Hysteresis Curve Fitting Optimization of Magnetic Controlled Shape Memory Alloy Actuator

Abstract

:1. Introduction

- (1)

- (2)

- (3)

2. Performance Experiment of MSMA Actuator

2.1. Sample and Device of the Experiment

- (1)

- The strain gauge is a series of BX (BX strain gauge refers to phenolic foil type strain gauge) whose properties include the following: the entire structure is sealed, stable performance, good flexibility, and applicability to the general accuracy of the sensor. The strain limit is 1.5%, and usage temperature range is −30 °C–+80 °C.

- (2)

- The strain gauge sampling frequency is 4 Hz.

- (1)

- Turn off the power, place the sample in the cup, and fix the cup on the hydraulic loading device intermediate.

- (2)

- The hydraulic drive loading device is directly placed in the working range. At the same time, the magnetic field is set from 0 to 1.5 T.

- (3)

- Turn on the power, and set up the pre load of the sample.

- (4)

- Turn on the power supply for the temperature loading system, set the temperature parameters, and check whether the outer circulation system makes good contact. When everything is acceptable, turn on the heating power supply and the oil pump power supply, and regulate the flow rate of silicone oil circulation to prevent the silicone oil spilling.

- (5)

- Start the test. The corresponding deformation of MSMA is measured.

- (6)

- After unloading, view and save the experimental data.

2.2. Experimental Results

3. Fitting and Results

3.1. Least Squares Method

3.2. BP Artificial Neural Network

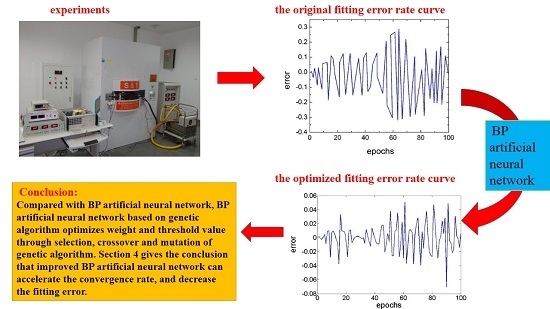

3.3. BP Artificial Neural Network Based on Genetic Algorithm

4. Validation

5. Conclusions

- (1)

- The fitting accuracy rate is quite high and can improve the accuracy of MSMA actuators. Because there are fewer undetermined parameters during the hysteresis curve fitting, the fitting speed of least squares method is fast.

- (2)

- Compared with BP artificial neural networks, BP artificial neural networks based on genetic algorithms can accelerate the convergence rate and decrease the fitting error. Therefore, they can improve the accuracy of MSMA actuators and enhance the utilization rate of MSMA actuators in precision positioning.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Ullakko, K.; Huang, J.K.; Kantner, C.; O’Handley, R.C.; Kokorin, V.V. Large magnetic-field-induced strains in Ni2MnGa single crystals. Appl. Phys. Lett. 1996, 69, 1966–1968. [Google Scholar] [CrossRef]

- Murray, S.J.; Marioni, M.; Allen, S.M.; O’Handley, R.C.; Lograsso, T.A. 6% magnetic-field-induced strain by twin-boundary motion in ferromagnetic Ni–Mn–Ga. Appl. Phys. Lett. 2000, 77, 886–888. [Google Scholar] [CrossRef]

- Murray, S.J.; Farinelli, M.; Kantner, C.; Huang, J.K.; Allen, S.M.; O’Handley, R.C. Field-induced strain under load in Ni-Mn-Ga magnetic shape memory materials. J. Appl. Phys. 1998, 83, 7297–7299. [Google Scholar] [CrossRef]

- Feuchtwanger, J.; Asua, E.; García-Arribas, A.; Etxebarria, V.; Barandiaran, J.M. Ferromagnetic shape memory alloys for positioning with nanometric resolution. Appl. Phys. Lett. 2009, 95, 054102. [Google Scholar] [CrossRef]

- Murray, S.J.; Marioni, M.; Tello, P.G.; O’Handley, R.C. Giant magnetic-field-induced strain in Ni–Mn–Ga crystals: Experimental results and modelling. J. Magn. Magn. Mater. 2001, 226, 945–947. [Google Scholar] [CrossRef]

- Conti, S.; Lenz, M.; Rumpf, M. Hysteresis in magnetic shape memory composites: Modelling and simulation. J. Mech. Phys. Solids 2016, 89, 272–286. [Google Scholar] [CrossRef]

- Krenke, T.; Aksoy, S.; Duman, E.; Acet, M.; Moya, X.; Mañosa, L.; Planes, A. Hysteresis effects in the magnetic-field-induced reverse martensitic transition in magnetic shape-memory alloys. J. Appl. Phys. 2010, 108, 043914. [Google Scholar] [CrossRef]

- Sadeghzadeh, A.; Asua, E.; Feuchtwanger, J.; Etxebarria, V.; García-Arribas, A. Ferromagnetic shape memory alloy actuator enabled for nanometric position control using hysteresis compensation. Sens. Actuators A Phys. 2012, 182, 122–129. [Google Scholar] [CrossRef]

- Tao, G. Adaptive control of systems with nonsmooth input and output nonlinearities. IEEE Trans. Autom. Control 1996, 41, 1348–1352. [Google Scholar]

- Ossart, F.; Davidson, R.; Charap, S.H. A 3D moving vector Preisach hysteresis model. IEEE Trans. Magn. 1995, 31, 1785–1788. [Google Scholar] [CrossRef]

- Sutor, A.; Rupitsch, S.J.; Lerch, R. A Preisach-based hysteresis model for magnetic and ferroelectric hysteresis. Appl. Phys. A 2010, 100, 425–430. [Google Scholar] [CrossRef]

- Takahashi, N.; Miyabara, S.H.; Fujiwara, K. Problems in practical finite element analysis using Preisach hysteresis model. IEEE Trans. Magn. 1999, 35, 1243–1246. [Google Scholar] [CrossRef] [Green Version]

- Annakkage, U.D.; McLaren, P.G.; Dirks, E.; Jayasinghe, R.P.; Parker, A.D. A current transformer model based on the Jiles–Atherton theory of ferromagnetic hysteresis. IEEE Trans. Power Deliv. 2000, 15, 57–61. [Google Scholar] [CrossRef]

- Toman, M.; Stumberger, G.; Dolinar, D. Parameter identification of the Jiles–Atherton hysteresis model using differential evolution. IEEE Trans. Magn. 2008, 44, 1098–1101. [Google Scholar] [CrossRef]

- Rao, I.J.; Rajagopal, K.R. On a new interpretation of the classical Maxwell model. Mech. Res. Commun. 2007, 34, 509–514. [Google Scholar] [CrossRef]

- Zhou, M.; Zhang, Q. Hysteresis Model of Magnetically Controlled Shape Memory Alloy Based on a PID Neural Network. IEEE Trans. Magn. 2015, 51, 1–4. [Google Scholar]

- Zhou, M.; He, S.; Zhang, Q.; Ji, K.; Hu, B. Hybrid control of magnetically controlled shape memory alloy actuator based on Krasnosel’skii–Pokrovskii model. J. Intell. Fuzzy Syst. 2015, 29, 63–73. [Google Scholar] [CrossRef]

- Zhou, M.; He, S.; Hu, B.; Zhang, Q. Modified KP model for hysteresis of magnetic shape memory alloy actuator. IETE Tech. Rev. 2015, 32, 29–36. [Google Scholar] [CrossRef]

- Liu, Y.; Liu, H.; Wu, H.; Zou, D. Modelling and compensation of hysteresis in piezoelectric actuators based on Maxwell approach. Electron. Lett. 2015, 52, 188–190. [Google Scholar] [CrossRef]

- Shi, Y.; Liang, C.H. The finite-volume time-domain algorithm using least squares method in solving Maxwell’s equations. J. Comput. Phys. 2007, 226, 1444–1457. [Google Scholar] [CrossRef]

- Wilamowski, B.M.; Iplikci, S.; Kaynak, O.; Efe, M.Ö. An algorithm for fast convergence in training neural networks. In Proceedings of the International Joint Conference on Neural Networks, Washington, DC, USA, 15–19 July 2001; Volume 3, pp. 1778–1782.

- Fu, Z.; Mo, J.; Chen, L.; Chen, W. Using genetic algorithm-back propagation neural network prediction and finite-element model simulation to optimize the process of multiple-step incremental air-bending forming of sheet metal. Mater. Des. 2010, 31, 267–277. [Google Scholar] [CrossRef]

| Serial Number | H (T) | B (T) | Serial Number | H (T) | B (T) | Serial Number | H (T) | B (T) |

|---|---|---|---|---|---|---|---|---|

| 1 | −0.5258 | −3.4152 | 11 | 0.0301 | 0.2790 | 21 | 0.0707 | 1.9553 |

| 2 | −0.4640 | −3.3831 | 12 | 0.0503 | 0.8144 | 22 | 0.0446 | 1.2415 |

| 3 | −0.31118 | −3.4097 | 13 | 0.0966 | 1.4583 | 23 | 0.0070 | 0.6694 |

| 4 | −0.2506 | −3.4061 | 14 | 0.1284 | 2.0656 | 24 | −0.0133 | 0.0627 |

| 5 | −0.1235 | −2.7931 | 15 | 0.2066 | 3.2812 | 25 | −0.0857 | −1.2237 |

| 6 | −0.0887 | −2.0787 | 16 | 0.3252 | 4.9266 | 26 | −0.1088 | −1.6881 |

| 7 | −0.0569 | −1.6138 | 17 | 0.4439 | 6.7145 | 27 | −0.1754 | −2.7962 |

| 8 | −0.0395 | −1.1853 | 18 | 0.3741 | 6.7028 | 28 | −0.2188 | −3.3261 |

| 9 | −0.0134 | −0.7208 | 19 | 0.2126 | 4.4432 | |||

| 10 | 0.0096 | −0.2920 | 20 | 0.1692 | 3.6708 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tu, F.; Hu, S.; Zhuang, Y.; Lv, J.; Wang, Y.; Sun, Z. Hysteresis Curve Fitting Optimization of Magnetic Controlled Shape Memory Alloy Actuator. Actuators 2016, 5, 25. https://doi.org/10.3390/act5040025

Tu F, Hu S, Zhuang Y, Lv J, Wang Y, Sun Z. Hysteresis Curve Fitting Optimization of Magnetic Controlled Shape Memory Alloy Actuator. Actuators. 2016; 5(4):25. https://doi.org/10.3390/act5040025

Chicago/Turabian StyleTu, Fuquan, Shengmou Hu, Yuhang Zhuang, Jie Lv, Yunxue Wang, and Zhe Sun. 2016. "Hysteresis Curve Fitting Optimization of Magnetic Controlled Shape Memory Alloy Actuator" Actuators 5, no. 4: 25. https://doi.org/10.3390/act5040025

APA StyleTu, F., Hu, S., Zhuang, Y., Lv, J., Wang, Y., & Sun, Z. (2016). Hysteresis Curve Fitting Optimization of Magnetic Controlled Shape Memory Alloy Actuator. Actuators, 5(4), 25. https://doi.org/10.3390/act5040025