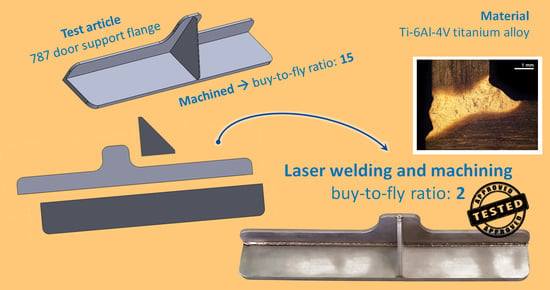

Laser Beam Welding of a Ti–6Al–4V Support Flange for Buy-to-Fly Reduction

Abstract

:1. Introduction

2. Materials and Methods

2.1. Process Set-Up

2.2. The Test-Article

3. Results and Discussion

3.1. Geometry

3.2. Microstructure and Microhardness

3.3. Testing of the Test-Article

3.4. Improving the Buy-to-Fly Ratio

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References and Notes

- Saha, P.K. Aerospace Manufacturing Processes, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2016. [Google Scholar]

- Hong, K.; Shin, Y.C. Prospects of laser welding technology in the automotive industry: A review. J. Mater. Process. Technol. 2017, 245, 46–69. [Google Scholar] [CrossRef]

- Liu, S.; Mi, G.; Yan, F.; Wang, C.; Jiang, P. Correlation of high power laser welding parameters with real weld geometry and microstructure. Opt. Laser Technol. 2017, 94, 59–67. [Google Scholar] [CrossRef]

- Caiazzo, F.; Alfieri, V.; Cardaropoli, F.; Sergi, V. Investigation on edge joints of Inconel 625 sheets processed with laser welding. Opt. Laser Technol. 2017, 93, 180–186. [Google Scholar] [CrossRef]

- Duley, W.W. Laser Welding, 1st ed.; Wiley: New York, NY, USA, 1998. [Google Scholar]

- Steen, W.M.; Mazumder, J. Laser Material Processing; Springer: London, UK, 2010. [Google Scholar]

- Cardaropoli, F.; Alfieri, V.; Caiazzo, F.; Sergi, V. Manufacturing of porous biomaterials for dental implant applications through Selective Laser Melting. Adv. Mater. Res. 2012, 535–537, 1222–1229. [Google Scholar] [CrossRef]

- Cao, X.; Jahazi, M. Effect of welding speed on butt joint quality of Ti–6Al–4V alloy welded using a high-power Nd:YAG laser. Opt. Laser Eng. 2009, 47, 1231–1241. [Google Scholar] [CrossRef]

- Donachie, M.J. Titanium: A Technical Guide, 2nd ed.; ASM International: Materials Park, OH, USA, 2000. [Google Scholar]

- Schneider, A.; Gumenyuk, A.; Lammers, M.; Malletschek, A.; Rethmeier, M. Laser beam welding of thick titanium sheets in the field of marine technology. Phys. Procedia 2014, 56, 582–590. [Google Scholar] [CrossRef]

- Gao, X.; Zhang, L.; Zhang, J. A comparative study of pulsed Nd:YAG laser welding and TIG welding of thin Ti6Al4V titanium alloy plate. Mater. Sci. Eng. A 2013, 559, 14–21. [Google Scholar] [CrossRef]

- Akman, E.; Demir, A.; Canel, T.; Sınmazc, T. Laser welding of Ti6Al4V titanium alloys. J. Mater. Process. Technol. 2009, 209, 3705–3713. [Google Scholar] [CrossRef]

- Caiazzo, F.; Alfieri, V.; Corrado, G.; Cardaropoli, F.; Sergi, V. Investigation and Optimization of Laser Welding of Ti–6Al–4V titanium alloy plates. J. Manuf. Sci. Eng. 2013, 135, 061012. [Google Scholar] [CrossRef]

- Panwisawas, C.; Perumal, B.; Ward, R.M.; Turner, N.; Turner, R.P.; Brooks, J.W.; Basoalto, H.C. Keyhole formation and thermal fluid flow-induced porosity during laser fusion welding in titanium alloys: Experimental and modeling. Acta Mater. 2017, 126, 251–263. [Google Scholar] [CrossRef]

- Li, C.; Li, B.; Wu, Z.; Qi, X.; Ye, B.; Wang, A. Stitch welding of Ti–6Al–4V titanium alloy by fiber laser. Trans. Nonferr. Met. Soc. 2017, 27, 91–101. [Google Scholar] [CrossRef]

- EN ISO 6520-1. Welding and Allied Processes—Classification of Geometric Imperfections in Metallic Materials—Part 1: Fusion Welding; ISO: Geneva, Switzerland, 2005. [Google Scholar]

- Alfieri, V.; Cardaropoli, F.; Caiazzo, F.; Sergi, V. Investigation on porosity content in 2024 aluminum alloy welding by Yb:YAG disk laser. Adv. Mater. Res. 2012, 383–390, 6265–6269. [Google Scholar] [CrossRef]

- Unt, A.; Poutiainen, I.; Salminen, A. Influence of filler wire feed rate in laser-arc hybrid welding of T-butt joint in shipbuilding steel with different optical setups. Phys. Procedia 2015, 78, 45–52. [Google Scholar] [CrossRef]

- Li, C.; Muneharua, K.; Takao, S.; Kouji, H. Fiber laser-GMA hybrid welding of commercially pure titanium. Mater. Des. 2009, 30, 109–114. [Google Scholar] [CrossRef]

- Ahmed, T.; Rack, H.J. Phase transformations during cooling in α + β titanium alloys. Mater. Sci. Eng. A 1998, 243, 206–211. [Google Scholar] [CrossRef]

- Balasubramanian, T.S.; Balakrishnan, M.; Balasubramanian, V.; Muthu Manickam, M.A. Influence of welding processes on microstructure, tensile and impact properties of Ti–6al–4V alloy joints. Trans. Nonferr. Met. Soc. 2011, 21, 1253–1262. [Google Scholar] [CrossRef]

- Sieniawski, J.; Ziaja, W.; Kubiak, K.; Motyka, M. Microstructure and Mechanical Properties of High Strength Two-Phase Titanium Alloys. In Titanium Alloys—Advances in Properties Control; Sieniawski, J., Ziaja, W., Eds.; InTechOpen: Rijeka, Croatia, 2013. [Google Scholar]

- Kabir, A.S.H.; Cao, X.; Gholipour, J.; Wanjara, P.; Cuddy, J.; Birur, A.; Medraj, M. Effect of postweld heat treatment on microstructure, hardness and tensile properties of laser-welded Ti–6Al–4V. Met. Mater. Trans. A 2012, 43, 4171–4184. [Google Scholar] [CrossRef]

- Lu, M.Y.; Tsay, L.W.; Chen, C. Notched Tensile Fracture of Ti6Al4V laser welds at elevated temperature. Mater. Trans. 2012, 6, 1042–1047. [Google Scholar] [CrossRef]

- Caiazzo, F.; Alfieri, V.; Astarita, A.; Squillace, A.; Barbieri, G. Investigation on laser welding of Ti–6Al–4V in corner joint. Adv. Mech. Eng. 2017, 9, 1–9. [Google Scholar] [CrossRef]

- Caiazzo, F.; Alfieri, V.; Fierro, I.; Sergi, V. Investigation and Optimization of Disk-Laser Welding of 1 mm thick Ti–6Al–4V titanium alloy sheets. Adv. Mech. Eng. 2015, 7, 1–8. [Google Scholar] [CrossRef]

- Caiazzo, F.; Sergi, V.; Corrado, G.; Alfieri, V.; Cardaropoli, F. Automated Apparatus of Laser Beam Welding. Patent EP2,931,468(A1) 21 October 2015. [Google Scholar]

- EN ISO 6507-1:2005. Metallic Materials—Vickers Hardness Test—Part 1: Test Method; ISO: Geneva, Switzerland, 2005. [Google Scholar]

- American Welding Society (AWS). D17.1—Specification for Fusion Welding for Aerospace Applications; AWS: Miami, FL, USA, 2001. [Google Scholar]

- Caiazzo, F.; Cardaropoli, F.; Alfieri, V.; Sergi, V.; Argenio, P.; Barbieri, G. Disk-laser welding of Ti–6Al–4V titanium alloy plates in T-joint configuration. Procedia Eng. 2017, 183, 219–226. [Google Scholar] [CrossRef]

| Joint Type | Power (kW) | Speed (mm∙min−1) | Approaching Angle (°) |

|---|---|---|---|

| L-joint | 6.0 | 2400 | 25 |

| 3000 | |||

| 3600 | |||

| T-joint | 6.0 | 4800 | 20 |

| 25 | |||

| 30 |

| Parameter | Value |

|---|---|

| Maximum output power (kW) | 10.0 |

| Laser light wavelength (nm) | 1030 |

| Beam parameter product (mm × mrad) | 6.0 |

| Delivering fibre core diameter (μm) | 200 |

| Focus diameter (μm) | 300 |

| Joint Type | Power (kW) | Speed (mm∙min−1) | Approaching Angle (°) |

|---|---|---|---|

| L-joint (5 mm web-plate to 8 mm cap-plate) | 6.0 | 1650 | 25 |

| T-joint (5 mm rib to 8 mm cap; 5 mm to 5 mm web-plate) | 4.5 | 1650 | 20 |

| Testing Condition | Welded Test-Articles | Machined Test-Articles | ||

|---|---|---|---|---|

| Compressive load (kN) | Strain (SG–1) (10−3 mm/mm) | Strain (SG–2) (10−3 mm/mm) | Strain (SG–1) (10−3 mm/mm) | Strain (SG–2) (10−3 mm/mm) |

| 10 | 1.17 | 1.11 | 1.32 | 1.19 |

| 15 | 1.79 | 1.71 | 1.97 | 1.83 |

| 20 | 2.43 | 2.32 | 2.59 | 2.45 |

| Technology | Theoretical Buy-to-Fly | Actual Buy-to-Fly |

|---|---|---|

| Machining from bulk | 11.0 | 15.1 |

| LBW and machining | 2.5 | 3.4 |

| LBW | 1.5 | 2.1 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Caiazzo, F.; Alfieri, V.; Corrado, G.; Argenio, P.; Barbieri, G.; Acerra, F.; Innaro, V. Laser Beam Welding of a Ti–6Al–4V Support Flange for Buy-to-Fly Reduction. Metals 2017, 7, 183. https://doi.org/10.3390/met7050183

Caiazzo F, Alfieri V, Corrado G, Argenio P, Barbieri G, Acerra F, Innaro V. Laser Beam Welding of a Ti–6Al–4V Support Flange for Buy-to-Fly Reduction. Metals. 2017; 7(5):183. https://doi.org/10.3390/met7050183

Chicago/Turabian StyleCaiazzo, Fabrizia, Vittorio Alfieri, Gaetano Corrado, Paolo Argenio, Giuseppe Barbieri, Francesco Acerra, and Vincenzo Innaro. 2017. "Laser Beam Welding of a Ti–6Al–4V Support Flange for Buy-to-Fly Reduction" Metals 7, no. 5: 183. https://doi.org/10.3390/met7050183

APA StyleCaiazzo, F., Alfieri, V., Corrado, G., Argenio, P., Barbieri, G., Acerra, F., & Innaro, V. (2017). Laser Beam Welding of a Ti–6Al–4V Support Flange for Buy-to-Fly Reduction. Metals, 7(5), 183. https://doi.org/10.3390/met7050183