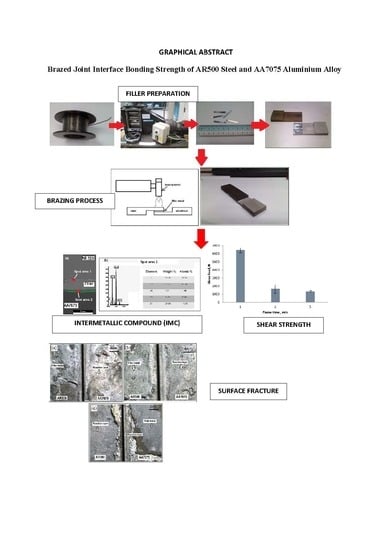

Brazed Joint Interface Bonding Strength of AR500 Steel and AA7075 Aluminium Alloy

Abstract

:1. Introduction

2. Materials and Experimental Studies

3. Result and Discussion

3.1. Intermetallic Compound Layer

3.2. Mechanical Properties

3.3. Fracture Surface Observation

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Salleh, M.S.; Omar, M.Z.; Alhawari, K.S.; Mohammed, M.N.; Mad Ali, M.A.; Mohamad, E. Microstructural evolution and mechanical properties of thixoformed A319 alloys containing variable amounts of magnesium. Trans. Nonferrous Met. Soc. China 2016, 26, 2029–2042. [Google Scholar] [CrossRef]

- Salleh, M.S.; Omar, M.Z. Influence of Cu content on microstructure and mechanical properties of thixoformed Al–Si–Cu–Mg alloys. Trans. Nonferrous Met. Soc. China 2016, 25, 3523–3538. [Google Scholar] [CrossRef]

- Salleh, M.S.; Omar, M.Z.; Syarif, J. The effects of Mg addition on the microstructure and mechanical properties of thixoformed Al–5%Si–Cu alloys. J. Alloys Compd. 2015, 621, 121–130. [Google Scholar] [CrossRef]

- Emel, T.; Jerry, E.G.; John, C.L. Dissimilar friction welding of 6061-T6 aluminum and AISI 1018 steel: Properties and microstructural characterization. Mater. Des. 2010, 31, 2305–2311. [Google Scholar]

- Choi, C.Y.; Kim, D.C.; Nam, D.G.; Kim, Y.D.; Park, Y.D. A hybrid joining technology for aluminum/zinc coated steels in vehicles. J. Mater. Sci. Technol. 2010, 26, 858–864. [Google Scholar] [CrossRef]

- Lee, C.-J.; Kim, J.-Y.; Lee, S.-K.; Ko, D.-C.; Kim, B.-M. Parametric study on mechanical clinching process for joining aluminum alloy and high-strength steel sheets. J. Mech. Sci. Technol. 2010, 24, 123–126. [Google Scholar]

- Rahman, N.A.; Abdullah, S.; Zamri, W.F.H.; Abdullah, M.F.; Omar, M.Z.; Sajuri, Z. Ballistic limit of high-strength steel and Al7075-T6 multi-layered plates under 7.62-mm armour piercing projectile impact. Latin Am. J. Solids Struct. 2016, 13, 1658–1676. [Google Scholar] [CrossRef]

- Kenji, M.; Shigeyuki, N.; Chika, S.; Hiroshi, S.; Akiro, H. Dissimilar joining of aluminum alloy and steel by resistance spot welding. SAE Int. J. Mater. Manf. 2009, 2, 58–67. [Google Scholar]

- Kim, K.; Lee, J.; Cho, H. Analysis of pulsed Nd:YAG laser welding of AISI 304 steel. J. Mech. Sci. Technol. 2010, 24, 2253–2259. [Google Scholar]

- Feng, J.-C.; He, P. High frequency induction contact reactive brazing of aluminum to stainless steel. Trans. Nonferrous Met. Soc. China 2005, 15, 11–15. [Google Scholar]

- Laik, A.; Shirzadi, A.A.; Tewari, R.; Anish, K.; Jayakumar, T.; Dey, G.K. Microstructure and interfacial reactions during active metal brazing of stainless steel to titanium. Metall. Mater. Trans. A 2013, 44, 2212–2225. [Google Scholar] [CrossRef]

- Dai, W.; Xue, S.; Lou, J.; Wang, S. Microstructure and properties of 6061 aluminum alloy brazing joint with Al–Si–Zn filler metal. Mater. Trans. 2012, 53, 1638–1643. [Google Scholar] [CrossRef]

- Chen, T.; Lin, W.B. Optimal FSW process parameters for interface and welded zone toughness of dissimilar aluminium–steel joint. Sci. Technol. Weld. Join. 2010, 15, 279–285. [Google Scholar] [CrossRef]

- Ogura, T.; Ueda, K.; Saito, Y.; Hirose, A. Nanoindentation measurement of interfacial reaction layers in 6000 series aluminum alloys and steel dissimilar metal joints with alloying elements. Mater. Trans. 2011, 52, 979–984. [Google Scholar] [CrossRef]

- Kimapong, K.; Watanabe, T. Lap joint of A5083 aluminum alloy and SS400 steel by friction stir welding. Mater. Trans. 2005, 46, 835–841. [Google Scholar] [CrossRef]

- Yamamoto, N.; Takahashi, M.; Ikuechi, K.; Aritosh, M. Interfacial layer in friction-bonded joint of low carbon steel to Al–Mg alloy (AA5083) and its influence on bond strength. Mater. Trans. 2004, 45, 296–299. [Google Scholar] [CrossRef]

- Yasuyama, M.; Ogawa, K.; Taka, T. Spot welding of aluminum and steel sheet with insert of aluminum clad steel sheet (1st report). J. Jpn. Weld. Soc. 1996, 14, 314–320. [Google Scholar] [CrossRef]

- Mathieu, A.; Pontevicci, S.; Viala, J.; Cicala, E.; Mattei, S.; Grevey, D. Laser brazing of a steel/aluminium assembly with hot filler wire (88% Al, 12% Si). Mater. Sci. Eng. A 2006, 435, 19–28. [Google Scholar] [CrossRef]

- Miyamoto, K.; Nakagawa, S.; Sugi, C.; Sakurai, H. Disimillar joining of aluminium alloy and steel by resistance spot welding. SAE Int. J. Mater. Manuf. 2009, 2, 58–67. [Google Scholar] [CrossRef]

- Khodir, S.A.; Shibayanagi, T. Microstructure and mechanical properties of friction stir welded dissimilar aluminum joints of AA2024-T3 and AA7075-T6. Mater. Trans. 2007, 48, 1928–1937. [Google Scholar] [CrossRef]

- Trimble, D.; Mitrogiannopoulos, H.; O’Donnell, G.E.; McFadden, S. Friction stir welding of AA2024-T3 plate–the influence of different pin types. Mech. Sci. 2015, 6, 51–55. [Google Scholar] [CrossRef]

- Rao, T.S.; Reddy, G.M.; Rao, S.R.K. Microstructure and mechanical properties of friction stir welded AA7075–T651 aluminum alloy thick plates. Trans. Nonferrous Met. Soc. China 2015, 25, 1770–1778. [Google Scholar] [CrossRef]

- Sepe, R.; Laiso, M.; De Luca, A.; Caputo, F. Evaluation of residual stresses in butt welded joint of dissimilar material by FEM. Key Eng. Mater. 2017, 754, 268–271. [Google Scholar] [CrossRef]

- Citarella, R.; Carlone, P.; Lepore, M.; Sepe, R. Hybrid technique to assess the fatigue performance of multiple cracked FSW joints. Eng. Fract. Mech. 2016, 162, 38–50. [Google Scholar] [CrossRef]

- Citarella, R.; Carlone, P.; Sepe, R.; Lepore, M. DBEM crack propagation in friction stir welded aluminum joints. Adv. Eng. Softw. 2016, 101, 50–59. [Google Scholar] [CrossRef]

- Carlone, P.; Citarella, R.; Sonne, M.R.; Hattel, J.H. Multiple crack growth prediction in AA2024-T3 friction stir welded joints, including manufacturing effects. Int. J. Fatigue 2016, 90, 69–77. [Google Scholar] [CrossRef] [Green Version]

- Carlone, P.; Citarella, R.; Lepore, M.; Palazzo, G.S. A FEM-DBEM investigation of the influence of process parameters on crack growth in aluminum friction stir welded butt joints. Int. J. Mater. Form. 2015, 8, 591–599. [Google Scholar] [CrossRef]

- Selamat, N.F.M.; Baghdadi, A.H.; Sajuri, Z.; Kokabi, A.H. Friction stir welding of similar and dissimilar aluminium alloys for automotive applications. Int. J. Automot. Mech. Eng. 2016, 13, 3401–3412. [Google Scholar] [CrossRef]

- Fellinger, J.; Citarella, R.; Giannella, V.; Lepore, M.; Sepe, R.; Czerwinski, M.; Herold, F.; Stadler, R. Overview of fatigue life assessment of baffles in Wendelstein 7-X. Fusion Eng. Des. 2018, in press. [Google Scholar] [CrossRef]

- Zhang, B.; Chen, G.; Zhang, C.; Ni, J. Structure and mechanical properties of aluminum alloy/Ag interlayer/steel non centered electron beam welded joints. Trans. Nonferrous Met. Soc. China 2011, 21, 2592–2596. [Google Scholar] [CrossRef]

- Liu, H.J.; Feng, J.C. Vacuum brazing TiAl-based alloy to 40Cr steel using Ag–Cu–Zn filler metal. J. Mater. Sci. Lett. 2002, 21, 9–10. [Google Scholar]

- Shah, L.H.; Akhtar, Z.; Ishak, M. Investigation of aluminium–stainless steel dissimilar weld quality using different filler metal. Int. J. Automot. Mech. Eng. 2013, 8, 1121–1131. [Google Scholar] [CrossRef]

- Wang, Q.; Leng, X.; Yang, T.; Yan, J. Effects of Fe–Al intermetallic compounds on interfacial bonding of clad materials. Trans. Nonferrous Met. Soc. China 2014, 24, 279–284. [Google Scholar] [CrossRef]

- Lee, K.J.; Kumai, S.J. Characterization of intermetallic compound layer formed at the weld interface of the defocused laser welded low carbon steel/6111 aluminum alloy lap joint. Mater. Trans. 2006, 47, 1178–1185. [Google Scholar] [CrossRef]

- Lee, K.-J.; Kumai, S.; Kawamura, N.; Ishikawa, N.; Furuya, K. Growth manner of intermetallic compounds at the weld interface of steel/aluminum alloy lap joint fabricated by a defocused laser beam. Mater. Trans. 2007, 48, 1396–1405. [Google Scholar]

- Muhamed, M.N.; Omar, M.Z.; Abdullah, S.; Sajuri, Z.; Zamri, W.F.H. The effect of surface texture on the joint shear strength of AR500 steel and AA7075. J. Mech. Eng. 2017, 4, 289–301. [Google Scholar]

- Sakiyama, T.; Murayama, G.; Naito, Y.; Saita, K.; Miyazaki, Y.; Oikawa, H.; Nose, T. Dissimilar metal joining technologies for steel sheet and aluminum alloy sheet in auto body. Nippon Steel Tech. Rep. 2013, 103, 91–98. [Google Scholar]

- Isadare, A.D.; Aremo, B.; Adeoye, M.O.; Olawale, O.J.; Shittuc, M.D. Effect of heat treatment on some mechanical properties of 7075 aluminium alloy. Mater. Res. 2013, 16, 190–194. [Google Scholar] [CrossRef]

- Okamoto, H. The C-Fe (Carbon-Iron) system. J. Phase Equilib. 1992, 13, 543–565. [Google Scholar] [CrossRef]

- Dai, W.; Xue, S.; Lou, J.; Wang, S. Torch brazing 3003 aluminum alloy with Zn–Al filler metal. Trans. Nonferrous Met. Soc. China 2012, 22, 30–35. [Google Scholar] [CrossRef]

- Suenger, S.; Kreissle, M.; Kahnert, M.; Zaeh, M.F. Influence of Process Temperature on Hardness of Friction Stir Welded High Strength Aluminum Alloys for Aerospace Applications. Procedia CIRP 2014, 24, 120–124. [Google Scholar] [CrossRef]

- Siahaan, E.; Soegijono, B.; Hikam, M. The effect of zinc composition in melting point and microstructure of lead-free solder. Int. J. Basic Appl. Sci. 2014, 14, 17–20. [Google Scholar]

- Hamada, N.; Uesugi, T.; Takigawa, Y.; Higashi, K. Effect of addition of small amount of zinc on microstructural evolution and thermal shock behavior in low-Ag Sn–Ag–Cu solder joints during thermal cycling. Mater. Trans. 2013, 54, 796–805. [Google Scholar] [CrossRef]

- Lee, K.-J.; Kumai, S.; Arai, T. Interfacial microstructure and strength of steel to aluminum alloy lap joints welded by a defocused laser beam. Mater. Trans. 2005, 46, 1847–1856. [Google Scholar]

- Tashi, R.S.; Mousavi, S.A.A.A.; Atabaki, M.M. Difussion brazing of Ti-6Al-4V and stainless steel 316L using AgCuZn filler metal. Metall. Mater. Eng. 2013, 19, 189–201. [Google Scholar]

- Ikeuchi, K.; Yamamoto, N.; Tkahashi, M.; Aritoshi, M. Effect of interfacial reaction layer on bonding strength of friction bonded joint of Al alloy to steel. Trans. JWRI 2005, 34, 1–10. [Google Scholar]

- Zaharinie, T.; Yusof, F.; Hamdi, M.; Ariga, T.; Moshwan, R. Effect of brazing temperature on the shear strength of Inconel 600 joint. Int. J. Adv. Manuf. Technol. 2014, 73, 1133–1140. [Google Scholar] [CrossRef]

- Muhamed, M.N.; Omar, M.Z.; Abdullah, S.; Sajuri, Z.; Zamri, W.F.H.; Rahman, M.A.I.A.; Abdullah, M.F. Investigation on brazing interface bonding characteristic of AA7075 and AA6061 aluminium alloy with AR500 steel using Al-Si-Zn filler metal. J. Teknol. 2016, 78, 129–135. [Google Scholar]

| Zn | Si | Sn | Fe | Ti | Mg | Ni | Mn | Pb | Cu | V | Ag | Cr | Al |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 15.60 | 14.84 | 3.75 | 3.13 | 2.02 | 1.70 | 1.49 | 1.42 | 0.87 | 0.58 | 0.13 | 0.1 | 0.06 | Balance |

| Point | Al (at %) | Fe (at %) | Al:Fe | IMC |

|---|---|---|---|---|

| spot 2 | 27.13 | 72.87 | 1:3 | Fe3Al |

| spot 4 | 43.01 | 56.99 | 1:1 | FeAl |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Muhamed, M.N.; Omar, M.Z.; Abdullah, S.; Sajuri, Z.; Wan Zamri, W.F.H.; Abdullah, M.F. Brazed Joint Interface Bonding Strength of AR500 Steel and AA7075 Aluminium Alloy. Metals 2018, 8, 668. https://doi.org/10.3390/met8090668

Muhamed MN, Omar MZ, Abdullah S, Sajuri Z, Wan Zamri WFH, Abdullah MF. Brazed Joint Interface Bonding Strength of AR500 Steel and AA7075 Aluminium Alloy. Metals. 2018; 8(9):668. https://doi.org/10.3390/met8090668

Chicago/Turabian StyleMuhamed, Mohd Najib, Mohd Zaidi Omar, Shahrum Abdullah, Zainuddin Sajuri, Wan Fathul Hakim Wan Zamri, and Mohd Faizal Abdullah. 2018. "Brazed Joint Interface Bonding Strength of AR500 Steel and AA7075 Aluminium Alloy" Metals 8, no. 9: 668. https://doi.org/10.3390/met8090668

APA StyleMuhamed, M. N., Omar, M. Z., Abdullah, S., Sajuri, Z., Wan Zamri, W. F. H., & Abdullah, M. F. (2018). Brazed Joint Interface Bonding Strength of AR500 Steel and AA7075 Aluminium Alloy. Metals, 8(9), 668. https://doi.org/10.3390/met8090668