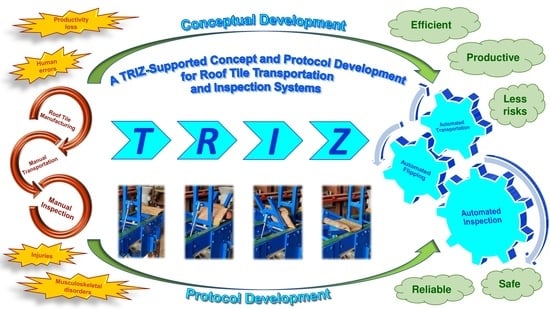

A TRIZ-Supported Concept and Protocol Development for Roof Tile Transportation and Inspection Systems

Abstract

:1. Introduction

| System | Key Findings | Ref. |

|---|---|---|

| Conveyor System |

| [12] |

| [16] | |

| [14] | |

| [13] | |

| AGV System |

| [18] |

| [17] | |

| [19] | |

| MHE |

| [20] |

| Industrial Trucks |

| [21] |

| Forklift |

| [34] |

| [22] | |

| [35] |

- To propose the most appropriate transportation and inspection system for the roof tile manufacturing industry in Indonesia with the support of the TRIZ approach;

- To propose an efficient, reliable, and productive protocol in evaluating the efficacy of the proposed manufacturing system compared to the manual process with the support of the TRIZ approach.

2. Methodology

2.1. Conceptualisation of Roof Tile Manufacturing System

2.2. Concept Selection

2.3. Conceptualisation of Protocol

2.4. Supporting Concept and Protocol Selection with TRIZ

- Formulation of engineering contradiction;

- Identification of system parameters in engineering contradiction;

- Intersection of system parameters within TRIZ contradiction matrix;

- Selection of inventive principle from the intersection of system parameters;

- Proposal of concept or solution based on selected inventive principle.

3. Results and Discussion

3.1. Concept Selection for an Appropriate Transportation System

3.1.1. Concept Screening Results

3.1.2. TRIZ Supporting Results for Concept Selection

EC1: If a semi-automated concept is applied, then the productivity is better than using manual labour (Parameter 39: Productivity), but the rate of work performed is not optimal compared to a fully automated concept (Parameter 21: Power).

3.1.3. Concept Scoring Results

3.2. Selection for Appropriate Protocol

3.2.1. Protocol Screening Results

3.2.2. TRIZ Supporting Results for Protocol Selection

EC2: If longitudinal data on productivity was used in the assessment of the system, then a thorough productivity assessment can be performed (Parameter 39: Productivity), but there is a risk of losing more important Information due to human error in the time-consuming process of evaluation (parameter 24: loss of information).

3.2.3. Protocol Scoring Results

3.3. Finalised Protocol

3.3.1. Efficiency Test

- How fast can the roof tiles be transported with the system (test group) compared to the manual process (control group)?

- How fast can the system (test group) be completed with the roof tile inspection compared to the manual (control group) inspection process?

- Time taken for the roof tiles to be transported from point A to B.

- Null hypothesis, H0a: The time taken to transport the roof tiles from point A to B with the system (test group) does not significantly differ from the manual process (control group) (p > 0.05).

- Alternative hypothesis, H1a: The time taken to transport the roof tiles from point A to B with the system (test group) significantly differs from the manual process (control group) (p < 0.05).

- Time taken for roof tiles to be inspected.

- Null hypothesis, H0b: The time taken to complete the roof tile inspection with the system (test group) does not significantly differ from the manual inspection process (control group) (p > 0.05).

- Alternative hypothesis, H1b: The time taken to complete the roof tile inspection with the system (test group) significantly differs from the manual inspection process (control group) (p < 0.05).

3.3.2. Reliability Test

- How foolproof can transporting roof tiles be with the system (test group) compared to the manual process (control group)?

- How foolproof can inspecting roof tiles be with the system (test group) compared to the manual inspection process (control group)?

- Several errors occur when roof tiles are transported from point A to B.

- Null hypothesis, H0a: The number of errors when transporting the roof tiles from point A to B with the system (test group) does not significantly differ from the manual process (control group) (p > 0.05).

- Alternative hypothesis, H1a: The number of errors when transporting the roof tiles from point A to B with the system (test group) significantly differs from the manual process (control group) (p < 0.05).

- Several errors occur when roof tiles are inspected (e.g., defect not being detected, or defect detected when there was none).

- Null hypothesis, H0b: The number of errors when inspecting the roof tiles with the system (test group) does not significantly differ from the manual inspection process (control group) (p > 0.05).

- Alternative hypothesis, H1b: The number of errors when inspecting the roof tiles with the system (test group) does not significantly differ from the manual inspection process (control group) (p < 0.05).

3.3.3. Productivity Test

- How productive can roof tiles transportation be with the system (test group) compared to the manual process (control group)?

- How productive can roof tiles inspection be with the system (test group) compared to the manual inspection process (control group)?

- c.

- A total number of roof tiles transported from point A to B at a fixed timeframe.

- H0a: The number of roof tiles transported from point A to B with the system (test group) does not significantly differ from the manual process (control group) (p > 0.05).

- H1a: The number of roof tiles transported from point A to B with the system (test group) significantly differs from the manual process (control group) (p < 0.05).

- d.

- A total number of roof tiles inspected at a fixed timeframe.

- H0b: The number of roof tiles inspected with the system (test group) does not significantly differ from the manual inspection process (control group) (p > 0.05).

- H1b: The number of roof tiles inspected with the system (test group) significantly differs from the manual inspection process (control group) (p < 0.05).

3.3.4. Proposed Analyses

3.3.5. Proposed Procedures

- The timer on the stopwatch is initiated when a roof tile is placed on the conveyor system at point A;

- The timer is stopped when the conveyor successfully transports the roof tile to point B. Time is then recorded;

- The timer is initiated when the automated roof tile inspection commences;

- The timer is stopped when the roof tile inspection is completed and recorded;

- Steps 1 to 4 are repeated until the total planned samples for the experiment have been achieved;

- It is important to note that the time taken for Steps 1 to 2 and 3 to 4 should be separated;

- It is important to note that the time taken is only valid if there are no errors during the trial.

- The timer on the stopwatch is initiated when the participant lifts and transports a batch of roof tiles at point A;

- The timer is stopped when the batch of roof tiles is successfully transported to point B. Batch time is then recorded;

- Steps 1 to 2 are repeated until the total planned samples for the experiment have been achieved;

- It is important to note that the time taken for one transportation batch needs to be divided with the total samples within the batch (5 samples) to be fairly compared with the test group;

- The timer is initiated when the participant’s manual inspection of the roof tile commences;

- The timer is stopped when the manual inspection for the roof tile is completed and recorded;

- Steps 5 to 6 are repeated until the total planned samples for the experiment have been achieved;

- It is important to note that the time taken for Steps 1 to 2 and 5 to 6 should be separated;

- It is also important to note that the time taken is only valid if there are no errors during the trial.

- Several errors occur when one roof tile is transported with the system from point A to B are recorded;

- Several errors occur during the automated inspection are recorded;

- Steps 1 to 2 are repeated until the total planned samples for the experiment have been achieved.

- Several errors occur when one roof tile is transported manually from point A to B are recorded;

- Several errors that occur during the manual inspection process are recorded;

- Steps 1 to 2 are repeated until the total planned samples for the experiment have been achieved.

- A fixed timeframe is established and clocked using a stopwatch;

- The total number of roof tiles transported within this fixed timeframe by the system from point A to B is recorded;

- Step 2 is repeated for five sessions;

- The total number of roof tiles inspected within the fixed timeframe by the system is also recorded;

- Step 4 is repeated for five sessions.

- A fixed timeframe is established and clocked using a stopwatch;

- The total number of roof tiles transported within this fixed timeframe manually from point A to B is recorded;

- Step 2 is repeated for five sessions;

- The total number of roof tiles inspected within this timeframe manually is also recorded;

- Step 4 is repeated for five sessions.

4. Conclusions

4.1. Limitations

4.2. Directions for Future Research

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ayub, Y.; Shah, Z.A. Assessment of Work Related Musculoskeletal Disorders in Manufacturing Industry. J. Ergon. 2018, 8, 1000233. [Google Scholar] [CrossRef]

- Fernandes, R.d.C.P.; Assunção, A.A.; Silvany Neto, A.M.; Carvalho, F.M. Musculoskeletal disorders among workers in plastic manufacturing plants. Rev. Bras. Epidemiol. 2010, 13, 11–20. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Trevelyan, F.C.; Haslam, R.A. Musculoskeletal disorders in a handmade brick manufacturing plant. Int. J. Ind. Ergon. 2001, 27, 43–55. [Google Scholar] [CrossRef]

- Silverstein, B.; Evanoff, B. Musculoskeletal Disorders: Recognizing and Preventing Disease and Injury. In Occupational and Environmental Health, 6th ed.; Levy, B.S., Wegman, D.H., Baron, S.L., Sokas, R.K., Eds.; Oxford University Press: New York, NY, USA, 2011. [Google Scholar]

- Choobineh, A.; Tabatabaei, S.H.; Mokhtarzadeh, A.; Salehi, M. Musculoskeletal problems among workers of an Iranian rubber factory. J. Occup. Health 2007, 49, 418–423. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Florescu, A.; Barabas, S.A. Modeling and Simulation of a Flexible Manufacturing System—A Basic Component of Industry 4.0. Appl. Sci. 2020, 10, 8300. [Google Scholar] [CrossRef]

- Khanna, K.; Kumar, R. Reconfigurable manufacturing system: A state-of-the-art review. Benchmarking Int. J. 2019, 26, 2608–2635. [Google Scholar] [CrossRef]

- McDermott, C.M.; Stock, G.N. Organizational culture and advanced manufacturing technology implementation. J. Oper. Manag. 1999, 17, 521–533. [Google Scholar] [CrossRef]

- Liu, P.; Zhang, Q.; Pannek, J. Development of Operator Theory in the Capacity Adjustment of Job Shop Manufacturing Systems. Appl. Sci. 2019, 9, 2249. [Google Scholar] [CrossRef] [Green Version]

- Hembecker, P.K.; Reis, D.C.; Konrath, A.C.; Gontijo, L.A.; Merino, E.A.D. Investigation of musculoskeletal symptoms in a manufacturing company in Brazil: A cross-sectional study. Braz. J. Phys. Ther. 2017, 21, 175–183. [Google Scholar] [CrossRef]

- Rinaldi, M.; Caterino, M.; Fera, M.; Macchiaroli, R. Reducing the physical ergonomic risk by job rotation: A simulation-based approach. IFAC-PapersOnLine 2021, 54, 1–6. [Google Scholar] [CrossRef]

- Butt, J.; Jedi, S. Redesign of an In-Market Conveyor System for Manufacturing Cost Reduction and Design Efficiency Using DFMA Methodology. Designs 2020, 4, 6. [Google Scholar] [CrossRef] [Green Version]

- Ananth, K.N.S.; Rakesh, V.; Visweswarao, P.K. Design and Selecting the Proper Conveyor-Belt. Int. J. Adv. Eng. Technol. 2013, 4, 43–49. [Google Scholar]

- Gupta, D.; Dave, D. Study and Performance of Belt Conveyor System with Different Type Parameter. Int. J. Innov. Res. Sci. Technol. 2015, 2, 29–31. [Google Scholar]

- Jiamruangjarus, P.; Naenna, T. An integrated multi-criteria decision-making methodology for conveyor system selection. Cogent Eng. 2016, 3, 1158515. [Google Scholar] [CrossRef]

- Salawu, G.; Bright, G.; Onunka, C. Modelling and simulation of a conveyor belt system for optimal productivity. Int. J. Mech. Eng. Technol. 2020, 11, 115–121. [Google Scholar] [CrossRef]

- Hu, Y.; Yang, H.; Huang, Y. Conflict-free scheduling of large-scale multi-load AGVs in material transportation network. Transp. Res. Part E Logist. Transp. Rev. 2022, 158, 102623. [Google Scholar] [CrossRef]

- Mantel, R.J.; Landeweerd, H.R.A. Design and operational control of an AGV system. Int. J. Prod. Econ. 1995, 41, 257–266. [Google Scholar] [CrossRef] [Green Version]

- Shneier, M.; Bostelman, R. Literature Review of Mobile Robots for Manufacturing, 1st ed.; National Institute of Standards and Technology, U.S. Department of Commerce: Washington, DC, USA, 2015. [Google Scholar]

- Soufi, Z.; David, P.; Yahouni, Z. A methodology for the selection of Material Handling Equipment in manufacturing systems. IFAC-PapersOnLine 2021, 54, 122–127. [Google Scholar] [CrossRef]

- Sonpimple, M.K.; Shelare, S.D.; Raghorte, A.N. Design and Modification of Innovative Motorized Hand Truck. Int. J. Adv. Eng. Manag. Sci. 2017, Special Issue-3, 97–103. [Google Scholar] [CrossRef]

- Widyotriatmo, A.; Pamosoaji, A.K.; Hong, K.-S. Control Architecture of an Autonomous Material Handling Vehicle. Int. J. Artif. Intell. 2013, 10, 139–153. [Google Scholar]

- Alper Selver, M.; Akay, O.; Alim, F.; Bardakçı, S.; Ölmez, M. An automated industrial conveyor belt system using image processing and hierarchical clustering for classifying marble slabs. Robot. Comput. -Integr. Manuf. 2011, 27, 164–176. [Google Scholar] [CrossRef]

- Boukouvalas, C.; Kittler, J.; Marik, R.; Petrou, M. Automatic color grading of ceramic tiles using machine vision. IEEE Trans. Ind. Electron. 1997, 44, 132–135. [Google Scholar] [CrossRef]

- Caggiano, A.; Zhang, J.; Alfieri, V.; Caiazzo, F.; Gao, R.; Teti, R. Machine learning-based image processing for on-line defect recognition in additive manufacturing. CIRP Ann. 2019, 68, 451–454. [Google Scholar] [CrossRef]

- Coskun, H.; Yiğit, T.; Üncü, İ.S. Integration of digital quality control for intelligent manufacturing of industrial ceramic tiles. Ceram. Int. 2022, 48, 34210–34233. [Google Scholar] [CrossRef]

- Fan, S.; Liang, X.; Huang, W.; Jialong Zhang, V.; Pang, Q.; He, X.; Li, L.; Zhang, C. Real-time defects detection for apple sorting using NIR cameras with pruning-based YOLOV4 network. Comput. Electron. Agric. 2022, 193, 106715. [Google Scholar] [CrossRef]

- Gao, Y.; Li, X.; Wang, X.V.; Wang, L.; Gao, L. A Review on Recent Advances in Vision-based Defect Recognition towards Industrial Intelligence. J. Manuf. Syst. 2022, 62, 753–766. [Google Scholar] [CrossRef]

- Iglesias, C.; Martínez, J.; Taboada, J. Automated vision system for quality inspection of slate slabs. Comput. Ind. 2018, 99, 119–129. [Google Scholar] [CrossRef]

- Nasrollahi, M.; Bolourian, N.; Hammad, A. Concrete Surface Defect Detection Using Deep Neural Network Based on Lidar Scanning. In Proceedings of the CSCE Annual Conference: Growing with Youth—Croître Avec Les Jeunes, Laval, QC, Canada, 12–15 June 2019. [Google Scholar]

- Shi, Y.; Cui, L.; Qi, Z.; Meng, F.; Chen, Z. Automatic Road Crack Detection Using Random Structured Forests. IEEE Trans. Intell. Transp. Syst. 2016, 17, 3434–3445. [Google Scholar] [CrossRef]

- Stephen, O.; Maduh, U.J.; Sain, M. A Machine Learning Method for Detection of Surface Defects on Ceramic Tiles Using Convolutional Neural Networks. Electronics 2022, 11, 55. [Google Scholar] [CrossRef]

- Ye, W.; Deng, S.; Ren, J.; Xu, X.; Zhang, K.; Du, W. Deep learning-based fast detection of apparent concrete crack in slab tracks with dilated convolution. Constr. Build. Mater. 2022, 329, 127157. [Google Scholar] [CrossRef]

- Facchini, F.; Mummolo, G.; Mossa, G.; Digiesi, S.; Boenzi, F.; Verriello, R. Minimizing the carbon footprint of material handling equipment: Comparison of electric and LPG forklifts. J. Ind. Eng. Manag. 2016, 9, 1035–1046. [Google Scholar] [CrossRef] [Green Version]

- Tamba, T.A.; Bui, Q.T.T.; Keum-Shik, H. Trajectory generation of an unmanned forklift for autonomous operation in material handling system. In Proceedings of the 2008 SICE Annual Conference, Chofu, Japan, 20–22 August 2008; pp. 1800–1805. [Google Scholar]

- Al Khawli, T.; Anwar, M.; Gan, D.; Islam, S. Integrating laser profile sensor to an industrial robotic arm for improving quality inspection in manufacturing processes. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2020, 235, 4–17. [Google Scholar] [CrossRef]

- Chen, Z.; Siu, S.; Tin, S.; Liu, Y.; Cao, H.; Gao, Y.; Zhou, J.; Liu, Y. A Dexterous Origami-inspired Soft (DOIS) Robot for Objects Reorientation and Overturn. In Proceedings of the 2021 IEEE International Conference on Real-time Computing and Robotics (RCAR), Xining, China, 15–19 July 2021; pp. 1379–1384. [Google Scholar]

- Gautam, R.; Gedam, A.; Zade, A.; Mahawadiwar, A. Review on Development of Industrial Robotic Arm. Int. Res. J. Eng. Technol. 2017, 4, 1752–1755. [Google Scholar]

- Kolathaya, S.; Guffey, W.; Sinnet, R.W.; Ames, A.D. Direct Collocation for Dynamic Behaviors With Nonprehensile Contacts: Application to Flipping Burgers. IEEE Robot. Autom. Lett. 2018, 3, 3677–3684. [Google Scholar] [CrossRef]

- Tahara, K.; Arimoto, S.; Yoshida, M. Dynamic object manipulation using a virtual frame by a triple soft-fingered robotic hand. In Proceedings of the 2010 IEEE International Conference on Robotics and Automation, Anchorage, AK, USA, 3–7 May 2010; pp. 4322–4327. [Google Scholar]

- Wada, K.; James, S.; Davison, A.J. ReorientBot: Learning Object Reorientation for Specific-Posed Placement. In Proceedings of the 2022 International Conference on Robotics and Automation (ICRA), Philadelphia, PA, USA, 23–27 May 2022; pp. 8252–8258. [Google Scholar]

- Chavan-Dafle, N.; Mason, M.T.; Staab, H.; Rossano, G.; Rodriguez, A. A two-phase gripper to reorient and grasp. In Proceedings of the 2015 IEEE International Conference on Automation Science and Engineering (CASE), Gothenburg, Sweden, 24-28 August 2015; pp. 1249–1255. [Google Scholar]

- Aggarwal, I.; Faujdar, N.; Verma, S.; Khanna, P. Development of a smart flipping system. Int. Res. J. Eng. Technol. 2019, 6, 7669–7672. [Google Scholar]

- Barosz, P.; Gołda, G.; Kampa, A. Efficiency Analysis of Manufacturing Line with Industrial Robots and Human Operators. Appl. Sci. 2020, 10, 2862. [Google Scholar] [CrossRef] [Green Version]

- Ahmudi; Mahachandra, M.; Handayani, N.U. Productivity Evaluation Through American Productivity Center Approach at PT Sejahtera Furnindo. IOP Conf. Ser. Mater. Sci. Eng. 2019, 598, 012074. [Google Scholar] [CrossRef]

- Lestari, F.; Nuari, I.; Devani, V. American Productivity Center Method for Measuring Productivity in Palm Oil Milling Industry. In Proceedings of the 2018 IEEE International Conference on Industrial Engineering and Engineering Management (IEEM), Bangkok, Thailand, 16–19 December 2018; pp. 754–757. [Google Scholar]

- Prasetyo, P.E.; Dzaki, F.Z. Efficiency Performance and Productivity of Creative Industries. Int. J. Sci. Technol. Res. 2020, 9, 122–132. [Google Scholar]

- Kliment, M.; Trebuňa, P.; Pekarcikova, M.; Straka, M.; Trojan, J.; Duda, R. Production Efficiency Evaluation and Products’ Quality Improvement Using Simulation. Int. J. Simul. Model. 2020, 19, 470–481. [Google Scholar] [CrossRef]

- Mishra, P.; Singh, U.; Pandey, C.M.; Mishra, P.; Pandey, G. Application of student’s t-test, analysis of variance, and covariance. Ann. Card. Anaesth. 2019, 22, 407–411. [Google Scholar] [CrossRef]

- Meeker, W.Q.; Escoba, L.A. Reliability: The Other Dimension of Quality. Qual. Technol. Quant. Manag. 2004, 1, 1–25. [Google Scholar] [CrossRef] [Green Version]

- Seidel, K. What Is the Benefit of Using a Conveyor System in the Food Industry? Available online: https://cablevey.com/what-is-the-benefit-of-using-a-conveyor-system-in-the-food-industry/ (accessed on 7 August 2022).

- Taglic, N. What Are Automated Guided Vehicles? Available online: https://6river.com/what-are-automated-guided-vehicles/ (accessed on 7 August 2022).

- Rahman, A.; Karim, A. Application of lean production to reducing operational waste in a tile manufacturing process. Int. J. Manag. Sci. Eng. Manag. 2013, 8, 131–139. [Google Scholar] [CrossRef] [Green Version]

- Subashi De Silva, G.H.M.J.; Mallwattha, M.P.D.P. Strength, durability, thermal and run-off properties of fired clay roof tiles incorporated with ceramic sludge. Constr. Build. Mater. 2018, 179, 390–399. [Google Scholar] [CrossRef]

- Raimondo, M.; Ceroni, C.; Dondi, M.; Guarini, G.; Marsigli, M.; Venturi, I.; Zanelli, C. Durability of clay roofing tiles: The influence of microstructural and compositional variables. J. Eur. Ceram. Soc. 2009, 29, 3121–3128. [Google Scholar] [CrossRef]

- Sheikh, M.S.; Kumar, R. Cognitive Manufacturing in Perspective of Future Manufacturing Industries. Int. J. Res. Appl. Sci. Eng. Technol. 2020, 8, 862–866. [Google Scholar] [CrossRef]

- De Silva, G.H.M.J.S.; Surangi, M.L.C. Effect of waste rice husk ash on structural, thermal and run-off properties of clay roof tiles. Constr. Build. Mater. 2017, 154, 251–257. [Google Scholar] [CrossRef]

- Rosida, A.W.; Astuti, D.P.; Widyaputra, F.A.A.; Puspitasari, W.; Seyanto, R.H.; Hisjam, M.; Zakaria, R. Proposed Design of Ergonomic Roof Tile Transportation Equipments in Bekonang Roof Tile Company. In Proceedings of the 11th Annual International Conference on Industrial Engineering and Operations Management Singapore, Singapore, 7–11 March 2021. [Google Scholar]

- Sutjana, I.D.P. Working Accidents among Mill Operators in Small-sized Factories Manufacturing Home Roof Tiles in Pejaten and Nyitdah Villages, Tabanan Regency Indonesia. J. Occup. Health 2000, 42, 91–95. [Google Scholar] [CrossRef] [Green Version]

- Kang, C.Q.; Ng, P.K.; Liew, K.W. The Conceptual Synthesis and Development of a Multifunctional Lawnmower. Inventions 2021, 6, 38. [Google Scholar] [CrossRef]

- Lim, S.H.; Ng, P.K. The Design and Development of a Foldable Wheelchair Stretcher. Inventions 2021, 6, 35. [Google Scholar] [CrossRef]

- Gan, K.W.; Ng, P.K.; Liew, K.W.; Ng, Y.J.; Yeow, J.A. The Conceptual Development of a Multifunctional Stepladder for Older People and Caregivers. Int. J. Environ. Res. Public Health 2022, 19, 14399. [Google Scholar] [CrossRef]

- Nazidizaji, S.; Tome, A.; Regateiro, F. Investigation about the Feasibility and Impediments of TRIZ Application in Architectural Design Process. Procedia Eng. 2015, 131, 651–660. [Google Scholar] [CrossRef] [Green Version]

- Zulhasni, A.R.; Nooh, A.B. Innovative Cases of TRIZ Application in the Automotive Industry. Appl. Mech. Mater. 2015, 735, 326–330. [Google Scholar] [CrossRef]

- Wang, F.-K.; Chen, K.-S. Applying Lean Six Sigma and TRIZ methodology in banking services. Total Qual. Manag. Bus. Excell. 2010, 21, 301–315. [Google Scholar] [CrossRef]

- Renev, I.A.; Chechurin, L.S. Application of TRIZ in Building Industry: Study of Current Situation. Procedia CIRP 2016, 39, 209–215. [Google Scholar] [CrossRef] [Green Version]

- Zheng, H.; Zhang, H.; Zhang, F. An innovative design of energy-saving products based on QFD/TRIZ/DEA integration. In Proceedings of the 2010 IEEE 17Th International Conference on Industrial Engineering and Engineering Management, Xiamen, China, 29–31 October 2010; pp. 831–834. [Google Scholar]

- Tan, R.E.J.H.; Ng, P.K.; Tan, D.W.H.; Lim, W.S. A triz-directed approach in proposing device-oriented ideas that cultivate water-drinking habits among children. Cogent Eng. 2021, 8, 1868134. [Google Scholar] [CrossRef]

- Kang, C.Q.; Ng, P.K.; Liew, K.W. A TRIZ-Integrated Conceptual Design Process of a Smart Lawnmower for Uneven Grassland. Agronomy 2022, 12, 2728. [Google Scholar] [CrossRef]

- Chong, P.L.; Ganesan, S.; Ng, P.K.; Kong, F.Y. A TRIZ-Adopted Development of a Compact Experimental Board for the Teaching and Learning of Operational Amplifier with Multiple Circuit Configurations. Sustainability 2022, 14, 14115. [Google Scholar] [CrossRef]

- Ng, P.K.; Prasetio, M.D.; Liew, K.W.; Lim, B.K.; Oktafiani, A.; Salma, S.A.; Safrudin, Y.N. A TRIZ-Inspired Conceptual Development of a Roof Tile Transportation and Inspection System. Buildings 2022, 12, 1456. [Google Scholar] [CrossRef]

- Navalertporn, T.; Afzulpurkar, N.V. Optimization of tile manufacturing process using particle swarm optimization. Swarm Evol. Comput. 2011, 1, 97–109. [Google Scholar] [CrossRef]

- Mills, J. Advantages and Disadvantages of Different Conveyor Systems. Available online: https://ocssystem.co.uk/conveyor-expertise/advantages-and-disadvantages-of-different-conveyor-systems/ (accessed on 8 August 2022).

- Fanigliulo, G. Business Models for the German Automotive Sector in 2030: Analysis of Market Trends and Development of Innovative Business Model Frameworks for German OEMs. Master Thesis, Leipzig Graduate School of Management, Leipzig, Germany, 2020. [Google Scholar]

- Yeow, J.A.; Ng, P.K.; Tan, K.S.; Chin, T.S.; Lim, W.Y. Effects of stress, repetition, fatigue and work environment on human error in manufacturing industries. J. Appl. Sci. 2014, 14, 3464–3471. [Google Scholar] [CrossRef] [Green Version]

- Yeow, J.A.; Khan, M.K.B.J.; Ng, P.K. Enforcement of safety and health policy reduces human error in SMEs in the manufacturing industry. Adv. Sci. Lett. 2017, 23, 10656–10659. [Google Scholar] [CrossRef]

- Yeow, J.A.; Ng, P.K.; Tai, H.T.; Chow, M.M. A Review on Human Error in Malaysia Manufacturing Industries. Management 2020, 5, 01–13. [Google Scholar] [CrossRef]

- Yeow, J.A.; Cheah, C.S.; Tan, P.K.; Chow, M.M.; Tai, H.T. Exploring the Root Causes of Human Error in Small, Medium Enterprise (SMEs) Manufacturing Industries in Malaysia. In Proceedings of the International Symposium on Applied Structural Equation Modeling and Methodological Matters (SASEM) 2019, Novotel Melaka, Malaysia, 21–24 August 2019. [Google Scholar]

- Choong, S.W.J.; Ng, P.K.; Yeo, B.C.; Draghici, A.; Gaureanu, A.; Ng, Y.J.; Wong, G.M.H.; Selvan, H.K.T. A Preliminary Study on Ergonomic Contribution to the Engineering Design Approach of a Wheel Loader Control Lever System. Sustainability 2022, 14, 122. [Google Scholar] [CrossRef]

- Cheng, H.Y.; Ng, P.K.; Nathan, R.J.; Saptari, A.; Ng, Y.J.; Yeow, J.A.; Ng, K.Y. The Conceptualisation and Development of a Space-Saving Multipurpose Table for Enhanced Ergonomic Performance. Inventions 2021, 6, 67. [Google Scholar] [CrossRef]

- Chia, X.W.; Ng, P.K.; Nathan, R.J.; Yeow, J.A.; Lim, W.S.; Ng, Y.J. The Development of an Automated Multi-Spit Lamb Rotisserie Machine for Improved Productivity. Machines 2021, 9, 165. [Google Scholar] [CrossRef]

- Tan, D.W.H.; Ng, P.K.; Noor, E.E.M.; Saptari, A.; Hue, C.C.; Ng, Y.J. Development and Usability Testing of a Finger Grip Enhancer for the Elderly. Robotics 2022, 11, 5. [Google Scholar] [CrossRef]

- Borken-Kleefeld, J.; Berntsen, T.; Fuglestvedt, J. Specific Climate Impact of Passenger and Freight Transport. Environ. Sci. Technol. 2010, 44, 5700–5706. [Google Scholar] [CrossRef]

- Nocera, S.; Cavallaro, F. A methodological framework for the economic evaluation of CO2 emissions from transport. J. Adv. Transp. 2014, 48, 138–164. [Google Scholar] [CrossRef]

- Nocera, S.; Cavallaro, F. Economic valuation of Well-To-Wheel CO2 emissions from freight transport along the main transalpine corridors. Transp. Res. Part D Transp. Environ. 2016, 47, 222–236. [Google Scholar] [CrossRef]

| Key Findings | Ref. |

|---|---|

| [5] |

| [10] |

| [2] |

| [11] |

| Key Findings | Ref. |

|---|---|

| [23] |

| [29] |

| [27] |

| [25] |

| [33] |

| [28] |

| [31] |

| [24] |

| [26] |

| [32] |

| [30] |

| System | Key Findings | Ref. |

|---|---|---|

| Robotic Arm |

| [37] |

| [41] | |

| [38] | |

| [36] | |

| [39] | |

| [40] | |

| Upright scanning |

| [42] |

| Flipping Conveyor |

| [43] |

| Content | Strengths | Ref. |

|---|---|---|

| Transportation system |

| [12] |

| [16] | |

| [20] | |

| [21] | |

| Flipping system |

| [43] |

| Inspection system |

| [23] |

| [29] | |

| [33] | |

| [32] | |

| [30] |

| Advantages | Ref. |

|---|---|

| [44] |

| [47] |

| [45] |

| [46] |

| [48] |

| [49] |

| Advantages | Disadvantages | Ref. |

|---|---|---|

|

| [23] |

|

| [29] |

|

| [30] |

| 1 | 2 | 3 | 4 | 5 |

| Very poor | Poor | Average | Good | Excellent |

| Criteria | Concepts | |||

|---|---|---|---|---|

| 1 (TTC) (Reference) | 2 (Belt) | 3 (AGV) | 4 (Hand Truck) | |

| Cost | 0 | + | + | + |

| Durability | 0 | − | − | − |

| Reliability | 0 | − | − | − |

| Versatility | 0 | + | − | − |

| Risk to the Product | 0 | + | + | + |

| Efficiency | 0 | + | - | − |

| Safety | 0 | + | + | 0 |

| Sum of “+” | 0 | 5 | 3 | 2 |

| Sum of “0” | 10 | 0 | 0 | 1 |

| Sum of “−“ | 0 | 2 | 4 | 4 |

| Net score | 0 | 3 | −1 | −2 |

| Ranking | 2 | 1 | 3 | 4 |

| Decision | Continue | Continue | Eliminated | Eliminated |

| Criteria | Weightage (%) | Concepts | |

|---|---|---|---|

| 1 (TTC) | 2 (Belt) | ||

| Cost | 10 | 2 | 4 |

| Durability | 15 | 4 | 3 |

| Reliability | 10 | 4 | 4 |

| Versatility | 15 | 4 | 5 |

| Risk to the Product | 20 | 3 | 5 |

| Efficiency | 20 | 4 | 4 |

| Safety | 10 | 3 | 4 |

| Weighted score | 3.5 | 4.2 | |

| Ranking | 2 | 1 | |

| Decision | Eliminated | Chosen | |

| Criteria | Protocols | |||

|---|---|---|---|---|

| 1 (OEE) | 2 (APC) (Reference) | 3 (Simulation) | 4 (T-Test) | |

| Simplicity | 0 | 0 | − | + |

| Cost | − | 0 | − | 0 |

| Time | 0 | 0 | + | + |

| Suitability | 0 | 0 | − | + |

| Ease of Implementation | − | 0 | − | + |

| Sum “+” | 0 | 0 | 1 | 4 |

| Sum “0” | 3 | 5 | 0 | 1 |

| Sum “−“ | 2 | 0 | 4 | 0 |

| Net score | −2 | 0 | −3 | 4 |

| Ranking | 3 | 2 | 4 | 1 |

| Decision | Eliminated | Continue | Eliminated | Continue |

| Criteria | Weightage (%) | Protocols | |

|---|---|---|---|

| 2 (APC) | 4 (T-Test) | ||

| Simplicity | 20 | 3 | 4 |

| Cost | 15 | 5 | 5 |

| Time | 10 | 3 | 5 |

| Suitability | 30 | 4 | 5 |

| Ease of Implementation | 25 | 3 | 4 |

| Weighted score | 3.6 | 4.55 | |

| Ranking | 2 | 1 | |

| Decision | Eliminated | Chosen | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Phuah, Z.Y.; Ng, P.K.; Prasetio, M.D.; Liew, K.W.; Lim, B.K.; Oktafiani, A.; Salma, S.A.; Safrudin, Y.N. A TRIZ-Supported Concept and Protocol Development for Roof Tile Transportation and Inspection Systems. Buildings 2023, 13, 197. https://doi.org/10.3390/buildings13010197

Phuah ZY, Ng PK, Prasetio MD, Liew KW, Lim BK, Oktafiani A, Salma SA, Safrudin YN. A TRIZ-Supported Concept and Protocol Development for Roof Tile Transportation and Inspection Systems. Buildings. 2023; 13(1):197. https://doi.org/10.3390/buildings13010197

Chicago/Turabian StylePhuah, Zhi Yuan, Poh Kiat Ng, Murman Dwi Prasetio, Kia Wai Liew, Boon Kian Lim, Ayudita Oktafiani, Sheila Amalia Salma, and Yunita Nugrahaini Safrudin. 2023. "A TRIZ-Supported Concept and Protocol Development for Roof Tile Transportation and Inspection Systems" Buildings 13, no. 1: 197. https://doi.org/10.3390/buildings13010197

APA StylePhuah, Z. Y., Ng, P. K., Prasetio, M. D., Liew, K. W., Lim, B. K., Oktafiani, A., Salma, S. A., & Safrudin, Y. N. (2023). A TRIZ-Supported Concept and Protocol Development for Roof Tile Transportation and Inspection Systems. Buildings, 13(1), 197. https://doi.org/10.3390/buildings13010197