H.; Guo, D.L. Microstructural evolution of a TC11 titanium alloy during linear friction welding. J. Mater. Sci. 2010, 45, 6218–6224. [Google Scholar] [CrossRef]

- Romero, J.; Attallah, M.M.; Preuss, M.; Karadge, M.; Bray, S.E. Effect of the forging pressure on the microstructure and residual stress development in Ti-6Al-4V linear friction welds. Acta Mater. 2008, 57, 5582–5592. [Google Scholar] [CrossRef]

- Corzo, V.; Casals, O.; Alcalá, J.; Mateo, A.; Anglada, M. Mechanical evaluation of linear friction welds in titanium alloys through indentation experiments. Weld. Int. 2007, 21, 125–128. [Google Scholar] [CrossRef]

- Schroeder, F.; Ward, R.M.; Turner, R.P.; Walpole, A.R.; Attallah, M.M.; Gebelin, J.-C.; Reed, R.C. Validation of a Model of Linear Friction Welding of Ti6Al4V by Considering Welds of Different Sizes. Metall. Mater. Trans. B 2015, 46, 2326–2331. [Google Scholar] [CrossRef]

- Turner, R.; Gebelin, J.-C.; Ward, R.M.; Reed, R.C. Linear friction welding of Ti-6Al-4V: Modelling and validation. Acta Mater. 2011, 59, 3792–3803. [Google Scholar] [CrossRef]

- McAndrew, A.R.; Colegrove, P.A.; Addison, A.C.; Flipo, B.C.D.; Russell, M.J. Modelling the influence of the process inputs on the removal of surface contaminants from Ti-6Al-4V linear friction welds. Mater. Des. 2015, 66, 183–195. [Google Scholar] [CrossRef] [Green Version]

- Grujicic, M.; Arakere, G.; Pandurangan, B.; Yen, C.-F.; Cheeseman, B.A. Process Modeling of Ti-6Al-4V Linear Friction Welding (LFW). J. Mater. Eng. Perform. 2012, 21, 2011–2023. [Google Scholar] [CrossRef]

- Ma, T.; Chen, T.; Li, W.-Y.; Wang, S.; Yang, S. Formation mechanism of linear friction welded Ti-6Al-4V alloy joint based on microstructure observation. Mater. Charact. 2011, 62, 130–135. [Google Scholar] [CrossRef]

- Ji, Y.; Chai, Z.; Zhao, D.; Wu, S. Linear friction welding of Ti-5Al-2Sn-2Zr-4Mo-4Cr alloy with dissimilar microstructure. J. Mater. Process. Technol. 2014, 214, 878–887. [Google Scholar] [CrossRef]

- Zhao, P.K.; Fu, L.; Zhong, D.C. Numerical simulation of transient temperature and axial deformation during linear friction welding between TC11 and TC17 titanium alloys. Comput. Mater. Sci. 2014, 82, 325–333. [Google Scholar] [CrossRef]

- Ma, T.J.; Li, W.-Y.; Yang, S.Y. Impact toughness and fracture analysis of linear friction welded Ti-6Al-4V alloy joints. Mater. Des. 2008, 30, 2128–2132. [Google Scholar] [CrossRef]

- Ji, Y.; Wu, S. Study on microstructure and mechanical behavior of dissimilar Ti17 friction welds. Mater. Sci. Eng. A 2014, 586, 32–40. [Google Scholar] [CrossRef]

| Alloy | Al | V | Sn | Zr | Mo | Cr | Fe | Si | C | N | H | O | Ti |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Ti64 | 6.06 | 3.93 | - | - | - | - | 0.103 | 0.15 | 0.106 | 0.033 | 0.015 | 0.13 | Balance |

| Ti17 | 5.05 | - | 2.13 | 2.07 | 4.12 | 4.13 | 0.30 | - | 0.05 | 0.05 | 0.013 | 0.08 | Balance |

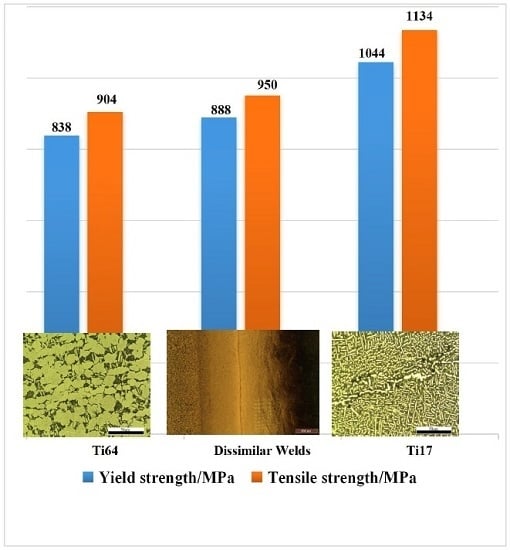

| Specimen | UTS/MPa | YS/MPa | Elongation δ% |

|---|---|---|---|

| Ti64 | 904 | 838 | 14.6 |

| Ti64/Ti17 Joints | 950 | 888 | 11.9 |

| Ti17 | 1134 | 1044 | 10.6 |

| Sample | Ti64 | WZ | Ti17 |

|---|---|---|---|

| ak (J/cm2) | 44.5 | 38.7 | 53.6 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ji, Y.; Wu, S.; Zhao, D. Microstructure and Mechanical Properties of Friction Welding Joints with Dissimilar Titanium Alloys. Metals 2016, 6, 108. https://doi.org/10.3390/met6050108

Ji Y, Wu S, Zhao D. Microstructure and Mechanical Properties of Friction Welding Joints with Dissimilar Titanium Alloys. Metals. 2016; 6(5):108. https://doi.org/10.3390/met6050108

Chicago/Turabian StyleJi, Yingping, Sujun Wu, and Dalong Zhao. 2016. "Microstructure and Mechanical Properties of Friction Welding Joints with Dissimilar Titanium Alloys" Metals 6, no. 5: 108. https://doi.org/10.3390/met6050108

APA StyleJi, Y., Wu, S., & Zhao, D. (2016). Microstructure and Mechanical Properties of Friction Welding Joints with Dissimilar Titanium Alloys. Metals, 6(5), 108. https://doi.org/10.3390/met6050108