Experimental Comparison of Efficiency of Water-Soluble and Solvent Hydrophobic Agents for Concrete

Abstract

:1. Introduction

2. Materials and Methods

2.1. Hydrophobic Agents and Substrate

2.2. Experimental Methods

2.2.1. Dynamic Viscosity

2.2.2. Thickness of Hydrophobic Agent

2.2.3. Adhesion on Concrete

2.2.4. Abrasion Resistance

2.2.5. Impact Resistance

2.2.6. Flexural and Compressive Strength

2.2.7. Shrinkage

2.2.8. Water Absorption

2.2.9. Resistance to Defrosting Chemicals

2.2.10. Chemical Resistance

3. Results and Discussion

3.1. Dynamic Viscosity

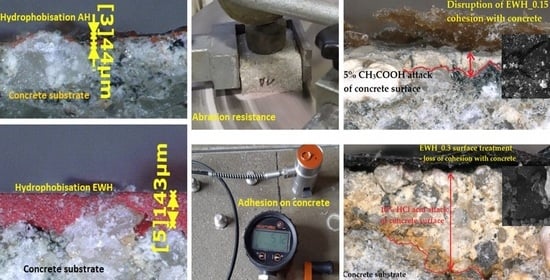

3.2. Thickness of Hydrophobisation

3.3. Adhesion on Concrete

3.4. Abrasion Resistance

3.5. Impact Resistance

3.6. Flexural and Compressive Strength

3.7. Shrinkage

3.8. Water Absorption

3.9. Resistance to Defrosting Chemicals

3.10. Chemical Resistance

4. Conclusions

- Water-soluble EWH hydrophobisation showed 50× higher viscosity than the AH acrylate solvent hydrophobisation. The AH surface treatment was significantly thinner than water-soluble EWH, even in the same consumption;

- Adhesion of the surface treatments on concrete was higher than 3.5 MPa, and the minimum adhesion on concrete is the same for the hydrophobisations AH and EWH;

- Hydrophobisation blocks the absorption of water into the underlying concrete, which was also confirmed by the absorption test;

- Water-based hydrophobisations have been shown to prevent the penetration of chemicals into concrete almost as well as solvent-based hydrophobisation agents, thereby ensuring their longer durability;

- Hydrophobic agents successfully prevented the evaporation of water from the concrete, and thus, the plastic shrinkage that inevitably leads to the appearance of cracks in cement-based constructions;

- No significant difference was recorded in the strengths of concrete treated with hydrophobisations and concrete without surface treatment, while the highest flexural and compressive strengths were achieved for concrete treated with hydrophobisations AH_0.15 and EWH_0.30. For a better comparison of strengths, it would be necessary to apply hydrophobisations on the entire surface of the samples;

- Highest abrasion resistance was shown with concrete treated by AH_0.15 surface treatment; nevertheless, even water-soluble hydrophobisation significantly increased the abrasion resistance of concrete;

- Compared to untreated concrete (C_REF), concrete with EWH_0.3 hydrophobisation showed up to three times lower shrinkage;

- The lowest water absorption was recorded with the concrete treated by EWH_0.3 hydrophobisation—after 120 days the water absorption was only 3.8%;

- By applying EWH hydrophobisation, a significant improvement in resistance to defrosting agents was achieved in comparison with untreated concrete;

- Exposure of the water-soluble EWH hydrophobisation agents to acetic acid caused significant deterioration of the surface treatment and concrete surface. However, resistance to 5% H2SO4, 10% HNO3 and 10% HCl of the surface concrete treated by EWH was very similar with the concrete with AH surface treatment;

- Through SEM observations, the microstructure of AH and EWH hydrophobisations and its disruption and loss of cohesion with surface concrete after chemical aggressive environment attack was revealed;

- By evaluating the results achieved, it can be concluded that water-soluble epoxy-based hydrophobic agents can be used in practice for the same applications as solvent acrylate hydrophobic agents. Moreover, EWH surface treatment is more ecological, as no toxic solvents are released to the ambient environment after application.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Liu, J.; Hu, L.; Tang, L.; Zhang, E.Q.; Ren, J. Shrinkage behaviour, early hydration and hardened properties of sodium silicate activated slag incorporated with gypsum and cement. Constr. Build. Mater. 2020, 248, 118687. [Google Scholar] [CrossRef]

- Tittarelli, F. Oxygen diffusion through hydrophobic cement-based materials. Cem. Concr. Res. 2009, 39, 924–928. [Google Scholar] [CrossRef]

- Al-Kheetan, M.J.; Ghaffar, S.H.; Madyan, O.A.; Rahman, M.M. Development of low absorption and high-resistant sodium acetate concrete for severe environmental conditions. Constr. Build. Mater. 2020, 230, 117057. [Google Scholar] [CrossRef]

- Dai, J.-G.; Akira, Y.; Wittmann, F.H.; Yokota, H.; Zhang, P. Water repellent surface impregnation for extension of service life of reinforced concrete structures in marine environments: The role of cracks. Cem. Concr. Comp. 2010, 32, 101–109. [Google Scholar] [CrossRef]

- Zhu, H.; Li, Q.; Ma, R.; Yang, L.; Hu, Y.; Zhang, J. Water-repellent additive that increases concrete cracking resistance in dry curing environments. Constr. Build. Mater. 2020, 249, 118704. [Google Scholar] [CrossRef]

- Jin, H.; Liu, J.; Jiang, Z.; Zhou, H.; Liu, J. Influence of the rainfall intensity on the chloride ion distribution in concrete with different levels of initial water saturation. Constr. Build. Mater. 2021, 281, 122561. [Google Scholar] [CrossRef]

- Matziaris, K.; Stefanidou, M.; Karagiannis, G. Impregnation and superhydrophobicity of coated porous low-fired clay building materials. Prog. Org. Coat. 2011, 72, 181–192. [Google Scholar] [CrossRef]

- Basheer, P.A.M.; Basheer, L.; Cleland, D.J.; Long, A.E. Surface treatments for concrete: Assessment methods and reported performance. Constr. Build. Mater. 1997, 11, 413–429. [Google Scholar] [CrossRef]

- Ibrahim, M.; Al-Gahtani, A.S.; Maslehuddin, M.; Almusallam, A.A. Effectiveness of concrete surface treatment materials in reducing chloride-induced reinforcement corrosion. Constr. Build. Mater. 1997, 11, 443–451. [Google Scholar] [CrossRef]

- Yang, C.C.; Wang, L.C.; Weng, T.L. Using charge passed and total chloride content to assess the effect of penetrating silane sealer on the transport properties of concrete. Mater. Chem. Phys. 2004, 85, 238–244. [Google Scholar] [CrossRef]

- Kong, X.; Liu, H.; Lu, Z.; Wang, D. The influence of silanes on hydration and strength development of cementitious systems. Cem. Concr. Res. 2015, 67, 168–178. [Google Scholar] [CrossRef]

- Aguiar, J.B.; Júnior, C. Carbonation of surface protected concrete. Constr. Build. Mater. 2013, 49, 478–483. [Google Scholar] [CrossRef] [Green Version]

- Concrete Society. Guide to Surface Treatments for Protection and Enhancement of Concrete. Surrey (UK); Technical Report 50; Concrete Society: London, UK, 1997; 87p. [Google Scholar]

- De Vries, R.B.; Polder, R.B. Hydrophobic treatment of concrete. Constr. Build. Mater. 1997, 11, 259–265. [Google Scholar] [CrossRef]

- Kim, K.H.; Kim, M.J.; Kim, H.; Ann, K. Effect of Hydrophobic Surface Treatment in Lowering Ionic Transport into Concrete. Adv. Mater. Sci. Eng. 2020, 2020, 1–13. [Google Scholar] [CrossRef]

- Zhu, Y.; Kou, S.; Poon, C.; Dai, J.; Li, Q. Influence of silane-based water repellent on the durability properties of recycled aggregate concrete. Cem. Concr. Compos. 2013, 35, 32–38. [Google Scholar] [CrossRef]

- Almusallam, A.A.; Khan, F.M.; Dulaijan, S.U.; Al-Amoudi, O.S.B. Effectiveness of surface coatings in improving concrete durability. Cem. Concr. Compos. 2003, 25, 473–481. [Google Scholar] [CrossRef]

- Schueremans, L.; Gemert, D.V.; Giessler, S. Chloride penetration in RCstructures in marine environment-Long term assessment of a preventive hydrophobic treatment. Constr. Build. Mater. 2007, 21, 1238–1249. [Google Scholar] [CrossRef]

- Medeiros, M.; Helene, P. Efficacy of surface hydrophobic agents in reducing water and chloride ion penetration in concrete. Mater. Struct. 2008, 41, 59–71. [Google Scholar] [CrossRef]

- Xue, X.; Li, Y.; Yang, Z.; He, Z.; Dai, J.G.; Xu, L.; Zhang, W. A systematic investigation of the waterproofing performance and chloride resistance of a self-developed waterborne silane-based hydrophobic agent for mortar and concrete. Constr. Build. Mater. 2017, 155, 939–946. [Google Scholar] [CrossRef]

- Mundo, R.D.; Labianca, C.; Carbone, G.; Notarnicola, M. Recent advances in hydrophobic and icephobic surface treatments of concrete. Coatings 2020, 10, 449. [Google Scholar] [CrossRef]

- Yan, B.; Ren, F.; Cai, M.; Qiao, C. Influence of new hydrophobic agent on the mechanical properties of modified cemented paste backfill. J. Mater. Res. Technol. 2019, 8, 5716–5727. [Google Scholar] [CrossRef]

- Al-Kheetan, M.J.; Rahman, M.M.; Chamberlain, D.A. Moisture evaluation of concrete pavement treated with hydrophobic surface impregnants. Int. J. Pavement Eng. 2020, 21, 1746–1754. [Google Scholar] [CrossRef] [Green Version]

- Wang, X.; Zhai, S.; Wang, K.; Xie, T. Modification of bonding properties and microstructure of resin-cement interface by coupling agents. Compos. Interfaces 2018, 25, 27–37. [Google Scholar] [CrossRef]

- EN 1339; Concrete Paving Flags–Requirements and Test Methods. European Committee for Standardization (CEN): Brussels, Belgium, 2006.

- EN ISO 2555; Plastics—Resins in the Liquid State or as Emulsions or Dispersions—Determination of Apparent Viscosity Using a Single Cylinder Type Rotational Viscometer Method. European Committee for Standardization (CEN): Brussels, Belgium; Technical Committee ISO/TC61/SC5: Geneva, Switzerland, 2018.

- EN ISO 4624; Plastics—Paints and Varnishes—Pull-off Test for Adhesion. European Committee for Standardization (CEN): Brussels, Belgium; Technical Committee ISO/TC35/SC9: Geneva, Switzerland, 2016.

- EN 13892-3; Methods of Test for Screed Materials—Part 3: Determination of Wear Resistance—Böhme. European Committee for Standardization (CEN): Brussels, Belgium, 2014.

- EN ISO 6272-2; Paints and Varnishes—Rapid—Deformation (Impact Resistance) Tests—Part 2: Falling-Weight Test, Small-Area Indenter. European Committee for Standardization (CEN): Brussels, Belgium; Technical Committee ISO/TC35/SC9: Geneva, Switzerland, 2011.

- EN 12390-5; Testing Hardened Concrete–Part 5: Flexural Strength of Test Specimens. European Committee for Standardization (CEN): Brussels, Belgium, 2019.

- EN 12390-3; Testing Hardened Concrete–Part 3: Compressive Strength of Test Specimens. European Committee for Standardization (CEN): Brussels, Belgium, 2019.

- EN 12390-16; Testing Hardened Concrete–Part 16: Determination of the Shrinkage of Concrete. European Committee for Standardization (CEN): Brussels, Belgium, 2019.

- EN 14617-1; Agglomerated Stone–Test Methods–Part 1: Determination of Apparent Density and Water Absorption. European Committee for Standardization (CEN): Brussels, Belgium, 2013.

- ČSN 73 1326; Determination of the resistance of the surface of cement concrete against the action of water and chemical deicers. Czech Standardization Institute (CSI): Prague, Czech Republic, 1985.

- Chatveera, B.; Lertwattanaruk, P. Evaluation of nitric and acetic acid resistance of cement mortars containing high-volume black rice husk ash. J. Environ. Manag. 2014, 133, 365–373. [Google Scholar] [CrossRef] [PubMed]

- Pavlík, V. Corrosion of hardened cement paste by acetic and nitric acids Part III: Influence of water/cement ratio. Cem. Concr. Res. 1996, 26, 475–490. [Google Scholar] [CrossRef]

- Teymouri, M.; Behfarnia, K.; Shabani, A. Mix design effects on the durability of alkali-activated slag concrete in a hydrochloric acid environment. Sustainability 2021, 13, 8096. [Google Scholar] [CrossRef]

- Shill, S.K.; Al-Deen, S.; Ashraf, M. Concrete durability issues due to temperature effects and aviation oil spillage at military airbase—A comprehensive review. Constr. Build. Mater. 2018, 160, 240–251. [Google Scholar] [CrossRef]

- Barnat-Hunek, D.; Smarzewski, P.; Suchorab, Z. Effect of hydrophobisation on durability related properties of ceramic brick. Constr. Build. Mater. 2016, 111, 275–285. [Google Scholar] [CrossRef]

- Dang, Y.; Xie, N.; Kessel, A.; McVey, E.; Pace, A.; Shi, X. Accelerated laboratory evaluation of surface treatments for protecting concrete bridge decks from salt scaling. Constr. Build. Mater. 2014, 55, 128–135. [Google Scholar] [CrossRef]

- Gupta, T.; Sharma, R.K.; Chaudhary, S. Impact resistance of concrete containing waste rubber fiber and silica fume. Int. J. Impact. Eng. 2015, 83, 76–87. [Google Scholar] [CrossRef]

- Pan, X.; Shi, Z.; Shi, C.; Ling, T.-C.; Li, N. A review on surface treatment for concrete—Part 2: Performance. Constr. Build. Mater. 2017, 133, 81–90. [Google Scholar] [CrossRef] [Green Version]

- Shi, L.; Liu, J.; Liu, J. Effect of polymer coating on the properties of surface layer concrete. Procedia Eng. 2012, 27, 291–300. [Google Scholar] [CrossRef] [Green Version]

- Raupach, M.; Wolff, L. Long-term durability of hydrophobic treatment on concrete. Coat. Int. Part B Coat. Trans. 2005, 88, 127–133. [Google Scholar] [CrossRef]

- Li, F.; Yang, Y.; Tao, M.; Li, X. A cement paste–tail sealant interface modified with a silane coupling agent for enhancing waterproofing performance in a concrete lining system. RSC Adv. 2019, 9, 7165–7175. [Google Scholar] [CrossRef] [Green Version]

- Mamaghani, I.; Moretti, C.; Dockter, B.; Falken, L.; Tonnenson, J. Evaluation of penetrating sealers for reinforced concrete bridge decks. Transport. Res. Rec. J. Transport. Res. Board. 2009, 2108, 86–96. [Google Scholar] [CrossRef]

- Suleiman, A.R.; Soliman, A.M.; Nehdi, M.L. Effect of surface treatment on durability of concrete exposed to physical sulfate attack. Constr. Build. Mater. 2014, 73, 674–681. [Google Scholar] [CrossRef]

- Marotta, A.; Faggio, N.; Ambrogi, V.; Mija, A.; Gentile, G.; Cerruti, P. Biobased furan-based epoxy/TiO2 nanocomposites for the preparation of coatings with improved chemical resistance. Chem. Eng. J. 2021, 406, 127107. [Google Scholar] [CrossRef]

- Sembokuya, H.; Negishi, Y.; Kubouchi, M.; Tsuda, K. Corrosion behavior of epoxy resin cured with different amount of hardener in corrosive solutions. Mater. Sci. Res. Int. 2003, 9, 230–234. [Google Scholar] [CrossRef]

- Aguiar, J.B.; Camoes, A.; Moreira, P.M.; Kruger, D. Performance of concrete in aggressive environment. Concr. Struct. Materials. 2008, 2, 21–25. [Google Scholar]

| Parameter | AH | EWH |

|---|---|---|

| Application temperature | min. +15 °C, max. 25 °C | min. +15 °C, max. 35 °C |

| Weight mixing ratio | - | 1:1.08 (A:B) |

| Consumption | 0.15 kg/m2 | 0.15 and 0.30 kg/m2 |

| Working time | No limitations | 30 min |

| Dry time | 30 min | 20 min |

| Specific weight | 0.92 kg/L | 1.1 kg/L |

| Substrate | concrete | concrete |

| Parameter | Concrete Paving Blocks | Concrete Prisms |

|---|---|---|

| Flexural strength | ≥4.0 MPa | ≥4.0 MPa |

| Compressive strength | ≥30 MPa | ≥25 MPa |

| Water/cement ratio | 0.4 | 0.5 |

| Weather resistance | ≤1.0 kg/m2 after 100 cycles | ≤1.0 kg/m2 after 100 cycles |

| skid/slip resistance | satisfactory | satisfactory |

| Substrate | AH_0.15 | EWH_0.15 | EWH_0.3 |

|---|---|---|---|

| Paving block | 24.0 | 24.0 | 24.0 |

| Beam (all surfaces) | 4.4 | 4.4 | 4.4 |

| Beam (1 top surface) | 1.0 | 1.0 | 2.0 |

| Type of Hydrophobisation | Viscosity [mPa·s] | Speed of Rotation [rpm] |

|---|---|---|

| AH | 42 | 250 |

| EWH | 2106 | 136 |

| Type of Hydrophobisation | Consumption [kg/m2] | Thickness of Layer (µm) |

|---|---|---|

| EWH_0.15 | 0.15 | 137 |

| EWH_0.30 | 0.30 | 243 |

| AH_0.15 | 0.15 | 53 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hodul, J.; Hodná, J.; Mészárosová, L.; Borg, R.P. Experimental Comparison of Efficiency of Water-Soluble and Solvent Hydrophobic Agents for Concrete. Buildings 2022, 12, 1857. https://doi.org/10.3390/buildings12111857

Hodul J, Hodná J, Mészárosová L, Borg RP. Experimental Comparison of Efficiency of Water-Soluble and Solvent Hydrophobic Agents for Concrete. Buildings. 2022; 12(11):1857. https://doi.org/10.3390/buildings12111857

Chicago/Turabian StyleHodul, Jakub, Jana Hodná, Lenka Mészárosová, and Ruben Paul Borg. 2022. "Experimental Comparison of Efficiency of Water-Soluble and Solvent Hydrophobic Agents for Concrete" Buildings 12, no. 11: 1857. https://doi.org/10.3390/buildings12111857

APA StyleHodul, J., Hodná, J., Mészárosová, L., & Borg, R. P. (2022). Experimental Comparison of Efficiency of Water-Soluble and Solvent Hydrophobic Agents for Concrete. Buildings, 12(11), 1857. https://doi.org/10.3390/buildings12111857