Effects of Cryogenic Treatment on the Microstructure and Residual Stress of 7075 Aluminum Alloy

Abstract

:1. Introduction

2. Materials and Methods

- the water-quenched specimens were placed into the CT equipment and slowly cooled down from room temperature to the target temperatures, with a cooling rate of 3 °C/min;

- the specimens were held at target temperature for 2 h;

- the specimens were taken out from the equipment and left in open air, until their temperatures reached room temperature.

3. Results and Discussion

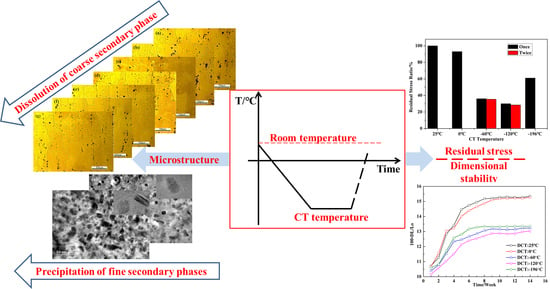

3.1. Effect of Cryogenic Treatment (CT) on the Microstructure of 7075 Aluminum Alloy

3.2. Effect of Cryogenic Treatment (CT) on the Residual Stress and Dimensional Stability of 7075 Alloys

4. Conclusions

- Cryogenic treatment (CT) can not only facilitate the dissolution of the coarse secondary phase into the α(Al) matrix of the 7075 Al alloy, but also promotes the precipitation of fine secondary phase particles.

- XRD analysis indicates that CT can result in rotation of the α(Al) grains towards the preferred (200) orientation, due to recovery and recrystallization during the following heating process from the CT temperature to room temperature.

- The residual stress of 7075 alloy can be significantly reduced by CT. The lowest residual stress rate (about 30%) was obtained for the sample that was treated at −120 °C.

- CT can improve the dimensional stability of the 7075 alloy through lowering the residual stress. The optimal dimensional stability for 7075 alloy was obtained at a CT temperature of −120 °C.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Li, S.L.; Deng, L.H.; Wu, X.C.; Min, Y.A.; Wang, H.B. Influence of deep cryogenic treatment on microstructure and evaluation by internal friction of a tool steel. Cryogenics 2010, 50, 754–758. [Google Scholar] [CrossRef]

- Lal, D.M.; Renganarayanan, S.; Kalanidhi, A. Cryogenic treatment to augment wear resistance of tool and die steels. Cryogenics 2001, 41, 149–155. [Google Scholar]

- Das, D.; Dutta, A.K.; Ray, K.K. Correlation of microstructure with wear behavior of deep cryogenically treated AISI D2 steel. Wear 2009, 267, 1371–1380. [Google Scholar] [CrossRef]

- Stratton, P. Optimising nano-carbide precipitation in tool steels. Mater. Sci. Eng. A 2007, 449, 809–812. [Google Scholar] [CrossRef]

- Stratton, P.; Graf, M. The effect of deep cold induced nano-carbides on the wear of case hardened components. Cryogenics 2009, 49, 346–349. [Google Scholar] [CrossRef]

- Becker, R.; Karabin, M.E.; Liu, J.C.; Smelser, R.E. Distortion and residual stress in quenched aluminum bars. J. Appl. Mech. 1996, 63, 699–705. [Google Scholar] [CrossRef]

- Koc, M.; Culp, J.; Altan, T. Prediction of residual stresses in quenched aluminum blocks and their reduction through cold working processes. J. Mater. Process. Technol. 2006, 174, 342–354. [Google Scholar] [CrossRef]

- Lados, D.A.; Apelian, D.; Wang, L.B. Minimization of residual stress in heat-treated Al–Si–Mg cast alloys using uphill quenching: Mechanisms and effects on static and dynamic properties. Mater. Sci. Eng. A 2010, 527, 3159–3165. [Google Scholar] [CrossRef]

- Nickola, W. Residual stress alterations via cold rolling and stretching of an aluminum alloy. In Mechanical Relaxation of Residual Stresses; ASTM International: West Conshohocken, PA, USA, 1988; pp. 7–18. [Google Scholar]

- Wu, S.; Zhao, H.Y.; Lu, A.L.; Fang, H.Z.; Tang, F. A micro-mechanism model of residual stress reduction by low frequency alternating magnetic field treatment. J. Mater. Process. Technol. 2003, 132, 198–202. [Google Scholar] [CrossRef]

- Araghchi, M.; Mansouri, H.; Vafaei, R.; Guo, Y.N. A novel cryogenic treatment for reduction of residual stresses in 2024 aluminum alloy. Mater. Sci. Eng. A 2017, 689, 48–52. [Google Scholar] [CrossRef]

- Steier, V.F.; Badibanga, R.K.; Silva, C.R.M.; Nogueira, M.M.; Araujo, J.A. Effect of chromium nitride coatings and cryogenic treatments on wear and fretting fatigue resistance of aluminum. Electr. Power Syst. Res. 2014, 116, 322–329. [Google Scholar] [CrossRef]

- Li, C.M.; Cheng, N.P.; Chen, Z.Q.; Guo, N.; Zeng, S.M. Deep cryogenic treatment induced phase transformation in the Al-Zn-Mg-Cu alloy. Int. J. Miner. Metall. Mater. 2015, 22, 68–77. [Google Scholar] [CrossRef]

- Zhou, J.Z.; Xu, S.Q.; Huang, S.; Meng, X.K.; Sheng, J.; Zhang, H.F.; Li, J.; Sun, Y.H.; Boateng, E.A. Tensile Properties and Microstructures of a 2024-T351Aluminum Alloy Subjected to Cryogenic Treatment. Metals 2016, 6, 279. [Google Scholar] [CrossRef]

- Wang, J.; Fu, R.D.; Li, Y.J.; Zhang, J.F. Effects of deep cryogenic treatment and low-temperature aging on the mechanical properties of friction-stir-welded joints of 2024-T351 aluminum alloy. Mater. Sci. Eng. A 2014, 609, 147–153. [Google Scholar] [CrossRef]

- Zhang, W.D.; Bai, P.K.; Yang, J.; Xu, H.; Dang, J.Z.; Du, Z.M. Tensile behavior of 3104 aluminum alloy processed by homogenization and cryogenic treatment. Trans. Nonferr. Met. Soc. China 2014, 24, 2453–2458. [Google Scholar] [CrossRef]

- Baldissera, P.; Delprete, C. Deep Cryogenic Treatment: A Bibliographic Review. Open Mech. Eng. J. 2008, 2, 1–11. [Google Scholar] [CrossRef]

- Sun, D.L.; Yang, F.; Wu, G.H. A new method for evaluation of dimensional stability—Open ring method. Phys. Test. Chem. Anal. Part A Phys. Test. 1990, 35, 447–448. [Google Scholar]

- Xu, D.K.; Birbilis, N.; Lashansky, D.; Rometsch, P.A.; Muddle, B.C. Effect of solution treatment on the corrosion behavior of the aluminum alloy AA7150: Optimisation for corrosion resistance. Corros. Sci. 2011, 53, 217–225. [Google Scholar] [CrossRef]

- Xu, L.Y.; Zhu, J.; Jing, H.Y.; Zhao, L.; Lv, X.Q.; Han, Y.D. Effects of deep cryogenic treatment on the residual stress and mechanical properties of electron-beam-welded Ti–6Al–4V joints. Mater. Sci. Eng. A 2016, 673, 503–510. [Google Scholar] [CrossRef]

- Feng, Z.Q.; Yang, Y.Q.; Huang, B.; Han, M.; Luo, X.; Ru, J.G. Precipitation process along dislocations in Al–Cu–Mg alloy during artificial aging. Mater. Sci. Eng. A 2010, 528, 706–714. [Google Scholar] [CrossRef]

- Ratchev, P.; Verlinden, B.; Smet, P.D.; Houttea, P.V. Precipitation hardening of anal–4.2 wt. % Mg–0.6 wt. % Cu alloy. Acta Mater. 1998, 46, 3523–3533. [Google Scholar] [CrossRef]

| Elements | Zn | Mg | Cu | Zr | Fe | Si | Mn | Cr | Ti | Other Total | Al |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Nominal | 5.7–6.7 | 1.9–2.6 | 2.0–2.6 | 0.08–0.15 | 0.15 | 0.12 | 0.1 | 0.04 | 0.06 | 0.15 | bal. |

| In this study | 6.2 | 2.1 | 2.2 | 0.11 | 0.14 | 0.13 | 0.1 | 0.03 | 0.05 | 0.15 | bal. |

| Sample | Solution Treatment | Cryogenic Treatment | Aging Treatment |

|---|---|---|---|

| A | 466 °C × 1 h | - | 107 °C × 6 h + 163 °C × 18 h |

| B | 466 °C × 1 h | 0 °C × 2 h | 107 °C × 6 h + 163 °C × 18 h |

| C | 466 °C × 1 h | −60 °C × 2 h | 107 °C × 6 h + 163 °C × 18 h |

| D | 466 °C × 1 h | −120 °C × 2 h | 107 °C × 6 h + 163 °C × 18 h |

| E | 466 °C × 1 h | −196 °C × 2 h | 107 °C × 6 h + 163 °C × 18 h |

| F | 466 °C × 1 h | −60 °C × 2 h, Twice | 107 °C × 6 h + 163 °C × 18 h |

| G | 466 °C × 1 h | −120 °C × 2 h, Twice | 107 °C × 6 h + 163 °C × 18 h |

| Sample | (111) | (200) | (220) | (311) |

|---|---|---|---|---|

| A | 57.37 | 100 | 53.69 | 22.2 |

| B | 78.91 | 100 | 50.35 | 20.3 |

| C | 19.04 | 100 | 40.49 | 16.2 |

| D | 22.68 | 100 | 30.84 | 5.54 |

| E | 40.14 | 100 | 54.79 | 8.89 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wei, L.; Wang, D.; Li, H.; Xie, D.; Ye, F.; Song, R.; Zheng, G.; Wu, S. Effects of Cryogenic Treatment on the Microstructure and Residual Stress of 7075 Aluminum Alloy. Metals 2018, 8, 273. https://doi.org/10.3390/met8040273

Wei L, Wang D, Li H, Xie D, Ye F, Song R, Zheng G, Wu S. Effects of Cryogenic Treatment on the Microstructure and Residual Stress of 7075 Aluminum Alloy. Metals. 2018; 8(4):273. https://doi.org/10.3390/met8040273

Chicago/Turabian StyleWei, Lijun, Dawei Wang, Haisheng Li, Di Xie, Fan Ye, Ruokang Song, Gang Zheng, and Sujun Wu. 2018. "Effects of Cryogenic Treatment on the Microstructure and Residual Stress of 7075 Aluminum Alloy" Metals 8, no. 4: 273. https://doi.org/10.3390/met8040273

APA StyleWei, L., Wang, D., Li, H., Xie, D., Ye, F., Song, R., Zheng, G., & Wu, S. (2018). Effects of Cryogenic Treatment on the Microstructure and Residual Stress of 7075 Aluminum Alloy. Metals, 8(4), 273. https://doi.org/10.3390/met8040273