Preparation, Microstructure Evolutions, and Mechanical Property of an Ultra-Fine Grained Mg-10Gd-4Y-1.5Zn-0.5Zr Alloy

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussions

3.1. Microstructure of As-Cast Alloy

3.2. Microstructure of ECAP (Equal Channel Angular Pressing) Alloy

3.3. Mechanical Properties of Cast and ECAP Alloys

4. Conclusions

- (1)

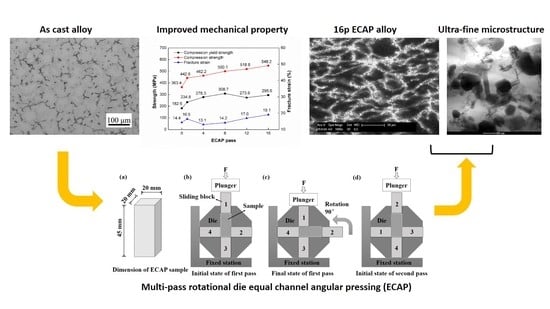

- The microstructure of as-cast Mg-10Gd-4Y-1.5Zn-0.5Zr alloy consists of α-Mg grains, island-like Mg3(Gd,Y,Zn) phases and 14H LPSO lamellas. The 14H lamellas are usually located within α-Mg near the boundaries of Mg3(Gd,Y,Zn) phase.

- (2)

- The Mg3(Gd,Y,Zn) blocks were broken into fine particles (0.5 μm) gradually during multi-pass ECAP. 14H lamellas were bent first, and then transformed into fine particles in submicron range. With ECAP pass number increasing, DRX was activated by fine particles through PSN mechanism. Moreover, nano-scale γ′ phases were dynamically precipitated in 16p-ECAP alloy.

- (3)

- The 16p-ECAP alloy exhibits excellent comprehensive mechanical properties with compression strength of 548.2 MPa and fracture strain of 19.1%. The significant improvement for both strength and toughness could be ascribed to strengthening of the ultra-fine grained DRX α-Mg, refined Mg3(Gd,Y,Zn) and 14H particles, and dynamically precipitated γ′ nanoparticles.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Pan, F.S.; Yang, M.B.; Chen, X.H. A review on casting magnesium alloys: Modification of commercial alloys and development of new alloys. J. Mater. Sci. Technol. 2016, 32, 1211–1221. [Google Scholar] [CrossRef]

- Liu, W.; Zhang, J.S.; Wei, L.Y.; Xu, C.X.; Zong, X.M.; Hao, J.Q. Extensive dynamic recrystallized grains at kink boundary of 14H LPSO phase in extruded Mg92Gd3Zn1Li4 alloy. Mater. Sci. Eng. A 2017, 681, 97–102. [Google Scholar] [CrossRef]

- Liu, H.; Cheng, Z.J.; Yan, K.; Yan, J.L.; Bai, J.; Jiang, J.H.; Ma, A.B. Effect of multi-pass equal channel angular pressing on the microstructure and mechanical properties of a heterogeneous Mg88Y8Zn4 alloy. J. Mater. Sci. Technol. 2016, 32, 1274–1281. [Google Scholar] [CrossRef]

- Xu, D.K.; Han, E.H.; Xu, Y.B. Effect of long-period stacking ordered phase on microstructure, mechanical property and corrosion resistance of Mg alloys: A review. Prog. Nat. Sci. Mater. Int. 2016, 26, 117–128. [Google Scholar] [CrossRef]

- Wang, Y.; Rong, W.; Wu, Y.J.; Peng, L.M.; Chen, J.; Ding, W.J. Effects of Mn addition on the microstructures and mechanical properties of the Mg-15Gd-1Zn alloy. J. Alloys Compd. 2017, 698, 1066–1076. [Google Scholar] [CrossRef]

- Tekumalla, S.; Seetharaman, S.; Almajid, A.; Gupta, M. Mechanical properties of magnesium-rare earth alloy systems: A review. Metals 2015, 5, 1–39. [Google Scholar] [CrossRef]

- Dini, H.; Andersson, N.E.; Jarfors, A.E.W. Effect of Mg17Al12 fraction on mechanical properties of Mg-9%Al-1%Zn cast alloy. Metals 2016, 6, 251. [Google Scholar] [CrossRef]

- Wang, J.F.; Song, P.F.; Huang, S.; Pan, F.S. High-strength and good-ductility Mg-RE-Zn-Mn magnesium alloy with long-period stacking ordered phase. Mater. Lett. 2013, 93, 415–418. [Google Scholar] [CrossRef]

- Zhang, J.S.; Zhang, W.B.; Bian, L.P.; Cheng, W.L.; Niu, X.F.; Xu, C.X.; Wu, S.J. Study of Mg-Gd-Zn-Zr alloys with long period stacking ordered structures. Mater. Sci. Eng. A 2013, 585, 268–276. [Google Scholar] [CrossRef]

- Li, Z.L.; Liu, F.; Yuan, A.P.; Duan, B.Y.; Li, Y.M.; Li, X.W. Effect of rolling deformation on microstructure and texture of spray-deposited magnesium alloy containing Mg-Nd-Zn typed LPSO. J. Mater. Sci. Technol. 2017, 33, 630–636. [Google Scholar] [CrossRef]

- Liu, X.; Zhang, Z.Q.; Hu, W.Y.; Le, Q.C.; Bao, L.; Cui, J.Z. Effects of extrusion speed on the microstructure and mechanical properties of Mg-9Gd-3Y-1.5Zn-0.8Zr alloy. J. Mater. Sci. Technol. 2016, 32, 313–319. [Google Scholar] [CrossRef]

- Itoi, T.; Inazawa, T.; Yamasaki, M.; Kawamura, Y.; Hirohashi, M. Microstructure and mechanical properties of Mg-Zn-Y alloy sheet prepared by hot-rolling. Mater. Sci. Eng. A 2013, 560, 216–223. [Google Scholar] [CrossRef]

- Xu, C.; Nakata, T.; Qiao, X.G.; Zheng, M.Y.; Wu, K.; Kamado, S. Effect of LPSO and SFs on microstructure evolution and mechanical properties of Mg-Gd-Y-Zn-Zr alloy. Sci. Rep. 2017, 7, 40846. [Google Scholar] [CrossRef] [PubMed]

- Sun, W.T.; Xu, C.; Qiao, X.G.; Zheng, M.Y.; Kamado, S.; Gao, N.; Starink, M.J. Evolution of microstructure and mechanical properties of an as-cast Mg-8.2Gd-3.8Y-1.0Zn-0.4Zr alloy processed by high pressure torsion. Mater. Sci. Eng. A 2017, 700, 312–320. [Google Scholar] [CrossRef]

- Jiang, H.S.; Qiao, X.G.; Xu, C.; Zheng, M.Y.; Wu, K.; Kamado, S. Ultrahigh strength as-extruded Mg-10.3Zn-6.4Y-0.4Zr-0.5Ca alloy containing W phase. Mater. Des. 2016, 108, 391–399. [Google Scholar] [CrossRef]

- Yin, D.D.; Wang, Q.D.; Gao, Y.; Chen, C.J.; Zheng, J. Effects of heat treatments on microstructure and mechanical properties of Mg-11Y-5Gd-2Zn-0.5Zr (wt %) alloy. J. Alloys Compd. 2011, 509, 1696–1704. [Google Scholar] [CrossRef]

- Liu, H.; Xue, F.; Bai, J.; Sun, Y.S. Effect of heat treatments on the microstructure and mechanical properties of an extruded Mg95.5Y3Zn1.5 alloy. Mater. Sci. Eng. A 2013, 585, 261–267. [Google Scholar] [CrossRef]

- Hu, J.; Shi, Y.N.; Sauvage, X.; Sha, G.; Lu, K. Grain boundary stability governs hardening and softening in extremely fine nanograined metals. Science 2017, 6331, 1292–1296. [Google Scholar] [CrossRef] [PubMed]

- Lu, K. Stabilizing nanostructures in metals using grain and twin boundary architectures. Nat. Rev. Mater. 2016, 1, 16019. [Google Scholar] [CrossRef]

- Valiev, R.Z.; Longdon, T.G. Principles of equal-channel angular pressing as a processing tool for grain refinement. Prog. Mater. Sci. 2006, 7, 881–981. [Google Scholar] [CrossRef]

- Wei, J.; Huang, G.H.; Yin, D.D.; Li, K.N.; Wang, Q.D.; Zhou, H. Effects of ECAP and annealing treatment on the microstructure and mechanical properties of Mg-1Y (wt %) binary alloy. Metals 2017, 7, 119. [Google Scholar] [CrossRef]

- Lapovok, R.; Gao, X.; Nie, J.F.; Estrin, Y.; Mathaudhu, S.N. Enhancement of properties in cast Mg-Y-Zn rod processed by severe plastic deformation. Mater. Sci. Eng. A 2014, 615, 198–207. [Google Scholar] [CrossRef]

- Chen, B.; Lin, D.L.; Zeng, X.Q.; Lu, C. Microstructure and mechanical properties of ultrafine grained Mg97Y2Zn1 alloy processed by equal channel angular pressing. J. Alloys Compd. 2007, 440, 94–100. [Google Scholar] [CrossRef]

- Wu, J.; Shi, Q.; Ma, H.C.; Chiu, Y.L. Microstructure and mechanical behaviour of a Mg94Zn2Y4 alloy processed by equal channel angular pressing. Mater. Sci. Eng. A 2016, 669, 417–427. [Google Scholar] [CrossRef]

- Liu, H.; Ju, J.; Lu, F.M.; Yan, J.L.; Bai, J.; Jiang, J.H.; Ma, A.B. Dynamic precipitation behavior and mechanical property of an Mg94Y4Zn2 alloy prepared by multi-pass successive equal channel angular pressing. Mater. Sci. Eng. A 2017, 682, 255–259. [Google Scholar] [CrossRef]

- Ma, A.B.; Suzuki, K.; Nishida, Y.; Saito, N.; Shigematsu, I.; Takagi, M.; Iwata, H.; Watazu, A.; Imura, T. Impact toughness of an ultrafine-grained Al–11mass%Si alloy processed by rotary-die equal-channel angular pressing. Acta Mater. 2005, 53, 211–220. [Google Scholar] [CrossRef]

- Zhu, Y.M.; Morton, A.J.; Nie, J.F. Growth and transformation mechanisms of 18R and 14H in Mg-Y-Zn alloys. Acta Mater. 2012, 60, 6562–6572. [Google Scholar] [CrossRef]

- Luo, Z.P.; Zhang, S.Q. High-resolution electron microscopy on the X-Mg12ZnY phase in a high strength Mg-Zn-Zr-Y magnesium alloy. J. Mater. Sci. Lett. 2000, 19, 813–815. [Google Scholar] [CrossRef]

- Zhang, S.; Yuan, G.Y.; Lu, C.; Ding, W.J. The relationship between (Mg,Zn)3RE phase and 14H-LPSO phase in Mg-Gd-Y-Zn-Zr alloys solidified at different cooling rates. J. Alloys Compd. 2011, 509, 3515–3521. [Google Scholar] [CrossRef]

- Liu, H.; Bai, J.; Yan, K.; Yan, J.L.; Ma, A.B.; Jiang, J.H. Comparative studies on evolution behaviors of 14H LPSO precipitates in as-cast and as-extruded Mg-Y-Zn alloys during annealing at 773 K. Mater. Des. 2016, 93, 9–18. [Google Scholar] [CrossRef]

- Wu, Y.J.; Lin, D.L.; Zeng, X.Q.; Peng, L.M.; Ding, W.J. Formation of a lamellar 14H-type long period stacking ordered structure in an as-cast Mg-Gd-Zn-Zr alloy. J. Mater. Sci. 2009, 44, 1607–1612. [Google Scholar] [CrossRef]

- Suzuki, M.; Kimura, T.; Koike, J.; Maruyama, K. Effects of zinc on creep strength and deformation substructures in Mg-Y alloy. Mater. Sci. Eng. A 2004, 378–389, 706–709. [Google Scholar]

- Liu, H.; Ju, J.; Yang, X.W.; Yan, J.L.; Song, D.; Jiang, J.H.; Ma, A.B. A two-step dynamic recrystallization induced by LPSO phases and its impact on mechanical property of severe plastic deformation processed Mg97Y2Zn1 alloy. J. Alloys Compd. 2017, 704, 509–517. [Google Scholar] [CrossRef]

- Liu, W.; Ma, Y.B.; Zhang, Y.G.; Fan, X.X.; Xu, C.X.; Zhang, J.S. Two dynamic recrystallization processes in a high-performance extruded Mg94.5Y2Gd1Zn2Mn0.5 alloy. Mater. Sci. Eng. A 2017, 690, 132–136. [Google Scholar] [CrossRef]

- Abe, E.; Kawamura, Y.; Hayashi, K.; Inoue, A. Long-period ordered structure in a high-strength nanocrystalline Mg-1 at% Zn-2 at% Y alloy studied by atomic-resolution Z-contrast STEM. Acta Mater. 2002, 50, 3845–3857. [Google Scholar] [CrossRef]

- Hagihara, K.; Yokotani, N.; Umakoshi, Y. Plastic deformation behavior of Mg12YZn with 18R long-period stacking ordered structure. Intermetallics 2010, 18, 267–276. [Google Scholar] [CrossRef]

- Shao, X.H.; Yang, Z.Q.; Ma, X.L. Strengthening and toughening mechanisms in Mg-Zn-Y alloy with a long period stacking ordered structure. Acta Mater. 2010, 58, 4760–4771. [Google Scholar] [CrossRef]

- Xu, C.; Nakata, T.; Qiao, X.G.; Zheng, M.Y.; Wu, K.; Kamado, S. Ageing behavior of extruded Mg-8.2Gd-3.8Y-1.0Zn-0.4Zr (wt %) alloy containing LPSO phase and γ′ precipitates. Sci. Rep. 2017, 7, 43391. [Google Scholar] [CrossRef] [PubMed]

- Rong, W.; Wu, Y.J.; Zhang, Y.; Sun, M.; Chen, J.; Peng, L.M.; Ding, W.J. Characterization and strengthening effects of γ′ precipitates in a high-strength casting Mg-15Gd-1Zn-0.4Zr (wt %) alloy. Mater. Charact. 2017, 126, 1–9. [Google Scholar] [CrossRef]

- Nie, J.F. Precipitation and hardening in magnesium alloys. Metall. Mater. Trans. A 2012, 43, 3891–3939. [Google Scholar] [CrossRef]

- Yu, Z.J.; Huang, Y.D.; Mendis, C.L.; Hort, N.; Meng, J. Microstructural evolution and mechanical properties of Mg-11Gd-4.5Y-1Nd-1.5Zn-0.5Zr alloy prepared via pre-ageing and hot extrusion. Mater. Sci. Eng. A 2015, 624, 23–31. [Google Scholar] [CrossRef]

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, H.; Ju, J.; Bai, J.; Sun, J.; Song, D.; Yan, J.; Jiang, J.; Ma, A. Preparation, Microstructure Evolutions, and Mechanical Property of an Ultra-Fine Grained Mg-10Gd-4Y-1.5Zn-0.5Zr Alloy. Metals 2017, 7, 398. https://doi.org/10.3390/met7100398

Liu H, Ju J, Bai J, Sun J, Song D, Yan J, Jiang J, Ma A. Preparation, Microstructure Evolutions, and Mechanical Property of an Ultra-Fine Grained Mg-10Gd-4Y-1.5Zn-0.5Zr Alloy. Metals. 2017; 7(10):398. https://doi.org/10.3390/met7100398

Chicago/Turabian StyleLiu, Huan, Jia Ju, Jing Bai, Jiapeng Sun, Dan Song, Jingli Yan, Jinghua Jiang, and Aibin Ma. 2017. "Preparation, Microstructure Evolutions, and Mechanical Property of an Ultra-Fine Grained Mg-10Gd-4Y-1.5Zn-0.5Zr Alloy" Metals 7, no. 10: 398. https://doi.org/10.3390/met7100398

APA StyleLiu, H., Ju, J., Bai, J., Sun, J., Song, D., Yan, J., Jiang, J., & Ma, A. (2017). Preparation, Microstructure Evolutions, and Mechanical Property of an Ultra-Fine Grained Mg-10Gd-4Y-1.5Zn-0.5Zr Alloy. Metals, 7(10), 398. https://doi.org/10.3390/met7100398