A Study on the Influence of Bolt Arrangement Parameters on the Bending Behavior of Timber–Steel Composite (TSC) Beams

Abstract

:1. Introduction

2. Materials and Methods

2.1. Specimens Design

2.2. Material Properties

2.3. Test Method

2.4. Theoretical Method

2.4.1. Park’s Method

2.4.2. Calculation of Bolts Relative Slip in Elastic State

- (1)

- Constitutive relationship of timber–steel interface

- (2)

- Equilibrium relationship at the timber–steel interface

- (3)

- Relative slip equation of bolt distance in elastic limit state

3. Results and Discussion

3.1. Failure Mode and Mechanism

3.2. Load–Midspan Deflection Curve

3.3. Slip Effect of Timber–Steel Interface

3.4. Comparison of Experimental and Theoretical Results

4. Conclusions

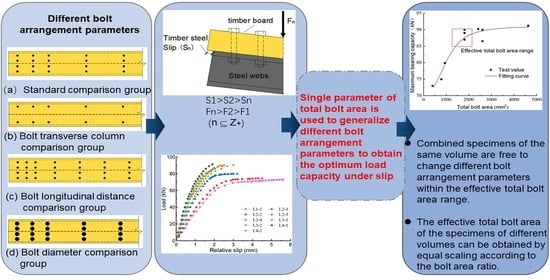

- (1)

- When the span deflection reached the limit value of 50 mm, the failure mode of nine timber–steel composite beams was as follows. ① Except for the top timber board of the L1 group, which had no obvious damage, the top surface of the board of all other specimens had longitudinal cracks (splitting) due to compression, and some of the boards of the specimens were crushed. ② The stress at the lower edge of the I-beam entered the flow amplitude stage, but the boards did not fracture. The composite beam connection was weak, and the stiffness was low due to the relatively few bolts assembled in the L1 group. Thus, when the midspan deflection reached an extreme value, there was no evident damage to the top board. Moreover, the bearing capacity was poor.

- (2)

- The load–deflection curve of the composite beam showed that the midspan deflection increased with the increase in the load. The elastic, elastic–plastic, and plastic stages were identified in the load–deflection curve. The composite beam had good ductility.

- (3)

- The maximum relative slip of the timber–steel interface was 2–6 mm. With the increase in bolt area ratio, the maximum slip of the interface decreased gradually, and the flexural bearing capacity of the specimen increased significantly, but the ductility coefficient decreased. Considering bolt number and economic and mechanical performance, the best bolt area ratio obtained was 8 × 10−3. Among the different bolt arrangement parameters, the longitudinal distance of bolts had a great influence on the slip, and the bolt diameter had little influence.

- (4)

- The constitutive, geometric, and equilibrium relationships of the timber–steel interface were used to derive the relative slip equations for each section. The total relative slip values after superposition were found to be in good agreement with the experimental data, and the error was controlled within 15%, which serves as a reference for predicting the relative slip of composite beams and bolts in practical engineering.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Awadhani, L.V.; Bewoor, A. Parametric Study of Single Bolted Composite Bolted Joint Subjected to Static Tensile Loading. IOP Conf. Ser. Mater. Sci. Eng. 2017, 225, 012257. [Google Scholar]

- Gu, Y.; Zhao, C.Q.; Yang, Y.; Zhao, W.R. Connection Performance of Bolted Aluminum Alloy Honeycomb Panel-Beam Composite Structure. Key Eng. Mater. 2019, 4830, 59–66. [Google Scholar] [CrossRef]

- Wang, Y.-H.; Yu, J.; Liu, J.-P.; Chen, Y.F. Experimental study on assembled monolithic steel-concrete composite beam in positive moment. Eng. Struct. 2019, 180, 494–509. [Google Scholar] [CrossRef]

- Xin, F.; Hongbin, X.; Bowang, C. Experimental study on splitting strength of sawn lumber loaded perpendicular to grain by bolted steel-wood-steel connections. J. Build. Eng. 2021, 44, 102554. [Google Scholar]

- Johanides, M.; Lokaj, A.; Mikolasek, D.; Mynarcik, P.; Dobes, P.; Sucharda, O. Timber Semirigid Frame Connection with Improved Deformation Capacity and Ductility. Buildings 2022, 12, 583. [Google Scholar] [CrossRef]

- Ganbaatar, A.; Mori, T.; Inoue, R.; Danzandorj, S. Strength Performance of the Connection between Brick and SPF Lumber. Buildings 2022, 12, 465. [Google Scholar] [CrossRef]

- Chybiński, M.; Polus, Ł. Experimental and numerical investigations of aluminium-timber composite beams with bolted connections. Structures 2021, 34, 1942–1960. [Google Scholar] [CrossRef]

- Tran, M.T.; Van Do, V.N.; Nguyen, T.A. Behaviour of steel-concrete composite beams using bolts as shear connectors. IOP Conf. Ser. Earth Environ. Sci. 2018, 143, 12–27. [Google Scholar] [CrossRef]

- Roman, P.A.; Osama, S. Structural fire performance of wood-steel-wood bolted connections with and without perpendicular-to-wood grain reinforcement. J. Struct. Fire Eng. 2019, 1, 1–20. [Google Scholar] [CrossRef]

- Ataei, A.; Chiniforush, A.A.; Bradford, M.A.; Valipour, H.R.; Ngo, T.D. Behaviour of embedded bolted shear connectors in steel-timber composite beams subjected to cyclic loading. J. Build. Eng. 2022, 54, 104581. [Google Scholar] [CrossRef]

- Hassanieh, A.; Valipour, H.R.; Bradford, M.A. Experimental and numerical study of steel-timber composite (STC) beams. J. Constr. Steel Res. 2016, 122, 367–378. [Google Scholar] [CrossRef]

- GB 50017-2003; Code for Design of Steel Structures. Ministry of Housing and Urban-Rural Development of the People’s Republic of China: Beijing, China, 2017; pp. 73–92.

- EN 1995-1-1-2008; DD ENV1995-1-1. Eurocode 5: Design of Timber Structures. British Standards Institution: London, UK, 1994; pp. 73–92.

- GB 50005-2017; Standard for Design of Timber Structures. Ministry of Housing and Urban-Rural Development of the People’s Republic of China: Beijing, China, 2017; pp. 41–60.

- (2007)D143-94 [S]; Standard Test Methods for Small Clear Specimens of Timber. ASTM: West Conshohocken, PA, USA, 2007.

- Design Handbook for Timber Structures Editorial Committee. Design Handbook for Timber Structures; Architecture & Building Press: Beijing, China, 2005; pp. 43–48. [Google Scholar]

- Feng, P.; Qiang, H.L. Discussion and definition on yield points of materies, members and structures. Eng. Mech. 2017, 34, 36–46. [Google Scholar]

- Park, R. State of the art report ductility evaluation from laboratory and analytical testing. In Proceedings of the Ninth World Conference on Earthquake Engineering, Tokyo, Japan, 2–9 August 1988. [Google Scholar]

- Wang, P.; Zhou, D.H. Calculation on slip of composite beams with stepwise uniform distribution of shear connectors. Build. Struct. 2011, 41, 96–101. [Google Scholar]

- Nie, J.G.; Shen, J.M. A general formula for predicting the deflection of simply supported composite steel-concrete beams with the consideration slip effect. Eng. Mech. 1994, 11, 21–27. [Google Scholar]

- Lam, D.; El-Lobody, E. Behavior of Headed Stud Shear Connectors in Composite Beam. J. Struct. Eng. 2005, 131, 96–107. [Google Scholar] [CrossRef]

- Gutkowski, R.; Brown, K.; Shigidi, A.; Natterer, J. Laboratory tests of composite wood-concrete beams. Constr. Build. Mater. 2008, 22, 1059–1066. [Google Scholar] [CrossRef]

- Mao, L.; Chen, D.W. Closed-form Solution of Composite Beam Considering Interfacial Slip Effects. J. Tongji Univ. (Nat. Sci.) 2011, 39, 1113–1119. [Google Scholar]

| Specimen No. | Longitudinal Stiffening Ribs | |||

|---|---|---|---|---|

| L1-1 | 2 | 5 | 210 | yes |

| L2-1 | 4 | 5 | 210 | yes |

| L2-2 | 4 | 5 | 140 | yes |

| L2-3 | 4 | 5 | 70 | yes |

| L2-4 | 4 | 5 | 70 | yes |

| L3-1 | 4 | 6 | 70 | no |

| L3-2 | 4 | 6 | 70 | yes |

| L4-1 | 4 | 8 | 70 | yes |

| L4-2 | 4 | 8 | 140 | yes |

| Moisture Content (%) | Compressive Strength along Grain (MPa) | Tensile Strength along Grain (MPa) | Shear Strength along Grain (MPa) | Elastic Modulus (MPa) |

|---|---|---|---|---|

| 13.6 | 26 | 20.79 | 7 | 12,000 |

| Yield Strength (MPa) | Tensile Strength (MPa) | Shear Strength (MPa) | Elastic Modulus in Compression (MPa) |

|---|---|---|---|

| 235 | 375 | 141 | 206,000 |

| Yield Strength (MPa) | Shear Strength (MPa) | Tensile Strength (MPa) |

|---|---|---|

| 320 | 141 | 400 |

| Specimen No. | |||||

|---|---|---|---|---|---|

| L1-1 | 57.08 | 10.63 | 73.00 | 50 | 4.70 |

| L2-1 | 60.09 | 8.15 | 75.00 | 50 | 6.13 |

| L2-2 | 61.26 | 10.18 | 79.90 | 50 | 4.91 |

| L2-3 | 66.01 | 13.38 | 89.00 | 50 | 3.73 |

| L2-4 | 67.68 | 14.08 | 90.00 | 50 | 3.55 |

| L3-1 | 67.32 | 10.88 | 90.00 | 50 | 4.59 |

| L3-2 | 64.99 | 12.18 | 86.52 | 50 | 4.10 |

| L4-1 | 68.45 | 12.88 | 91.14 | 50 | 3.88 |

| L4-2 | 67.39 | 12.76 | 90.25 | 50 | 3.91 |

| Specimen No. | (kN) | (mm) | (Piece) | |||

|---|---|---|---|---|---|---|

| L1-1 | 73.00 | 5.6 | 20 | 392.70 | 225,000 | 1.75 |

| L2-1 | 75.00 | 4.5 | 40 | 785.40 | 3.49 | |

| L2-2 | 79.90 | 3.2 | 48 | 942.48 | 4.19 | |

| L2-3 | 89.00 | 2.4 | 92 | 1806.42 | 8.03 | |

| L2-4 | 90.00 | 2.5 | 92 | 1806.42 | 8.03 | |

| L3-1 | 90.00 | 2.3 | 92 | 2601.24 | 11.56 | |

| L3-2 | 86.52 | 2.0 | 92 | 2601.24 | 11.56 | |

| L4-1 | 91.14 | 1.9 | 92 | 4624.42 | 20.55 | |

| L4-2 | 90.25 | 2.3 | 48 | 2412.74 | 10.72 |

| Specimen No. | |||

|---|---|---|---|

| L1-1 | 1.32 | 1.41 | 0.93 |

| L2-1 | 1.14 | 1.22 | 0.93 |

| L2-2 | 0.78 | 0.85 | 0.91 |

| L2-3 | 0.61 | 0.71 | 0.85 |

| L2-4 | 0.62 | 0.71 | 0.87 |

| L3-1 | 0.54 | 0.64 | 0.84 |

| L3-2 | 0.60 | 0.72 | 0.83 |

| L4-1 | 0.50 | 0.58 | 0.86 |

| L4-2 | 0.72 | 0.81 | 0.89 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, R.; Liu, J.; Wu, Z.; Chen, L.; Wang, J. A Study on the Influence of Bolt Arrangement Parameters on the Bending Behavior of Timber–Steel Composite (TSC) Beams. Buildings 2022, 12, 2013. https://doi.org/10.3390/buildings12112013

Liu R, Liu J, Wu Z, Chen L, Wang J. A Study on the Influence of Bolt Arrangement Parameters on the Bending Behavior of Timber–Steel Composite (TSC) Beams. Buildings. 2022; 12(11):2013. https://doi.org/10.3390/buildings12112013

Chicago/Turabian StyleLiu, Ruiyue, Jiatong Liu, Zhenzhen Wu, Ling Chen, and Jiejun Wang. 2022. "A Study on the Influence of Bolt Arrangement Parameters on the Bending Behavior of Timber–Steel Composite (TSC) Beams" Buildings 12, no. 11: 2013. https://doi.org/10.3390/buildings12112013

APA StyleLiu, R., Liu, J., Wu, Z., Chen, L., & Wang, J. (2022). A Study on the Influence of Bolt Arrangement Parameters on the Bending Behavior of Timber–Steel Composite (TSC) Beams. Buildings, 12(11), 2013. https://doi.org/10.3390/buildings12112013