Constitutive Model Based on Dynamic Recrystallization Behavior during Thermal Deformation of a Nickel-Based Superalloy

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

3.1. Thermal Deformation Behavior

3.2. Arrhenius Constitutive Model

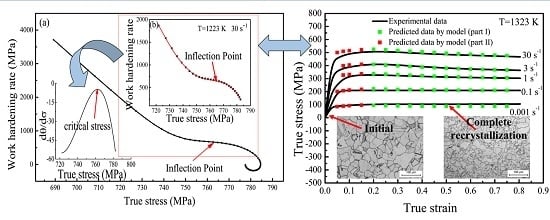

3.3. Determination of the Critical Strain

3.4. Constitutive Model of Flow Stress

3.4.1. Part I. Constitutive Model Based on Work Hardening and Dynamic Recovery

3.4.2. Part II. Constitutive Model Based on Dynamic Recrystallization

3.4.3. Verification of the Developed Constitutive Model

4. Conclusions

- (1)

- The flow stress of the nickel-based superalloy is significantly sensitive to the deformation temperature and strain rate under all experimental conditions. The flow stress decreases with the increase of temperature and the decrease of strain rate. In addition, DRX occurs more easily under higher deformation temperature and lower strain rate in the process of thermal deformation.

- (2)

- Critical strain of DRX is indispensable data to calculate the recrystallization volume fraction. The stress value of the inflection point is the critical stress. Based on the conventional work-hardening rate curves, the critical strain model can be determined by analyzing the θ~σ curve. There is a good linear relationship between peak strain and critical strain. This method for determining the critical strain is also more conducive to the establishment of a flow stress constitutive model.

- (3)

- Based on the dislocation density theory and kinetics of DRX, the constitutive model of flow behavior for the nickel-based superalloy can be divided into two parts: Part I. The constitutive model based on work hardening and dynamic recovery. Part II. The constitutive model based on DRX. Comparisons between the predicted and experimental flow stress under different deformation conditions indicate that the developed constitutive model has very good prediction capability.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Pollock, T.M.; Tin, S. Nickel-based superalloys for advanced turbine engines: Chemistry, microstructure and properties. J. Propuls. Power 2006, 22, 361–374. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, Y.W.; Zhang, N.; Jia, J. Heat treatment processes and microstructure and properties research on P/M superalloy FGH97. J. Aeronaut. Mater. 2008, 28, 5–9. [Google Scholar]

- Zhang, M.J.; Li, F.G.; Wang, S.Y.; Liu, C.Y. Characterization of hot deformation behavior of a P/M nickel-base superalloy using processing map and activation energy. Mater. Sci. Eng. A 2010, 527, 6771–6779. [Google Scholar]

- Lee, H.W.; Im, Y.T. Numerical modeling of dynamic recrystallization during nonisothermal hot compression by cellular automata and finite element analysis. Int. J. Mech. Sci. 2010, 52, 1277–1289. [Google Scholar]

- El Mehtedi, M.; Gabrielli, F.; Spigarelli, S. Hot workability in process modeling of a bearing steel by using combined constitutive equations and dynamic material model. Mater. Des. 2014, 53, 398–404. [Google Scholar] [CrossRef]

- Arisoy, Y.M.; Guo, C.; Kaftanoglu, B.; Özel, T. Investigations on Microstructural Changes in Machining of Inconel 100 alloy using Face Turning Experiments and 3D Finite Element Simulations. Int. J. Mech. Sci. 2016, 107, 80–92. [Google Scholar] [CrossRef]

- Wang, K.L.; Fu, M.W.; Lu, S.Q.; Li, X. Study of the dynamic recrystallization of Ti-6.5Al-3.5Mo-1.5Zr-0.3Si alloy in β-forging process via Finite Element Method modeling and microstructure characterization. Mater. Des. 2011, 32, 1283–1291. [Google Scholar] [CrossRef]

- Laasraoui, A.; Jonas, J.J. Prediction of steel flow stresses at high temperatures and strain rates. Metall. Trans. A 1991, 22, 1545–1558. [Google Scholar] [CrossRef]

- Lin, Y.C.; Chen, X.M.; Liu, G. A modified Johnson-Cook model for tensile behaviors of typical high-strength alloy steel. Mater. Sci. Eng. A 2010, 527, 6980–6986. [Google Scholar] [CrossRef]

- Lin, Y.C.; Xia, Y.C.; Chen, X.M.; Chen, M.S. Constitutive descriptions for hot compressed 2124-T851 aluminum alloy over a wide range of temperature and strain rate. Comput. Mater. Sci. 2010, 50, 227–233. [Google Scholar] [CrossRef]

- Watanabe, H.; Mukai, T.; Higashi, K. Deformation mechanism of fine-grained superplasticity in metallic materials expected from the phenomenological constitutive equation. Mater. Trans. 2004, 45, 2497–2502. [Google Scholar] [CrossRef]

- Wang, L.; Liu, F.; Zuo, Q.; Chen, C.F. Prediction of flow stress for N08028 alloy under hot working conditions. Mater. Des. 2013, 47, 737–745. [Google Scholar] [CrossRef]

- He, A.; Xie, G.L.; Yang, X.Y.; Wang, X.T.; Zhang, H.L. A physically-based constitutive model for a nitrogen alloyed ultralow carbon stainless steel. Comput. Mater. Sci. 2015, 98, 64–69. [Google Scholar] [CrossRef]

- Lin, Y.C.; Chen, X.M.; Wen, D.X.; Chen, M.S. A physically-based constitutive model for a typical nickel-based superalloy. Comput. Mater. Sci. 2014, 83, 282–289. [Google Scholar] [CrossRef]

- Sun, Z.C.; Liu, L.; Yang, H. Microstructure evolution of different loading zones during TA15 alloy multi-cycle isothermal local forging. Mater. Sci. Eng. A 2011, 528, 5112–5121. [Google Scholar] [CrossRef]

- Mandal, S.; Bhaduri, A.K.; Sarma, V.S. A study on microstructural evolution and dynamic recrystallization during isothermal deformation of a Ti-modified austenitic stainless steel. Metall. Mater. Trans. A 2011, 42, 1062–1072. [Google Scholar] [CrossRef]

- Zhang, D.X.; Yang, X.Y.; Sun, H.; Li, Y.; Wang, J.; Zhang, Z.R.; Ye, Y.X.; Sakai, T. Dynamic recrystallization behaviors and the resultant mechanical properties of a Mg-Y-Nd-Zr alloy during hot compression after aging. Mater. Sci. Eng. A 2015, 640, 51–60. [Google Scholar] [CrossRef]

- Agnoli, A.; Bernacki, M.; Logé, R.; Franchet, J.M.; Laigo, J.; Bozzolo, N. Selective Growth of Low Stored Energy Grains During δ Sub-solvus Annealing in the Inconel 718 Nickel-Based Superalloy. Met. Mater. Trans. A 2015, 46, 4405–4421. [Google Scholar] [CrossRef] [Green Version]

- Liang, H.Q.; Guo, H.Z.; Ning, Y.Q.; Peng, X.N.; Shi, Z.F.; Nan, Y. Dynamic recrystallization behavior of Ti-5Al-5Mo-5V-1Cr-1Fe alloy. Mater. Des. 2014, 63, 798–804. [Google Scholar] [CrossRef]

- Xu, Y.; Hu, L.X.; Sun, Y. Dynamic recrystallization kinetics of as-cast AZ91D alloy. Trans. Nonferrous Met. Soc. China 2014, 24, 1683–1689. [Google Scholar] [CrossRef]

- Fang, B.; Ji, Z.; Liu, M.; Tian, G.F.; Jia, C.C.; Zeng, T.T.; Hu, B.F.; Chang, Y.H. Critical strain and models of dynamic recrystallization for FGH96 superalloy during two-pass hot deformation. Mater. Sci. Eng. A 2014, 593, 8–15. [Google Scholar] [CrossRef]

- Chen, X.M.; Lin, Y.C.; Wen, D.X.; Zhang, J.L.; He, M. Dynamic recrystallization behavior of a typical nickel-based superalloy during hot deformation. Mater. Des. 2014, 57, 568–577. [Google Scholar] [CrossRef]

- Shamsolhodaei, A.; Zarei-Hanzaki, A.; Ghambari, M.; Moeneni, S. The high temperature flow behavior modeling of NiTi shape memory alloy employing phenomenological and physical based constitutive models: A comparative study. Intermetallics 2014, 53, 140–149. [Google Scholar] [CrossRef]

- Gottstein, G.; Frommert, M.; Goerdeler, M.; Schafer, N. Prediction of the critical conditions for dynamic recrystallization in the austenitic steel 800H. Mater. Sci. Eng. A 2004, 387, 604–608. [Google Scholar] [CrossRef]

- Gottstein, G.; Brünger, E.; Frommert, M.; Goerdeler, M.; Zeng, M. Prediction of the critical conditions for dynamic recrystallization in metals: Dedicated to Professor Dr. Ottmar Vöhringer on occasion of his 65th birthday. Z. Metallkunde 2003, 94, 628–635. [Google Scholar] [CrossRef]

- Mirzadeh, H.; Najafizadeh, A. Prediction of the critical conditions for initiation of dynamic recrystallization. Mater. Des. 2010, 31, 1174–1179. [Google Scholar] [CrossRef]

- Zhang, P.; Hu, C.; Ding, C.; Zhu, Q.; Qin, H.Y. Plastic deformation behavior and processing maps of a Ni-based superalloy. Mater. Des. 2015, 65, 575–584. [Google Scholar] [CrossRef]

- Wu, K.; Liu, G.Q.; Hu, B.F.; Wang, C.Y.; Zhang, Y.W.; Tao, Y.; Liu, J.T. Effect of processing parameters on hot compressive deformation behavior of a new Ni-Cr-Co based P/M superalloy. Mater. Sci. Eng. A 2011, 528, 4620–4629. [Google Scholar] [CrossRef]

- Sellars, C.M.; McTegart, W.J. On the mechanism of hot deformation. Acta Metall. 1966, 14, 1136–1138. [Google Scholar] [CrossRef]

- Jonas, J.J.; Sellars, C.M.; Tegart, W.M. Strength and structure under hot-working conditions. Metall. Rev. 1969, 14, 1–24. [Google Scholar] [CrossRef]

- Quan, G.Z.; Mao, A.; Luo, G.C.; Liang, J.T.; Wu, D.S.; Zhou, J. Constitutive modeling for the dynamic recrystallization kinetics of as-extruded 3Cr20Ni10W2 heat-resistant alloy based on stress-strain data. Mater. Des. 2013, 52, 98–107. [Google Scholar] [CrossRef]

- Yu, Q.Y.; Yao, Z.H.; Dong, J.X. Deformation and recrystallization behavior of a coarse-grain, nickel-base superalloy Udimet720Li ingot material. Mater. Charact. 2015, 107, 398–410. [Google Scholar] [CrossRef]

- Li, H.Y.; Li, Y.H.; Wang, X.F.; Liu, J.J.; Wu, Y. A comparative study on modified Johnson Cook, modified Zerilli-Armstrong and Arrhenius-type constitutive models to predict the hot deformation behavior in 28CrMnMoV steel. Mater. Des. 2013, 49, 493–501. [Google Scholar] [CrossRef]

- Lin, Y.C.; He, M.; Zhou, M.; Wen, D.X.; Chen, J. New constitutive model for hot deformation behaviors of Ni-based superalloy considering the effects of initial δ phase. J. Mater. Eng. Perform. 2015, 24, 3527–3538. [Google Scholar] [CrossRef]

- Lv, B.J.; Peng, J.; Shi, D.W.; Tang, A.T.; Pan, F.S. Constitutive modeling of dynamic recrystallization kinetics and processing maps of Mg-2.0Zn-0.3Zr alloy based on true stress-strain curves. Mater. Sci. Eng. A 2013, 560, 727–733. [Google Scholar] [CrossRef]

- Galindo-Nava, E.I.; Rae, C.M.F. Microstructure evolution during dynamic recrystallisation in polycrystalline nickel superalloys. Mater. Sci. Eng. A 2015, 636, 434–445. [Google Scholar] [CrossRef]

- Galindo-Nava, E.I.; Rivera-Díaz-del-Castillo, P.E.J. Grain size evolution during discontinuous dynamic recrystallization. Scr. Mater. 2014, 72, 1–4. [Google Scholar] [CrossRef]

- Lin, Y.C.; Chen, M.S.; Zhong, J. Prediction of 42CrMo steel flow stress at high temperature and strain rate. Mech. Res. Commun. 2008, 35, 142–150. [Google Scholar] [CrossRef]

- Poliak, E.I.; Jonas, J.J. Initiation of dynamic recrystallization in constant strain rate hot deformation. ISIJ Int. 2003, 43, 684–691. [Google Scholar] [CrossRef]

- Kim, S.I.; Lee, Y.; Lee, D.L.; Yoo, Y.C. Modeling of AGS and recrystallized fraction of microalloyed medium carbon steel during hot deformation. Mater. Sci. Eng. A 2003, 355, 384–393. [Google Scholar] [CrossRef]

- Liu, J.; Cui, Z.; Ruan, L. A new kinetics model of dynamic recrystallization for magnesium alloy AZ31B. Mater. Sci. Eng. A 2011, 529, 300–310. [Google Scholar] [CrossRef]

- Xu, T.C.; Peng, X.D.; Qin, J.; Chen, Y.F.; Yang, Y.; Wei, G.B. Dynamic recrystallization behavior of Mg-Li-Al-Nd duplex alloy during hot compression. J. Alloy. Compd. 2015, 639, 79–88. [Google Scholar] [CrossRef]

- Lin, Y.C.; Chen, X.M. A critical review of experimental results and constitutive descriptions for metals and alloys in hot working. Mater. Des. 2011, 32, 1733–1759. [Google Scholar] [CrossRef]

- Honeycombe, R.W.K. Steels-Microstructure and Properties; Edward Arnold Ltd.: London, UK, 1981. [Google Scholar]

| Element | Cr | C | Mo | Al | Ti | Nb | Fe | Ni |

|---|---|---|---|---|---|---|---|---|

| Content (wt. %) | 14.50 | 0.042 | 3.18 | 1.70 | 2.68 | 2.02 | <0.2 | Bal. |

| Constant | n1 | β (MPa−1) | α (MPa−1) | A (s−1) | n | Q (kJ/mol) |

|---|---|---|---|---|---|---|

| Value | 6.691416 | 0.026792 | 0.003849 | 2.764 × 1024 | 4.672582 | 646.341 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, P.; Yi, C.; Chen, G.; Qin, H.; Wang, C. Constitutive Model Based on Dynamic Recrystallization Behavior during Thermal Deformation of a Nickel-Based Superalloy. Metals 2016, 6, 161. https://doi.org/10.3390/met6070161

Zhang P, Yi C, Chen G, Qin H, Wang C. Constitutive Model Based on Dynamic Recrystallization Behavior during Thermal Deformation of a Nickel-Based Superalloy. Metals. 2016; 6(7):161. https://doi.org/10.3390/met6070161

Chicago/Turabian StyleZhang, Peng, Cen Yi, Gang Chen, Heyong Qin, and Chuanjie Wang. 2016. "Constitutive Model Based on Dynamic Recrystallization Behavior during Thermal Deformation of a Nickel-Based Superalloy" Metals 6, no. 7: 161. https://doi.org/10.3390/met6070161

APA StyleZhang, P., Yi, C., Chen, G., Qin, H., & Wang, C. (2016). Constitutive Model Based on Dynamic Recrystallization Behavior during Thermal Deformation of a Nickel-Based Superalloy. Metals, 6(7), 161. https://doi.org/10.3390/met6070161