Reversed Microstructures and Tensile Properties after Various Cold Rolling Reductions in AISI 301LN Steel

Abstract

:1. Introduction

2. Materials and Methods

2.1. Test Material

2.2. Reversion Heat Treatments

2.3. Mechanical Testing and Sample Preparation

2.4. Microstructure Examinations

3. Results and Discussion

3.1. Initial Grain Structures

3.1.1. Cold Rolled Microstructure

3.1.2. Reversed Microstructures

3.1.3. Early Stages of Reversion

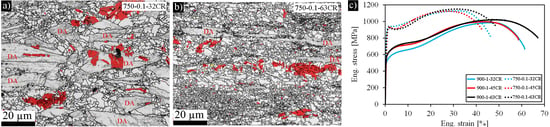

3.2. Tensile Properties

3.3. Austenite Stability

3.4. Martensite Nucleation during Tensile Straining

4. Conclusions

- Decreasing the CR reduction reduces the general grain refinement in the reversion. At CR reductions of 32% and 45%, the fraction of medium-sized grains (grain size ≥ 3 µm) is significant in both structures.

- The medium-sized austenite grains nucleate mainly in the slightly-deformed martensite and in a minor amount in the retained austenite; these fractions increase with a decrease in the CR reduction.

- Local disappearance of dislocations close to high-angle grain boundaries, leading to gradual evolution of subgrains to grains, seems to be the mechanisms of the formation of the medium-sized grains from shear-reversed austenite.

- In spite of a larger average grain size, the tensile properties of the reversed structures after the 32–45% CR reductions were practically equal to those after the 63% reduction. Increasing the fraction of retained austenite in the partially reversed structure balances the influence of an increasing fraction of medium-sized grains.

- The stability of the reversed austenite, formed at a given annealing temperature, under tensile straining, decreases with a decrease in the CR reduction.

- Medium-sized grains are the most unstable under tensile straining, which can be explained by their larger size than that of submicron grains formed from heavily-deformed martensite, and their orientation. The dependence of the fraction of slightly-deformed martensite, and thereby, that of medium-sized grains, on the CR reduction explains the influence of degree of CR on the stability of a certain structure. Also, the grain orientations between {111}<uvw> and {100}<uvw>, favored by a low CR reduction, reduce the austenite stability.

- The results indicate that CR reductions as low as 32–45%, instead of 63%, can be used in the manufacturing of a reversion-treated austenitic stainless steel of 301LN type with considerably refined grain structure and significantly enhanced tensile strength properties.

Acknowledgment

Author Contributions

Conflicts of Interest

References

- Di Schino, A.; Salvatori, I.; Kenny, J.M. Effects of martensite formation and austenite reversion on grain refining of AISI 304 stainless steel. J. Mater. Sci. 2002, 37, 4561–4565. [Google Scholar] [CrossRef]

- Di Schino, A.; Barteri, M.; Kenny, J.M. Development of ultra fine grain structure by martensitic reversion in stainless steel. J. Mater. Sci. Lett. 2002, 21, 751–753. [Google Scholar] [CrossRef]

- Somani, M.C.; Juntunen, P.; Karjalainen, L.P.; Misra, R.D.K.; Kyröläinen, A. Enhanced mechanical properties through reversion in metastable austenitic stainless steels. Metall. Mater. Trans. A 2009, 40, 729–744. [Google Scholar] [CrossRef]

- Järvenpää, A.; Karjalainen, L.P.; Jaskari, M. Effect of grain size on fatigue behaviour of Type 301LN stainless steel. Int. J. Fatigue 2014, 65, 93–98. [Google Scholar] [CrossRef]

- Kisko, A.; Hamada, A.; Karjalainen, L.P.; Talonen, J. Microstructure and Mechanical Properties of Reversion Treated High Mn Austenitic 204Cu and 201 Stainless Steels, HMnS 2011; Paper B-19; Grand Hilton Hotel: Seoul, Korea, 2011. [Google Scholar]

- Tomimura, K.; Takaki, S.; Tanimoto, S.; Tokunaga, Y. Optimal chemical composition in Fe-Cr-Ni alloys for ultra grain refining by reversion from deformation induced martensite. ISIJ Int. 1991, 31, 721–727. [Google Scholar] [CrossRef]

- Takaki, S.; Tomimura, K.; Ueda, S. Effect of pre-cold-working on diffusional reversion of deformation induced martensite in metastable austenitic stainless steel. ISIJ Int. 1994, 34, 522–527. [Google Scholar] [CrossRef]

- Misra, R.D.K.; Nayak, S.; Mali, M.A.; Shah, J.S.; Somani, M.C.; Karjalainen, L.P. On the significance of nature of strain-induced martensite on phase-reversion-induced nanograined/ultrafine-grained austenitic stainless steel. Metall. Mater. Trans. A 2010, 41, 3–12. [Google Scholar] [CrossRef]

- Misra, R.D.K.; Zhang, Z.; Venkatasurya, P.K.C.; Somani, M.C.; Karjalainen, L.P. Martensite shear phase reversion-induced nanograined/ultrafine-grained Fe–16Cr–10Ni alloy: The effect of interstitial alloying elements and degree of austenite stability on phase reversion. Mater. Sci. Eng. A 2010, 527, 7779–7792. [Google Scholar] [CrossRef]

- Matsuoka, Y.; Iwasaki, T.; Nakada, N.; Tsuchiyama, T.; Takaki, S. Effect of grain size on thermal and mechanical stability of austenite in metastable austenitic stainless steel. ISIJ Int. 2013, 3, 1224–1230. [Google Scholar] [CrossRef]

- Poulon-Quintin, A.; Brochet, S.; Vogt, J.-B.; Glez, J.-C.; Mithieux, J.-D. Fine grained austenitic stainless steels: The role of strain induced martensite and the reversion mechanism limitations. ISIJ Int. 2009, 49, 293–301. [Google Scholar] [CrossRef]

- Ravi Kumar, B.; Das, S.K.; Mahato, B.; Ghosh, R.N. Role of strain-induced martensite on microstructural evolution during annealing of metastable austenitic stainless steel. J. Mater. Sci. 2010, 45, 911–918. [Google Scholar] [CrossRef]

- Maréchal, D. Linkage between Mechanical Properties and Phase Transformation in a 301LN Austenitic Stainless Steel. Ph.D. Thesis, The University of British Columbia, Vancouver, BC, Canada, 2011. [Google Scholar]

- Rajasekhara, S.; Karjalainen, L.P.; Kyröläinen, A.; Ferreira, P.J. Microstructure evolution in nano/submicron grained AISI 301LN stainless steel. Mater. Sci. Eng. A 2010, 527, 1986–1996. [Google Scholar] [CrossRef]

- Roy, B.; Kumar, R.; Das, J. Effect of cryorolling on the microstructure and tensile properties of bulk nano-austenitic stainless steel. Mater. Sci. Eng. A 2015, 631, 241–247. [Google Scholar] [CrossRef]

- Yi, X.; He, T.; Wang, J.; Lu, Y.; Chen, L.; Ren, F.Z.; Liu, Y.; Volinsky, A.A. Cryorolling effect on microstructure and mechanical properties of Fe–25Cr–20Ni austenitic stainless steel. Mater. Des. 2015, 88, 398–405. [Google Scholar]

- Ma, Y.; Jin, J.-E.; Lee, Y.-K. A repetitive thermomechanical process to produce nano-crystalline in a metastable austenitic steel. Scripta Mater. 2005, 52, 1311–1315. [Google Scholar] [CrossRef]

- Behjati, P.; Kermanpur, A.; Karjalainen, L.P.; Järvenpää, A.; Jaskari, M.; Samaei Baghbadorani, H.; Najafizadeh, A.; Hamada, A. Influence of prior cold rolling reduction on microstructure and mechanical properties of a reversion annealed high-Mn austenitic steel. Mater. Sci. Eng. A 2016, 650, 119–128. [Google Scholar] [CrossRef]

- Behjati, P.; Kermanpur, A.; Najafizadeh, A.; Samaei Baghbadorani, H.; Karjalainen, L.P.; Jung, J.-G.; Lee, Y.-K. Design of a new Ni-free austenitic stainless steel with unique ultrahigh strength-high ductility synergy. Mater. Des. 2014, 63, 500–507. [Google Scholar] [CrossRef]

- Järvenpää, A.; Jaskari, M.; Man, J.; Karjalainen, L.P. Austenite stability in reversion-treated structures of a 301LN steel under tensile loading. Mater. Charact. 2017, 127, 12–26. [Google Scholar] [CrossRef]

- Järvenpää, A.; Jaskari, M.; Man, J.; Karjalainen, L.P. Stability of grain-refined reversed structures in a 301LN austenitic stainless steel under cyclic loading. Mater. Sci. Eng. A 2017, 703, 280–292. [Google Scholar] [CrossRef]

- Ravi Kumar, B.; Sharma, S. Recrystallization behavior of a heavily deformed austenitic stainless steel during iterative type annealing. Metall. Mater. Trans. A 2014, 45, 6027–6038. [Google Scholar] [CrossRef]

- Kisko, A.; Hamada, A.S.; Talonen, J.; Porter, D.; Karjalainen, L.P. Effects of reversion and recrystallization on microstructure and mechanical properties of Nb-alloyed low-Ni high-Mn austenitic stainless steels. Mater. Sci. Eng. A 2016, 657, 359–370. [Google Scholar] [CrossRef]

- Misra, R.D.K.; Nayak, S.; Venkatasurya, P.K.C.; Ramuni, V.; Somani, M.C.; Karjalainen, L.P. Nanograined/ultrafine-grained structure and tensile deformation behavior of shear phase reversion-induced 301 austenitic stainless steel. Metall. Mater. Trans. A 2010, 41, 2162–2174. [Google Scholar] [CrossRef]

- Talonen, J.; Aspegren, P.; Hänninen, H. Comparison of different methods for measuring strain induced α’-martensite content in austenitic steels. Mater. Sci. Technol. 2004, 20, 1506–1512. [Google Scholar] [CrossRef]

- Beese, A.M.; Mohr, D. Identification of the direction-dependency of the martensitic transformation in stainless steel using in situ magnetic permeability measurements. Exp. Mech. 2011, 51, 667–676. [Google Scholar] [CrossRef]

- Tomimura, K.; Takaki, S.; Tokunaga, Y. Reversion austenite mechanism from deformation induced martensite in metastable austenitic stainless steels. ISIJ Int. 1991, 31, 1431–1437. [Google Scholar] [CrossRef]

- Lee, S.-J.; Park, Y.-M.; Lee, Y.-K. Reverse transformation mechanism of martensite to austenite in a metastable austenitic alloy. Mater. Sci. Eng. A 2009, 515, 32–37. [Google Scholar] [CrossRef]

- Rajasekhara, S.; Ferreira, P.J.; Karjalainen, L.P.; Kyröläinen, A. Hall-Petch behavior in ultra-fine-grained AISI 301LN stainless steel. Metall. Mater. Trans. A 2007, 38, 1202–1210. [Google Scholar] [CrossRef]

- Järvenpää, A.; Jaskari, M.; Juuti, T.; Karjalainen, L.P. Demonstrating the effect of precipitation on mechanical stability of austenite in a reversion-treated 301LN stainless steel. Metals 2017, 7, 344. [Google Scholar] [CrossRef]

- Weidner, A.; Glage, A.; Martin, S.; Man, J.; Klemm, V.; Martin, U.; Polák, J.; Rafaja, D.; Biermann, H. Microstructure of austenitic stainless steels of various phase stabilities after cyclic and tensile deformation. Int. J. Mater. Res. 2011, 102, 1374–1377. [Google Scholar] [CrossRef]

- Hu, H. Texture of metals. Texture 1974, 1, 233–258. [Google Scholar] [CrossRef]

- Hirsch, J.; Lücke, K. Overview No. 76. Mechanism of deformation and development of rolling textures in polycrystalline f.c.c. metals-I. Description of rolling texture development in homogeneous CuZn alloys. Acta Metall. 1988, 36, 2863–2882. [Google Scholar] [CrossRef]

- Ravi Kumar, B.; Singh, A.K.; Mahato, B.; De, P.K.; Bandyopadhyay, N.R.; Bhattacharya, D.K. Deformation-induced transformation textures in metastable austenitic stainless steel. Mater. Sci. Eng. A 2006, 429, 205–211. [Google Scholar] [CrossRef]

- Dmitrieva, O.; Ponge, D.; Inden, G.; Millán, J.; Choi, P.; Sietsma, J. Chemical gradients across phase boundaries between martensite and austenite in steel studied by atom probe tomography and simulation. Acta Mater. 2011, 59, 364–374. [Google Scholar] [CrossRef]

- Shintani, T.; Murata, Y. Evaluation of the dislocation density and dislocation character in cold rolled Type 304 steel determined by profile analysis of X-ray diffraction. Acta Mater. 2011, 59, 4314–4322. [Google Scholar] [CrossRef]

| C | Si | Mn | P | S | Cr | Ni | Mo | Cu | Al | O | N |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 0.025 | 0.53 | 1.25 | 0.024 | 0.001 | 17.5 | 6.5 | 0.09 | 0.20 | 0.014 | 0.004 | 0.15 |

| Structure | Grain Size | Phase Fractions | ||||||

|---|---|---|---|---|---|---|---|---|

| (µm) | (%) | |||||||

| AGS | SD | RA | SD | DA | SD | DIM | SD | |

| 32CR | 23 * | 15 | 0 | 0 | 30 | 1.4 | 70 | 2.0 |

| 45CR | 23 * | 15 | 0 | 0 | 11 | 2.1 | 89 | 2.4 |

| 63CR | 23 * | 15 | 0 | 0 | 4 | 4.5 | 96 | 2.2 |

| 900-1-32CR | 3.4 | 3.1 | 100 | 0 | 0 | 0 | 0 | 0 |

| 900-1-45CR | 2.1 | 1.3 | 100 | 0 | 0 | 0 | 0 | 0 |

| 900-1-63CR | 1.4 | 1.4 | 100 | 0 | 0 | 0 | 0 | 0 |

| 750-0.1-32CR | 1.2 | 1.1 | 61 | 5.1 | 30 | 3.6 | 9 | 5.8 |

| 750-0.1-45CR | 0.8 | 0.8 | 81 | 4.9 | 11 | 4.9 | 8 | 3.9 |

| 750-0.1-63CR | 0.6 | 0.6 | 94 | 0.6 | 4 | 0.6 | 2 | 1.0 |

| Structure | YS | SD | UTS | SD | UEl | SD | TEl | SD |

|---|---|---|---|---|---|---|---|---|

| (Mpa) | (%) | |||||||

| 32CR | 1260 | 17 | 1480 | 8 | 5 | 0.4 | 19 | 1.2 |

| 45CR | 1480 | 27 | 1670 | 32 | 2 | 0.8 | 14 | 0.6 |

| 63CR | 1770 | 7 | 1840 | 3 | 2 | 0.2 | 5 | 3.1 |

| 900-1-32CR | 490 | 6 | 990 | 11 | 47 | 1.1 | 61 | 1.6 |

| 900-1-45CR | 550 | 6 | 1000 | 18 | 45 | 0.8 | 60 | 0.5 |

| 900-1-63CR | 550 | 8 | 1025 | 15 | 47 | 4.0 | 67 | 2.8 |

| 750-0.1-32CR | 940 | 14 | 1130 | 20 | 31 | 0.9 | 46 | 0.3 |

| 750-0.1-45CR | 900 | 11 | 1150 | 40 | 28 | 1.9 | 42 | 0.9 |

| 750-0.1-63CR | 900 | 23 | 1150 | 13 | 31 | 2.2 | 49 | 4.9 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Järvenpää, A.; Jaskari, M.; Karjalainen, L.P. Reversed Microstructures and Tensile Properties after Various Cold Rolling Reductions in AISI 301LN Steel. Metals 2018, 8, 109. https://doi.org/10.3390/met8020109

Järvenpää A, Jaskari M, Karjalainen LP. Reversed Microstructures and Tensile Properties after Various Cold Rolling Reductions in AISI 301LN Steel. Metals. 2018; 8(2):109. https://doi.org/10.3390/met8020109

Chicago/Turabian StyleJärvenpää, Antti, Matias Jaskari, and Leo Pentti Karjalainen. 2018. "Reversed Microstructures and Tensile Properties after Various Cold Rolling Reductions in AISI 301LN Steel" Metals 8, no. 2: 109. https://doi.org/10.3390/met8020109

APA StyleJärvenpää, A., Jaskari, M., & Karjalainen, L. P. (2018). Reversed Microstructures and Tensile Properties after Various Cold Rolling Reductions in AISI 301LN Steel. Metals, 8(2), 109. https://doi.org/10.3390/met8020109