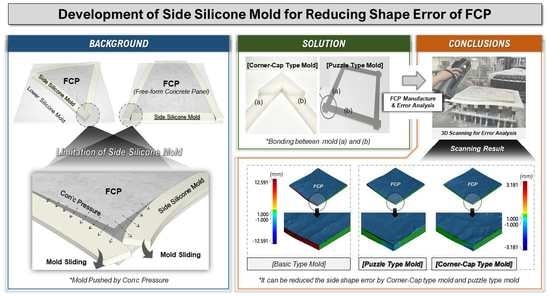

Development of Side Silicone Mold for Reducing Shape Error of Free-Form Concrete Panel

Abstract

:1. Introduction

2. Literature Review

2.1. Side Silicone Mold

2.2. Variable Side Mold

2.3. Side Mold Control Equipment

3. Methodology

4. Development of Side Silicone Mold

4.1. Design and Fabrication of Side Silicone Mold

4.1.1. Side Silicone Mold (Puzzle-Type)

4.1.2. Side Silicone Mold (Corner-Cap-Type)

5. FCP Manufacturing Experiments and Error Analysis

5.1. Results of FCP Manufacturing Experiments

5.2. FCP Error Analysis

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Jeong, S.C. An Analysis of the Conceptualization, Representation and Implementation Process of Major Free-Form Buildings in South Korea since Year 2000. Master’s Thesis, University of YONSEI, Seoul, Republic of Korea, June 2014. Available online: https://library.yonsei.ac.kr/search/detail/CAT000000894269?briefLink=/main/searchBrief?q=%EC%A0%95%EC%84%B1%EC%B2%A0 (accessed on 11 October 2022).

- Lee, E.Y.; Kim, Y.S. An Analysis and Improvement of Free Form Building’s Construction Productivity—Focused on Exposed Concrete Work. Korean J. Constr. Eng. Manag. 2013, 15, 38–46. [Google Scholar] [CrossRef]

- Lee, K. Construction Issues of Irregular-Shaped Buildings. J. Archit. Inst. Korea 2008, 52, 63–65. [Google Scholar]

- Jeong, K. Development of Two-Sided CNC and Side Mould Control Equipment for Automatic Manufacture of Free-Form Concrete Panel. Master ’s Thesis, Hanbat National University, Daejeon, Republic of Korea, February 2021. Available online: http://lib.hanbat.ac.kr/search/detail/CATTOT000000403731 (accessed on 11 October 2022).

- An, J.Y. A Study on the Lessons Learned for Improving Efficiency of Free-Form Facade Construction. Master’s Thesis, Seoul National University of Science and Technology, Seoul, Republic of Korea, August 2011. Available online: https://library.seoultech.ac.kr/#/search/detail/526979 (accessed on 11 October 2022).

- Lim, J.S.; Ock, J.H. Development of the Preliminary Cost Estimate Method for the Free-Form Building Facade Trade in Conjunction with the Panel Optimization Algorithm Process. Korean J. Constr. Eng. Manag. 2014, 15, 95–106. [Google Scholar] [CrossRef]

- Kim, H.H.; Kang, E.C. Dongdaemun Design Plaza & Park. Mag. Korea Concr. Inst. 2010, 22, 100–104. [Google Scholar]

- Yun, J.; Youn, J.; Kim, J.; Lee, D. Development of Connection Technology between Multi-Point Press and Flexible Mold for Manufacturing Free-form Concrete Panel. Buildings 2022, 12, 767. [Google Scholar] [CrossRef]

- Yun, J.; Jeong, K.; Youn, J.; Lee, D. Development of Side Mold Control Equipment for Producing Free-Form Concrete Panels. Buildings 2021, 11, 175. [Google Scholar] [CrossRef]

- Yun, J.; Youn, J.; Lee, D. Development of Double-Sided Multipoint Press CNC and Operational Technology for Producing Freeform Molds. Buildings 2021, 11, 426. [Google Scholar] [CrossRef]

- Youn, J.; Yun, J.; Kim, J.; Lee, D. Development of Variable Side Mold for Free-Form Concrete Panel Production. Buildings 2022, 12, 728. [Google Scholar] [CrossRef]

- Lim, J.; Son, S.; Kim, D.; Fitriani, H.; Kim, S. A Solution of Subordinate Vertices for Quality Connections of External Free-form Concrete Panels. J. Civ. Eng. Manag. 2018, 24, 399–409. [Google Scholar] [CrossRef]

- Kim, S. Digital Fabrication in Architectural Design and Construction Engineering for a Complex Geometry. Rev. Archit. Build. Sci. 2015, 59, 46–52. [Google Scholar]

- Gard, F. Flexible Mold: An Innovative Production Method to Produce Precast Double Curved Concrete Panels. Master’s Thesis, Eindhoven University of Technology, Eindhoven, The Netherlands, October 2013. Available online: https://research.tue.nl/en/studentTheses/flexible-mold (accessed on 11 October 2022).

- Janssen, B. Double Curved Precast Load Bearing Concrete Elements. Master’s Thesis, Delft University of Technology, Delft, The Netherlands, March 2011. Available online: https://repository.tudelft.nl/islandora/object/uuid%3A3a118436-be3d-474f-857b-0f3be4dc78ba (accessed on 11 October 2022).

- Yeo, H.K.; Jeong, H.S. Synthesis and Properties of Silicone Rubber Compound. Prospect. Ind. Chem. 1999, 2, 30–40. [Google Scholar]

- Jung, S.J. Study of Trends in The Architecture and The Economic Efficiency of 3D Printing Technology. J. Korea Acad. Ind. Coop. Soc. 2014, 15, 6336–6343. [Google Scholar]

- Choi, S.K. 3D Printing Technology and Architectural Application. Rev. Archit. Build. Sci. 2014, 58, 17–25. [Google Scholar]

| W/C | Cement | Sand | Water | PVA | Superplasticizer |

|---|---|---|---|---|---|

| 0.4 | 6500 g | 6500 g | 2600 g | 97.5 g | 19.5 g |

| FCP Type | N | Mean | Std. Deviation | Std. Error | Minimum | Maximum |

|---|---|---|---|---|---|---|

| FCP 1 | 160 | 2.772 | 3.720 | 0.294 | 0.007 | 12.150 |

| FCP 2 | 160 | 0.534 | 0.526 | 0.042 | 0.001 | 2.564 |

| FCP 3 | 160 | 0.796 | 0.577 | 0.046 | 0.002 | 2.753 |

| Group (FCP Type) | t | df | Sig (2-Tailed) | Mean Difference | Std. Error Difference | 95% Confidence Interval of the Difference | |

|---|---|---|---|---|---|---|---|

| Lower | Upper | ||||||

| A Group (FCP 1 and FCP 2) | 6.639 | 318 | 0.000 | 1.976 | 0.298 | 1.390 | 2.562 |

| B Group (FCP 1 and FCP 3) | 7.536 | 318 | 0.000 | 2.238 | 0.297 | 1.654 | 2.823 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jeong, K.; Lee, M.; Oh, J.; Lee, D. Development of Side Silicone Mold for Reducing Shape Error of Free-Form Concrete Panel. Buildings 2023, 13, 480. https://doi.org/10.3390/buildings13020480

Jeong K, Lee M, Oh J, Lee D. Development of Side Silicone Mold for Reducing Shape Error of Free-Form Concrete Panel. Buildings. 2023; 13(2):480. https://doi.org/10.3390/buildings13020480

Chicago/Turabian StyleJeong, Kyeongtae, Moonse Lee, Jisu Oh, and Donghoon Lee. 2023. "Development of Side Silicone Mold for Reducing Shape Error of Free-Form Concrete Panel" Buildings 13, no. 2: 480. https://doi.org/10.3390/buildings13020480

APA StyleJeong, K., Lee, M., Oh, J., & Lee, D. (2023). Development of Side Silicone Mold for Reducing Shape Error of Free-Form Concrete Panel. Buildings, 13(2), 480. https://doi.org/10.3390/buildings13020480