Enhanced Age Strengthening of Mg-Nd-Zn-Zr Alloy via Pre-Stretching

Abstract

:1. Introduction

2. Experimental Section

3. Results

3.1. Microstructures

3.2. Mechanical Properties

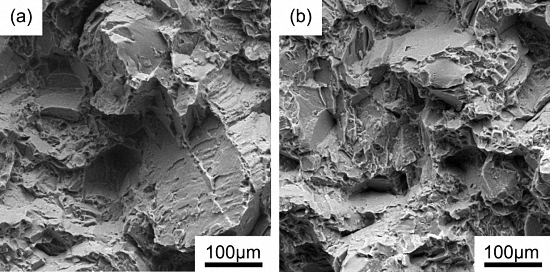

3.3. Fractography

4. Discussion

4.1. Effect of Pre-Stretching on the Precipitation Evolution

4.2. Effect of Pre-Stretching on the Mechanical Properties

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Sravya, T.; Sankaranarayanan, S.; Abdulhakim, A. Mechanical properties of magnesium-rare earth alloy systems: A review. Metals 2015, 5, 1–39. [Google Scholar]

- Ahmad, M.; Mamoun, M. Experimental investigation of the Mg-Nd-Zn isothermal section at 300 °C. Metals 2015, 5, 84–101. [Google Scholar]

- Li, R.; Xin, R.; Chapuis, A.; Liu, Q.; Fu, G.; Zong, L.; Yu, Y.; Guo, B.; Guo, S. Effect of cold rolling on microstructure and mechanical property of extruded Mg-4Sm alloy during aging. Mater. Charact. 2016, 112, 81–86. [Google Scholar] [CrossRef]

- Peng, Q.; Dong, H.; Wang, L.; Wu, Y.; Wang, L. Aging behavior and mechanical properties of Mg-Gd-Ho alloys. Mater. Charact. 2008, 59, 983–986. [Google Scholar] [CrossRef]

- Ma, L.; Mishra, R.K.; Balogh, M.P.; Peng, L.; Luo, A.A.; Sachdev, A.K.; Ding, W. Effect of Zn on the microstructure evolution of extruded Mg-3Nd (-Zn)-Zr (wt. %) alloys. Mater. Sci. Eng. A 2012, 543, 12–21. [Google Scholar] [CrossRef]

- Sanaty-Zadeh, A.; Luo, A.A.; Stone, D.S. Comprehensive study of phase transformation in age-hardening of Mg-3Nd-0.2Zn by means of scanning transmission electron microscopy. Acta Mater. 2015, 94, 294–306. [Google Scholar] [CrossRef]

- Sanaty-Zadeh, A.; Xia, X.; Luo, A.A.; Stone, D.S. Precipitation evolution and kinetics in a magnesium-neodymium-zinc alloy. J. Alloy. Compd. 2014, 583, 434–440. [Google Scholar] [CrossRef]

- Paliwal, M.; Das, S.K.; Kim, J.; Jung, I.H. Diffusion of Nd in hcp Mg and interdiffusion coefficients in Mg-Nd system. Scr. Mater. 2015, 108, 11–14. [Google Scholar] [CrossRef]

- Geng, J.; Gao, X.; Fang, X.Y.; Nie, J.F. Enhanced age-hardening response of Mg-Zn alloys via Co additions. Scr. Mater. 2011, 64, 506–509. [Google Scholar] [CrossRef]

- Buha, J. The effect of micro-alloying addition of Cr on age hardening of an Mg-Zn alloy. Mater. Sci. Eng. A 2008, 492, 293–299. [Google Scholar] [CrossRef]

- Elsayed, F.R.; Sasaki, T.T.; Mendis, C.L.; Ohkubo, T.; Hono, K. Significant enhancement of the age-hardening response in Mg-10Sn-3Al-1Zn alloy by Na microalloying. Scr. Mater. 2013, 68, 797–800. [Google Scholar] [CrossRef]

- Gazizov, M.; Kaibyshev, R. Effect of pre-straining on the aging behavior and mechanical properties of an Al-Cu-Mg-Ag alloy. Mater. Sci. Eng. A 2015, 625, 119–130. [Google Scholar] [CrossRef]

- Ozaki, J.; Yosida, M.; Horibe, S. The effect of pre-compressive strain on the fatigue life of the AZ31 magnesium alloy. Mater. Sci. Eng. A 2014, 604, 192–195. [Google Scholar] [CrossRef]

- Pike, T.J.; Noble, B. The formation and structure of precipitates in a dilute magnesium-neodymium alloy. Less. Common Met. 1973, 30, 63–74. [Google Scholar] [CrossRef]

- Wang, Y.; Choo, H. Influence of texture on Hall-Petch relationships in an Mg alloy. Acta Mater. 2014, 81, 83–97. [Google Scholar] [CrossRef]

- Gao, X.; Muddle, B.C.; Nie, J.F. Transmission electron microscopy of Zr-Zn precipitate rods in magnesium alloys containing Zr and Zn. Philos. Mag. Lett. 2009, 89, 33–43. [Google Scholar] [CrossRef]

- Capolungo, L. Dislocation junction formation and strength in magnesium. Acta Mater. 2011, 59, 2909–2917. [Google Scholar] [CrossRef]

- Zheng, K.Y.; Dong, J.; Zeng, X.Q.; Ding, W.J. Effect of pre-deformation on aging characteristics and mechanical properties of a Mg-Gd-Nd-Zr alloy. Mater. Sci. Eng. A 2008, 491, 103–109. [Google Scholar] [CrossRef]

- Zhang, Z.; Chen, D. Consideration of Orowan strengthening effect in particulate-reinforced metal matrix nanocomposites: A model for predicting their yield strength. Scr. Mater. 2006, 54, 1321–1326. [Google Scholar] [CrossRef]

- Shi, G.L.; Zhang, D.F.; Zhang, H.J.; Zhao, X.B.; Qi, F.G.; Zhang, K. Influence of pre-deformation on age-hardening response and mechanical properties of extruded Mg-6%Zn-1%Mn alloy. Trans. Nonferr. Met. Soc. China. 2013, 23, 586–592. [Google Scholar] [CrossRef]

- Robson, J.D.; Paa-Rai, C. The interaction of grain refinement and ageing in magnesium-zinc-zirconium (ZK) alloys. Acta Mater. 2015, 95, 10–19. [Google Scholar] [CrossRef]

- Karnesky, R.A.; Meng, L.; Dunand, D.C. Strengthening mechanisms in aluminum containing coherent Al3Sc precipitates and incoherent Al2O3 dispersoids. Acta Mater. 2007, 55, 1299–1308. [Google Scholar] [CrossRef]

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guo, E.; Zhao, S.; Wang, L.; Wu, T. Enhanced Age Strengthening of Mg-Nd-Zn-Zr Alloy via Pre-Stretching. Metals 2016, 6, 196. https://doi.org/10.3390/met6090196

Guo E, Zhao S, Wang L, Wu T. Enhanced Age Strengthening of Mg-Nd-Zn-Zr Alloy via Pre-Stretching. Metals. 2016; 6(9):196. https://doi.org/10.3390/met6090196

Chicago/Turabian StyleGuo, Erjun, Sicong Zhao, Liping Wang, and Tong Wu. 2016. "Enhanced Age Strengthening of Mg-Nd-Zn-Zr Alloy via Pre-Stretching" Metals 6, no. 9: 196. https://doi.org/10.3390/met6090196

APA StyleGuo, E., Zhao, S., Wang, L., & Wu, T. (2016). Enhanced Age Strengthening of Mg-Nd-Zn-Zr Alloy via Pre-Stretching. Metals, 6(9), 196. https://doi.org/10.3390/met6090196