Microstructure and Properties of Friction Stir Welded 2219 Aluminum Alloy under Heat Treatment and Electromagnetic Forming Process

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

3.1. Compound Technologies of FSW and Heat Treatment

3.1.1. Microstructure of the Welding Joint

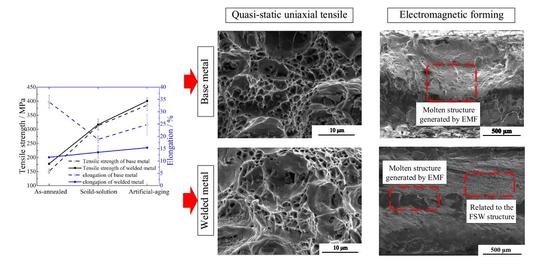

3.1.2. Mechanical Properties

3.1.3. Fracture Appearance

3.2. EMF Treatment

3.2.1. Forming Characteristics

3.2.2. Fracture Appearance

4. Conclusions

- The effects of high temperature during heat treatment caused a coarsening of grains and reprecipitation of precipitated phase in the welding join; it was able to recover the strength reduced during the FSW process, but ductility remained reduced after heat treatment. The performance of FSW after a solid-solution treatment on 2219 aluminum alloy caused an overaging effect during subsequent aging treatment and led to poor ductility.

- The formability of welded samples under EMF was lower compared with base metal samples because of the poor mechanical properties. The onion ring structure formed during FSW treatment caused a variation in both the microstructure and properties of the 2219 aluminum alloy and led to the banded structure on the fracture surface. A multi-fracture-type structure was generated due to the interaction of plastic flow caused by FSW and induced eddy current caused by EMF.

- During the EMF process, an intergranular fracture appearance was generated as a result of the Joule effect of the induced eddy current. The induced eddy current also caused the molten surface on the fracture through the electric arc when the fracture occurred. The melted surface covered the original fracture appearance and formed the bright silver appearance on the fracture surface of the 2219 aluminum alloy under EMF treatment.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Narayana, G.V.; Sharma, V.M.J.; Diwakar, V. Fracture behaviour of aluminium alloy 2219-T87 welded plates. Sci. Technol. Weld. Join. 2013, 9, 121–130. [Google Scholar] [CrossRef]

- Gupta, R.K.; Panda, R.; Mukhopadhyay, A.K. Study of Aluminum Alloy AA2219 after Heat Treatment. Met. Sci. Heat Treat. 2015, 57, 350–353. [Google Scholar] [CrossRef]

- Klett, A.; Hegels, J.; Bartesch, G. Spinforming of Friction Stir Welded AA2219 Circular Blanks for ARIANE 5 Main Stage Tank Bulkheads. DVS Ber. 2004, 229, 90–94. [Google Scholar]

- Regensburg, A.; Schürer, R.; Weigl, M. Influence of Pin Length and Electrochemical Platings on the Mechanical Strength and Macroscopic Defect Formation in Stationary Shoulder Friction Stir Welding of Aluminium to Copper. Metals 2018, 8, 85. [Google Scholar] [CrossRef]

- Zhang, Z.; Xiao, B.L.; Ma, Z.Y. Effect of welding parameters on microstructure and mechanical properties of friction stir welded 2219Al-T6 joints. J. Mater. Sci. 2012, 47, 4075–4086. [Google Scholar] [CrossRef]

- Son, S.K.; Takeda, M.; Mitome, M. Precipitation behavior of an Al-Cu alloy during isothermal aging at low temperatures. Mater. Lett. 2005, 59, 629–632. [Google Scholar] [CrossRef]

- Seth, M.; Vohnout, V.J.; Daehn, G.S. Formability of steel sheet in high velocity impact. J. Mater. Process. Technol. 2005, 168, 390–400. [Google Scholar] [CrossRef]

- Psyk, V.; Risch, D.; Kinsey, B.L. Electromagnetic forming—A review. J. Mater. Process. Technol. 2011, 211, 787–829. [Google Scholar] [CrossRef]

- Zhu, H.; Huang, L.; Li, J. Strengthening mechanism in laser-welded 2219 aluminium alloy under the cooperative effects of aging treatment and pulsed electromagnetic loadings. Mater. Sci. Eng. A 2018, 714, 124–139. [Google Scholar] [CrossRef]

- Mohammadi-pour, M.; Khodabandeh, A.; Mohammadi-pour, S. Microstructure and mechanical properties of joints welded by friction-stir welding in aluminum alloy 7075-T6 plates for aerospace application. Rare Metals 2016, 1–9. [Google Scholar] [CrossRef]

- Hamilton, C.; Dymek, S.; Blicharski, M. A model of material flow during friction stir welding. Mater. Charact. 2008, 59, 1206–1214. [Google Scholar] [CrossRef]

- Krishnan, K.N. On the formation of onion rings in friction stir welds. Mater. Sci. Eng. A 2002, 327, 246–251. [Google Scholar] [CrossRef]

- Chu, G.; Sun, L.; Lin, C. Effect of Local Post Weld Heat Treatment on Tensile Properties in Friction Stir Welded 2219-O Al Alloy. J. Mater. Eng. Perform. 2017, 26, 5425–5431. [Google Scholar] [CrossRef]

- Wang, S.C.; Starink, M.J. Precipitates and intermetallic phases in precipitation hardening Al-Cu-Mg-(Li) based alloys. Int. Mater. Rev. 2005, 50, 193–215. [Google Scholar] [CrossRef]

- An, L.; Cai, Y.; Liu, W. Effect of pre-deformation on microstructure and mechanical properties of 2219 aluminum alloy sheet by thermomechanical treatment. Trans. Nonferr. Met. Soc. China 2012, 22, s370–s375. [Google Scholar] [CrossRef]

- Ning, A.; Liu, Z.; Zeng, S. Effect of large cold deformation after solution treatment on precipitation characteristic and deformation strengthening of 2024 and 7A04 aluminum alloys. Trans. Nonferr. Met. Soc. China 2006, 16, 1341–1347. [Google Scholar] [CrossRef]

- Owolabi, G.M.; Bolling, D.T.; Odeshi, A.G. The Effects of Specimen Geometry on the Plastic Deformation of AA 2219-T8 Aluminum Alloy Under Dynamic Impact Loading. J. Mater. Eng. Perform. 2017, 26, 5837–5846. [Google Scholar] [CrossRef]

- Olasumboye, A.; Owolabi, G.; Odeshi, A. Dynamic Response and Microstructure Evolution of AA2219-T4 and AA2219-T6 Aluminum Alloys. J. Dyn. Behav. Mater. 2018, 1–17. [Google Scholar] [CrossRef]

- Tan, J.; Zhan, M.; Liu, S. Guideline for Forming Stiffened Panels by Using the Electromagnetic Forces. Metals 2016, 6, 267. [Google Scholar] [CrossRef]

- Liu, Z.; Fan, T.; Hu, H. Possible Mechanism of Plasticity Influenced by Magnetic Field. Chin. Phys. Lett. 2006, 23, 175–177. [Google Scholar]

- Ruszkiewicz, B.J.; Grimm, T.; Ragai, I. A Review of Electrically-Assisted Manufacturing with Emphasis on Modeling and Understanding of the Electroplastic Effect. J. Manuf. Sci. Eng. 2017, 139, 110801. [Google Scholar] [CrossRef]

- Kaltenboeck, G.; Demetriou, M.D.; Roberts, S. Shaping metallic glasses by electromagnetic pulsing. Nat. Commun. 2016, 7, 10576. [Google Scholar] [CrossRef] [PubMed]

- Ringer, S.P.; Hono, K. Microstructural Evolution and Age Hardening in Aluminium Alloys: Atom Probe Field-Ion Microscopy and Transmission Electron Microscopy Studies. Mater. Charact. 2000, 44, 101–131. [Google Scholar] [CrossRef]

- Feng, J.C.; Chen, Y.C.; Liu, H.J. Effects of post-weld heat treatment on microstructure and mechanical properties of friction stir welded joints of 2219-O aluminium alloy. Mater. Sci. Technol. 2006, 22, 86–90. [Google Scholar] [CrossRef]

- Chen, Y.C.; Feng, J.C.; Liu, H.J. Precipitate evolution in friction stir welding of 2219-T6 aluminum alloys. Mater. Charact. 2009, 60, 476–481. [Google Scholar] [CrossRef]

- Gang, L.; Jun, S. A Model for Age Strengthening of plate-like-precipitate-containing Al Alloys. Chin. J. Nonferr. Met. 2001, 11, 337–347. (In Chinese) [Google Scholar]

- Ning, A.; Liu, Z.; Zeng, S. Effect of large cold deformation on characteristics of age-strengthening of 2024 aluminum alloys. Trans. Nonferr. Met. Soc. China 2006, 16, 1121–1128. [Google Scholar] [CrossRef]

- Mittra, J.; Banerjee, S.; Tewari, R. Fracture behavior of Alloy 625 with different precipitate microstructures. Mater. Sci. Eng. A 2013, 574, 86–93. [Google Scholar] [CrossRef]

- Huang, C.; Kou, S. Partially Melted Zone in Aluminum Welds—Liquation Mechanism and Directional Solidification. Weld. J. 2000, 79, 113. [Google Scholar]

| Al | Cu | Mn | Ti | Zr | V |

|---|---|---|---|---|---|

| bal. | 6.2 | 0.3 | 0.058 | 0.15 | 0.08 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Z.; Huang, L.; Li, J.; Li, X.; Zhu, H.; Ma, F.; Ma, H.; Cui, J. Microstructure and Properties of Friction Stir Welded 2219 Aluminum Alloy under Heat Treatment and Electromagnetic Forming Process. Metals 2018, 8, 305. https://doi.org/10.3390/met8050305

Wang Z, Huang L, Li J, Li X, Zhu H, Ma F, Ma H, Cui J. Microstructure and Properties of Friction Stir Welded 2219 Aluminum Alloy under Heat Treatment and Electromagnetic Forming Process. Metals. 2018; 8(5):305. https://doi.org/10.3390/met8050305

Chicago/Turabian StyleWang, Zeyu, Liang Huang, Jianjun Li, Xiaoxia Li, Hui Zhu, Fei Ma, Huijuan Ma, and Junjia Cui. 2018. "Microstructure and Properties of Friction Stir Welded 2219 Aluminum Alloy under Heat Treatment and Electromagnetic Forming Process" Metals 8, no. 5: 305. https://doi.org/10.3390/met8050305

APA StyleWang, Z., Huang, L., Li, J., Li, X., Zhu, H., Ma, F., Ma, H., & Cui, J. (2018). Microstructure and Properties of Friction Stir Welded 2219 Aluminum Alloy under Heat Treatment and Electromagnetic Forming Process. Metals, 8(5), 305. https://doi.org/10.3390/met8050305